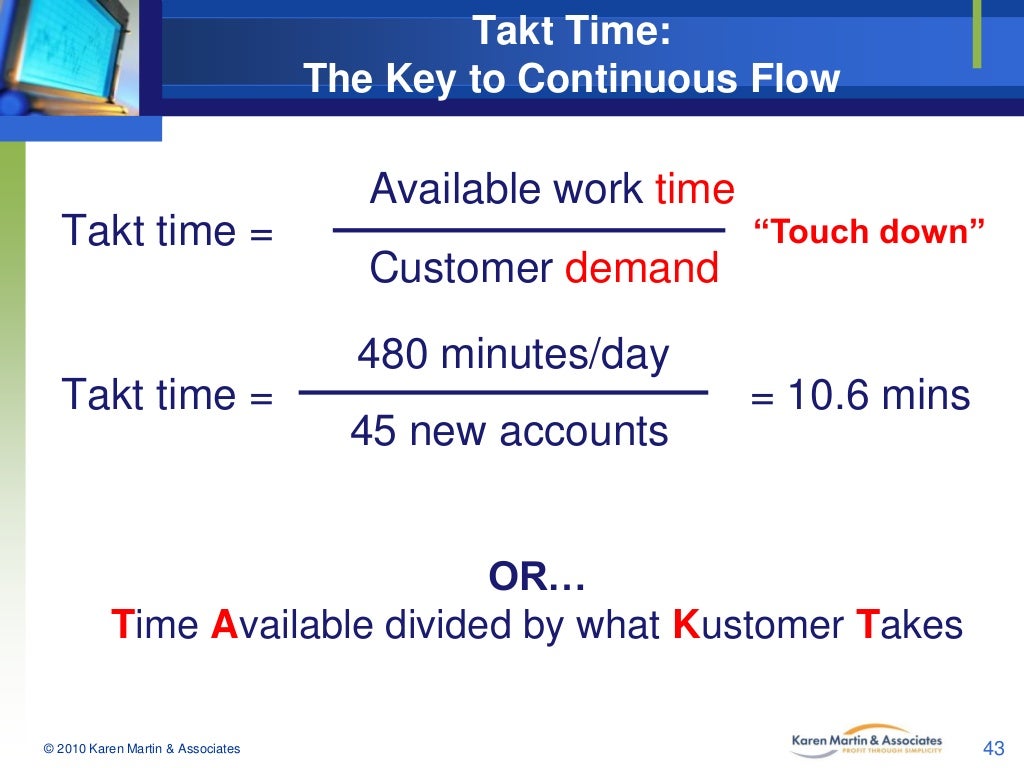

What is a takt time example?

Takt Time = Total available production time/ Customer demand Example: Say your company makes wholesale coffee travel mugs. Your employee is working a daily shift. After meetings and lunch breaks, they have 450 minutes a day to work on production. The customer places an order for 50 travel mugs. The total available production time is 450 minutes.

What should be included and excluded from takt time?

This means that you should exclude breaks, scheduled maintenances, and shift changeovers (if there are any). When defining takt time, you should include a relatively short time frame for the average customer demand (e.g., a week or a month).

What is the takt time for all the parts?

If I can hear your inputs, it would be appreciated. Thx. Adrian Reply Mark Rosenthalsays: March 25, 2013 at 5:44 pm Adrian – The takt time for all of the parts is 40 seconds.

What does takt time include?

Takt time is calculated by dividing the available production time by customer demand. Available production time can be defined as the time needed to build a product from start to finish. Workers' breaks, scheduled maintenance, and shift changeovers are excluded when computing available production time.

Does takt time include efficiency?

Without takt time, it would be difficult to correctly measure the efficiency, reduce waste, and optimize costs of your production process. Takt time ensures availability and increases efficiency throughout the plant.

How is takt time appropriately calculated?

The classic calculation for takt time is:Available Minutes for Production / Required Units of Production = Takt Time. ... 8 hours x 60 minutes = 480 total minutes. ... 480 – 45 = 435. ... 435 available minutes / 50 required units of production = 8.7 minutes (or 522 seconds) ... 435 minutes x 5 days = 2175 total available minutes.More items...•

Is takt time in seconds?

In Lean Manufacturing, the term Takt time is used as the average customer demand time for an article. This takes into account the average productive, working time of the manufacturing process. It is measured in "seconds per unit".

What happens if takt time is greater than cycle time?

If Cycle Time is more than Takt Time it means the process is not sufficient enough to keep up with demand. This can result in overtime, expedited freight charges, upset customers, poor KPIs/metrics, loss of sales, delinquencies or backlog and at some point loss of customers.

What is the difference between cycle time and takt time?

Three time-management strategies In a nutshell, Takt Time is the time between starting to work on one unit and starting the next. Cycle Time is the average time it takes to finish one unit.

What is the takt time in minutes if 500 units are needed per day the company has two eight hour shifts per day?

The takt time is the [time available]/customer demand. In this case [2 shifts per day x 8 hours per shift x 60 minutes per hour]/500 units = 1.9 minutes.

How do you calculate takt time and cycle time?

And here is the formula:Takt Time = Net Production Time/Customer Demand.Cycle Time = Net Production Time/Number of Units made.Lead Time (manufacturing) = Pre-processing time + Processing time + Post-processing time.Lead Time (supply chain management) = Supply Delay + Reordering Delay.More items...•

How do you calculate takt time multiple products?

The formula for TAKT time is: (Available Time per period)/(Demand in that period).

What is the takt time in minutes?

The TAKT Time per form in terms of delivery is 12 minutes. TAKT Time assumes a constant daily demand during the day; if demand fluctuates during the day, TAKT Time needs to be adjusted.

What does takt time stand for?

Takt time is the rate at which you need to complete a product to meet customer demand. For example, if you receive a new product order every 4 hours, your team needs to finish a product in 4 hours or less to meet demand. Takt time is your sell rate and can easily be categorized as the heartbeat of your work process.

How do you calculate total lead time?

Lead time = supply delay + reorder delay , where: supply delay is the time between ordering and getting the supplies; and. reorder delay is the time you have to wait before reordering the supplies.

What is takt time lead time and process efficiency?

Lead time is essentially the total time it takes from the initial product order to the final delivery, whereas cycle time, a shorter period of time, is the average time it takes to complete a product. Lastly, takt time calculates the rate at which a manufacturer must complete a product to meet customer demand.

How do you calculate OEE overall equipment effectiveness?

In practice, OEE is calculated as:OEE = (Good Count × Ideal Cycle Time) / Planned Production Time.Availability = Run Time / Planned Production Time.Performance = (Ideal Cycle Time × Total Count) / Run Time.Quality = Good Count / Total Count.OEE = Availability × Performance × Quality.More items...

Does throughput time include wait time?

Definition: Throughput time or cycle time is the amount of time it takes for a manufacturer to make a product including process time, inspection time, move time, and wait time.

How do you calculate takt time and cycle time?

And here is the formula:Takt Time = Net Production Time/Customer Demand.Cycle Time = Net Production Time/Number of Units made.Lead Time (manufacturing) = Pre-processing time + Processing time + Post-processing time.Lead Time (supply chain management) = Supply Delay + Reordering Delay.More items...•

What is Takt time?

Want to learn about takt time? Takt time is an essential metric used in the manufacturing process that functions as the heartbeat of your production line. It lets you manage every business operation efficiently and without waste. Toyota used and perfected takt time in its famous Just-in-Time manufacturing system.

What Is The Purpose Of Takt Time?

The takt time calculation can be used to predict future production problems and identify a potential bottleneck.

How Do You Calculate Takt Time?

At first glance, measuring takt time seems like a complicated process, but the calculation is actually quite simple.

What Are The Benefits Of Takt Time?

Even though takt time is an extremely simple concept, it’s powerful enough to supercharge the manufacturing unit of your company.

What Is The Difference Between Takt Time And Cycle Time?

While both cycle and takt times are used by Lean practitioners, they’re used to measure different things and are used at different times in the production cycle.

Why use takt time in lean manufacturing?

Since your production system is usually consistent, it’s easy to plan out your shift schedule. That is if you use takt time to create a value stream map.

Why is Takt time called Takt?

That’s why it’s no coincidence that that takt time is named after ‘Takt’: a German term for the baton used by an orchestra conductor to regulate the tempo of the song. Similar to how a conductor uses their baton to manage the pace of the orchestra, using takt time helps you regulate the speed of the production line.

What is takt time?

Takt time is used to synchronize pace of production with the pace of sales. A sort of just-in-time production measure that helps remove and avoid waste.

How many hours is net available time?

Net available time = 8.5 + 8.5 = 17 hours per day (Note that we DO NOT subtract the 30 minute breaks because Takt time includes planned downtime.)

What is the purpose of pacing the process to a planned cycle time?

Pace the process to a planned cycle time to accommodate system problems.

How many hours does a Kanban factory operate?

The demand for the part produced in the target process is 75/units per hr and MLT of the process is .6 days. The factory operates two 8.5 hour shifts, with 30 minutes of break timer per shift. Assuming the safety stock should be set at 10% and container capacity is held at 10% of daily demand, how many Kanban card sets should be authorized?

What is Takt time?

Takt time, or simply Takt, is a manufacturing term to describe the required product assembly duration that is needed to match the demand. Often confused with cycle time, takt time is a tool used to design work and it measures the average time interval between the start of production of one unit and the start of production ...

What are the benefits of takt time?

Once a takt system is implemented there are a number of benefits: The product moves along a line, so bottlenecks (stations that need more time than planned) are easily identified when the product does not move on in time.

What is takt planning?

Takt, as used in takt planning or takt-time planning (TTP) for construction, is considered one of the several ways of planning and scheduling construction projects based on their utilization of space rather than just time, as done traditionally in the critical path method.

How is Takt time adjusted?

Takt time may be adjusted according to requirements within a company. For example, if one department delivers parts to several manufacturing lines, it often makes sense to use similar takt times on all lines to smooth outflow from the preceding station. Customer demand can still be met by adjusting daily working time, reducing down times on machines, and so on.

When customer demand rises so much that takt time has to come down, what happens?

When customer demand rises so much that takt time has to come down, quite a few tasks have to be either reorganized to take even less time to fit into the shorter takt time, or they have to be split up between two stations (which means another station has to be squeezed into the line and workers have to adapt to the new setup)

How many hours between production starts?

For example, if the customer demand is 10 units per week, then, given a 40-hour workweek and steady flow through the production line, the average duration between production starts should be 4 hours, ideally. This interval is further reduced to account for things like machine downtime and scheduled employee breaks.

What is net available time?

Net available time is the amount of time available for work to be done. This excludes break times and any expected stoppage time (for example scheduled maintenance, team briefings, etc.).

What is tak time?

TAKT time, different from cycle time and lead time, is a key element to use in any production process. German for ‘beat’ or ‘pulse’, TAKT time refers to the rhythm in which you need to create and complete a product in order to meet customer demand. To determine TAKT time, you need to divide your available production time by the customer demand.

What does tak time reflect?

If your daily orders are increasing and production time is slowing down, your TAKT time will reflect that and may encourage you to seek out more employees or resources.

How does the Takt time formula work?

Using TAKT time formula can boost your sales rate and strengthen your overall production process. If you’re able to keep up with the daily customer demand and capacity, you’ll have the ability to minimize costs, predict future growth, and maximize your return.

What is total available production time?

Total available production time refers to the amount of time you and your employees have to dedicate to your current orders. This is specific to active time on the project (lunch breaks and meetings are not included). Keep track of your current schedule and pace and use that to determine your total available production time.

What is the key point of takt time?

The key point here is that to get the benefit, you have to have a takt time that actually paces production. It has to be real, tangible, and practically applied on the shop floor. Otherwise it is just an abstract, theoretical number.

How long is takt time?

So when determining takt time, we would use 435 minutes as the baseline. If leveled customer demand was 50 units / day, then the takt time would be:

Why is Takt time important?

More importantly, though, takt time gives your team members a way to know exactly what “success” looks like for each and every unit of production. (assuming you give them a way to compare every work cycle against the takt time – you do that, don’t you?)

What happens if you run a factory at 522 second Takt?

Because if you were to run this factory at a 522 second takt time, you will come up short of your production targets. You will have to work overtime to make up the difference, or simply choose not to make it up.

What happens when you expect people to do something other than produce all day?

If you expect people to do something other than produce all day, you have to give them time to do it.

Is Takt time a tool?

Takt time is just a tool for doing this. It is, however, a very effective tool. It is so effective, in fact, that it is largely considered a necessary fundamental. Honestly, in day to day conversation, that is how I look at it. I made the above statements to get you to think outside the mantras for a minute.

What is cycle time?

And, of course, “cycle time” is used to express the work cycle of a single person, not including end-of-cycle wait time. None of these definitions is wrong. The source of confusion is when the users have not first been clear on their context. Therefore, it is critically important to establish context when you are talking.

What is Takt time?

Understand what Takt time is. Takt time is the pace of production (E.g in Manufacturing one piece every minute) that aligns production with customer demand.

How to calculate takt time?

More importantly, Takt time enables you to set real time targets for production that show the staff exactly where to focus their output efforts. To calculate Takt time, simply divide your available time by the rate of customer demand.

What happens when you produce faster than Takt time?

Producing faster than Takt time results in "overproduction" - the most fundamental waste.

What happens if the cycle time is greater than the takt time?

If the cycle time is greater than the Takt time in some operations, you need to improve in those operations. Also, if the cycle time is less than the Takt time in certain operations, you can look into whether some additional work from the operation whose cycle time was greater can be given to this operation. Thanks!

Why is it important to know takt time?

Knowing takt time gives you a better understanding of your service delivery process, thereby giving you the ability to help maximize efficiency and minimize waste.

What is 8 hours?

8 hrs is the working time in your 9 hours working day (so you need to exclude your breaks, meetings etc) to mention the available time (numerator).

What is available time?

Available time = Planned production time - Down time and Stop time. Planned production time = Shift length - Breaks. Stop time = break time, meeting time, and/or changeover time.