What are ceramic brake pads?

The ceramic pads are composed of dense ceramic material with embedded copper fiber. The manufacturer uses this since the 1980s. The ceramic brake pads developed as an alternative replacement for organic and semi-metallic brake pads. Let’s see, why ceramic brake pads are good?

Are motorcycle brake pads made from the same material as cars?

Motorcycle brake pads are manufactured using the same materials used in automotive brake pads; however, ceramic and organic brake pads are the most common. Because motorcycles are smaller and weigh considerably less than cars and trucks, organic brakes pads don't wear as quickly as they would on a car.

What are semi-metallic brake pads made of?

Semi metallic brake pads are between 30% and 70% metal, including copper, iron, steel, and other composite alloys. These various metals are combined with graphite lubricant and other fillers to complete the brake pad.

What are organic brake pads?

Organic brake pads, sometimes called nonasbestos organic brake pads, are made from natural materials liked glass and rubber, as well as resins that can withstand high heat. In fact, the high heat helps to bind the brake pad materials together.

How are ceramic brake pads manufactured?

The production process of the ceramic brake body requires a preform pressed with binding resin to a so called green body which will be converted in the ceramic component by first carbonizing at 900 °C and second by liquid silicon infiltration (siliconization) at 1700 °C in vacuum athmosphere.

What material is used for ceramic brake pads?

Today's “ceramic” pads are more of a composite material with predominately ceramic materials in an organic resin matrix, and they may still include small amounts of metal, such as copper fiber for heat transfer.

Why are brake pads made out of ceramic?

Made from ceramic materials mixed with copper fibers, ceramic pads were designed for driver comfort. They are the least noisy, produce very little messy brake dust, and are stable over a wide range of temperatures. And they last the longest.

How are brake pads made step by step?

11:5121:06How Brake Pads are Made - YouTubeYouTubeStart of suggested clipEnd of suggested clipFirst the worker places the friction material into the holder followed by the backing plate with aMoreFirst the worker places the friction material into the holder followed by the backing plate with a mechanical attachment facing. Down into the friction. Material. Next the fusion machine rotates.

Do ceramic pads wear rotors faster?

Ceramic brake pads typically last longer than semi-metallic brake pads, and through their lifespan, provide better noise control and less wear-and-tear to rotors, without sacrificing braking performance.

Do ceramic brakes stop faster?

Ceramic brake pads offer quieter stops, cleaner wheels, and longer pad life due to their harder composition. However, the downsides include less cold bite, rendering them less effective in cold weather or before the brakes are up to temperature.

How long do ceramic brakes last?

Ceramic composite brake discs are tough and highly resistant to wear, making them very durable compared to your average iron rotors. While conventional cast iron discs or iron rotors may last up to 60,000 miles, carbon ceramic rotors can go without replacement over 100,000 miles or even outlive your vehicle.

Do ceramic brakes leave dust?

Ceramic brake pads produce a dust that is lighter in color and less likely to stick to wheels. Longer lasting, compared to organic or semi-metallic brake pads, due to the compounds in the friction material.

Are ceramic brakes loud?

Noise-Level: Ceramic brake pads are very quiet, creating little-to-no extra sound when the brakes are applied. Wear & Tear Residue: Compared to organic brake pads, ceramic brake pads tend to produce less dust and other particles as they wear down.

Do they still use asbestos in brake pads?

Because some, but not all, automotive brakes and clutches available or in use today may contain asbestos, professional automotive technicians and home mechanics who repair and replace brakes and clutches may be exposed to asbestos dust.

What are modern brake pads made of?

Perhaps the most commonly found brake pads, semi-metallic models consist of between 30% and 65% metal. Additional material could include steel wool, wire and copper among others. Once settled upon these elements are bound together by organic resin.

What is the main manufacturing process in making brakes?

The production process for brake pads is based on some basic phases: mixing, molding, and curing. The manner and technology through which these phases are executed lead to products with different quality levels and production rates. Blending has been underestimated till now.

What material is brake pads made of?

Perhaps the most commonly found brake pads, semi-metallic models consist of between 30% and 65% metal. Additional material could include steel wool, wire and copper among others. Once settled upon these elements are bound together by organic resin.

What kind of material is the brake pads?

Brake pads are composed of steel backing plates with friction material bound to the surface that faces the disc brake rotors.

What type of brake pad material is best?

CERAMIC. Ceramic brake pads have excellent stopping power and disperse heat well. Ideal for most normal driving applications, they produce very little dust or noise and are long lasting.

Do ceramic brake pads contain asbestos?

When asbestos use was banned, brake manufacturers developed modern brake pads and friction material. These brake pads were advertised as having no asbestos in their manufacture. Today, brake pads no longer have asbestos in their formulation.

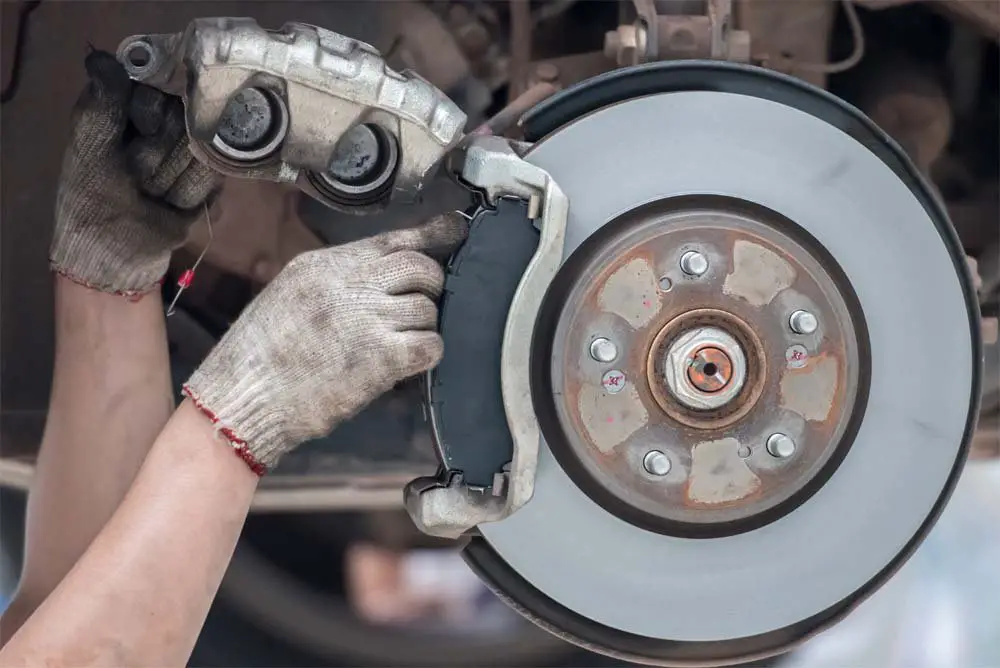

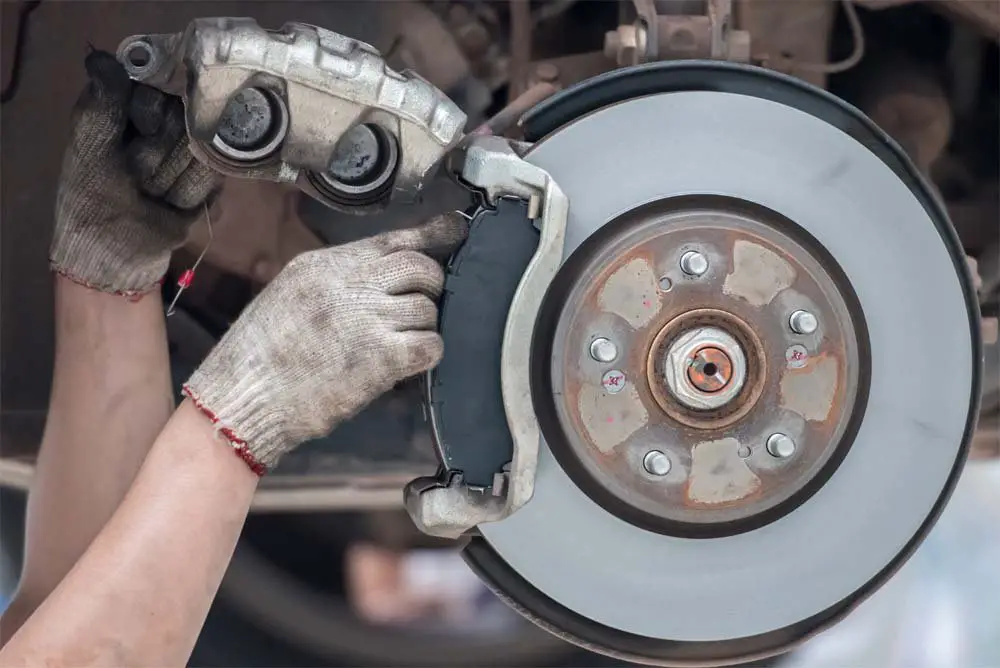

What is the most important part of a brake pad?

One of the most critical elements of a brake pad is the backing plate . All brake pads must have a backing plate to hold the brake material against the caliper, which is then pushed out or squeezed against the rotor. Backing plates are usually made of steel of a certain thickness (which depends on the application).

What is a quality bed pad made of?

Lower-priced pads are made with black steel that may have some impurities. But a quality pad uses pickled and oiled steel because it is cleaner and resists corrosion. Some manufacturers take it a step further, galvanizing the backing plate, and using a heat treatment after the pad is made to ensure a faster bed-in time.

Why do you put a pad in the oven?

This gives the pad a mechanical grip on the backing plate to prevent delamination. After the friction material is bonded onto the backing plate, the pads are placed in an oven to cure. Heat is used to activate and solidify resins, binders and other ingredients and to let out any trapped gases.

How is friction material bonded to the backing plate?

During the molding process, the friction material is bonded to the backing plate using high pressure and heat. Some of the material is forced through the holes in the backing plate to increase retention in what’s called integral molding, or IM for short. IM is only one method for attaching the friction material. There’s also a mechanical bonding process that some manufacturers use by stamping small, shark-like teeth into the backing plate. This gives the pad a mechanical grip on the backing plate to prevent delamination.

What is the last step in installing a pad?

The last step is where the pad is ground to the proper height for the application. After that, some pads are sprayed with anti-corrosion paint and labeled and boxed to be sent to your store before being sold to a technician or a DIYer who will install them. It sounds pretty simple, but it isn’t. Advertisement.

What are brake pads made of?

Brake pads come in three basic types—organic, metallic, ceramic. While organic pads might still contain metal and ceramic, they’re infused with resin, glass, and Kevlar. Metallic or semi-metallic pads are made up of mostly metal.

What is a carbon ceramic brake?

Carbon-ceramic brakes also called composite brake discs or CC brakes, are the type of disc brake commonly found in high-performance cars like Porsche, Ferrari, or BMW. In disc brakes, the rotor or disc is made from cast iron or steel. Carbon-ceramic brakes have a disc or rotor built from a mixture of carbon and ceramic specially treated for the brake itself, built out of carbon fiber, silicon carbide, and epoxy resin. When these properties are combined with carbon fiber and ceramic material, they produce a high-performance application for your vehicle.

Are Carbon Ceramic Brakes Right For Me?

There are many reasons to make the switch to CC brakes, but you should know what it is you’re getting into. Carbon-ceramic brakes are for high-performance drivers, vehicles on the track, luxury vehicles, and vehicles where you don’t want to service the brakes or braking system very often.

How long do carbon ceramic brakes last?

The average cast-iron disc or rotor system lasts up to 60,000 miles, but CC brakes and rotors can travel without replacement for well over 100,000 miles.

What happens when you brake while driving?

When you brake while driving, the conventional metallic system doesn’t dissipate the heat generated by friction. As this heat builds up, the temperature of the steel wears on your entire braking system. Over time, these temperatures will degrade the cast iron and steel within the components of your brakes. Degraded components of course reduce your overall stopping power and can make driving dangerous.

What is CC brake?

This includes brake dust and other materials that accumulate around the wheel of your vehicle. Carbon-ceramic brakes are resistant to abrasion as well, and the dust generated by CC brakes is much finer than a traditional braking system.

Do ceramic brakes feel spongy?

In addition to their cost, ceramic brakes feel “spongy” compared to traditional brakes. This feel typically only happens when the vehicle is cold, and once the brakes warm up from use, that feeling should vanish. This sensation is still something to get used to, and needs to be managed.

What are ceramic brake pads made of?

The ceramic pads are composed of dense ceramic material with embedded copper fiber. The manufacturer uses this since the 1980s. The ceramic brake pads developed as an alternative replacement for organic and semi-metallic brake pads. Let’s see, why ceramic brake pads are good? The ceramic brake pads are usually quieter than the other way on the market.

How fast can you brake with ceramic brake pads?

Step A: At first, use the ceramic brake pads around a hundred miles’ speed. Try to avoid harder brakes. Always heavy braking can damage ceramic brake pads. Step B: Take the vehicle speed up to 35 miles per hour, apply the brake with moderate pressure.

How many times do you have to brake a ceramic brake?

When you see you have to brake, push the brake pedal 3 times to stop the vehicle. So, stop the vehicle with less friction. If you follow this braking system, your ceramic brake will last for a long time.

How long do brake pads last?

Typically, a brake pad’s lifetime is somewhere around 25,000 miles to 65,000 miles. However, some automotive engineers said, brake pads lasting more than 70,000 miles, even beyond the 80,000 miles threshold. Now is your turn to extend your ceramic brake pad’s performance and life.

What does it mean when your brake pads are overloaded?

When you make your vehicle overload and run with it, means your brake pads have to do harder work to stop the vehicle. Don’t do this always when you drive big trucks and cargo. Lose some weight from your vehicle to keeps well your ceramic brake pads. It also saves fuel too.

Why do you have to brake faster when you drive?

When you driving so fast, you have to brake faster as peanut butter goes with jelly. The fast braking makes a lot of friction, which increases wear on journeys ceramic brake pads shortens their lifetime.

Why do you need a brake pedal?

A brake pedal is meant to stop the car , so don’t use the brake pedal as a footrest. Some drivers lightly press the brake pedal and run the car, it makes more friction on the braking system and shortens the brake life.

What is brake pad?

Brake pads provide the friction to slow or stop your vehicle. Dusty Cline/ iStockphoto. There's a lot more to effectively using your car's braking system than simply stomping on the pedal when a squirrel darts out in front of you. The braking systems of cars, trucks and motorcycles are made up of a number of parts that translate ...

Why are brake pads made of asbestos?

Brake pads were formerly manufactured using mainly asbestos as the friction material. That's because brake pads are exposed to a lot of friction, which generates a lot of heat. Asbestos is a good material for absorbing and dissipating heat.

Why are metallic brake pads so durable?

But because there isn't as much "give" in metallic brake pads, they can cause more wear on the brake rotors than other types of brake pads. The metallic brake pads themselves hold up well, but they often negatively impact the durability of other brake parts.

What is the most common brake pad?

Metallic brake pads are perhaps the most common brake pads found on cars today. The brake pad on the left is new; the pad on the right is used.

Why are brake pads so common?

The reason that these pads are so common is simple -- metallic brake pads are cost-effective and durable. They provide good performance and are good at transferring the heat generated by friction with the brake rotors. The downside of metallic brake pads is that they're heavy, which can have a (small) negative impact on the car's fuel economy. Also, because of the extra weight, metallic brake pads aren't the best choice for high-performance driving. Being made of metal makes the pads very hard. That's what makes them durable. But because there isn't as much "give" in metallic brake pads, they can cause more wear on the brake rotors than other types of brake pads. The metallic brake pads themselves hold up well, but they often negatively impact the durability of other brake parts. Finally, metallic brake pads work best when they're warm. When a vehicle with metallic brake pads first gets going on a very cold day, stops may take slightly longer than usual until the brake pads heat up.

Why do brake pads have to be stressed?

Because of how fast a vehicle's wheels rotate and how much a typical car or truck weighs, brake pads undergo extreme stress every time you slow down or come to a stop. Think about it: Would you want to grab and hold on to a heavy metal disc that was spinning really fast? Imagine slowly squeezing that disc until the vehicle rolls to a halt -- it's a thankless job, but brake pads do it repeatedly for thousands and thousands of miles without complaint.

Why are organic brake pads so soft?

The downside of organic brake pads is that, because they're softer, they typically wear faster. As they wear, they also create more dust than other types of brake pads. Advertisement.

What is a ceramic brake pad?

Ceramic brake pads are made from material very similar to the type of ceramic used to make pottery and plates. Ceramic brake pad material, however, is denser and considerably more durable. Ceramic brake pads also have fine copper fibers embedded within them, to help increase their friction and heat conductivity.

When were brake pads invented?

These days, drivers typically have a choice between three types of brake pads: ceramic vs. semi metallic vs. organic brake pads. That wasn’t always the case. The first use of brake pads goes all the way back to the 19th century. Bertha Benz — famous inventor and wife of Mercedes-Benz founder Karl Benz — is credited with creating the first brake pads out of leather for an early patent of their automobile in 1888.

What is the best brake pad for a sports car?

If you have a high-performance sports car, or at least drive your vehicle like one, you’re likely better off choosing semi metallic brake pads. On the other hand, if you do a lot of urban commuting, you might find a solid ceramic brake pad to be the better option. If you don’t put a lot of mileage on your vehicle, an organic brake pad might be the best, low-price option for your driving habits.

What are the disadvantages of metal brake pads?

ceramic and organic brake pads. Metallic brake pads tend to be noisier than their ceramic or organic counterparts, leading to a louder ride. Metallic pads also put more stress on the brake system, adding more strain and wear on the brake rotors. As far as price goes, metallic brake pads tend to fall somewhere between organic and ceramic pads. They tend to produce more brake dust than the other two varieties as well.

What is a semi metal brake pad?

Semi metallic brake pads are different from fully metal brake pads in that they use fillers to create the pad compound instead of using 100% metal. Full metal brake pads are typically reserved for truly extreme braking requirements

How do you know if your brake pads need replacing?

You’ll know your brake pads need replacement when you hear the squeal of the metal “tang” at the base of the pad as it comes into contact with the rotor. Tangs are built into all types of brake pads as an indicator of wear; if you hear it, don’t wait too long to get new pads. At that point, deciding between ceramic vs. metallic brake pads — or organic pads for a price-friendly option — is up to you.

Why are organic brake pads bad?

However, organic brake pads do have some disadvantages when compared to other types of brake pads. Organic brake pads can tend to wear out more quickly because of their composite nature, meaning they might have to be replaced more often. They also tend to function best within a smaller range of temperatures. They don’t perform as well as semi metallic brake pads in extreme weather or when they are being pushed too hard and overheat. Organic brake pads also have a higher compressibility level, which means the driver has to press on the brake pedal with more force to engage them.

What are OEM brake pads made of?

On the other hand, OEM brake pads are often semi-metallic and are made of various metallic materials, such as shredded metal wire, iron powder, and steel wool.

When were ceramic brake pads invented?

They were created in the 1980s to offer a viable alternative for organic and semi-metallic brake pads since these were noisier and produced a lot of dust. Ceramic brake pads are generally softer and easier on brake rotors compared to OEM brake pads.

Why Choose Ceramic Brake Pads?

Ceramic brake pads are ideal if you want a smooth, quiet braking system for your car under a wide range of temperatures.

What is the difference between ceramic and OEM brake pads?

Ceramic brake pads are often softer, more consistent, and easy on the brake rotors. In contrast, OEM semi-metallic brake pads are more rigid and vary significantly , depending on the metal used to create them. Ceramic and OEM brake pad prices also differ.

How do brake pads work?

Brake pads are fitted on calipers and work by squeezing against brake rotors. When pressure is exerted on the brake pedal, the calipers close, causing friction between brake pads and brake rotors to slow or stop the car. Most car models are designed with front disc brakes and rear drum brakes.

What happens when you step on the brakes?

When you step on the brake pedals, the calipers squeeze, forcing the brake pads to grab brake rotors, slowing the wheels and eventually stopping the car.

Why does friction material wear away?

The friction material often wears away as it causes damage to the brake rotors.

What are semi metal brake pads made of?

As the name implies, semi-metallic pads contain anywhere from 30-65 percent metal by weight, typically consisting of steel, iron, copper, etc., combined with friction modifiers and fillers, as well as a graphite lubricant. Semi-metallic brake pads are arguably the most versatile style available, with the slight compromise being more noise and dust. They are also longer lasting and more durable, and their metallic composition can help draw heat away from the rotor and aid in more efficient brake cooling.

Why are ceramic brake pads quieter than semi metal brake pads?

Nobody likes hearing a loud sound after pressing down on their brakes. Ceramic brake pads are much quieter than semi-metallic pads because they are not as abrasive. The noise they do emit is above the range of human hearing. Thus, you should hear very little or no sound when braking.

How long should you wait to stop with ceramic brake pads?

With ceramic brake pads, it is a good idea to avoid stopping quickly or braking heavily for at least the first few 100 miles.

Why do my brake pads squeak?

However, if squeaking sounds occur, it is often the result of not using a brake lining shim or needing more anti-squeal lubricant on the back of the brake pads.

How to know if brake pads are worn out?

Know When Your Brake Pads are Wearing Out. Your vehicle needs new pads if you start hearing high-pitched noises (squealing, squeaking, or grinding) whenever applying pressure to the brake, either when slowing down or stopping the vehicle. These noises are a good indication that your vehicle’s brake pads need replacing.

What is the best brake pad to replace a brake pad?

Ceramic brake pads are a popular option, and they can be a great replacement for your existing brake pads. Made out of ceramic materials and copper fibers, ceramic brake pads are some of the quietest and cleanest you can buy. They produce less noise, less dust, and can last a very long time.

Why are brake pads important?

The pads are there to help bring you to a stop — and that means they face a lot of pressure and a lot of critical power. That’s why it’s so important to make sure your car is equipped with reliable, durable brake pads. Ceramic brake pads are a popular option, ...

Why are ceramic brake pads better than semi metal?

Also, when ceramic brake pads wear down, they create a finer, lighter dust than semi-metallic pads, and the dust doesn’t stick to wheels.

What are the pros and cons of ceramic brake pads?

One con of ceramic brake pads is the cost. Ceramic brake pads tend to be more expensive than semi-metallic pads. Also, ceramic pads aren’t suitable for all vehicles, so always be sure to check your owner’s manual before making a purchase.

What are friction pads made of?

Since they were first used on a few original equipment applications in 1985, friction materials that contain ceramic formulations have become recognized for their desirable blend of traits. These pads use ceramic compounds and copper fibers in place of the semi-metallic pad’s steel fibers. This allows the ceramic pads to handle high brake temperatures with less heat fade, provide faster recovery after the stop, and generate less dust and wear on both the pads and rotors. And from a comfort standpoint, ceramic compounds provide much quieter braking because the ceramic compound helps dampen noise by generating a frequency beyond the human hearing range.

Why are asbestos pads bad?

Asbestos pads caused health issues and organic compounds can’t always meet a wide range of braking requirements . Unfortunately the steel strands used in semi-metallic pads to provide strength and conduct heat away from rotors also generate noise and are abrasive enough to increase rotor wear.

Why are ceramic compounds used in braking?

And from a comfort standpoint, ceramic compounds provide much quieter braking because the ceramic compound helps dampen noise by generating a frequency beyond the human hearing range. The ingredients in ceramic compounds produce a light-colored dust that is much less noticeable and less likely to stick to the wheels.

What makes ceramic materials attractive?

Another characteristic that makes ceramic materials attractive is the absence of noticeable dust. All brake pads produce dust as they wear. The ingredients in ceramic compounds produce a light colored dust that is much less noticeable and less likely to stick to the wheels. Consequently, wheels and tires maintain a cleaner appearance longer.

Is every brake pad the best?

Every brake pad manufacturer says that they’re the best, and that they’re an upgrade from whatever you already have. In the real world, though, not every brake pad is created equally, and it can be hard to find what you need. We don’t want noisy brakes and dust annoying us during our daily driving.