What is the difference between round and rectangular tubing bending?

Bending rectangular tubing is a more difficult process than round tube bending(all else being equal: surface area, radius, wall thickness, material type, etc.). As with almost all metal bending processes, the tighter the bend, the more difficult it becomes.

Does rectangular tube bending result in distortion?

Without the correct tooling, machinery, and method, and a skilled operator, rectangular tube bending can result in distortion.

How to ease bending square or rectangular material?

Several tips can help to ease bending square or rectangular material and reduce the amount of distortion in bent sections. Wall Thickness. Bending round, square, or rectangular material involves stretching the outside diameter (OD) of the bend and compressing its ID.

Can you bend a rectangular tube to 11’ inside radius?

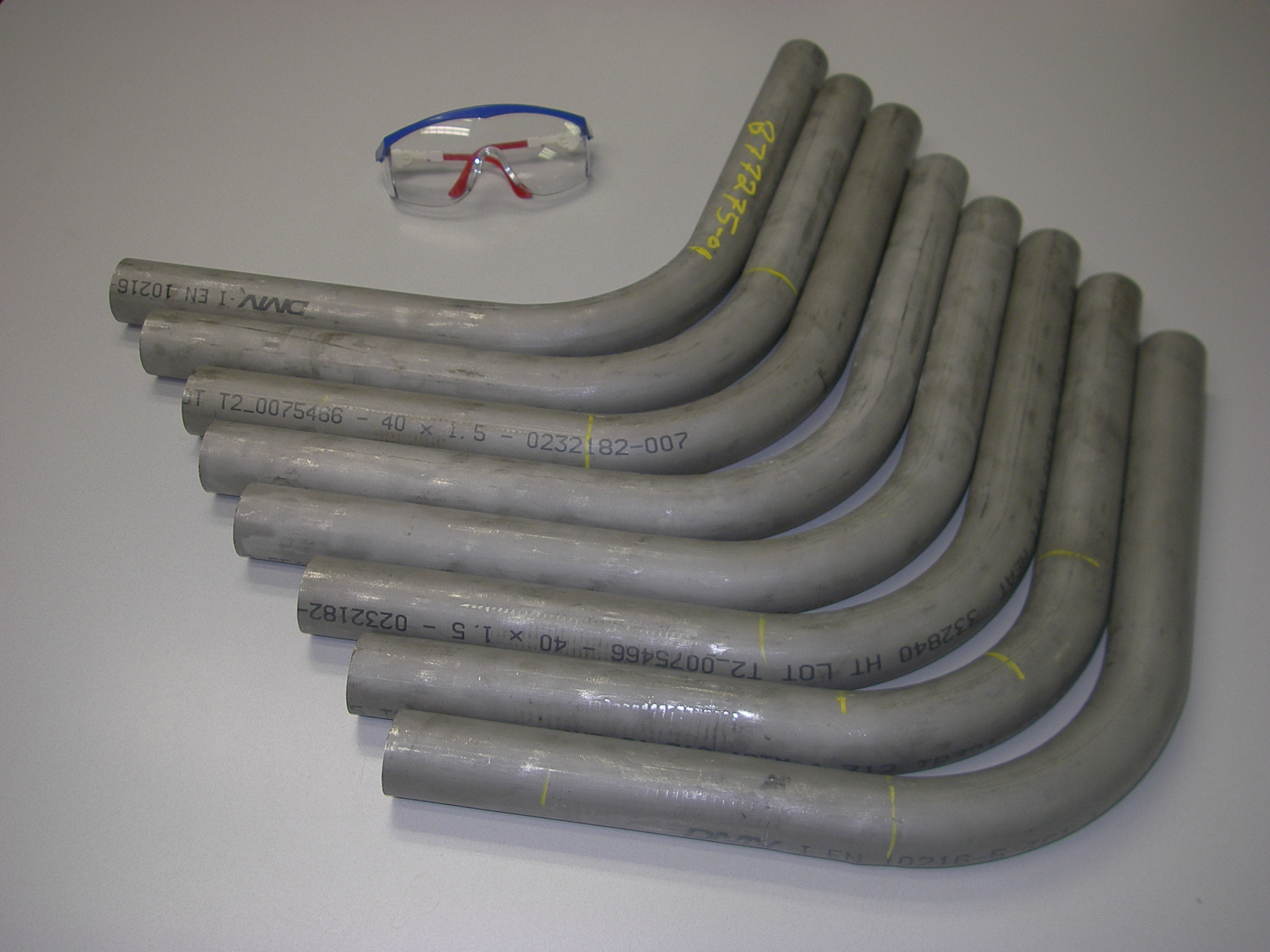

With the correct tooling, machinery, and procedures, excellent quality can be achieved, even with tight-radius, thin-wall rectangular tube bending. For example, Chicago Metal Rolled Products has curved 16” x 8” x 1/2” rectangular tube the easy way to an 11’ inside radius.

How do you bend a rectangular tube?

5:2723:41How To Make Rectangle Tube Bends WITHOUT a Bender in ANY Size + ...YouTubeStart of suggested clipEnd of suggested clipJust just a little bit snug so that we can kind of tap around with a hammer after make sure that we'MoreJust just a little bit snug so that we can kind of tap around with a hammer after make sure that we're as perfect as we can be. So just a little snug.

How do you bend square tubing without kinking?

0:244:30How to Bend Square Tubing So It Doesn't Kink - Kevin Caron - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo when you're trying to roll a piece of pipe. This upper edge of the dye is going to help hold theMoreSo when you're trying to roll a piece of pipe. This upper edge of the dye is going to help hold the sides of the pipe. And keep them from kinking. So the square tubing. You need a square die.

How do you bend a 2x2 square tubing?

0:577:31Introduction to Square Tube Bending @ Trick-Tools - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo you need to have this happen because there's. So much shrinking and stretching going on on aMoreSo you need to have this happen because there's. So much shrinking and stretching going on on a square tube in that. You have to give it a little bit of a push in the right direction.

What is stronger square or rectangle tubing?

Assuming that the rectangular section's smallest dimension is equal to (or greater than) the square section's side and their thicknesses are equal, then the rectangular section will always be stronger than the square, for any load in any orientation.

How do you bend tubing without a bender?

Use a blow torch (for harder materials) or a hair dryer (for softer materials) and heat the area where you want to bend the pipe. Once the material gets extremely hot, put on heat-resistant gloves and bend the pipe by hand.

How do you bend square tubing at home?

1:146:49Square tube bending DIY - YouTubeYouTubeStart of suggested clipEnd of suggested clipYou can mount it however you want and that's one way show you another okay so it's just a conduitMoreYou can mount it however you want and that's one way show you another okay so it's just a conduit bender.

Can you bend box section?

Rolling box section into curves will always deform the cross section of the box, to get it perfect you would need to buy extruded section to suit. Not sure on price. If you are putting a angle bend into box section try cutting and welding?

How do you twist square tubing?

0:309:00Twisting square tubing - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo the first thing we need to do is go get a bar hot and twist it to see just what I'm talking aboutMoreSo the first thing we need to do is go get a bar hot and twist it to see just what I'm talking about because it's easy to crush the ends of the square tubing I'm going to quench just the ends.

How do you bend tubing?

1:367:48How To Bend Tubing - YouTubeYouTubeStart of suggested clipEnd of suggested clipPlace the tubing in the bender. We want to put that four inch mark we just made right on the 90.MorePlace the tubing in the bender. We want to put that four inch mark we just made right on the 90. Make sure use your tubing. Clamp. Make your Bend to where the zero meets the 90.

How strong is rectangular tubing?

Rectangular TubingGrade BGrade CTensile Strength58,000 psi62,000 psiYield Strength46,000 psi50,000 psi

What is the strongest tube shape?

Round tubeTube Shape Matters Round tube is about the strongest shape by weight. It's more resistant to both bending and torsion (twisting) than square or rectangular tubing of the same weight, chemical composition, production method, and roughly same dimensions.

What is the strongest type of tubing?

Metal Tubes Information. Metal tube (tubing) is made of metallic elements or alloys and is designed for specific industrial applications. Compared to other types of tubing, metal tube is stronger and most robust, making it better suited for structural applications and high-pressure fluid flow.

What is bending tubing?

The process of bending tubing is based largely on modern science and technology. Bending dies are designed with computer software, bending machines are computer-controlled, and the stresses and strains can be predicted accurately with mathematics. However, the principles aren't based solely on modern gadgets and sophisticated mathematics.

What are the factors that determine the bending method?

Design distortion and material size are important factors for determining the bending method. In many cases, there is no better factor than experience. Many trained bending artisans know what is required to produce an acceptable product.

Why is it important to design and plan bending?

Design and planning are necessary to help solve bending problems before they arise. Tooling. After the parts have been designed, the method of bending has been chosen, and procedures to bend to proper tolerances are established, the machine must be set up with the proper tooling.

What is rotary draw bending?

Generally, smaller material requires rotary draw bending or compression bending, which can incorporate wiper dies and mandrels. Induction and increment bending should be used with larger material bent to a larger radius. Design distortion and material size are important factors for determining the bending method.

Where should a weld seam be placed?

Location of the Weld Seam. The ideal position of the weld seam is in the center of one of the four sides. The closer the weld seam is to the radiused corner, the greater the chance for improper mandrel fit and cracking of the weld seam. When possible, the weld seam should be placed on a neutral axis of the bent section.

What are the challenges of square and rectangular materials?

The challenges associated with square and rectangular material include its physical dimensions and characteristics.

Can shop fabricated material be bent?

Shop-fabricated material may be bent in the same manner as mill-produced material. However, when shop-fabricated square or rectangular material is formed, the corner edges become work-hardened. This can cause bending difficulty or cracking at the corner. Hard Way Versus Easy Way.

What is the easiest way to bend rectangular tubing?

I was visiting Portland, Oregon this weekend and saw some really clean looking gates on some residences out in the country. I wouldn’t mind duplicating this design for my farm gates, but am not sure how to make a clean, gentle radius in rectangular tubing.

Re: What is the easiest way to bend rectangular tubing?

My Swag Off Road tubing roller would work. Will work up to 2” square tube. Not sure what gauge off hand.

Re: What is the easiest way to bend rectangular tubing?

Lis, wow that’s the bomb! Pretty interesting concept with the grinder drive too. Thanks for your response.

What is the easiest way to bend rectangular tubing?

Scott. Apparently Harbor Freight makes a tubing roller that can be upgraded with Swag parts and kits including various roller configurations. You may want to check that out too. Good luck. BTW that is a HF electric pipe threader driving mine. Pretty funny really. An HF upgrade to a Swag product. Go figure. Lol

Re: What is the easiest way to bend rectangular tubing?

Doubt any of those rollers back the capacity in the photo Not unheard of to burn it and form the rectangular tube.

Re: What is the easiest way to bend rectangular tubing?

A lot of those gates (of similar design as in photo) are relatively light weight imports. You may have a difficult time match the light gauge tubing for the girth, so bending will take a real machine for like cross section. I am sure you could heat and bend a nice a arc with some effort and a whole lot of heat and some water.

Re: What is the easiest way to bend rectangular tubing?

Thx for the feedback. I’m thinking that the main components will be 2” x 6” .120 wall rectangular tubing. It may make more sense for me to have someone local do the bends.

Similarities Between Bending Round and Rectangular Tubing

Getting The Material to Cooperate

- All the available modern tools—sophisticated mathematical formulas, computer-generated programs, and CNC bending machines—may not create the desired product. This is because the workpiece being formed does not know what the tools are telling it to do. The workpiece has a mind of its own, and the operator must be the liaison between the tools and the workpiece to ov…

Factors That Influence The Bending Process

- Several tips can help to ease bending square or rectangular material and reduce the amount of distortion in bent sections. Wall Thickness.Bending round, square, or rectangular material involves stretching the outside diameter (OD) of the bend and compressing its ID. Consequently, a heavier wall thickness allows for a tighter bend radius and more material stretchability with less distorti…

Modern Science and Ancient Art

- The art of bending comprises all of the activities that come before the machine is turned on. The roots of that art go back to a time when tongs, hammers, and anvils were the tools of the trade. The moment the bender is turned on, the process takes on the knowledge and technology of modern times—blacksmiths' accumulated experience is augmented with calculus and differenti…