How does the production of chocolate affect the environment?

The results demonstrated that:

- The global warming potential (GWP) of chocolate ranges from 2.9–4.2 kg CO2 eq./kg

- 10,000 l of water is needed to produce a kilogram of chocolate.

- Cacao production increases total GWP by 3–4 times due to land-use change associated with its cultivation

What is the most expensive kind of chocolate?

What is the most expensive type of chocolate?

- Chocopologie Chocolate Truffle by Fritz Knipschildt $2,600.

- Wispa Gold Chocolate by Cadbury $1,600. …

- Le Grand Louis XVI by Debauve and Gallais. …

- Chocolates with Edible Gold by DeLafee. …

- Amedei Toscano Black Truffles in Swarovski Chocolate Box by the-chocolate.com. …

What does the production of chocolate entail?

Chocolate production starts with harvesting coca in a forest. Cocoa comes from tropical evergreen Cocoa trees, such as Theobroma Cocoa, which grow in the wet lowland tropics of Central and South America, West Africa and Southeast Asia (within 20 C of the equator) (Walter,1981) . Cocoa needs to be harvested manually in the forest.

What is the manufacturing process of chocolate?

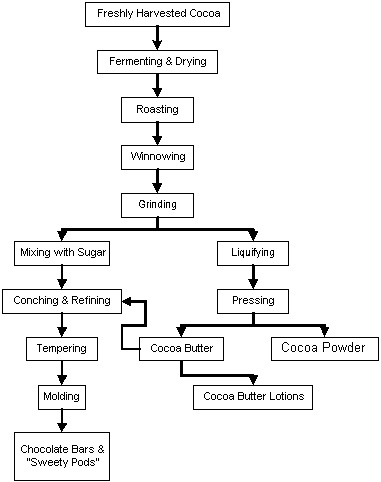

The production of chocolate

- Step #1: Plucking and opening the Pods. Cocoa beans grow in pods that sprout off of the trunk and branches of cocoa trees. ...

- Step #2: Fermenting the cocoa seeds. ...

- Step #3: Drying the cocoa seeds. ...

- Step #1: Roasting and Winnowing the Cocoa. ...

- Step #2: Grinding the Cocoa Nibs. ...

- Step #3: Blending Cocoa liquor and molding Chocolate. ...

How is chocolate made in 10 steps?

Bean-to-Bar: Chocolate in 10 StepsRaw Cacao Nibs. Straight out of the bag, fermented and dried cocoa beans present a serious microbiological risk, including E. ... Roasting Cocoa Beans. ... Winnowing. ... Grinding Cacao Nibs. ... Pressing Cocoa Butter. ... Refining. ... Conching. ... Formulation.More items...•

How is chocolate made?

0:143:31How Chocolate is Made - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd set of blades. For cracking the cocoa. Beans. We use them for separating the shell from the nib.MoreAnd set of blades. For cracking the cocoa. Beans. We use them for separating the shell from the nib. Like this just pure nibs. And what we want to do is start to refine.

How is chocolate made in simple words?

The seeds of the cacao tree have a bitter taste and must first be fermented to develop flavor. After fermentation the beans are dried, cleaned and then roasted. The shell of the cacoa bean is removed to produce cacao nibs. The nibs are then ground to produce cocao mass or pure chocolate in a rough form.

How do you make chocolate step by step?

The Chocolate Making ProcessStep 1: Cleaning. ... Step 2: Roasting. ... Step 3: Shell Removal. ... Step 4: Nibs are ground. ... Step 5: Cocoa is separated from Cocoa Butter. ... Step 6: Other ingredients are added to the Chocolate Liquor. ... Step 7: Conching machines knead the Chocolate Paste.More items...

What is in real chocolate?

'Real' chocolate is made using sugar and two ingredients obtained from the cocoa bean (cocoa mass and cocoa butter) as well as sugar for dark chocolate, but sugar and milk powder for milk chocolate. White chocolate is made from cocoa butter (usually up to 50% of the cocoa bean), milk powder and sugar.

How is chocolate made short paragraph?

Production of chocolate The kernels are ground to form a pasty fluid chocolate liquor, which may be hardened in molds to form bitter (baking) chocolate, pressed to reduce the cocoa butter content and then pulverized to make cocoa powder, or mixed with sugar and additional cocoa butter to make sweet (eating) chocolate.

Where is chocolate made from?

Chocolate is made from the fruit of cacao trees, which are native to Central and South America. The fruits are called pods and each pod contains around 40 cacao beans. The beans are dried and roasted to create cocoa beans. It's unclear exactly when cacao came on the scene or who invented it.

How chocolate is made step by step for kids?

2:243:43Where Does Chocolate Come From? - YouTubeYouTubeStart of suggested clipEnd of suggested clipThe first thing they do is to roast the beans in big ovens after cacao bean is roasted it turns darkMoreThe first thing they do is to roast the beans in big ovens after cacao bean is roasted it turns dark. And looks like this next they take off the hard outside of the cacao beans leaving the soft.

What are the 4 types of chocolate?

Ten Types of ChocolateMilk Chocolate.White Chocolate.Dark Chocolate.Semisweeet Chocolate.Bittersweet Chocolate.Unsweetened Chocolate (or Baking Chocolate)Cocoa Powder.Sweet German Chocolate.More items...•

Is white chocolate really made of chocolate?

What's white chocolate? Actually it isn't even chocolate because it does not contain cocoa particles. It is just cocoa butter mixed with sugar, often with a little vanilla added for flavoring.

What is Nutella made of?

Nutella contains sugar, palm oil, hazelnuts, cocoa, milk powder, lecithin and synthetic vanillin. It is high in calories, sugar and fat.

Which kind of chocolate is healthiest?

Dark chocolateDark chocolate is best for you because it's the least processed chocolate, which means it contains the highest percentage of flavonoid-filled cocoa bean (cocoa).

How To Make Chocolate: From Cacao Bean to Chocolate

Cocoa beans are stored in silos or warehouses in their original sacks. Imported raw cocoa is subject to strict quality control. Laboratory technicians ensure that the beans are healthy, perfectly fermented and dried, and have suffered no damage during transport.

Step 1: Cleaning

The process of making chocolate starts with the cocoa beans being passed through a machine that removes dried cocoa pulp, pieces of pod and other extraneous material. The beans are carefully weighed and blended according to specifications.

Step 2: Roasting

To bring out the characteristic chocolate aroma, the beans are roasted in large rotary cylinders. Depending upon the variety of the beans and the desired end result, the roasting lasts from 30 minutes to two hours at temperatures of 250 degrees Fahrenheit and higher.

Step 3: Shell Removal

The cocoa beans are cooled quickly and their thin shells, which have become brittle by roasting, are removed. A giant winnowing machine that passes the beans between serrated cones so they are cracked rather than crushed.

Step 4: Nibs are ground

The nibs, which contain about 53 % cocoa butter, pass through refining mills and are ground between large grinding stones or heavy steel discs creating a cocoa paste.

Step 5: Cocoa is separated from Cocoa Butter

Up to this point, the manufacturing of cocoa and chocolate is identical. The by-product of cocoa, cocoa butter, is the essential component of chocolate… about 25% of the weight of most chocolate bars.

Step 6: Other ingredients are added to the Chocolate Liquor

Milk chocolate is made by adding milk, sugar, cocoa butter and other ingredients to the bitter chocolate liquor. At this point, Chocolate is prepared in according to individual recipes. The blending of the various types of cocoa pastes and other ingredients determine the ultimate taste.

Cacao

The cacao tree is a tropical plant that grows only within 20 degrees latitude of the Equator. The main cacao-producing countries are the Ivory Coast and Ghana, although there are numerous smaller markets in South America and Africa.

The Process

Chocolate begins with the harvest of the cacao pods. Because the pods grow in all degrees of ripeness and at any location on the tree, most harvesting is done by hand with machetes. Two important steps must happen before the cacao can be packaged and shipped to the manufacturer.

Harvesting Cacao Fruits

The cacao tree’s football-shaped fruits grow all over the trunk and branches of the tree. There are different types and colors of cacao, but each fruit pod will signal that it’s ripe with a brilliant color change. Farmers pick these ripe pods by cutting them off at the base using a sharp knife, often a machete, so as to not damage the tree.

Cacao Fermentation

Once all the ripe pods in one area of a farm have been harvested, they’re taken to a central area for fermentation. Opening the fruits yields a few dozen almond-shaped seeds per pod, settled in an aromatic white pulp which smells similar to floral lychee. The seeds are scooped out from the pods and put in a pile.

Drying Cacao Beans

Following fermentation, the beans must be dried to a low moisture level; around 7% is ideal. Farmers often dry the beans in direct sunlight as much as possible, usually for 5-7 days, but some areas with very high humidity use fire to finish fully drying the beans.

Roasting Cacao Beans

Once a chocolate maker receives their cacao, it must be inspected and cleaned of debris. This can be anything from twigs and pieces of cacao pods to trash and bits of metal. Cleaned cacao is then roasted, usually in a specialized roaster, but sometimes in an oven or a pan over fire.

Cracking & Winnowing Cacao Beans

Similar to peanuts or Brazil nuts, cacao beans must be cracked and have their shells removed. The shell is hard and has little to no chocolaty flavor, and could still have bacteria from the farm on it. The shells are very thin, so once the beans are cracked they can be put into a winnowing machine.

Refining & Conching Chocolate

The process of turning cacao nibs into chocolate is often divided into two parts: refining and conching. First, the nibs must be reheated and ground down into a paste, which can take as little as a couple of minutes.

Tempering Chocolate

After chocolate is refined, it can be eaten straight out of the machine! But most chocolate is tempered before being packaged for sale. Tempering is the process of heating, cooling, and then slightly re-heating chocolate, so that it stays smooth and shiny.