The dangers of not curing soap are:

- soap may not last very long

- soap may be unstable

- soap may not be as hard

- saponification may not be complete, resulting in a lower quality soap product.

What is saponification?

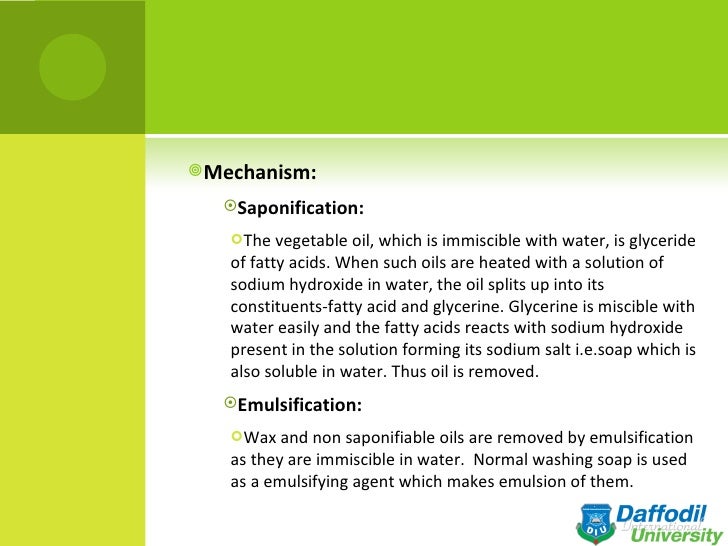

Saponification is at the heart of soap-making. It is the chemical reaction in which the building blocks of fats and oils (triglycerides) react with lye to form soap. Saponification literally means "turning into soap" from the root word, sapo, which is Latin for soap. The products of the saponification reaction are glycerin and soap.

What is the difference between saponification time and cure time for soap?

Many new soapmakers seem to get confused when it comes to defining saponification time and cure time when making handmade soap. The two terms are not interchangeable. Both are important to learn. Saponification is the chemical reaction that occurs when we mix oils with a lye solution. This process usually takes about 24-48 hours to occur.

Why does soap need to cure before use?

When we are making soap we use distilled water or milk to dissolve the Sodium hydroxide (lye), which is needed for producing the soap. When we take out the soap from the mold, it still contains water and lye. This is why the soap needs a period of time, called curing, to allow it to be in the best condition to be used.

What factors can affect saponification?

There are many variables that will impact saponification and different soap ingredients have very distinct characteristics. Be sure to research the types of fatty acids you are using (for example, coconut oil, olive oil, etc.) and the results they may have on the final soap product.

How Do You Know When Your Soap is Done Curing?

How long does it take for soap to saponify?

What happens during the cure time of soap?

How long does it take for saponification to occur?

How long before I use soap with water discount?

Is saponification time interchangeable?

Does heat make soap saponify faster?

See 2 more

Why is it important to cure soap?

Harden the Soap The more important reason to cure your soap is for the water to slowly evaporate over time, which causes the soap to harden. A harder bar of soap will last longer, produce more lather, and just be an overall better bar of soap.

Why does cold process soap need to cure?

Cold process soap requires patience. It needs several days to harden in the mold. Then, it needs to cure for 4-6 weeks to allow excess water to evaporate. Curing creates a firmer bar that lasts longer in the shower.

What happens if you use soap before it cures?

It's necessary to cure the soap to ensure that it is completely dry. As the moisture remaining in the soap evaporates, the bar will become harder and will last longer when you begin to use it.

Do you need to cure liquid soap?

Liquid soaps don't need curing in the same way as bar soaps for several reasons. First, liquid soaps are pretty much always made by hot-processing. The finished soap paste will normally have already completed the saponification process.

What is curing in soap making?

Most soaps need 4 or more weeks to cure, or to complete the saponification process, during which fats, water, and lye turn into soap. The longer it sits, the harder and milder it will become.

How do you know when saponification is complete?

The Zap Test for Soap The zap test is when you stick a bar of soap to your tongue. If it zaps you like a 9-volt battery, your soap is still not saponfied. If it doesn't, it is probably done with the process. Again, saponification takes about 24-48 hours.

What temperature do you cure soap?

120-130 ° FThe temperature range of 120-130 ° F is a safe range that should not look cloudy, or lead to false trace. It's also important that your lye is an appropriate soaping temperature. Just like soaping oils, a great lye temperature for soaping is 120-130 ° F.

How long to let soap cure before cutting?

24-48 hoursWhile the exact time varies for each batch depending on size and ingredients, we suggest waiting for 24-48 hours before removing and cutting your nearly finished soaps. However, you can use a gloved hand to check the soap to determine whether the soap is too soft.

Does hot process soap need to cure?

Since hot process soap uses a heat source, like a crock pot or pan, that keeps the soap batter at higher temperatures. These higher temperatures will speed up the saponification process. So, your hot process soaps won't need to cure as long as they would if they were made using the cp soap method.

Do you have to cure melt and pour soap?

The benefit of melt and pour soap is that the soap base has already gone through that process, meaning you don't have to handle lye and there's no need to cure the soap-it's ready to use as soon as it's cooled and hardened.

Where should soap be stored when curing?

While curing, soap should be stored in a cool, dry and well ventilated space. If the moisture cannot escape while curing, the chance for dreaded orange spots increases (click here to learn more about DOS). Here at Bramble Berry, we use large bakers racks to cure cold process soap.

How long does glycerin soap need to cure?

Ideally, 4-6 hours will be enough for the soap in the molds to harden enough to be removed. If not, the molds can be placed in the refrigerator for 10-15 minutes to facilitate the hardening process, though this should be avoided if possible. Once unmolded, the soap bars will be ready to use.

What happens if you use cold process soap before it cures?

If you use your soap before it has fully cured it will dissolve more quickly not just because it has a higher water content but because not all of the longer chain fatty acids have formed soap crystals at that point and it is the crystalline component of soap that is predominantly made up of longer chain soaps which ...

Can I use cold process soap right away?

To sum up the answer to the question: “When can I use my soap?” in the most commonly known and widely familiar response: You're free to use your cold process soaps in about 4 to 6 weeks; as soon as the bars have reached full cure.

Can you use uncured soap?

You never want to use or sell a bar of soap that has not cured completely. An uncured bar means that there is still active lye solution in your soap. Washing with this soap could result in very serious skin irritation and even burns.

Can you use hot process soap right away?

Most hot process soap will be fully cooled and ready to unmold and cut in about 24 hours. As with any bar of soap, the longer it sits, the harder and better it will be. Letting it sit for at least a week will really make a difference in the overall quality of your bar.

Saponification CH.docx - CHEM1412 Making Soap - Course Hero

CHEM1412 Making Soap - Saponification (Experiment) Soap making has remained unchanged over the centuries. The ancient Roman tradition called for mixing rainwater, potash and animal tallow (rendered form of beef or mutton fat). Making soap was a long and arduous process. First, the fat had to be rendered (melted and filtered). Then, potash solution was added.

How to pH Test Soap the Right Way & Why It Matters! - Modern Soapmaking

One of the common questions that come up on Modern Soapmaking, especially in hot process tutorials and liquid soapmaking tutorials, is how to pH test handmade soap.It's easy to understand why when there is so much conflicting information on the internet pH testing soap!

How Do You Know When Your Soap is Done Curing?

There isn’t really a hard and fast rule and that is why most soap makers advocate for a minimum cure of 4 weeks.

How long does it take for soap to saponify?

If it doesn’t, it is probably done with the process. Again, saponification takes about 24-48 hours. If you have a zappy soap after 72 hours, let it set a week and retest. Occasionally, you might get a soap that takes longer to saponify. You probably didn’t stir in the right direction (always stir counter-clockwise).

What happens during the cure time of soap?

The cure time is all about water evaporation. During the cure time water dissolves from your soap creating a harder and longer-lasting bar in your shower. Curing = drying. If you were to step into your shower with a brand new bar of soap it would dissolve pretty quickly. It is very important not to sell fresh soap.

How long does it take for saponification to occur?

Saponification is the chemical reaction that occurs when we mix oils with a lye solution. This process usually takes about 24-48 hours to occur. During saponification the sodium hydroxide and oils are binding, doing their love dance and turning into salts of the fatty acids.

How long before I use soap with water discount?

So I personally cure soap with a water discount at least 3 weeks before I use it. I feel like it gets milder.

Is saponification time interchangeable?

Many new soapmakers seem to get confused when it comes to defining saponification time and cure time when making handmade soap. The two terms are not interchangeable. Both are important to learn.

Does heat make soap saponify faster?

Heat quickens saponification. If your soap goes through gel phase or if you force gel phase by adding heat, your soap finishes saponification faster.

What is cold process soap?

With cold process soaps nature takes care of the curing process by allowing the soaps sit out in the open. When the soap is made, the fatty ingredients (coconut, olive, shea, soybean) and blended with sodium hydroxide (lye) along with essential oils and color and spices or herbs.

What happens when you mix lye and water?

As the bars of soap are allowed to sit out in the air, the lye works its way out of the batch and the water continues to evaporate. ...

How to make soap last longer?

When you cut your soaps into bars, spread the bars out a bit. A slight space between each one is enough to allow air to reach all sides of the bar.

How long does it take for soap to cure?

It won’t harm you. But, softer soaps melt away faster in the shower or tub. When your bars of soap are allowed to cure a full four to six weeks, the end result is a very hard bar of soap.

Does honey soap have oil?

Soaps that contain honey usually feel more ‘oily’ in the beginning. If you label your honey soaps too soon it will leave an oily stain on the label. If you follow the simple rules of how to cure your soap, it will make all the difference in the feedback you receive from customers.

Do soaps have to cure?

True, there won’t be as much air circulating in there but the soap s will still cure and your clothes will smell amazing. Another reason why some soaps need a longer cure time has to do with their ingredients. Soaps that contain honey usually feel more ‘oily’ in the beginning.

Is cold process soap the same as hot process soap?

The Hot Process method of making soap does make for a bar that can be sold right away however, their look and feel is not the same as cold process. Cold process soaps are usually smooth and hard bars of soap.

How is the soap cured?

After the soap is made, it takes about 24 to 48 hours until it is un-molded and cut.

Why is the curing process necessary?

Even though the saponification of Cold Process soap is mainly complete in the first 48 hours, there is, still, a chance that the soap bars will contain lye for up to a month. To avoid skin or eye irritation, the handmade soap needs to go through all this period of curing, before it is used. Also, the curing period will ensure that the bar of soap will last longer and will not disintegrate in contact with water.

What is water discounting in soap?

Water discounting method means that we use less water to make our lye solution. For example: we can use more than 33% lye concentration for our soap. There can be use an equal amount of lye and water (which is the minimum amount of water), but this drastic water discount can be used only by advanced soap makers. The risk is, for a beginner, is that the high lye concentration will speed up the trace and the soap batter will harden, very quickly, becoming unworkable.#N#Using a dehumidifier, in the place where we are curing the soaps, will reduce the curing period. If it rains a lot and the humidity is high, we use a dehumidifier in the space that we are making the soap.

Why does soap need to cure?

Homemade soap needs to cure for two reasons. 1.) The saponification process needs enough time to convert the fats, oils, and lye into soap; and 2.) Curing hardens the bars of soap so they last much longer.

Why does cold process soap have more moisture than hot process soap?

This is because the added heat in hot process evaporates most of the remaining liquid from the lye solution.

What is the process of making soap?

The first is called “saponification.” This means “to make soap.” It is the process that occurs when the lye solution has an organic bio-chemical reaction with the fats and oils in the mix. This neutralizes the base (lye) and makes the fats and oils gel and then harden into usable soap.

How long does it take to saponify soap?

The important thing is you do not want to cut the soap loaf into bars until the saponification process completes. For hot process this generally takes 12 to 24 hours. For cold process it typically takes 24 to 36 hours. Again, follow the recipe instructions. Once the mix has fully saponified, cut the loaf into bars.

What is the hot process in soap making?

Hot Process. The hot process of soap making uses an additional heat source to speed the saponification process and reduce cure time by an average of 70% or more.

What is cold process soap?

Cold process soap making is a simple method that involves combining fats, oils, lye solution and any exfoliates, colors, and fragrances in exact proportions and letting the concoction turn to soap through a natural occurring thermal reaction that occurs between the lye solution and fats/oils.

Why is soap called cold process?

It is called “cold process” because there is no need to add an external heat source. The entire batch can be made in a bowl. Pot or bucket as long as the container can withstand the 200F+ degree temperature the soap reaches while saponification occurs.

What is saponification in soap making?

He currently owns Bath Rabbit Soap Company and is the author of "The Complete Photo Guide to Soap Making.". Saponification is at the heart of soap-making. It is the chemical reaction in which the building blocks of fats and oils (triglycerides) ...

What is the name of the reaction that turns soap into glycerin?

Saponification literally means "turning into soap" from the root word, sapo, which is Latin for soap. The products of the saponification reaction are glycerin and soap. Chemically, soap is a fatty acid salt.

What is the name of the chemical reaction that makes soap?

Illustration: The Spruce / Michela Buttignol. Saponification is at the heart of soap-making. It is the chemical reaction in which the building blocks of fats and oils (triglycerides) react with lye to form soap. Saponification literally means "turning into soap" from the root word, sapo, which is Latin for soap.

How long does it take for soap to saponify?

For some types of soap, salt is then added to precipitate the solid soap. The saponification generally takes about 24 to 48 hours to complete once the lye and oils have been mixed and the raw soap has been poured into the mold. This process can be sped up by adding more heat or slowed down by keeping the process cold.

How long does soap need to dry?

Homemade soap should be left to air-dry for approximately four to six weeks. This is known as the curing time, and it will allow for any excess water to evaporate out of the soap. It's best for the soap to be in a cool, dry location, not touching anything else while it is drying.

Can you add lye to soap?

Be sure to buy pure high-quality lye that is made specifically for soap-making. In addition to the basic soap ingredients, there are many options that can be added to the soap to alter the fragrance, consistency, and color of the soap. Once the basic soap-making has proven successful, try experimenting with other soap variations .

Is it safe to make soap with chemicals?

Soap-making is a simple process, and it's likely you have many of the ingredients and tools already in your kitchen. However, it requires careful measurements , as you are using chemicals, some of which can be dangerous.

Why cure soap?

There are several reasons that you should cure homemade bar soaps before using them.

Do hot-process soaps need curing?

One of the biggest soap myths I see over and over again is that hot-process soaps don’t need curing.

Do liquid soaps need curing?

Liquid soaps don’t need curing in the same way as bar soaps for several reasons.

How long should you cure soap?

Generally, it’s recommended that soaps be cured for around a month. That said, some soaps benefit from a longer cure time. Other soaps may not show obvious changes after only a few weeks.

What is the process of saponification?

Basically, they are waiting for the saponification process to complete so that no lye remains. Saponification is the chemical reaction between the lye and the oils converting into soap. Saponification Process (Bar soap) Oil + NaOH => Glycerol + Soap. When finished, the resulting soap should have no remaining lye.

Why do you need to cure bar soap?

One of the main reasons to cure homemade bar soaps is that when they are first made, they tend to be on the softer side. A soft soap will dissolve away more quickly as it’s used, meaning that your uncured soap won’t last as long as one that has been allowed to dry and harden.

How long should soap cure before use?

It’s often said that soaps should be left to cure for several weeks before using them. Why is it important, though, and how should it be done?

How long can you keep a potted weed in a container?

After a few weeks, you’ll be able to burp your containers less frequently (once every few days to a week, for example) while the bud continues curing. Though your bud will be fine to smoke after two to four weeks, continued curing for four to eight weeks or more will improve the flavor and potency even more. Properly cured cannabis can be stored for up to six months in these containers or for long-term storage, it can be kept in vacuum-sealed storage for a year or more.

What happens to cannabis flowers when they are kept at the proper temperature?

When freshly-harvested cannabis flowers are kept at the proper temperature and humidity, non-psychoactive cannabinoids will continue to transform into THCa, a precursor to psychoactive THC.

How does cannabis degrade?

From the moment the crop is harvested it begins to degrade as enzymes and aerobic bacteria break down excess sugars and starches. Curing cannabis essentially forces the plant to use up those sugars, starches and excessive nutrients before they’ve had the chance to dry out and get stuck inside the plant.

How to cure a bud?

To effectively cure your harvested cannabis (if you’re unsure when to harvest, click here ), begin by hanging trimmed bud upside down in a dark room from a laundry line or clothing hangers. Buds that are still attached to the stock will hang easily at the node while smaller, “popcorn” buds may need to be dried on a screen to encourage airflow.

Why does my bud smell like mold?

Note: if you notice the smell of mold or ammonia after burping your containers the first few times, it likely means the bud is not dry enough to cure yet. Remove the buds from the jars and continue air-drying for a few more days to avoid mold.

Why is cannabis less flavorful?

If you’ve ever wondered why some cannabis is harsher or less flavorful when you smoke it, it is because these residual components have not been properly cured out of the plant prior to drying and/or distribution to the consumer. A good cannabis cure will not only improve the flavor and smoothness of a smoke sesh, it will also improve product potency, too!

How long does it take for a bud to break?

After one to two weeks , the stems should gently break when bent (instead of folding like they do when they’re fresh) and the outside of the flower should be slightly crisp. When this happens, it’s time for the next step: sweating your bud. You’ll do this by removing the bud from the larger stems (use this time to finish manicuring them if necessary) and placing them in sealable containers.

How Do You Know When Your Soap is Done Curing?

There isn’t really a hard and fast rule and that is why most soap makers advocate for a minimum cure of 4 weeks.

How long does it take for soap to saponify?

If it doesn’t, it is probably done with the process. Again, saponification takes about 24-48 hours. If you have a zappy soap after 72 hours, let it set a week and retest. Occasionally, you might get a soap that takes longer to saponify. You probably didn’t stir in the right direction (always stir counter-clockwise).

What happens during the cure time of soap?

The cure time is all about water evaporation. During the cure time water dissolves from your soap creating a harder and longer-lasting bar in your shower. Curing = drying. If you were to step into your shower with a brand new bar of soap it would dissolve pretty quickly. It is very important not to sell fresh soap.

How long does it take for saponification to occur?

Saponification is the chemical reaction that occurs when we mix oils with a lye solution. This process usually takes about 24-48 hours to occur. During saponification the sodium hydroxide and oils are binding, doing their love dance and turning into salts of the fatty acids.

How long before I use soap with water discount?

So I personally cure soap with a water discount at least 3 weeks before I use it. I feel like it gets milder.

Is saponification time interchangeable?

Many new soapmakers seem to get confused when it comes to defining saponification time and cure time when making handmade soap. The two terms are not interchangeable. Both are important to learn.

Does heat make soap saponify faster?

Heat quickens saponification. If your soap goes through gel phase or if you force gel phase by adding heat, your soap finishes saponification faster.