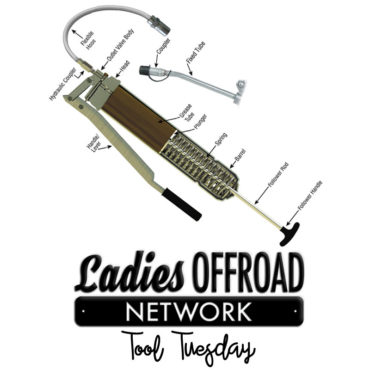

Here are some of the possible reasons for a grease gun, not working:

- The pump of the grease gun may stop working.

- The gun spring may get loose and stop working.

- The piston rod may become defective.

- The plunger may be too stiff.

- Air may be trapped in the gun.

Full Answer

Why is my grease gun not working?

If you are using an older grease gun, then there is a change that the following rod has corroded or has some rust build-up, and this causes an obstruction, so the piston doesn’t work properly. When you purchase a new grease gun, it’s easy to check whether or not the follower rod is working okay or not.

How to get air out of your grease gun?

- To purge the air out of the grease gun, flip the grease gun base in an anti-clockwise direction. ...

- Keep pumping the grease gun while you are turning it anti-clockwise, so the air leaves the extension gradually

- As you see the grease’s way is cleared, you can now turn it in a clockwise direction and cap the grease gun.

How do you change Grease in a grease gun?

- Unscrew the cartridge cap.

- Pull back on the metal handle.

- Secure the piston rod and remove the cartridge.

- Prepare the new grease cartridge for loading.

- Insert the cartridge into the barrel.

- Reattach the barrel to the head of the grease gun.

What is the normal working pressure of a grease gun?

This model is recommended for both industrial and personal use, having a pressure output of up to 7000 psi. The Utool grease gun comes with a variety of materials that include a 2-extension rigid pipe, an 18-inch flex hose that has spring guards, one sharp-type nozzle, and an instructive manual.

Why is my grease gun not pumping?

The grease gun won't pump grease. The most common cause is an air lock. This can be fixed by continuously pumping to see if the air will pump out. Secondly by unscrewing the barrel one turn and continuously pumping, then tightening the barrel when the grease pumps.

How do you get a grease gun to work again?

0:080:45How to purge air from Grease Gun - YouTubeYouTubeStart of suggested clipEnd of suggested clipNothing is coming out to fix this problem. Simply turn anti-clockwise two or three turns. This willMoreNothing is coming out to fix this problem. Simply turn anti-clockwise two or three turns. This will release the air to the top of the tube pump.

How do I get my grease gun to start pumping grease?

1:513:16How to Load and Prime a Grease Gun - Part 2 - YouTubeYouTubeStart of suggested clipEnd of suggested clipProblems getting the grease gun primed. Simply unscrew this a few times and now. That's probably aMoreProblems getting the grease gun primed. Simply unscrew this a few times and now. That's probably a full turn two turns probably three three four full turns.

Why is no grease coming out after changing tube on grease gun?

The problem is that without grease already in the head of the grease gun, the piston is pumping air and you may need to help push the grease up and out of the cartridge to get things moving. 1) When you screw on the barrel after loading a new tube of grease, back it off a full turn to allow a little air to seep out.

How do you bleed air from a grease gun?

1:053:47How to Fill and Bleed a Grease Gun | KINCROME Tool Talk - YouTubeYouTubeStart of suggested clipEnd of suggested clipStep two it pays to know how the grease gun actually works start by unscrewing the gun head from theMoreStep two it pays to know how the grease gun actually works start by unscrewing the gun head from the main barrel turn the head upside down you can see that this one hasn't been used.

How do I know if my grease gun is working?

1:342:17How To Use Grease Guns - YouTubeYouTubeStart of suggested clipEnd of suggested clipContinue. This until grease starts flowing again on the smaller 120 mil gun just loosen theMoreContinue. This until grease starts flowing again on the smaller 120 mil gun just loosen the cartridge tuber turn or two this should release the air then pump until the grease comes out and retighten.

How does a manual grease gun work?

The grease gun depresses the ball (tiny ball bearing) allowing grease to pass. When you remove the tool a spring pushes the ball back into the opening, sealing it. If the bearing doesn't return and grease leaks out, there may be particulate matter obstructing its proper operation and you should get a new Zerk.

How do you calibrate a grease gun?

Of these three, the simplest method of calibrating grease guns is by taking a shot of grease and measuring the mass. Pump 10 strokes of grease onto a scale and measure the mass. Divide by 10 to get the average amount of grease being delivered per stroke. Do this calibration at least once a year.

How do you know when a grease fitting is full?

If this is the case, the best tactic is to “feel” the grease into the bearing cavity until slight resistance or back pressure is felt against the trigger, or lever, signaling the bearing cavity is now full.

How do you fix a grease gun plunger?

0:191:31Grease gun plunger rod is stuck - what to do?! - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo we've gotten old tube here that we're going to use we just opened it up and we'll try to figureMoreSo we've gotten old tube here that we're going to use we just opened it up and we'll try to figure out what the problem is and what's going on kind of little ahead of myself there let me pull this.

How do you fix a grease gun plunger?

0:191:31Grease gun plunger rod is stuck - what to do?! - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo we've gotten old tube here that we're going to use we just opened it up and we'll try to figureMoreSo we've gotten old tube here that we're going to use we just opened it up and we'll try to figure out what the problem is and what's going on kind of little ahead of myself there let me pull this.

How do you fix a pneumatic grease gun?

0:003:04Grease Gun Problem- Easy Fix - YouTubeYouTubeStart of suggested clipEnd of suggested clipIt's very very simple all right the first thing you do is disconnect the air pull the plunge thisMoreIt's very very simple all right the first thing you do is disconnect the air pull the plunge this plunger. Pull it all the way back. Now. This air release right here push in the air release.

How do you know when a grease gun is empty?

0:121:05How to Check the Level in a Grease Gun - YouTubeYouTubeStart of suggested clipEnd of suggested clipSimply pull the plunger out until it stops. The amount of grease on the raw which is exposed willMoreSimply pull the plunger out until it stops. The amount of grease on the raw which is exposed will show you how much grease is left in the cartridge. So taking the same distance.

Why is my grease gun so stiff?

Some people have mentioned that they think it’s because the plunger is too large for the grease gun to work properly. Look when you get a new grease gun, it can be a little stiff at first, but just keep at it, perhaps push a little harder, and it will become easier to use.

How to tell if a grease gun is working?

When you depress the pressure out of the grease gun, do so slowly, and you’ll be able to see if the piston is moving correctly or not.

How to avoid air bubbles from grease gun?

To avoid getting air bubbles, make sure to store your grease gun hung on your wall correctly.

How to get air out of grease gun?

Turn the base of your grease gun anti-clockwise, this will help you release the air as easily as possible. You shouldn’t need to turn the base more than two to three times. Now, continually pump the grease gun while you are rotating the base, this will allow the trapped air to flow out.

How to seal grease gun?

When you start to see grease come out of the nozzle, you can twist the base clockwise again to seal your grease gun up

What happens if you damage a grease gun?

If you do accidentally damage yours, this will affect whether or not grease can come out of your grease guns nozzle, you may need to replace your grease gun.

Can you replace a grease gun spring?

This is another easy problem to fix, but it will require you to purchase a new grease gun spring to replace the existing one in your grease gun. Quite the inconvenience as you may be in the middle of a job. This has happened to me more than a few times.

Why does my grease gun stop working?

The spring may have come loose and then not give the chamber adequate pressure to power the chamber with the coupler.

What is problem 5 on a grease gun?

The damage may have been caused by so many things like an accident with the grease gun.

How to change the base of a grease gun?

Step one: Change the base of the grease gun by turning it anti-clockwise. The goal of this step is to allow as much air to go out as possible. Do this by twitching the base two to three times at the most.

Can air be trapped in a gun?

Air may be trapped in the gun.

Can a loose gun spring be fixed?

The spring may have come loose and then not give the chamber adequate pressure to power the chamber with the coupler. This problem can easily be fixed with the help of a new gun spring. It may come as an inconvenience if it interrupts a job’s process, but it should fix the problem.

What Can Go Wrong When Using a Grease Gun?

Grease guns are relatively simple devices that can be broken down into just four main components: The lever or trigger, the hose, the piston chamber, and the nozzle.

The grease gun spring stops working. How to solve it?

The grease gun spring works well when it’s new, but after using it for a while, the grease gun spring stops working. How to solve it?

Other Common Troubleshooting of Grease Guns

There are many common troubleshooting problems that come up with grease guns. Here are the most 7 common troubleshooting of grease guns that you should know.

Some More FAQs Related to Grease Gun Troubleshooting

The most common cause of a mini grease gun not working is a lack of pressure. Make sure you release the trigger to switch from continuous to intermittent mode. This will allow the gunk to clear out of the end of your nozzle, then you can switch back to continuous mode and get that pressure re-established.

Bottom Line

If you’re trying to fix your stuck or locked trigger or lever, then it’s best to replace the entire assembly. You also need to make sure the metal tubing, hose, and connector are all undamaged before using your grease gun again.

How to prime a grease gun?

Priming a grease gun can be tough, but here's a quick and easy way to fix that. By locking out the follower rod, pushing against a hard surface, and giving the air somewhere to escape, you'll haver your grease gun primed in no time !

Can grease guns be primed?

Priming a grease gun is not a tough task when you know a few tricks to bleed air from the grease gun and get the grease moving easily through the hose or extension. Follow these quick and easy steps to get your grease gun primed and ready.

Can grease gun follower rods get locked?

On occasion the grease gun follower rod can get locked unexpectedly, preventing it from moving up through the grease and storing before use . Watch this video to learn the best way to resolve this issue.