Process capability, Cpk, is important because it indicates whether a process potentially can meet a specification. Essentially, it is a prediction of the ability of a process to meet a specification.

What is the capability of a process?

The capability of a process, statistically speaking, is the ability of that process – based on historical performance – to achieve measurable results that satisfy established specifications and statistical limits. In a nutshell, process capability indicates how well a process is able to perform its specified purpose.

What is the importance of process capability and process performance indices?

IMPORTANCE OF PROCESS CAPABILITY ANDPROCESS PERFORMANCE INDICES IN MACHINE TOOL Shinde. J.H* KatikarR S* ABSTRACT A process is a unique combination of machines, tools, methods and personnel engagedin providing a product or service. Process capability indices have been used in the

What is a capableprocess?

A process where almost all the measurements fall inside the specification limits is a capableprocess. This can be represented pictorially by the plot below: There are several statistics that can be used to measure the capability

What is capability analysis and how is it used?

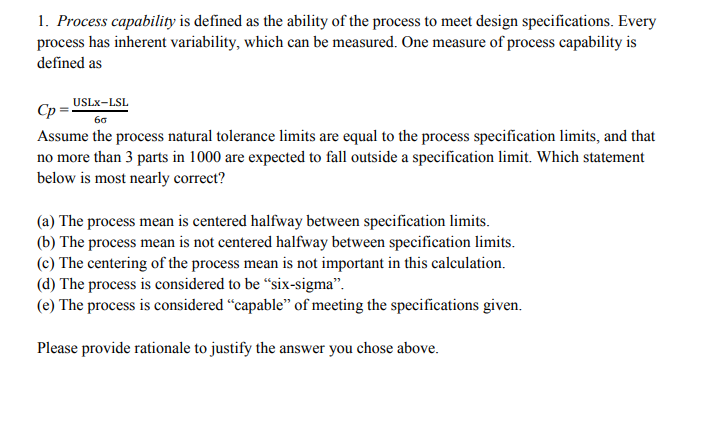

Capability analysis is considered part of the Black Belt Body of Knowledge. In order to analyze capability, look to a graphical or statistical tool that visually or mathematically compares actual process performance to performance standards. The two indices for measuring capability are Cp and Cpk.

What is the purpose of process capability?

Process capability is defined as a statistical measure of the inherent process variability of a given characteristic. You can use a process-capability study to assess the ability of a process to meet specifications.

What are the benefits of process capability?

The benefits of conducting a Process Capability Study allows you to determine the “short” term stability and capability of a process. Process Performance Studies are performed to identify how well a process, that is in statistical control, performs long term (for example, one week or longer).

Why is process capability index important?

Process capability index measures the extent of variation a process experiences relative to its specification limits. It also helps us to compare different processes with respect to the optimal situation or if they come up to our expectations.

Why is capability analysis important?

If, however, a system is stable, capability analysis shows not only the ability of the system in the past, but also, if the system remains stable, predicts the future performance of the system. Capability analysis is summarized in indices; these indices show a system's ability to meet its numerical requirements.

What is process capability with example?

Process Capability Example 1: The ice cream that must be served in an ice cream parlor has to be between -15 degrees Celsius and -35 degrees Celsius. The process of refrigeration that keeps the temperature has a standard deviation (SD) of 2 degrees Celsius. And the mean value of this temperature is -25 degrees Celsius.

How do you perform process capability?

How to Perform a Process Capability StudySelect a candidate for the study. ... Define the process. ... Procure resources for the study. ... Evaluate the measurement system. ... Prepare a control plan. ... Select a method for the analysis. ... Gather and analyze the data. ... Track down and remove special causes.More items...

What is Cpk in process capability?

Process Capability Index is abbreviated as Cpk (Cpk). It assesses a manufacturer's capacity to create a product within the tolerance range of a client. Cpk is used to determine how near you are to achieving a goal and how consistent your performance is compared to your average.

Is higher Cpk better?

The higher the Cpk, the better is the capability of the process to meet its requirements. In the industry, a Cpk of less than 1.66 needs a closer look. A Cpk that's less than 1.33 needs some action to make it higher, and a Cpk of less than 1.0 means that the process is not capable of meeting its requirements.

What is the difference between CP and Cpk?

The Cp and Cpk indices are the primary capability indices. Cp shows whether the distribution can potentially fit inside the specification, while Cpk shows whether the overall average is centrally located. If the overall average is in the center of the specification, the Cp and Cpk values will be the same.

How do you interpret process capability results?

Assess potential capability Generally, higher Cpk values indicate a more capable process. Lower Cpk values indicate that your process may need improvement. Compare Cpk with a benchmark that represents the minimum value that is acceptable for your process. Many industries use a benchmark value of 1.33.

What will be your objective in finding the process capability?

Process Capability describes a set of statistical techniques used to predict the complete output of a process by analyzing data from a small, random sample. Practitioners evaluate a process's ability to deliver on customer expectations by measuring the inherent variation that exists within that process.

What are good Cp and Cpk values?

Six Sigma Process Capability & Performance Limits According to Six Sigma philosophy, Cp or Pp and Cpk or Ppk should be greater than 1.50.

What is the objective of process capability in process improvement?

Process Capability is a continuous improvement practice that uses statistical techniques to quantify the extent to which a stable process meets end user requirements.

What will be your objective in finding the process capability?

8 Process Capability The customary method for defining the process capability for attributes data is to use the mean rate of nonconformity. The purpose of a capability study is to determine whether a process is capable of meeting customer specifications and to devise a course of action if it cannot.

What are the three major types of process capability studies?

To determine how our process is operating, we can calculate Cp (Process Capability), Cpk (Process Capability Index), or Pp (Preliminary Process Capability) and Ppk (Preliminary Process Capability Index), depending on the state of the process and the method of determining the standard deviation or sigma value.

Why is it important that a process is in control before process capability is calculated?

While we discuss process capability, we must assure that data must be normal and in control. If data is not normal and in control, it is fruitless to check for the process capability. Process capability gives a long-term performance once it is under the statistical boundaries.

How does process capability help manufacturing?

When we look at the bigger picture, process capability is more than just measuring Cp and Cpk values. Process capability is just one tool in the Statistical Process Control (SPC) toolbox. Implementing SPC involves collecting and analyzing data to understand the statistical performance of the process and identifying the causes of variation within. Important knowledge is obtained through focusing on the capability of process. Monitoring process capability allows the manufacturing process performance to be evaluated and adjusted as needed to assure products meet the design or customer’s requirements. When used effectively this information can reduce scrap, improve product quality and consistency and lower the cost to manufacture and the cost of poor quality.

What is process capability?

Process Capability (Cp) is a statistical measurement of a process’s ability to produce parts within specified limits on a consistent basis. To determine how our process is operating, we can calculate Cp (Process Capability), Cpk (Process Capability Index), or Pp (Preliminary Process Capability) and Ppk (Preliminary Process Capability Index), depending on the state of the process and the method of determining the standard deviation or sigma value. The Cp and Cpk calculations use sample deviation or deviation mean within rational subgroups. The Pp and Ppk calculations use standard deviation based on studied data (whole population). The Cp and Cpk indices are used to evaluate existing, established processes in statistical control. The Pp and Ppk indices are used to evaluate a new process or one that is not in statistical control.

Why is information gained important?

As previously mentioned the information gained is generally used to reduce waste and improve product quality. In addition, by knowing your process capabilities, the design team can work with manufacturing to improve product quality, and processes that are “not in control” may be targeted for improvement.

Can capability indices be calculated manually?

The capability indices can be calculated manually, although there are several software packages available that can complete the calculations and provide graphical data illustrating process capability. For the example in this section, we will utilize a popular statistical software package. For our example, we will utilize data from randomly collected measurements of a key characteristic of a machined part. To better represent the population values, the sample data must be randomly collected, preferably over time from a large production run. A few things to keep in mind:

What is process capability?

A process is a unique combination of machines, tools, methods and personnel engaged in providing a product or service. Process capability indices have been used in the manufacturing industry to provide quantitative measures on process potential and performance. The output of a process can be product characteristic or process output parameter.

How are process capability indices used?

Process capability indices have been used in the manufacturing industry to provide quantitative measures on process potential and performance. The formulae for these indices are easy to understand and straightforward to apply. But, since sample data must be collected in order to calculate these indices, a great degree of uncertainty may be introduced into capability assessments due to sampling errors. Currently, most practitioners simply look at the value of the index calculated from the sample data and then make a conclusion on whether their processes meet the capability requirement. This approach is not reliable since sampling errors are ignored. Procedures for two-sided capability indices, Cp, Cpk, and Cpm have been developed to assist practitioners to determine whether their processes meet the capability requirement based on sample information. In this paper, we first obtain unbiased estimators of CPU and CPL. We then develop a procedure similar to those of Cp, Cpk, and Cpm, for the one-sided capability indices CPU and CPL. Practitioners can use the procedure to test whether their processes meet the capability requirement.

What is the output of a process?

performance. The output of a process can be product characteristic or proces s output

What is a CPK in a process?

Cpk measures how close a process is performing compared to its specification limits and accounting for the natural variability of the process. Larger is better. The larger Cpk is, the less likely it is that any item will be outside the specification limits.

Why do CPK and PPK converge?

The values for Cpk and Ppk will converge to almost the same value because sigma and the sample standard deviation will be identical ( use an F test to determine ).

What is the CPK of a 3-2/3s function?

Now you end up with a Cpk of (3-2)/3s = 1/3s , but your Cp is still the same 1s as before. It is important to note that because Cpk uses the minimum function, it will always be equal to or smaller than the Cp for the same set of data.

Why do we take large samples from the process to account for variation?

Because there is not a lot of historical data we take large samples from the process to account for variation. Process Performance generally uses sample sigma in its calculation. In theory Cpk will always be greater than or equal to Ppk.

Is capability ration the inverse of Cp?

The capability ration is the inverse of Cp

Why are processes important?

Processes bring in customer confidence. Processes will bring consistency. Processes will help with monitoring and audits. Processes make business outcomes predictable. Process behavior will make life easier for internal stakeholders as well. Processes help improve employee satisfaction.

What are the advantages of a process?

Processes enable planning. One of the greatest advantages of the process is that it helps the planning processes. From input provisioning to resource requirement to supervision need...process gives us a lot of information which are mandatory inputs to the planning processes.

What is the importance of processes in customer service?

Processes bring in customer confidence. When you are required to create any product or service for a customer the customer requires that faith in your ability to be able to provide him the product in a cost-effective timely and height and with high quality.

Why is process definition important?

Similarly, the process definition will also help identify resource requirement and such identification and its usage will ensure timely and correct estimation of resource requirements for process performance.

What is a well defined process?

Any organization that has to do well must be governed by processes instead of people. The process is nothing but setup defined activities that are carried out which it consumes input uses resources is supervised to create defined output. So organizations that have well-defined processes will be able to understand and subsequently implement input ...

Why is it important to have a process that is well defined and followed?

Processes which are well defined and followed shall bring unpredictability which is one of the most important elements of any organizations success. In order to be successful, the organization shall need everything to be predictable.

How does process help employees?

Processes make employees and vendors gain more confidence in the firm if there are defined ways of doing things instead of randomness in governance. All process concerning employees, if well laid down will help employees gain more confidence in the company .

What is process capability?

The capability of a process, statistically speaking, is the ability of that process – based on historical performance – to achieve measurable results that satisfy established specifications and statistical limits. In a nutshell, process capability indicates how well a process is able to perform its specified purpose.

What is capability analysis?

Capability analysis is considered part of the Black Belt Body of Knowledge. Capability Analysis Example. In order to analyze capability, look to a graphical or statistical tool that visually or mathematically compares actual process performance to performance standards.