12 Most Common Relay Failures: Technical Analysis

- 1. Flashover Flashover is the trouble where discharge between opposing conductors causes a short circuit. ...

- 2. Sticking Welding, locking or gluing make it difficult to open contacts. ...

- 3. Contact wear Contact wear is the wear of contacts due to mechanical causes, such as wear during repeated operations. ...

- 4. Contact erosion ...

- 5. Activation ...

- 6. Contact film ...

- 7. Humming ...

- 8. Abnormal heat generation ...

What is the most common type of relay failure?

End-of life failures are the most common type of failure, but using a relay to switch voltages and currents beyond its rated specifications can also cause them to fail.

What are relays and why are they important?

Relays are one of the first things to be examined when a failure has occurred in an electrical cabinet. Why is this the case? It is simple – most relays have moving parts (except for solid state) to achieve electrical switching using a coil and a set of contacts and anything that moves mechanical is going to suffer an eventual failure.

What is a relay in troubleshooting?

While troubleshooting, you have probably heard the term “relay” come up during your checks. Relays are one of the first things to be examined when a failure has occurred in an electrical cabinet. Why is this the case?

What causes corrosion in relays?

Condensation might form inside a relay when the outside temperature is cold. When the electronics are turned on, water droplets are emitted and sprayed onto the contacts of the relay. As a result, corrosion will appear on these contact points. Corrosion in a relay can cause electrical failures.

What is a relay?

What is relay in machine?

What is contactor relay?

What is a solid state relay?

Is a solid state relay more reliable than a mechanical relay?

How do you know if a relay is bad?

1:022:19Easiest Way to Check a Relay - YouTubeYouTubeStart of suggested clipEnd of suggested clipAlright and swap them and then see if the problem goes away with your horn see if it blows if itMoreAlright and swap them and then see if the problem goes away with your horn see if it blows if it blows then you probably had a bad relay.

How long does a relay last?

The electrical life expectancy of general purpose and power relays is generally rated to be 100,000 operations minimum, while mechanical life expectancy may be one million, 10, or even 100 million operations.

How often do relays go out?

Most relays are rated for about 50,000 cycles, so it is possible that the automatic shutdown relay will last you the life of your car. However, if it does fail, you won't be going anywhere until you have it replaced.

Do relays wear out?

Relays tend to be quite reliable in benign environments, however they have a limited lifetime. Typically something like 50,000-100,000 operations at full rated load. At lighter loads, the life will increase, generally up to many millions of operations with a negligible load (the so-called mechanical life).

How do you check if a relay is working?

5:188:08How To Test a Relay (and How Relays Work) - in 8 minutesYouTubeStart of suggested clipEnd of suggested clipFirst thing you can do is perform a click test run a couple wires from the battery to the controlMoreFirst thing you can do is perform a click test run a couple wires from the battery to the control circuit pins 85 and 86. And see if the relay clicks.

Is a relay good if it clicks?

If you hear or feel the relay click, the relay and its wiring aren't the problem. But if it's not clicking, the problem could be in the relay itself or in the wiring.

What happens if a relay fails?

If the relay fails it will cut off power to fuel pump and ignition system, which will result in a no power, and therefore no start condition. You may find that turning the key may power on the accessories, and may even crank the engine.

How much do relays cost?

How Much Does a Relay Cost? An aftermarket relay usually costs around $50 to $250. Prices can vary depending on various factors, like its brand, quantity, product fit, and condition. Labor costs for this type of replacement usually range from $30 to $60.

How much does it cost to repair a car relay?

The average starter relay replacement cost is between $50 and $75, depending on the car model and labor costs. The starter relay parts should cost you around $20, with the labor price at $30 to $55.

How do you tell if a relay is bad with a multimeter?

Take the leads of the multimeter and connect them across the coil terminals of the relay. For a normal coil, the multimeter should read anywhere between 40Ω to 120Ω. If the coil is damaged i.e., it is open, the meter shows out of range and you have to replace the relay.

How do I test a relay without a multimeter?

How to test a relay without multimeter? Apply a 12 volt/9 volt/5-volt power supply to the coil (apply voltage according to the rating printed on it) and you will hear “crisp-click” sound, this indicates that your movable contact is working fine and thus the relay coil is in good condition.

Can relays get stuck?

The most common cause of relays sticking is because of micro-welding of the contacts caused by arcing when the contacts close/open. This can occur even when the current being switched is within the rating of the relay.

Do car relays wear out?

Your electronic control relay is a huge part of your vehicle's electrical systems. This part needs to be working properly in order for your car to start and run correctly. It's prone to all kinds of wear and tear type damage, so there's a good chance you will be faced with replacing it at some point.

How long does a relay race last?

The most common distances for relay races are 100 meters and 400 meters, but there are also races of 50 meters, 200 meters, and 800 meters. There are other variations of the relay race, such as sprint medleys, long-distance, and cross-country relays.

How long do Starter relays last?

The starter relay is a long-lasting component that can last up to 100,000 miles. So replacing it is worth the cost.

How long does an AC relay last?

about ten yearsThe life of the compressor relay is measured in cycles, not miles – in other words, how many times it is turned on and off. Most are rated for about 50,000 cycles. For the typical driver, this usually translates to about ten years' worth of driving.

Flashover

Flashover is the trouble where discharge between opposing conductors causes a short-circuit. This often occurs with contacts used with medium and large power. Flashover is dangerous when the current is high.

Sticking

Welding, locking, or gluing make it difficult to open contacts. Welded contacts are usually caused by high inrush currents as the contacts are closed creating molten or soft metal in the contact area. Welded contacts are also caused by high- frequency switching.

Contact wear

Contact wear is the wear of contacts due to mechanical causes, such as wear during repeated operation. Relays open and close millions of times. Sometimes this repeated operation causes contact wear.

Contact erosion

Contact erosion is the expending of contacts due to electrical, thermal, chemical, and other causes all through the repeated operation. Contacts having variable or intermittent contact resistance. This occurs particularly at low current levels because of erosion of the contact materials.

Activation

Activation is the failure where contact surfaces become dirty. Dirty contact surfaces increase the possibility of discharge.

Contact film

Metal oxide, sulfide, and other films are generated on or attached to contact surfaces and cause boundary resistance. If there is a film on the surface of contact and the contacts retouching, the film electrically breaks down and the contact resistance drops rapidly when the contact voltage exceeds a certain value.

Humming

Mechanical relays create a humming noise when turned on. Humming noise is continuous during operation. Humming occurs due to mechanical vibration caused by AC poles or a rectifier wave drive with insufficient smoothing.

Why do relays fail?

Relays fail for a variety of reasons (see article: What Causes a Relay to Fail ). Some are accidents, some are caused by manufacturing defects, and some are simply end-of-life failures.

How long does a relay last?

Full load life. This is the life of the relay when hot switching a load at the maximum current, voltage, or power rating. When operated at full load, a relay is said to have failed when its contacts fail to operate (often because they weld together) or when contact material erosion results in an unacceptable high path resistance. When asked to hot switch a load, a relay may only be good for 100,000 operations. On the other hand, if a signal is cold-switched, i.e. is applied only after the relay contacts have been operated, the relay's lifetime will be much longer and approach the relay's mechanical life.

Can a Pickering switch have a spare relay?

In many instances, a Pickering Interfaces switch module may have a spare relay included on the PCB. This will be noted in the PCB layout information.

Can a DMM be used to check for relay failure?

Users can also use a DMM to check for relay failures, but when testing high current relays keep in mind that these relays typically have a minimum operating current/voltage that is needed to overcome surface films that can accumulate on the contacts. If the relay has not been used for a while, or if it has been used for hot switching loads, the contacts at low current/voltage may exhibit variable or even open circuit values.

Can a relay be replaced?

Using the number of operations as a predictive maintenance tool, and replacing relays when they have operated a pre-determined number of times, can easily degrade the reliability of a switching system. Replacing a relay can disturb adjacent devices (not just relays), especially if the board uses surface-mount devices. Pickering only uses surface-mount devices when the switching characteristics demand it (for example for RF applications). In addition, there's always a chance that the replacement relay will experience an “infant mortality” failure.

Can you replace relays on a pickering module?

Be careful when replacing relays to avoid damaging the PCB or other components. Most Pickering Interfaces switching modules use thru-hole mounted relays to make this easier. Frequent replacement of surface mounted relays carry a considerably higher risk of damaging both the PCB and surrounding components.

What are the common faults of relays?

During the use of the relay, due to various reasons, such as poor product quality, improper use, poor maintenance, etc., various failures often occur. Relay troubleshooting is usually analyzed from two aspects: electromagnetic components and contact components. ( What are the precautions when using relays?)

What happens if a relay coil collides?

The coils should be separated and placed in special appliances. If they collide and are connected, they will break when they are separated.

Why is my coil damaged?

2. The coil is damaged due to the coil voltage exceeding 110% of the rated voltage. 3. During maintenance, the coil insulation may be damaged due to the tool's bruising, or the wire may break. 4.

Why is my AC coil burning out?

5.When the coil voltage exceeds 110% of the rated voltage, the operating frequency is too high, or when the voltage is lower than 85% of the rated voltage, the AC coil may be burned out because the armature fails to pull in.

What causes the armature to vibrate?

When the sub-magnetic ring on the iron core of the AC relay is broken, or the armature and the pole face of the iron core are rusted or invaded , it will cause the armature to vibrate and generate noise. 4.

Why is my armature so loud?

The armature is noisy after power-on, which may be caused by uneven contact surfaces of the moving and static iron cores, or oil pollution. The coil can be removed and the contact surface can be filed or polished. If there is oil stains, it can be cleaned. The break of the short-circuit ring can also cause loud noise.

Why is my AC coil not closing?

6. When the AC coil is connected to voltage, the armature of the AC coil may not be closed due to the failure of the transmission mechanism or jamming, which will cause the coil to burn out.

Why Use a Relay?

Relays are highly versatile components that are just as effective in complex circuits as in simple ones.

Why are relays important?

Relays can reduce the need for high-amperage wiring and switches, which are expensive and take up space.

What Is a Relay?

Relays are electric switches that use electromagnetism to convert small electrical stimuli into larger currents.

How to measure voltage in relay?

After identifying this location, you can use the multimeter to measure the voltage at each point.

What is an automotive relay?

Automotive Relays. Relays have almost unlimited uses in automotive applications, and these applications encompass many of the relay types discussed. Many automotive relays allow manufacturers to implement advanced safety features and modern electrical conveniences.

What is an on delay timer?

On-delay timers begin timing when the input is applied, powering the second circuit after a set wait time. This can be used to stagger the powering of multiple components, preventing power surges, or for applications like alarms and warning systems.

What is a sequence relay?

Sequential Relays. Sequential relays can be used to power multiple components in turn, typically in a set order. A common application for this type of relay involves powering multiple systems or sets of lights one after another, such as in runway lights or power supply sequencing.

Why does a relay fail?

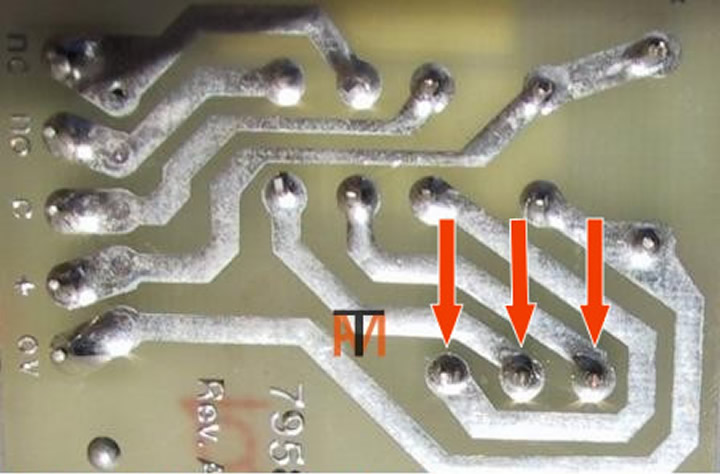

Another way they can fail is the solder joints can fail.

Do relays work in British cars?

Relays in British cars always work intermittently. benzbaronDaryn wrote: A relay is a lot like a breaker and each time the relay clicks there is a small arc of electricity between the contacts, after awhile the electrical arcing will cause corrosion which builds up and prevents contact.

What is a relay?

It is simple – most relays have moving parts ( except for solid state) to achieve electrical switching using a coil and a set of contacts and anything that moves mechanical is going to suffer an eventual failure. The term relay can describe a variety of components in your machine systems.

What is relay in machine?

The term relay can describe a variety of components in your machine systems . Here we will go over a few of them and what causes them to fail. Electro-Mechanical Type Relays. These are one of the most common and oldest types of relays. Originally, they were invented for amplifying signals in telegraph systems.

What is contactor relay?

A contactor is a larger more robustly built type of relay that is designed to withstand large currents. This type of relay is extensively used in motor control, sometimes as a stand-alone device and other times as a component of a larger motor control system.

What is a solid state relay?

The solid-state relay is usually much smaller than the mechanical type as it does not use a coil and mechanical mechanism to control its switching action.

Is a solid state relay more reliable than a mechanical relay?

Solid state relays are considered to be somewhat more reliable than mechanical ones however they do still suffer the same age, heat and wear and tear failure modes that most electronic devices are subject to.