As the wire is pulled through the die, its volume remains the same, so as the diameter decreases, the length increases. Very fine wires are usually drawn in bundles. In a bundle, the wires are separated by a metal with similar properties, but with lower chemical resistance so that it can be removed after drawing.

What is wire bundling and how does it work?

The purpose of the bundling is to keep specific cables together over a medium to long distance. What this does is efficiently organizes those cables in a way that simplifies your application. With various constructions available as well as custom binding requests, wire bundling can effectively help a wide variety of difficult applications.

How do you separate wires in a wire bundle?

In a bundle, the wires are separated by a metal with similar properties, but with lower chemical resistance so that it can be removed after drawing. If the reduction in area is greater than 50%, the process may require an intermediate step of annealing before it can be redrawn.

What is a straight wire bundle?

The straight wire bundle is one of the more popular configurations because of the benefits it offers, the applications it's used within, and because we offer custom printing and striping for increased organization. The straight bundling configuration helps with heat distribution and minimizes the risks that accompany it.

What are the benefits of spiral wire bundling?

The second major benefit that spiral wire bundling offers is the ability to be pulled through a conduit. Unlike other constructions (straight and staggered) that have to be laid in conduits or trays, the spiral wire bundle can be pulled through and makeup to 90° turns.

What did a wire drawer do?

1) Occupational term, for a workman making wire by drawing a metal rod through a series of holes.

How are wires drawn?

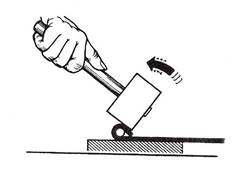

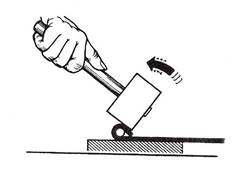

The wire-drawing process consists of pointing the rod, threading the pointed end through a die, and attaching the end to a drawing block. The block, made to revolve by an electric motor, pulls the lubricated rod through the die, reducing it in diameter and increasing its length.

What does it mean to be drawn into a wire?

Solution : (1) The property due to which a substance can be drawn into a thin wire without cracking or breaking is called ductility. (2) Metals are ductile. Thus, a metal can be drawn into a wire.

What are the process variables in wire drawing process?

Major variables in drawing process include reduction ratio, die angle, friction at the interface of the wire and the die, and drawing velocity. Plastic deformation of the wire and heat generation due to fric- tion between the wire and the die increase the temperature of the die, which results in thermal expansion.

What is the drawing process?

Drawing is a metalworking process that uses tensile forces to stretch (elongate) metal, glass, or plastic. As the metal is drawn (pulled), it stretches to become thinner, to achieve a desired shape and thickness. Drawing is classified into two types: sheet metal drawing and wire, bar, and tube drawing.

What is wire drawing and bar drawing?

Bar or wire drawing is a deformation process in which the work piece in the form of cylindrical bar or rod is pulled through a converging die. The stress applied is tensile. However, the material is subjected to compressive stress within the die thereby deforming plastically.

Why are metals drawn into wires?

Most importantly metals can pass an electric current without being affected and changed by the electricity. Electrical conductivity combined with ductility makes metals the most suitable materials for electrical transmission wires.

Why is copper drawn wire?

Surpassed only by silver, copper is a highly conductive metal. This means electricity can pass through it with greater ease, making it ideal for use in electrical wires. Companies can use other conductive metals to create electrical wires.

Why can metals be stretched into wires?

Metals are described as malleable (can be beaten into sheets) and ductile (can be pulled out into wires). This is because of the ability of the atoms to roll over each other into new positions without breaking the metallic bond.

Which one of the following stresses are needed in wire drawing process?

Which of the following stresses is takes place during performing the wire drawing operation? Explanation: Wire drawing is a forming process in which a round metallic bar is pulled by a machine by generating indirect compressive stresses in the bar.

What is wire bundling?

Wire bundling is when you take 2 or more electrical cables and bundle them together using a specific bind. The purpose of the bundling is to keep specific cables together over a medium to long distance. What this does is efficiently organizes those cables in a way that simplifies your application. With various constructions available as well as ...

Why is spiral wire bundling used?

This is typically why the spiral bundle is preferred over other constructions in data centers and communication systems. 2. The second major benefit that spiral wire bundling offers is the ability to be pulled through a conduit.

What is straight wire bundle?

Straight Wire Bundle. The straight wire bundle has all of its wires tied beside one another rather than twisted. The bundle is typically kept together from Point A to Point B, having little to no breakouts. The straight wire bundling configuration is typically laid in trays and can be installed quite easily.

Why is it important to break out multiple cables?

Being able to break out at multiple points helps customers complete multiple wiring applications, as different types of cable can break away when required. Being able to have building wire, lighting wire, data cable and any other type of cabling group bundled together saves a tremendous amount of space and time.

Is there a charge for cutting wire?

Yes, there's a small extra charge, but is it most cost-effective to have a powerful machine cut tens of thousands of meters of wire in a couple of hours to the exact length required, or is it better to have one of your skilled labourers stand there with scissors and cut it. This will cost more.

Is spiral wire bundling reliable?

Having the ability to be pulled through instead of laid down, enables the spiral bundles to be used is very tight difficult to reach locations. The spiral wire bundling configuration is very reliable and is one of the most popular among general and transmission applications.

Why is bundling the wrong thing to do?

Because many wires converge and heat is concentrated in an electric panel, even if the length does not exceed 24-inches, bundling is still the wrong thing to do.

Why are wires and breakers needed?

Both the wiring and breakers in a panel generate heat and air space around the components is needed for heat dissipation. When the wires are bundled, heat generated by the inner wires is trapped by the surrounding ones. Also, each wire connected to a breaker helps to conduct heat away from the breaker, but this is nullified if ...

How to tell if an electric panel is wired?

Neat and organized wiring is one of the ways you can tell that an electric panel was wired by a professional electrician. Wires from breakers on the right side of the panel exit the box on the same side. They don’t cross over the service cables or run around the bottom.

Do electrical wires cross over the service cables?

They don’t cross over the service cables or run around the bottom. This requires planning and careful execution, and the completed work sometimes resembles a wiring diagram, with each wire turning at a right angle next to the breaker before it heads up or down and out of the box. A good electrician is justifiably proud of a well-organized panel.