Does glass bead blasting remove metal?

Sandblasting and bead blasting are incredibly effective methods for cleaning hard metal surfaces, removing corrosion, or even strip paint.

Is bead blasting better than sandblasting?

Sandblasting is much quicker than bead blasting. However, it is harsher on the metal material and comes with increases health risks. Also, glass bead blasting does not change the dimension of the component. On the other hand, sandblasting can reshape and smoothen the underlying component.

Is sandblasting same as bead blasting?

Bead blasting is a process similar to sandblasting, but the air pressure used is much lower, making it a slower and gentler process. It is perfect for stripping the metal clean when causing any damage is a concern.

Can you bead blast aluminum?

Bead blasting is the process most often used to achieve a surface finish that is both “rough” but consistent. Fine glass bead blasting is commonly used on aluminum parts that need a “dull” or “satin” finish.

Does bead blasting remove material?

A bead blast finish can clean corroded metal, remove cosmetic defects like textures and contaminants, and prepare a part for paint and other coatings.

How much does bead blasting cost?

Most homeowners spend between $3,000 and $7,500 to sandblast a 1,500 square foot surface, which is $2 to $5 per square foot. Sandblasting services cost around $45 to $75 per hour, although most professionals charge per square foot at an average rate of $1.50 to $3 per square foot.

What does a bead blaster do?

A tire changer's bead blaster system delivers a large volume of high pressure air into the interior cavity of a tubeless tire in order to help seat the “beads” of the tire to the wheel assembly.

How do you polish aluminum after bead blasting?

What you'll have to do is use the finest grit polishing grit sandpaper that will remove the sand blast surface. You'll need to go progressively finer and you'll probably need to finish out with a 400 grit finish that could be buffed to a mirror finish.

Does sandblasting remove material?

Whatever material is used, abrasive blasting can strip paint, remove mold and fungus, add surface finishes, prepare material for painting or coating and even improve the characteristics of the surface, like fatigue resistance.

What is the best blasting media for aluminum?

If you are blasting aluminum surfaces, the abrasive media most often used is glass beads, sodium bicarbonate, or walnut shells. Steel shot or steel grit should be avoided.

Can you bead blast copper?

Abrasive Blasting(Glass Bead Blasting) is a safe & effective process on copper to remove the sand, completely clean the blackish surface and create a uniform surface.

Can you polish metal with a sand blaster?

Micro-abrasive sandblasters are preferred for metal finishing and surfacing applications over other post-processing methods because they are more precise, accurate, and customizable.

Is sand blasting better than sanding?

Both sandblasting and hand sanding are great options for auto paint removal. For an inexpensive DIY project at home, you can go for hand sanding. However, if you want professional paint-stripping services that will guarantee excellent results, sandblasting is the best technique.

Is glass bead blasting safe?

Glass bead blasting is considered one of the safest and most efficient blasting media.

What is soda blasting best for?

Soda blasting is suitable for cleaning timber, wood, oak beams, oak floors, doors, stairs and banisters, cars, boat hulls, masonry, food processing equipment, and structural steel.

What's the difference between sandblasting and soda blasting?

Sandblasting uses sand particles alone to scrape the surface of a vehicle with small particles propelled at a high pressure. Soda blasting uses sodium bicarbonate, otherwise known as baking soda. Dustless sandblasting is the same as sandblasting with the addition of water and usually a rust inhibitor.

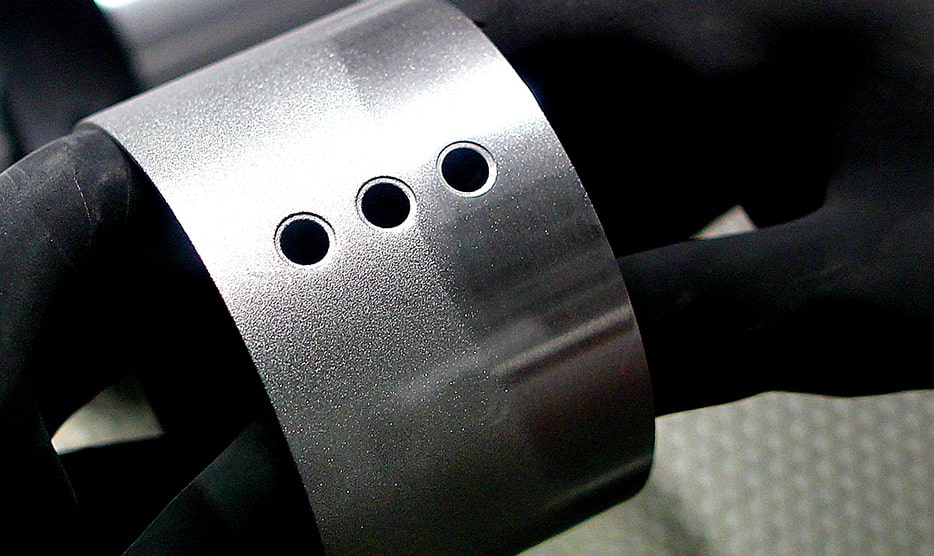

What is Bead Blasting?

Generally, blasting is a finishing process that manages the surface of a wide variety of objects. Bead blasting is one type of shot blasting. This process releases, at high pressure, fine glass beads to clean or finish a surface.

How to achieve the best result from bead blasting?

To achieve the best result from your bead blasting process, you need to ensure that you use the most effective tooling. This section will give you a run-down on the various equipment and materials for the process.

What are bead blast gloves?

This is where bead blasting gloves come into play. They help you confer a bead blast finish in the cabinet comfortably and safely. These gloves usually come connected to the cabinet. It would help if you had these gloves to protect your hands from blasts. They also provide a solid grip on bead blaster guns.

Why do you need a bead blast finish?

This bead blast finish is due to the spherical media dimpling the material’s surface. This process is most desirable when there is a need for a smooth uniform finish. Also, this surface finish will leave a “dull” or “satin” finish on your part. Bead shots, sometimes, also offer tensile conditioning of the given component.

What is a good alternative to sandblasting?

Glass bead blasting is a good alternative to sandblasting.

How much pressure should I use for a glass bead blaster?

The first tip is to turn down the pressure of your bead blaster, with 50 PSI (3.5 Bar) usually a good point to start. You must note that glass beads work best at low pressures. Therefore, the pressure should be as low as possible. This way, you can increase how long your beads stay and get a much better metal surface finishing.

What is the difference between medium size and large beads?

For instance, smaller beads help with lighter processes that require finely detailed works. On the other hand, medium-size beads are the best choice when dealing with metal materials like stainless steel and aluminum. They are popular for their ability to hide defects on components surfaces. Larger beads are perfect for deburring and cleaning rough surfaces on metal castings and automotive parts.

What is bead blasting?

Bead blasting is used to finish metal and other objects like some plastics. The friction created by the glass beads chips away at the paint on objects, leaving a clean surface. Bead blasting is used most in vehicle restoration but can be used for many things, including refinishing metal toys and machines. The following article will explain ...

What equipment is needed for bead blasting?

Bead blasting requires all kinds of equipment in order to be successful. You can utilize a portable blasting cabinet. These are usually powered by an air compressor using diesel fuel. Pots are attached to the cabinets that contain the material used in the bead blasting.

What can be used to remove mold from tile?

You can also use bead blasting to finish a surface and remove burrs from it. The friction from the glass beads creates a perfect balance to do these things without damaging the metal. Bead blasting can also be used to remove fungus and mold from tiles and grout.

How many times can glass beads be reused?

This material is then formed into tiny glass balls or beads. These glass beads can be reused approximately 30 times before needing to be replaced. They are environmentally safe and chemically inert. The beads are found in several sizes. Continue reading below Our Video of the Day.

Does bead blasting change the dimension of an object?

Angular abrasives create a rougher finish. Bead blasting does not change the dimension of the item you are working on. The process of bead blasting removes burrs in the object as well as foreign matter like rust. Paint will also be removed.

Can you recycle materials in a bead blasting cabinet?

This type of cabinet limits the size of the object you can work on. These may also not recycle the materials. You can also have a bead blasting apparatus that holds the air and the materials and has a gun. These are used for large items like vehicles and metal pillars. The media is not recycled.

Is media recycled in blasting?

The media is not recycled. A blast room is another piece of bead blasting equipment. A blast room is considerably larger than a blast cabinet and is self-contained. This means that you, the thing being blasted and the gun will all be in the same room, whereas you stand outside of a blast cabinet.

What is bead blasting?

The bead blasting process uses a blasting media – beads – under high pressure. Propelling the beads at a surface cleans, polishes, or roughens the surface to the desired finish. These beads are shot out toward the component from a high-pressure bead-blaster. When the beads hit the surface, the impact creates a uniform “dimpling” on the surface. A bead blast finish can clean corroded metal, remove cosmetic defects like textures and contaminants, and prepare a part for paint and other coatings.

What is the best bead blasting material?

You can use steel beads or glass beads for a bead blast surface finish. Steel beads are tough and are often used to clean contaminants and remove unwanted textures from hard metal surfaces. Glass or quartz sand beads are gentler than steel and are the primary type of bead used for bead blasting. This is because glass bead blasting leaves a more smooth, uniform surface finish on a material than steel beads. Glass bead blasting is also more variable because the size of the glass bead changes the quality of the finish it will impart. Fine glass beads leave a “dull” or “satin” smooth finish that’s a cross between a dull and high-gloss finish. Coarse glass beads yield uniform roughness and mask any imperfections.

How many times can you reuse beads?

Bead media can be reused many times before needing replacement, and glass beads can be recycled up to 30 times .

Can you mask a part with bead blasting?

Some surfaces on a part can be masked from bead blasting if desired; however, doing so is a manual process that adds to labor time and cost.

Can glass bead blasting be used for paint?

Although glass bead blasting is the more popular option, it doesn’t allow for paint adherence because it doesn’t leave a profile (steel blasting, on the other hand, can do this).

How Does Bead Blasting Work?

The term bead blasting can refer to the process of sandblasting or abrasive blasting, however, in most cases, it refers to the projecting of media in the form of a bead or sphere against a substrate such as stainless steel, aluminum or any material that requires a surface conditioned via blasting.

What is bead blasting?

Bead blasting refers to the use of round spherical media that , when impacted against the surface of a part, will leave a more uniform finish caused by the sphere “dimpling” the surface.

What is the difference between glass bead blasting and aluminum oxide?

Other materials such as aluminum oxide, silica carbide, or garnet, even in their finest grits, will leave any substrate it impacts with a much darker “grayer” finish, whereas glass bead blasting allows the substrate to maintain its base color resulting in a whiter or brighter finish.

What is fine glass blasting?

Fine glass bead blasting is commonly used on aluminum parts that need a “dull” or “satin” finish. Coarser glass bead is used to give a uniform “rough” finish while masking any imperfections in the substrate surface.

What is bead blasting?

Bead blasting is used to remove paint and rust from metal, wood, plastic and fiberglass. The material is not damaged with bead blasting. Instead, it is left with a clean and smooth finish. Projects that have minor rust or paint can be finished with a sanding block. Bead blasting is for tougher projects. For example, when something is covered with rust, calcium or many layers of paint. You can also use bead blasting on delicate surfaces to add shine and polish the surface.

What is glass beads made of?

Bead blasting uses many kinds of media, but glass beads are made from lead-free glass. These materials are formed into tiny glass balls. You can recycle the beads that you use in the course of bead blasting up to 30 times before replacing them. The glass beads used in the process are free of chemicals and safe for the environment. They come in several sizes and the size you choose will depend on your needs.

Is it dangerous to bead blast?

Bead blasting can be very dangerous. You can be pelted by hot glass as well as inhale paint and rust during the process. This means you need to protect yourself. Glass beads can cause severe damage to the skin. Wear thick work gloves when handling the bead blasting gun. Wear long sleeves, work boots and jeans to protect your body.