Why does air leak from my air compressor? Main causes: loose air tube fitting connections, bad check valve, faulty safety valve, damaged or corroded air tank, bad air pump Read more

Why is my air conditioner compressor not working?

- Capacitors – In many cases, compressor problems are caused by faulty or broken capacitors. ...

- Start Relays – As with the capacitor, the HVAC technician may try replacing the start relay, which is the only surefire way to determine whether it’s working right or not. ...

- Valves – A broken valve can create major problems in a compressor. ...

Why is my aircon not blowing out cold air?

We can categorize the issues that might lead to the AC unit not blowing cold air into 3 categories:

- Electricity issues (power and thermostat problem; #1 and #2).

- Clogging issues (drains, filters, and ice buildup issues; #3 – #5).

- Compressor issue; #6.

- Airflow switch issue; #7.

- Low freon levels; #8.

Why is my air conditioner losing Freon?

Why is my AC losing Freon? The most common cause of AC freon leaks is likely erosion of the metal over time due to formic acid or formaldehyde corrosion. Small holes are formed when the acid eats away at the metal and the unit eventually releases freon. Finally, the last major cause of freon leaks are factory defects.

Why your air compressor is not building pressure?

Why Does My Air Compressor Take so Long to Fill Up?

- Pump. The air compressor may fail to build enough pressure if there is a problem with the pump.

- Improper Connections of the Pump to the Intake Valve. The intake valve is very essential in the air compressor for home garage brands, since, it permits the air to go ...

- Gaskets Problem. ...

- Leaks. ...

- Pressure Switch leakage. ...

- Tank Leaks. ...

- Check Valve leaks. ...

How do you fix a leaking air compressor?

If your leak is at a place like an air hose connection, coupling, seal, gasket or control or shut-off valves, you might be able to fix the leak by tightening the connection. Tightening parts is one of the most straightforward ways to fix air compressor leaks.

What causes an air compressor to leak?

Water accumulates when compressed air sits in the tank, and if not properly drained will lead to corrosion and rust. Pinholes will eventually develop and cause both water and air to leak. If the pinholes aren't dealt with, they will simply get biggerand your tank will no longer be able to hold air.

How do I find a leak in my air compressor?

The most reliable tool in detecting any air compressor or air line leaks is an ultrasonic acoustic detector. These detectors can recognize the high frequency hissing sounds that are associated with air leaks.

How do I stop my air fitting from leaking?

2:405:44Leaking air couplers fixed in seconds - YouTubeYouTubeStart of suggested clipEnd of suggested clipIt just make sure that's all those edges are nice and square and flat and that'll help if you haveMoreIt just make sure that's all those edges are nice and square and flat and that'll help if you have one just that kind of leaks once in a while do that.

What are 3 common issues problems with a pneumatic air compressor?

Most Common Air Compressor ProblemsAir compressor won't operate.Leaking air.Excessive noise.Compressor humming.Oil doesn't last long enough.Excessive oil in the air compressor discharge air.Constant vibration.Compressor won't build pressure.More items...•

How do you know if your air compressor valve is bad?

“The symptoms could be a loss of cooling or refrigeration, higher-than-normal suction pressures with low discharge pressures, the compressor being very quiet, or low amp draw,” he said. Griewahn said he normally hears complaints of the system not maintaining the temperature setting during a mild load.

How tight should air compressor fittings be?

“Snug” with either Teflon tape on the male threads or a liquid thread sealant (not the same as threadlocker but loctite sells both products). For the really small 10-32 fittings, assuming it has the gasket that comes with those fittings, we have had good success (leak free) with just finger tight installation.

What do you seal air compressor fittings with?

2:0811:02How To: Seal Air Compressor Fittings - No More Leaks - FOR GOOD!YouTubeStart of suggested clipEnd of suggested clipThey do come apart we are going to use Loctite to seal. All of these threads. A couple of caveats.MoreThey do come apart we are going to use Loctite to seal. All of these threads. A couple of caveats. You really want to make sure that.

Should I use Teflon tape on air compressor fittings?

Should I use Teflon tape on air fittings? It is a good idea to use Teflon/PTFE tape on threaded fittings. Quick-release fittings are designed to seal using internal o-rings, so any additional sealant or tape is not required.

How would leaky oil rings affect a compressor?

When the compressor rings are worn, high-side discharge gases will leak through them during the compression stroke, giving the system a lower head pressure. Because discharge gases have leaked through the rings and into the crankcase, the suction pressure will also be higher than normal.

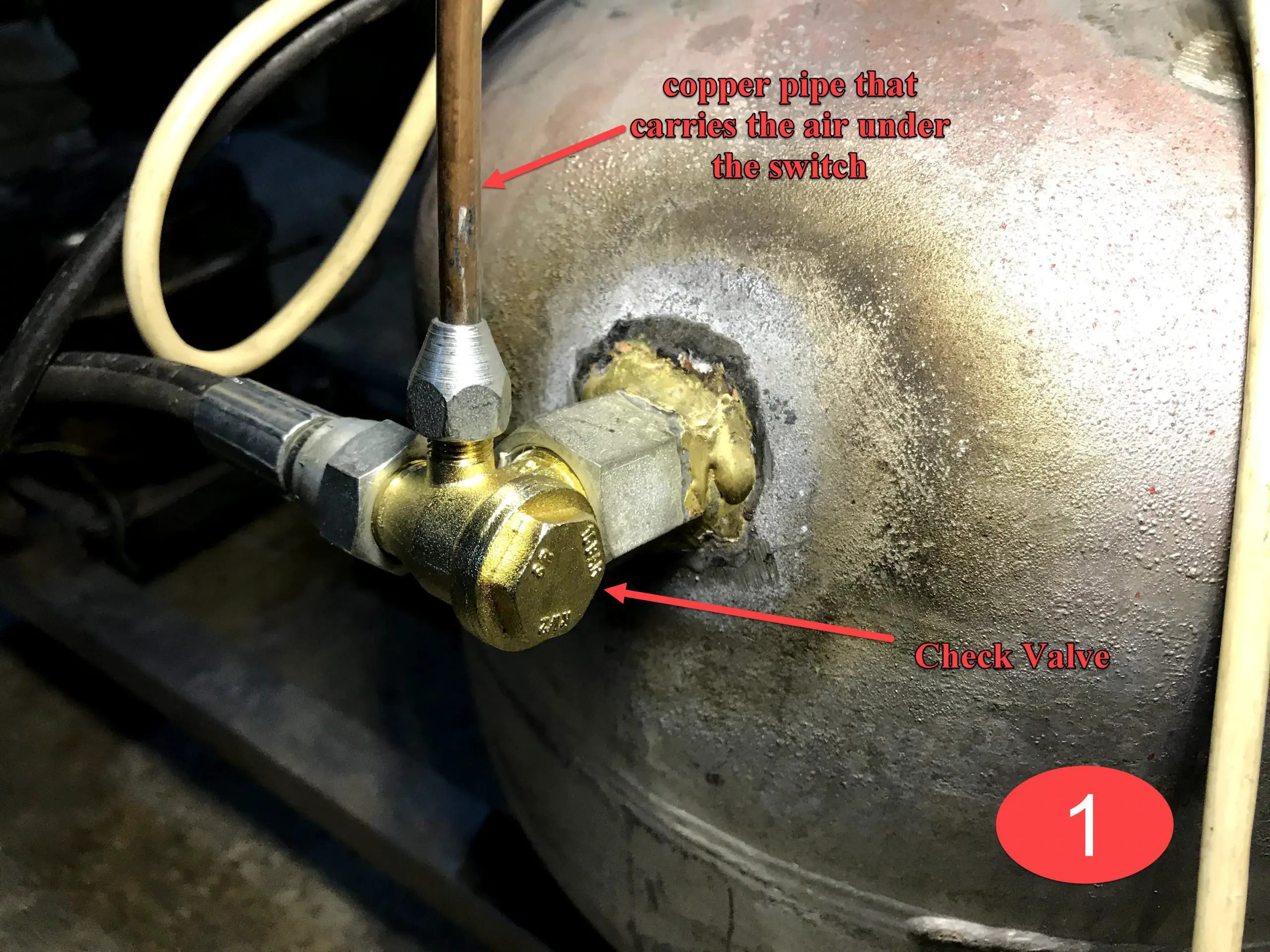

Where is the check valve on an air compressor?

Located between the compressor and the air receiver tank or main header, a check valve is designed to prevent air from bleeding out of the tank or header and back into the inlet line when a compressor shuts down.

Why is My Air Compressor Leaking?from about-air-compressors.com

Air compressor leaks can happen due to several reasons and appear in many parts of a compressed air system. The most common leaks found on air compressors are:

How to find leaks in compressor?from quincycompressor.com

By listening closely or using ultrasonic leak detectors, you can more effectively find leaks. They can appear throughout your compressor system, and some components can also be checked in other ways:

Why is it important to keep compressed air running?from quincycompressor.com

With such high energy demands and effects, it is essential to keep your compressed air system running at peak performance. Knowing how to find a leak in an air compressor and how to fix and prevent leaks in the future can offer enormous benefits for any company that regularly uses an air compression system.

How to use an ultrasonic leak detector?from quincycompressor.com

To use an ultrasonic leak detector, an operator will walk the plant with the unit in hand. Headphones or displays within the detector signal the operator to the precise location of the leaks.

How does an air compressor affect business operations?from quincycompressor.com

In addition to the financial downsides, air compressor leaks can affect business operations due to: Productivity losses: If your tools aren’t getting the right amount of air, they aren’t going to work as effectively.

How does leak maintenance help an industrial plant?from quincycompressor.com

With a consistent leak maintenance schedule, you keep your machines running continuously and can rely on them more than you would a system that crashes all the time. You can worry less about performing repairs and more about running your plant.

What to do with a leaky hose?from quincycompressor.com

Hoses and tubes: Swap out the section with a leak for a new, well-fitted replacement.

Why do compressors leak air?

Rebuild the air compressor pump if it leaks air through the pump head when the pump runs because a broken valve plate seal is allowing air to escape through the pump head.

Why won't my air compressor restart?

If your air compressor won't restart after the tank fills, the check valve might be the problem. This DIY repair guide and video explain how to replace an air compressor check valve in less than 15 minutes.

What does it mean when your air compressor gauges show that the tank isn't building pressure?

If your air compressor's gauges show that the tank isn't building pressure, the pump might be the problem . This DIY repair guide and video shows step-by-step instructions for rebuilding an air compressor pump.

Why does the safety valve pop open?

The safety valve pops open to relieve excessive air pressure if the pressure switch fails to shut off the air compressor at the cut-out pressure setting. Replace the safety valve if it leaks or pops open at normal operating pressure.

How long does it take to replace an air compressor valve?

You can replace a defective air compressor check valve in about 10 minutes.

Why replace check valve on a pump?

The check valve prevents tank air from back flowing to the pump and unloader. If air leaks out the unloader when the pump stops, replace the check valve because the check valve leaks air back towards the unloader.

What happens when an air compressor leaks?

What has happened to it when your air compressor pressure switch is leaking air? Essentially, there are two reasons why this can occur. But first, lets talk about what the pressure switch does for the air compressor. A pressure switch reacts to pressure. In the case of your air compressor, the pressure switch is typically plumbed ...

Why is my compressor pressure switch leaking air?

Reason one why your compressor pressure switch is leaking air is that, over time, the diaphragm inside the switch has cracked or worn a hole, and air is blowing from inside the tank, through the hole in the diaphragm, and existing the switch housing through any convenient opening.

Why is air leaking from the unloader valve when the air compressor is stopped?

If air is leaking from the unloader valve when the air compressor is stopped, that points to a problem with the compressor tank check valve not seating properly, or its failure.

Why is the pressure switch on an air compressor plumbed?

In the case of your air compressor, the pressure switch is typically plumbed so that the air from the compressor air tank can flow to the switch. It is the air in the compressor tank that the pressure switch is sensing. Compressed air pressure pushes equally in all directions at the same time.

Can you replace a compressor pressure switch?

If it were us, we’d simply purchase a new switch and replace the old. In this manner the removal and re-installation is straightforward, you get a new diaphragm in the switch, and you also get new points, which are another wear item in a typical compressor pressure switch.

Can you pull the cover off a pressure switch?

In the photo above, the electric wire ports would be logical places for air to exit the cover should the pressure switch diaphragm have become holed. If the wire strain-relief fittings fill the apertures in the switch, then it may be necessary to pull the cover off the switch to investigate for leaks. If you do this, ensure that the compressor has been unplugged from any power source.

Why does my air compressor get water?

Air compressors get water in them due to condensation and wringing of vapor from atmospheric air. There is a bevy of factors affecting the amount of condensation and wringing that occurs, sometimes leading to significant amounts of water byproduct.

Why does water build up in air compressors?

As mentioned in the introduction, water builds up in air compressors due to condensation and wringing of water vapor from atmospheric air. While many are familiar with the process of condensation, which causes dew to form on the grass on a chilly summer morning, ...

Why do air compressors have air drying components?

Many industrial air compressors have air drying components To combat this issue of high water content in humid ambient air that evaporate the humidity from the ambient air before it enters the compression motor. However, not all personal air compressors have this feature, meaning that there is likely to be a greater air compressor water byproduct in humid locales.

What is the characteristic of compressed air?

An essential characteristic of compressed air is that it cannot contain the same amount of water vapor as the ambient air. Ambient air squeezes as it enters the compression chamber, sort of like how water gets squeezed from a sponge. additionally, as water vapor escapes while being squeezed, the air gets colder as its volume decreases.

What does it mean when your compressor is too large?

If you have a very large or extremely high volume air compressor, it is all but a certainty that you will notice significant water buildup.

What is the number two factor in ambient air?

Number Two: High Humidity Content in the Ambient Air and High Ambient Air Temperatures

How to get moisture out of air compressor?

Therefore, regular drainage of the receiver tanks is crucial to getting rid of the moisture in your air compressor system. In most cases, you can accomplish this through a simple manual drain, but timer-based drains and pneumatic drains are also very useful options.

How to tell if compressor is leaking air?

If you shut down the compressor when the tank is filled with air and then find that the pressure gauge is showing a drop in pressure, you know that the compressor is leaking air. If you plug in the compressor, the pressure switch response to the air leak and dropping compressor pressure will be to start the compressor again. To try and find the leak, do the following.

Why does my compressor not turn on when it is powering on?

Power switch failure — When the compressor fails to power on, it could be due to a lack of contact between the pressure switch and inner circuitry . This can possibly be remedied with adjustments to the pressure switch.

What causes noise in a car?

Loose parts — Noise is often the result of loose internal parts. Check for looseness in the pulleys, cooler, flywheel, clamps, belt, accessories, etc. and perform tightening as needed.

What is a Quincy compressor?

Throughout the industries that use compressed air for operations, Quincy Compressor is among the most trusted providers of compressors and air tools.

Why does my air compressor vibrate?

Vibrations from any piece of machinery can be troublesome. In the case of an air compressor, vibration could be the result of looseness in any number of areas. The following parts should be inspected for looseness or alignment problems and tightened or adjusted accordingly if tremors/vibrations persist.

How much power does an air compressor need?

Overdrawn power circuit — An air compressor needs the undivided power of a 15-20 amp breaker at minimum. If other machines are also being powered on this same circuit, turn them off so the compressor can receive the full power source.

Why do compressors need oil?

A compressor needs oil to run properly, pure and simple. That said, few aspects of compressor operation are more annoying than periods where the oil expires too quickly. If a compressor’s oil supply is in constant need of replacement, it’s likely down to one of the following four factors:

Why won't my air compressor build air pressure?from ipowertoolz.com

When the air compressor won’t build air pressure due to a faulty unloader valve, install a replacement valve from another brand. An unloader valve from California Air Tools can fit into a DEWALT. However, you must ensure that your replacement valve aligns with the connection of your compressor’s pressure switch.

Why does my air compressor keep shutting off?from ipowertoolz.com

Sometimes, your Central pneumatic air compressor keeps shutting off if the circuit breakers malfunction.

What happens when a compressor unloader valve is faulty?from ipowertoolz.com

When the unloading valve is faulty, it either stays in an open or closed position. A closed unloader valve will give startup problems to your compressor. Also, these faulty unloader valve problems might trigger a blow-down of compressed air.

What does the clicking sound on my air compressor mean?from ipowertoolz.com

The clicking sound indicates the pressure switch trying to send electrical power to the compressor motor. A pressure switch replacement got my air compressor operational.

How to turn on a compressor?from antler.nyc

We offer these tips regarding power and wiring that might affect your machine’s ability to turn on: 1 Always plug your compressor directly into an outlet, never a power strip. 2 Use three-prong extension cords that are less than 25 feet long to reduce resistance. They should also be at least 10 gauge. 3 Check to see if the compressor has tripped your circuit breaker. Repeated circuit breaker issues could be a problem with the air compressor wiring, an electrical circuit of insufficient amperage, or your electrical panel. If other machinery making the same electrical demands doesn’t trip your breaker, the problem is probably with the compressor. 4 Check to see that rodents or wear and tear haven’t frayed any wiring. 5 Make sure the contact is good between the power switch and internal circuitry. Sometimes switches need tightening due to vibration, and old switches may need replacement.

Why do circuit breakers trip off?from ipowertoolz.com

Mechanical equipment that uses electricity often work with circuit breakers. Circuit breakers will trip-off when power surge blows their fuses. Also, circuit breakers offer protection for power panels and equipment. They could trip-off to protect your air compressor when there’s a very high voltage.

Why is my air compressor making noise?from antler.nyc

An air compressor that’s making excessive noise usually has internal problems that require professional servicing. If you check and tighten the compressor floor mounting, replace worn vibration pads, and top off the oil without any success in reducing noise, we’re happy to take a look at it. The problem is likely:

What does it mean when an air compressor has air coming out?

Air coming out the intake filter. What does it mean when your air compressor has air coming out the intake filter? This is often a symptom of an air compre ssor that will run, and run and the air pressure in the tank only rises a little bit. Because the air pressure in the tank cannot reach the pressure switch cut out pressure level, ...

What does it mean when an air compressor valve is faulty?

These include a higher than normal suction pressure, a low discharge pressure, the compressor being very quiet, low amp draw, an unusually high discharge temperature, contamination of the valve plate, an overloaded or overheated compressor, and cut-in and cut-out pressure being too close together.

What to do when compressor symptom is air coming out intake filter?

Really, you have only one choice when the compressor symptom is air coming out the intake filter. You need to replace the valve plate.

Why is my air tank leaking?

If air is continuously leaking from the unloader valve, then it may be that your compressor check valve has completely failed or is faulty. Another possibility is a broken valve plate, which is resulting in the air coming out of the intake rather than forcing the air towards the tank.

Why does my air compressor self destruct?

Because the air pressure in the tank cannot reach the pressure switch cut out pressure level, it is possible that the air compressor will run to the point were it starts to self destruct. To understand what is happening when the air compressor has air coming out the intake filter, it helps to know how the valves on the air compressor work.

Why does air come out of the intake?

When air comes out of the intake air filter it is likely that the valve plate is broken. The valve plate should normally keep air coming out of the intake so that the piston is able to force air into the tank. To inspect this, you will need to remove the covers on the motor to gain access to the pump head.

What does it mean when air comes out of an intake filter?

Air coming out the intake filter. When you have air coming out of the intake filter, it is is sign that the LP – the low pressure valve, is failing, or has failed. Just like a piece of wire that you bend very quickly in your hands, the metal in these valves gets very hot.

What does it mean when air leaks out of an air compressor?

If air continuously leaks out of the unloader valve when the air compressor is running, that indicates that it is the unloader valve itself that has failed, and it needs cleaning and / or replacing. If you cannot resolve the leak by cleaning the unloader valve (which may be more trouble than it’s worth to attempt) then replace ...

Where is the air leak?

Since the Condor pressure switch has an internal unloader, if air is leaking from it, it may be blowing out any opening in the switch cover.

How to fix it?

In order to stop the air leak out of the unloader valve you will want to…

Why does air leak out of the unloader valve?

If air continuously leaks out of the unloader valve when the compressor is not running, then your compressor tank check valve has either failed completely, or the internal seal has not seated properly and this is allowing air from the tank to blow by that seat and escape out the unloader valve which, when the compressor is stopped, is open to atmosphere.

Can compressed air be bleeding out?

Or, in some cases, compressed air can be bleeding out as fast as the compressor can pump it, and this leads to overheating of the compressor motor and other issues you would rather not have to deal with. First though… where is the unloader valve.

Is Air Coming Out the Check Valve?

It’s gone. That means that if compressed air continuously leaks out of the unloader valve, the only other place where that compressed air might be coming from is the air tank itself.