All brake lines need to be double flared, due to the high hydraulic pressure. If your brakes leak or the hoses crack, it could prove to be fatal. Single flared lines are suitable for low-pressure lines in other applications, but not your vehicle’s brakes.

What is a double flare brake line?

The double flare is similar to the most basic flare called single flare but more durable. Manufacturers from all over the world adapted double flares for all the brake lines, but still you would find bubble flares in the vehicles manufactured in the European countries.

What is a 37 degree flare on brake lines?

What is a 37 degree flare? If you are fitting aftermarket/high performance parts you may run into 37 degree flares. standardized as A.N. (Army/Navy) during WWII for aircraft use.AN/37 degree nuts and fittings accept single and double flares. It is acceptable practice to single flare Cunifer™ (seamless) Never single flare steel brake line.

What is the difference between bubble and double flared lines?

Double flared lines help control friction wear and cracking at the sight of the flare that can ultimately lead to a leak in the line. Bubble flared lines (DIN): These line fittings are more common in European models but are considered equal in safety to a double flared line when they are used in high-pressure systems on a vehicle.

Why are single flared fittings bad for your brakes?

The reason that single flared fittings are such a big no-no when putting your brake system back together is that a single flared fitting almost always tears the metal during the fitting and creates a chink in the brake line.

Can you double flare steel brake lines?

1:362:43How to double flare a steel brake line - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo now you put your forcing screw back in. And then this gives you your 45-degree double flareMoreSo now you put your forcing screw back in. And then this gives you your 45-degree double flare because what a double flare is is the metal has pushed on top of itself to make it stronger.

Are brake lines 37 or 45 degree flares?

Most do think that flared stainless should be 37 degree. And it is easier to get a good flare with questionable tubing with 37 degrees. But you can do 45 degree double flares with the right tool and tubing.

Why should single flares not be used for brake lines?

A single flare line looks much like a double flare, but it has only one lip that is not folded over. It can fit in the socket where double flare fits but is not used in the braking system. The reason is that it is not sturdy enough to handle high pressure in the braking system.

Are single flare brake lines OK?

Single Flares are only acceptable on low-pressure lines, but not acceptable for high-pressure brake systems. A single flare is just as it sounds, the line is flared out just once in a conical shape. Single flares are not acceptable for brake lines and tend to crack and leak quite easily.

What angle flare is used on brake lines?

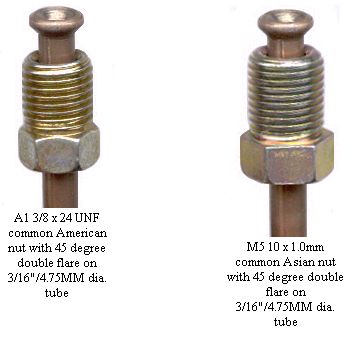

The basic types of brake line fittings. All Automotive fittings are “45 degree” fittings. The head of the flare is made at a 45 degree angle. AN or army/navy fittings are always a 37 degree fitting.

What are 37 degree flares used for?

Defined by MIL-F-18866 and SAE J514 standards, these flare fittings have been machined to have a 37° flare seating surface. These fittings are most commonly used in fluid power and fuel delivery applications, especially those using high pressure.

Do all brake lines have to be double flared?

All brake lines need to be double flared, due to the high hydraulic pressure. If your brakes leak or the hoses crack, it could prove to be fatal. Single flared lines are suitable for low-pressure lines in other applications, but not your vehicle's brakes.

Can you use a double flare instead of a single flare?

The single flare is very identical to the double flare. Although they look a lot alike, the double flare is much stronger and can hold more pressure build up inside the braking system. The double flare is a flare that is especially popular in vehicles imported from Europe.

What is the purpose of a double flare?

The double flare is used for installations that require repeated tightening/untightening. The fitting moves against the folded over section causing that to wear and not the already thinned outer pipe wall. There is no difference between the pressure rating of single and double flares.

Is double flaring necessary on steel tubing?

A double flare should be used on 5052-O and 6061-T aluminum alloy tubing for all sizes from 1/8 to 3/8 inch outside diameter. This is necessary to prevent cutting off the flare and failure of the tube assembly under operating pressures. Double flaring is not necessary on steel tubing.

What are the two types of brake line flares?

There are two types of flares: 45-degree and 37-degree. 45-degree flares are the most common in automotive use. AN or Army-Navy fittings require 37-degree single flares.

How do you double flare a brake line without tool?

3:515:50DIY Brake line flaring - YouTubeYouTubeStart of suggested clipEnd of suggested clipTime with your die head turned to op 1/4 3/16 which is the size that we're doing take your lever andMoreTime with your die head turned to op 1/4 3/16 which is the size that we're doing take your lever and pull it all the way. And then move it back this forms the first half of the flare.

Is a Double Flare the Same as a Bubble Flare?

No, they are two distinct flare styles. But to achieve a double flare, you’ll need to make a bubble flare first. These two styles of brake line fla...

Can You Make a Bubble Flare with a Double Flare Tool?

Yes, you can make bubble flares with the double flaring tool kit. Most of the double flare tool is an all-in-one kit that is capable of making all...

How Do You Double Flare a Brake Line?

There are several types of tools available on the market for flaring brake lines. You’ll require a double flare tool to make such flares in the bra...

Why do brake lines need to be double flared?

All brake lines need to be double flared, due to the high hydraulic pressure. If your brakes leak or the hoses crack, it could prove to be fatal. Single flared lines are suitable for low-pressure lines in other applications, but not your vehicle’s brakes.

What does flared brake line mean?

A flared brake line simply means that the ends of the metal lines are stretched out so they can seamlessly fit with another section of metal line. The idea is to make sure there aren’t any breaks between the lines that would lead to leaks or broken lines.

Why do brakes have double flares?

Double flared lines, on the other hand, help reduce friction at the flares, which can cause cracking or leaks. You’ll see double flared lines in automotive brakes, usually in American and Asian models. European vehicles use bubble flared lines, which are similar in safety for high pressure hydraulic lines. If you see single flares on your brake ...

Do European brakes have bubble flares?

European vehicles use bubble flared lines, which are similar in safety for high pressure hydraulic lines. If you see single flares on your brake system, replace them right away with double flared lines. While other parts of your car may use single flares, your brake system should never use anything but double or bubble flared lines.

How to cut brake line?

1. Cut the tubing to the required length with your tubing cutter. Use your old brake lines as guides, cutting each line ahead of time so that you can visualize how much extra tubing you have (or need to buy, if you're short). ...

What to do if you have never made brake lines?

If you've never made brake lines before, you'll need to do some research to ensure you're installing the correct parts. Look in the owners manual, or bring the old brakes lines off your car and into an automobile shop. ...

How to make a flare on a flat anvil?

Tighten the flaring cone, boring into the anvil, until the anvil is flush with the base. Just turn until the bottom of the anvil sits comfortably on the flat anvil base, then unscrew it and remove the anvil. This creates your first flare. Don't use excessive force here, or you could damage the flare.

Where should the flaring tool hang?

The actual flaring tool should hang over the edge of the table, as the brake lines need to drop down below the tool as you work.

Can you buy pre-flared brake lines?

Know that you can purchase pre-fabricated lines at most auto stores to save time and energy. As long as you have the right sizes and fittings, you can buy brake lines that are already double flared. Make sure, however, that the pre-flared line will fit your car by comparing to the old lines.

What is the most commonly used brake line flare?

Automotive experts use both the Bubble and Double flare in brake lines. But the most commonly used brake line flare is the SAE double flare. It’s also known as the inverted flare, which is essentially the enhanced variant of the single flare. The quality of the brake flares is a crucial factor.

What degree are brake line flares?

What Degree is Brake Line Flares? There are two types of brake flare fittings available – 37 and 45 degrees. 45-degree brake line flares are the most commonly used in all kinds of vehicles all around the world. AN-fittings require 37-degree brake flares – AN stands for US Army and Navy.

Can you use a double flare tool?

Basically, the bubble flare is the first step in producing a double flare. So it’s apparent that you can use a double flare tool for making bubble flares. Having an all-in-one tool that can make all kinds of flares is an exceptional benefit for you.

Can you make bubble flares with a flaring tool?

Yes, you can make bubble flares with the double flaring tool kit. Most of the double flare tool is an all-in-one kit that is capable of making all kinds of flares out there – single, bubble, and of course, double. Basically, the bubble flare is the first step in producing a double flare.

Do you need a bubble flare for a double flare?

No, they are two distinct flare styles. But to achieve a double flare, you’ll need to make a bubble flare first. These two styles of brake line flares are the most common flares found in all sorts of vehicles. The double flare is similar to the most basic flare called single flare but more durable.

Can you make double flares with a bubble flare?

You’ll require a double flare tool to make such flares in the brake lines. You can’t make double flares with a single or bubble flare tool unless it’s an all-in-one flaring kit. So make sure your device is capable of producing double flares.

What type of flare do you need for a fitting?

For AN fitting, you need a single 37-degree flare. This kit looks like the double flaring kit, but does not have the dies and has a 37-degree head. Hydraulic – Hydraulic flaring tools are generally only used in shops where a lot of line flares are made on a regular basis, the average DIY mechanic does not need one.

What is the most common tool for flaring lines?

This is the most common tool you will find for flaring lines, the manual clamp. You can use these under the car on in a vise, making them very versatile. There are two types of flares: 45-degree and 37-degree. 45-degree flares are the most common in automotive use.

Can you install a fitting on a line before flaring?

Don’t forget this, as you can’t install the fitting once the line is flared. Make sure that the fitting is on the line and facing the right direction before flaring the end.

Is it hard to make a double flare brake line?

It is not difficult, but if you have never done it before, it can seem like a bit of voodoo. There are several key points that you need to know before you get started, so get ready to learn how to make a double flare brake line.

How to make a double brake line?

Steps for How to Make a Double Flare Brake Line. Place the Fitting onto the Brake Line. Place the fitting onto the brake line before flaring the line. Thread the Brake Line so It Protrudes from the Concaved Threads on the Flare Bar.

How to make brake line fit over lip?

Having the brake line a little over the lip is okay, but you do not want the brake line to be falling below the lip’s height. Tighten the Screws on the Flare Bar. Tighten the screws on the flare bar. Double Check the Alignment of the Brake Line and Adaptor Lip. Double check the measurement of the brake line and lip on the adaptor.

How to tighten a brake line?

Thread the brake line through the tool so the end that will be flared is level with the concaved threads. Tighten the screws on the bar—tightening the side closest to the line first. Tighten the adaptor to the yoke press tool. Place the pressing tool into the brake line. Tighten the pressing tool until it bottoms out.

What is the difference between a single flare and a bubble flare?

Single flare, double flare, and bubble flare (left to right) A double flare bends the metal over and in, while a bubble flare bubbles the metal up. These flares add more protection to the brake lines with double the safety and thickness, and will last longer.

How to bend brake line to 90 degrees?

Place the first marked bend on the brake line at the 0 marker on the bender tool. The numbers on the tool represent the amount of degrees the brake line will be bent to. With the mark on the brake line lined up at zero, hold the brake bender steady and bend the brake line to 90 degrees, stopping the tool at the 90 mark.

Do brake flares bend over?

These flares add more protection to the brake lines with double the safety and thickness, and will last longer. A single flare flares the metal out, but it doesn’t bend over. They’ll cause leaks and aren’t safe to use with brake lines.

Can you replace brake lines on your own?

If the brake or clutch lines are rusted or leaking, it’s a good idea to replace them, and it’s usually cheaper to replace them on your own. The steps involve cutting, bending, and flaring the brake lines, and these can be done with a few special tools.

Why do you need to flare brake lines?

Flaring brake lines ensures a leak-proof connection without extra materials or sealants. If the brake lines aren't properly flared, you can lose fluid that will cause your brakes to fail. This article will explain how to flare your brake lines using single and double flares.

How to make a double thickness flare?

Clamp your tubing into the flaring bar. Ensure the depth is equal to the edge of your tubing size insert. Install the yoke and use it to advance the cone into the tube until a bell shape forms. Remove the insert and finish advancing the cone into the bell. The bell shape of the tube forms the double thickness flare.

How to flare a tubing?

The instructions for both types of single flare tools are given below. Put the cone of the tool over the end of the tubing. Lower the cone down until it is centered over the tube's end .