What is the purpose of a bull float in concrete?

A bull float is used to level and smooth freshly poured concrete. Concrete used for visible projects, such as driveways, patios and sidewalks, often requires finishing. A bull float is a tool used for finishing concrete. How long do you wait to float concrete?

When should I bull float my concrete driveway?

Darbying or bull floating should be done immediately after “screeding”, or after the concrete has been tamped if tamping was done. This process should be finished before excess moisture or bleedwater appear on the surface. Do you have to bull float concrete? A bull float is used to level and smooth freshly poured concrete.

What are the disadvantages of a bull float?

3: Cleaning ability – After a long day placing concrete, bull floats can become heavy when caked in concrete. Some bull floats are of simple designs, and others have nooks and crannies that are annoying to get concrete out of. 4: The weight of the bull float – Heavier the better right?

What is a float on concrete?

A float compacts the concrete surface, giving it a smooth look. Putting a smooth, durable finish on concrete is a skill you can only master with the proper set of tools and practice. We’ll show you the tools and how to use them for each step of the concrete finishing process.

Can you finish concrete with a magnesium float?

Once your top is flat from screeding, use a magnesium float to flatten and smooth the top while opening the pores of the fresh concrete, allowing bleed water to evaporate and air to escape. Once the concrete is firm enough and all bleed water has evaporated, use a steel trowel for your final finish.

How long do you wait to bull float concrete?

Darbying or bull floating should be done immediately after "screeding", or after the concrete has been tamped if tamping was done. This process should be finished before excess moisture or bleedwater appear on the surface.

What float should I use for concrete?

Magnesium. Although they are slightly weaker than their aluminum counterparts, magnesium floats are lighter and are the most popular choice among professionals. Magnesium smooths the surface of fresh concrete and opens the pores for proper evaporation, all without pulling the surface like a wood or resin tool.

Can you finish concrete with a trowel?

Trowel-finished concrete floors are seamless surfaces that recreate the concrete effect. They can be applied to any kind of surface, indoor and outdoor, horizontally or vertically. The decorative effects that can be obtained with a trowel-finished concrete surface are several and always customizable.

How do I get a smooth finish on concrete?

3:4511:30Learn How To Finish Concrete Smooth | Steel Trowel ... - YouTubeYouTubeStart of suggested clipEnd of suggested clipYou always want to float the concrete. First this will help level it a little better help smooth itMoreYou always want to float the concrete. First this will help level it a little better help smooth it a little better. And it just makes the whole process go a little easier.

How do you make concrete smooth and shiny?

If the concrete floor is sloped, self leveling cement can be applied to make the surface even. Ardex or other similar self leveling cementitous mixes can be applied and poured on to the surface and then ground afterwords just like regular concrete to get a smooth shine.

Do you need a bull float for concrete?

1:052:46Bull Floats - Finishing Tips for Concrete - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo if you are using a concrete with air the mag. Float is a great tool to use let's take a look atMoreSo if you are using a concrete with air the mag. Float is a great tool to use let's take a look at how they're used. As.

What is the difference between a trowel and a float?

A float has a thicker base than a trowel and is usually made of plastic, sponge, rubber, wood or magnesium – a lightweight pale grey metal. It's used to even up the surface on plaster or concrete, make it firmer and give whatever texture is required. The finish will depend on the float chosen.

How do you edge concrete after it dries?

These are the 4 steps in how to smooth concrete after it dries:Remove all imperfections on the surface.Vacuum up all debris and apply the adherent.Apply a new layer of concrete.Sand the surface and wash the concrete.Apply a layer of vitrifier to protect the concrete.

How many times do you float concrete?

Push the bull float in one direction only across the concrete, keeping its front edge slightly above the surface by raising or lowering the handle. Two or three times is enough. Don't overwork the concrete or you'll weaken it by drawing too much sand and cement to the surface.

What is the best concrete finish?

1. Troweled Finish. Trowel finish is the most common and popular finish of concrete used for major types of applications.

What is float finish concrete?

Float finishes Prior to the introduction of power tools, a floated finish was that produced by a large, generally wooden or sometimes metal, hand float moved over the surface when the concrete was still plastic. This produced a flattish slightly textured surface which often contained float marks.

What does troweling concrete do?

Trowel Finishing Concrete This type of concrete finishing equipment is used to create a polished, level finish on a variety of concrete surfaces. Floating, finishing, and combination blades are used to create the desired end result.

Is bull float necessary?

1:544:00How to Finish Concrete with a Bull Float - YouTubeYouTubeStart of suggested clipEnd of suggested clipNow if you have to move concrete around if you find if you feel a high high spot. Then you do wantMoreNow if you have to move concrete around if you find if you feel a high high spot. Then you do want to bury the front end a little bit and push that hump around but in this case we're pretty flat we

How do you power float concrete?

2:0011:48Concrete Finishing Tips For Beginners | Power Troweling Floors - YouTubeYouTubeStart of suggested clipEnd of suggested clipIn a pan is just a big round circular piece of metal kind of thing that goes under the power trowel.MoreIn a pan is just a big round circular piece of metal kind of thing that goes under the power trowel. And the blades clip inside the pan. And then you can float the concrete with that pan.

What defects can be caused by bull floating too soon?

More often, premature finishing or improper first (bull floating) or second floating results in trapping rising bleed water and air below the top surface of the concrete (Image 2). When this occurs, the resulting weak or soft zone below the surface causes the top surface of the concrete to flake or scale off.

How long do you wait to bull float concrete?

Darbying or bull floating should be done immediately after “screeding”, or after the concrete has been tamped if tamping was done. This process should be finished before excess moisture or bleedwater appear on the surface.

Do you have to bull float concrete?

A bull float is used to level and smooth freshly poured concrete. Concrete used for visible projects, such as driveways, patios and sidewalks, often requires finishing. A bull float is a tool used for finishing concrete.

How long do you wait to float concrete?

Allow all of the water to disappear before you do anything else. This can take 20 minutes or 4 hours depending on the temperature, humidity and how hard the wind is blowing. After the bleed water is all gone, you can get out your steel finishing trowel and put on the final touches.

Can you finish concrete without a bull float?

Fresnos are used for troweling slabs that do not require a hard trowel surface. A Fresnos will speed up the troweling process. Fresnos should not be used as bull floats. Troweling can also be accomplished by machine.

What defects can be caused by bull floating too soon?

More often, premature finishing or improper first ( bull floating ) or second floating results in trapping rising bleed water and air below the top surface of the concrete (Image 2). When this occurs, the resulting weak or soft zone below the surface causes the top surface of the concrete to flake or scale off.

Why does magnesium float on concrete?

Magnesium smooths the surface of fresh concrete and opens the pores for proper evaporation, all without pulling the surface like a wood or resin tool. Most magnesium floats are extruded or cast. Molten magnesium can be cast into any shape desired.

When should I start finishing my concrete?

When all traces of the water are gone and the concrete starts to harden, you can resume finishing activities. Test by pressing your gloved thumb onto the surface near the perimeter. The concrete is ready when pressing hard only leaves a 1/4-in.

What is a float for concrete?

A float also helps bring paste to the surface by pushing down the coarse aggregate. What's available: The most common floats for decorative concrete work are made of magnesium, aluminum, or wood. Less common float materials include stainless steel, rubber, and laminated wood or canvas resin.

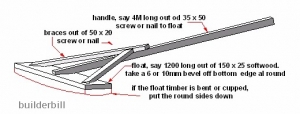

How long is a bull float?

Bull floats have a long handle that you push or pull across large areas of concrete. They are typically 8 inches in width and 3 to 10 feet in length. Hand floats, or darbies, range in width from 3 to 5 inches and in length from 12 to 24 inches. Use a bull float for areas too large to reach with a darby, though it may produce a wavier surface.

How much does a rubber float cost?

Average costs: You'll pay about $100 to $125 for a 4-foot magnesium bull float with bracket, and $18 for a 14-inch magnesium hand float.

What is the purpose of darbying concrete?

The purpose of darbying or bull floating concrete is to level ridges and fill voids left by the screeding operation. It should also slightly embed the coarse aggregate to make subsequent finishing operations easier.

What wood is used for floats?

Wood hand floats are available in variety of types, including teakwood, bodark wood, and redwood. Each type may produce a different surface texture, so it's always wise to experiment.

What is round end float?

Most floats are available with rounded or square ends. Round-end floats work more easily in tight corners and help to minimize lap marks. Watch Bob Harris demonstrate the use of various hand floats and darbies. Watch Bob Harris demonstrate the use of various bull floats, including wood and magnesium floats.

Do bull floats come with a handle?

Not all bull floats come with bracket assemblies for attaching handles, so you may need to purchase those separately as well. For better control, buy an adjustable tilt-action bracket that lets you change the float pitch with a simple turn of the handle.

How do you make concrete floats?

Concrete can be made to float if it is shaped like a boat. A boat-shaped or hollow object will displace a volume of water greater than the actual volume of solid material in the object. The object is said to be “buoyant” when it floats due to low density.

Do you have to use a bull float on concrete?

After pouring the concrete and screeding it level, the bull float is the first tool we use when finishing the slab. The job must be done right after screeding because the concrete will still be wet enough to shape. This keeps the surface smooth without digging the magnesium board into the concrete by accident.

How much does a concrete bull float cost?

Average costs: You’ll pay about $100 to $125 for a 4-foot magnesium bull float with bracket, and $18 for a 14-inch magnesium hand float. The price of wood floats varies, depending on the type of wood used, but will generally be lower than the cost of magnesium.

Can you finish concrete without a bull float?

Fresnos are used for troweling slabs that do not require a hard trowel surface. A Fresnos will speed up the troweling process. Fresnos should not be used as bull floats. Troweling can also be accomplished by machine.

How long do you wait to float concrete?

Allow all of the water to disappear before you do anything else. This can take 20 minutes or 4 hours depending on the temperature, humidity and how hard the wind is blowing. After the bleed water is all gone, you can get out your steel finishing trowel and put on the final touches.

What is the difference between a trowel and a float?

A float has a thicker base than a trowel and is usually made of plastic, sponge, rubber, wood or magnesium – a lightweight pale grey metal. It’s used to even up the surface on plaster or concrete, make it firmer and give whatever texture is required.

What defects can be caused by bull floating too soon?

More often, premature finishing or improper first ( bull floating ) or second floating results in trapping rising bleed water and air below the top surface of the concrete (Image 2). When this occurs, the resulting weak or soft zone below the surface causes the top surface of the concrete to flake or scale off.

What is a g and finishing concrete flatwork book?

g and Finishing Decorative Concrete Flatwork books provide concrete industry professionals with indispensable information. Together with the other books in ACI’s Concrete Craftsman Series— Slabs-on-Ground , Supported Beams and Slabs , and Shotcrete for the Craftsman —these new publications form p...

What is CWT in concrete?

The comparative analysis of the various methods of measuring waviness in concrete slabs reveals that the 2-Dimensional (2D) Continuous Wavelet Transform (CWT) provides results that strongly correlate with those of the Waviness Index method (the current state of the art), but has num...

What is float concrete?

A float compacts the concrete surface, giving it a smooth look. Putting a smooth, durable finish on concrete is a skill you can only master with the proper set of tools and practice. We’ll show you the tools and how to use them for each step of the concrete finishing process. And equally important, we’ll help you determine when the concrete is ready for the next finishing step.

How to use a darby to flatten concrete?

Sweep the darby across the concrete in overlapping arcs to flatten the surface, push down lumps and fill voids. Lift the leading edge slightly but keep the darby level with the surface. Make two passes.

How many times do you trowel concrete?

You’ll have to practice to develop a feel for it. For a really smooth finish, repeat the troweling step two or three times, letting the concrete harden a bit between each pass.

How do I remove concrete from a concrete slab?

Push or pull the screed board across the forms with a back-and-forth sawing motion. Shove concrete into low spots in front of the screed board. Repeat to remove excess concrete.

How to prevent concrete from getting in your eyes?

By the time you realize you’re being burned, you may already have skin damage. That’s why it’s essential to prevent prolonged skin exposure to wet concrete. And why you should be extra careful to keep wet concrete from getting in your eyes. Wear rubber gloves, a long-sleeve shirt, long pants and safety glasses. Wear rubber boots if you’ll be wading in concrete. Rinse wet concrete from your skin immediately and remove clothes that have become saturated with concrete.

What is concrete made of?

Concrete is a blend of Portland cement, sand, aggregate (gravel) and water that harden when mixed. While there are additives that can slow down or speed up the process, and special bagged mixes that set fast, in general, the speed of the process largely depends on the temperature and humidity.

Can you move a garbage can pad to a larger slab?

So it’s smart to start with a small project like this garbage can pad. When you get the hang of it, you can move up to a larger slab. But keep in mind that finishing larger slabs (more than about 100 sq. ft.) is trickier because the concrete may set up too fast.