Refrigerants are recovered to prevent them from leaking or being dispersed into the atmosphere. All types of refrigerant should be recovered either when opening a unit to work on it or during the disposal of a unit. If refrigerant is vented into the atmosphere there will be one of two effects:

Why does it take so long to recover my refrigerant?

The lower temperature of the cylinder reduces the pressure of the refrigerant inside it. Conversely, if the system from which you are removing refrigerant is at a low ambient temperature, the recovery process will be slower. Before beginning recovery, check the positions of all service valves and the oil level of the recovery unit.

What is refrigerant evacuation and why is it important?

What Is Refrigerant Evacuation? Refrigerant evacuation is the removal of moisture, air and non-condensable gases from a refrigeration system. During this process, a vacuum pump is used to draw the sealed HVAC system into a vacuum. This removes air, nitrogen and moisture from the unit.

How do you recover refrigerant from an air conditioner?

Before beginning recovery, check the positions of all service valves and the oil level of the recovery unit. Recover the refrigerant into the system’s own receiver or storage tank if it has one. It is most efficient to recover liquid first (from the system’s liquid line), then vapor.

What is refrigerant and why do you need it?

Why Do You Recover Refrigerant? Refrigerants play an important role in the heat transfer process that makes air conditioning and heating systems possible. Some of the most common refrigerants are chlorofluorocarbons (CFCs), hydrochlorofluorocarbons (HCFCs), and hydrofluorocarbons (HFCs).

What is recovered refrigerant?

Liquid Refrigerant Recovery This refers to the ability to transfer refrigerant while it is still in the liquid state. This method is especially good for transferring refrigerant from one container to another.

Why must R 134a refrigerant be recovered and recycled?

That is why recovery is so important. Reducing global warming was the logic behind not venting R-134a. Although R-134a contains no chlorine and poses no danger to the ozone layer, it is a "greenhouse" gas that retains heat and contributes to the global warming problem.

Can you recover refrigerant without a recovery machine?

In order to recover refrigerant without a machine, you must first obtain the Environmental Protection Agency (EPA) section 608 Technician Certification. Under this section, technicians are required to pass the EPA-approved test to earn Section 608 Technician Certification.

What refrigerants do not need to be recovered?

The U.S. Environmental Protection Agency (EPA) does not currently mandate the recovery and recycling of natural refrigerants, such as carbon dioxide; HCs, such as propane, isobutane, blends like R-441A, or ethane; or ammonia.

Can you reuse refrigerant that is recovered?

Keep in mind, recycled refrigerant may only be reused in the system that it was recovered from, or in any other system owned by the same equipment's owner. Only reclaimed refrigerant can be resold or used in a system of a different owner.

Does R-134a need to be recovered?

If you need to crack open your A/C for repairs or parts replacement, then you need to recover the refrigerant first. You should never vent R134a into the atmosphere or the EPA and the Tree Huggers will kick the crap out of you.

Can I use a vacuum pump to recover refrigerant?

There's absolutely no need to use a vacuum pump to remove the refrigerant. It's really easy to remove the refrigerant by condensing it out. If you're a shade tree mechanic, this is what has worked for me to recover and store R134a: Get a refrigerant recovery tank with 1/4" fittings.

Can you pull a vacuum with a recovery machine?

Just wondering if any manufacturer of recovery units can double as a vacuum pump? He11 yes, they all can. You can use the rec machine to get the air out of the system and filter-driers to take care of moisture.

Do you recover refrigerant from high or low side?

Connect your manifold to the system being serviced: high-side to the liquid port, and low-side to the vapor port. Connect the ¼-in. utility hose of your manifold to the suction port of the recovery machine. Finally, connect a hose from the liquid side of the recovery cylinder to the discharge port.

Do all refrigerants need to be recovered?

Refrigerants should only be reclaimed if the ownership has changed. All manufacturers and importers of refrigerant recovery equipment are required to have their equipment tested by an EPA-approved organization to lessen the involved hazards.

When recovery is first started at what phase?

TYPE IIQuestionAnswer6. When recovery is first started, at what phase is the refrigerant removed to save recovery time,C. Liquid phase7. Where must you connect the hose in order to recover liquid refrigerant,C. Liquid line23 more rows

How do you recover refrigerant?

7:358:57Refrigerant Recovery Machine, Hose, and Tank Setup! Recovery Process!YouTubeStart of suggested clipEnd of suggested clipYou can go ahead and and open that up all right the refrigerants going to flow through here thenMoreYou can go ahead and and open that up all right the refrigerants going to flow through here then it's going to flow into the yellow hose.

Can you recycle r134a refrigerant?

Be Aware, California! It is illegal to destroy or discard used or unused small refrigerant containers under Section 95360 et seq. of the California Code of Regulations. AT THIS TIME, THE DEPOSIT AND RETURN PROGRAM APPLIES TO SPECIALLY MARKED CONTAINERS AND ONLY IN THE STATE OF CALIFORNIA.

How do you dispose of 134a refrigerant?

In general, if the refrigerant is not contaminated it can be recycled and reused. You can typically take the noncontaminated refrigerant back to the wholesaler for exchange. If the refrigerant is contaminated, you'll need to send it to a reclamation facility.

What does it mean to recycle refrigerant?

Recycle. “Refrigerant recycle refers to the reduction of used refrigerant contaminants using devices that reduce oil, water, acidity, and particulates,” writes DuPont. “Recycle is usually a field or shop procedure with no analytical testing of refrigerant.

What is the difference between recycling refrigerant and reclaiming refrigerant?

It's a used refrigerant that should have gone through a basic, on-site, cleaning process, which is normally carried out by the contractor completing the work. Conversely, reclaimed refrigerant is product that has been reprocessed by a licensed facility to the industry standard AHRI 700 to match that of virgin product.

How to recover refrigerant?

10 Important Safety Practices for Recovering Refrigerants 1 Always follow safety precautions: wear goggles, safety equipment, and gloves when servicing chilling equipment and reclaiming refrigerants. 2 Never guess the quantity or type of refrigerant used. 3 Be cautious when connecting gauges. Low-side gauges can become damaged by over-pressuring from high-side pressure liquid or vapour. 4 Don’t assume you know how the unit works. Be sure to read the operating instructions for the specific recovery machine you are using. Each unit’s instructions will differ by manufacturer. 5 Always use a machine with a high vapour recovery rate. Vapour recovery can account for up to 80% of the process. 6 Avoid using long hoses. The shorter and wider the hose, the faster the refrigerant will be removed. 7 Always remove liquid first. After this has been completed, work to eliminate the vapour. 8 Don’t expose your recovery machine to harmful elements. Always use an inline filter at the inlet port to keep out slivers to avoid internal damage. 9 Always remember to purge your recovery equipment between jobs. 10 Don’t forget to check the recovery tank certification. It must be recertified every 5 years.

Why Recover, Recycle, and Reclaim Industrial Refrigerants?

Since the introduction of the Clean Air Act of 1990 and the Montreal Protocol Treaty, the industrial refrigeration industry has been required to recover, recycle, and reclaim refrigerants or face hefty government fines. Whether in gas or liquid form, synthetic refrigerants can have a damaging impact on the environment.

How does synthetic refrigerant affect the environment?

When chilling equipment and refrigeration systems are being serviced or replaced, the release of synthetic refrigerants into the atmosphere can have a harmful, lasting effect on the ozone layer.

How can refrigeration improve the bottom line?

Industrial refrigeration system operators can improve their bottom line by ensuring that safety guidelines for refrigerant recovery are practiced and observed when servicing or replacing their equipment.

What is the best way to transfer refrigerant from one container to another?

1. Liquid Refrigerant Recovery. This refers to the ability to transfer refrigerant while it is still in the liquid state. This method is especially good for transferring refrigerant from one container to another. 2. Vapour Refrigerant Recovery. The refrigerant is removed in a vapour state.

How is refrigerant removed?

The refrigerant is removed in a vapour state. The vapour is then condensed into a liquid form by the recovery unit, and finally, transferred to the recovery cylinder. 3. Push-Pull Refrigerant Recovery. This method is used for transferring large volumes of liquid refrigerant—usually greater than 20 pounds of refrigerant.

How much liquid is transferred in a refrigerant recovery unit?

This method is used for transferring large volumes of liquid refrigerant—usually greater than 20 pounds of refrigerant. The recovery unit “Pulls” vapour from the recovery cylinder and produces a high-pressure discharge gas that “Pushes” liquid out of the system and back into the recovery cylinder.

How to recover refrigerant?

Refrigerants are recovered to prevent them from leaking or being dispersed into the atmosphere. All types of refrigerant should be recovered either when opening a unit to work on it or during the disposal of a unit. If refrigerant is vented into the atmosphere there will be one of two effects: 1 The Chlorine contained in CFC/HCFC refrigerants will work it’s way up into the atmosphere and will end up causing damage to the O-Zone layer. CFCs/HCFCs were phased out by the Montreal Protocol but there are still quite a few units in working order in 2015. If you are dealing with CFC/HCFC refrigerant be sure to recover as much refrigerant as possible. CFCs/HCFC are strictly monitored in the United States and across the world. 2 If you are working with HFC refrigerants you will find that they do not harm the O-Zone layer if released into the atmosphere but they will contribute significantly to greenhouse gases that get trapped in the Earth’s atmosphere. These greenhouse gases have a direct effect on Global Warming. HFC refrigerants were the replacement for the old Chlorine containing refrigerants but it was found out that HFCs have a large Global Warming Potential, or GWP. HFCs will most likely be discontinued in the near future and either replaced with HFO refrigerants or Natural refrigerants.

What happens if you vent refrigerant into the atmosphere?

If refrigerant is vented into the atmosphere there will be one of two effects: The Chlorine contained in CFC/HCFC refrigerants will work it’s way up into the atmosphere and will end up causing damage to the O-Zone layer.

What is the purpose of refrigerant in a refrigeration system?

Many types of heating, cooling and refrigeration systems rely on refrigerants to transfer heat. [1] They can be essential to how the refrigeration process works in such equipment. [2]

When Is Refrigerant Evacuation Necessary?

There are a few instances when an HVAC technician may need to evacuate water, air and other unwanted substances from a system:

What Are Some Keys to Successful Refrigerant Evacuation?

Taking certain measures can help make for a successful refrigerant evacuation:

What is refrigeration evacuation?

What Is Refrigerant Evacuation? Refrigerant evacuation is the removal of moisture, air and non-condensable gases from a refrigeration system. [3] . During this process, a vacuum pump is used to draw the sealed HVAC system into a vacuum. This removes air, nitrogen and moisture from the unit.

How does a refrigerant transfer heat?

Refrigerants transfer heat when they change phases. They absorb heat while in the evaporator, transforming from a liquid to a vapor. When the gaseous refrigerant enters the condenser, it releases heat to the outside air, cooling the refrigerant. It then flows into the expansion valve and returns to a lower pressure, cooler liquid.

Why does my air conditioner compressor fail?

Water in a heat pump or air conditioner can mix with the lubricating oil in the compressor, forming an acid sludge that can corrode the component, causing it to fail. Since the compressor is one of the most expensive parts in an HVAC system, this can be a serious problem.

Can you evacuate an HVAC system?

As you can see, a lot can go wrong when contaminants like air, water or nitrogen infiltrate an HVAC system. The good news is you can evacuate them from the unit and restore it to proper functioning.

How to recover refrigerant?

Recovering refrigerant can be a lengthy procedure and there are various methods that can be utilised to improve the speed of recovery, including the push-pull method where the recovery unit ‘pulls’ vapor from the recovery cylinder and produces high-pressure discharge gas that ‘pushes’ liquid out of the system and back into the recovery cylinder. There are also specialist recovery units which can recover refrigerants quickly from systems with bigger volumes, particularly where the time to recover the refrigerant may be critical and installation shut down time limited.

How long can you use HFC refrigerant?

The F-Gas Legislation states that all HFC refrigerants from refrigeration and air conditioning systems must be recovered and any reclaimed and recycled refrigerants with a GWP >2500 can continue to be used for a further 10 years after the service ban on virgin product use came into effect on 01/01/2020.

Where is Climalife refrigerant returned?

At Climalife UK, the recovered refrigerant is returned to the filling plant in Swansea, adhering strictly to the Hazardous waste regulation procedures along with correct documentation, with the site holding a waste licence to reprocess refrigerant. Typically, all recovered refrigerant that is returned can be out of specification for moisture content, acidity and high boiling residue such as particulates.

Is reclaimed refrigerant the same as virgin refrigerant?

Reclaimed refrigerant is often mistakenly called recycled refrigerant. They sound similar, but in reality, they are vastly different. A correctly reclaimed refrigerant which is normally reprocessed by your supplier of refrigerants, will have the same specification as virgin refrigerant.

What is refrigerant recovery?

Simply put, recovery means transferring the system’s refrigerant into a refillable refrigerant cylinder. If the refrigerant was not contaminated by a hermetic motor burnout or other cause, it may be of adequate quality to be charged back into the system after repairs are completed. Or, the recovered refrigerant may require further processing ...

How to recover refrigerant from a cylinder?

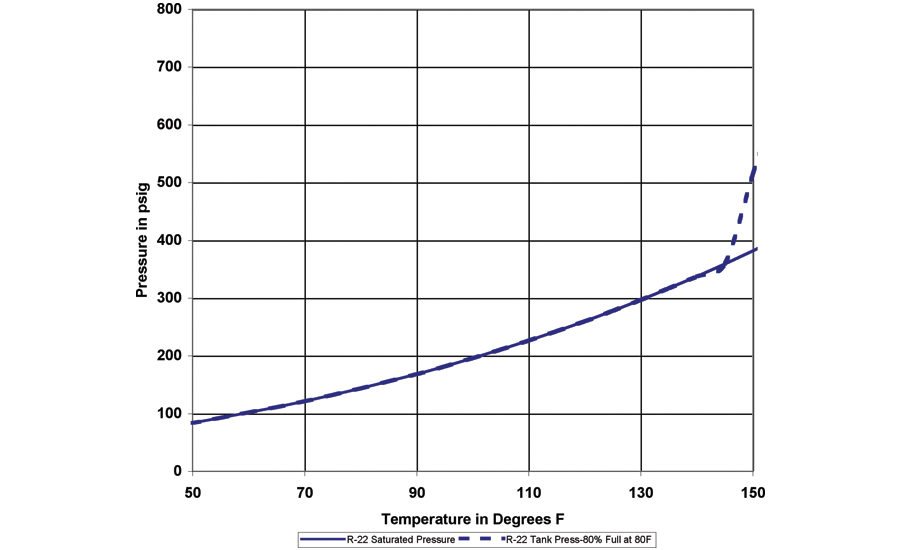

For a faster and more efficient recovery, chill the ref illable cylinder and keep it cool during the procedure. This can be done by setting the cylinder in a bucket of ice. There are also dry chemicals on the market that can be mixed with water to create low temperatures. The mixture is then poured into the bucket in which the cylinder is immersed during the transfer process. The lower temperature of the cylinder reduces the pressure of the refrigerant inside it. Conversely, if the system from which you are removing refrigerant is at a low ambient temperature, the recovery process will be slower.

What happens if you don't separate oil from the recovery unit?

If the recovery unit does not separate the oil, the refrigerant is ready to send on to a reclaiming station. If the oil is separated, drain and handle it according to local legislation. Caution: Never mix refrigerants in a recovery vessel. This may render the refrigerant impossible to reclaim.

How many microns should a recovery cylinder be evacuated?

This avoids contamination of the recovered refrigerant by air, moisture, or remaining traces of other refrigerants. Evacuate to a minimum of 1,000 microns.

How many microns do you need to evacuate a refrigerant?

If only a storage cylinder is used, it must be evacuated to at least 1,000 microns. Once the initial set-up has been completed, recovery can begin.

When did recycling equipment meet EPA requirements?

Remember that recovery and recycling equipment manufactured on or after November 15, 1993 must be tested by an EPA-approved testing organization to ensure that it meets EPA requirements. Equipment that was manufactured before November 15, 1993 , does not need to be certified by an EPA-approved testing organization, even if it was purchased after that date. When you buy equipment, be sure to check the date of manufacture. Also check that equipment manufactured before the 1993 date can achieve the required vacuums required by EPA regulations.

Can refrigerant escape?

Slight amounts of refrigerant may escape during these procedures, but U.S. Federal regulations state that “de minimis (minimal) releases associated with good faith attempts to recapture and recycle or safely dispose of any such substance (refrigerant) shall not be subject to the prohibition” (against venting).