The actual diamond-cutting process

- Planning. The first step is almost always the most important — and that’s especially true for diamond cutting. ...

- Cleaving. In this step, the diamond cutting expert splits the rough diamond into separate pieces. ...

- Bruting. Also called girdling, bruting takes the separated rough diamonds and turns them into round stones by placing them on a spinning axle and grinding them against each other to ...

- Polishing. This is technically a two-step process that involves taking the round shape and turning it into a diamond, complete with the smooth and reflective facets we know and love ...

- Inspecting. Though it sounds similar, the diamond cut inspecting process is not the same as diamond grading. ...

What tool do you use to cut diamonds?

- Metal-bonded diamond tools: The tool's bonding material is sintered metal containing diamond grit. ...

- Resin-bonded diamond tools: The tools' bonding material is mainly resin powder. ...

- Plated diamond tools: These tools are made by fixing the diamonds onto the tool's base via electroplating method or via CVD (Chemical Vapor Deposition) method. ...

What do they use to cut diamonds?

- Cleaving - splitting the diamond into two pieces, usually with a steel blade and a hammer.

- Cutting - with a diamond saw or laser.

- Faceting - grinding away areas of the diamond on a metal wheel with diamond dust, to form flat surfaces.

- Bruting - forming a round girdle by rotating two diamonds against each other.

What are the 4 Cs of diamonds?

Which is the most important of the four C’s?

- Cut: The most important of all the diamond characteristics as it most readily impacts a diamond’s beauty. ...

- Color: The second most important aspect to focus on. A diamond should look white or colorless to the naked eye. ...

- Clarity: The third most important characteristic on the list. Choose a diamond that is eye clean. ...

- Carat: Last but not least. ...

What does it cost to cut a diamond?

The average price for a one-carat Round Brilliant cut is $7,291, which as you can tell is quite a pretty price to pay, especially in comparison to the Asscher cut diamond. It is a vast difference of $3,154 just because of the diamond cut. The next most expensive diamond cut, which is the Pear cut costs $1,489 less.

Is it true that only diamonds cut diamonds?

Cleaving and sawing Because diamonds are the hardest natural material on Earth, only other diamonds can cut them. Diamond-bladed edges are used on the equipment to make the cuts. In some cases, special lasers may be used to assist in this process.

How do they cut real diamonds?

Diamond manufacturers cut a groove in the diamond with a laser or saw, and then split the diamond with a steel blade. Sawing is the use of a diamond saw or laser to cut the diamond rough into separate pieces. Unlike cleaving, this step does not involve cleavage planes. This step gives diamonds their initial shape.

How do diamond cutters cut diamonds?

0:442:16See how diamonds are cut from rocks - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo they're not holding with their hands it gets very very hot that. Gets put very gently onto aMoreSo they're not holding with their hands it gets very very hot that. Gets put very gently onto a rotating wheel that cuts the diamond. And also polishes the diamond.

Is diamond difficult to cut?

Though diamonds are one of the hardest materials in the world, the cutting process is extremely delicate as one small incorrect angle could drastically impact the diamond's final value.

Are diamonds bulletproof?

Diamond Armor is certified bulletproof by NATO standards, waterproof thanks to nano-technology sealing and has an EMPA air conditioning system in-built to keep the wearer cool.

What type of rock is diamond found in?

kimberliteDiamond is only formed at high pressures. It is found in kimberlite, an ultrabasic volcanic rock formed very deep in the Earth's crust.

What is the only thing that can cut a diamond?

Each of these forms is valuable, either as gems or as grinding and cutting grit. Using these imperfect stones as cutting grit belies the main theory: only a diamond can truly cut another diamond. Diamonds are cut with specialized tools that make use of diamond tipped phosphor bronze or diamond dusted steel blades.

What is the largest diamond ever found?

CullinanOn January 25, 1905, at the Premier Mine in Pretoria, South Africa, a 3,106-carat diamond is discovered during a routine inspection by the mine's superintendent. Weighing 1.33 pounds, and christened the “Cullinan,” it was the largest diamond ever found.

How old are natural diamonds?

Remarkable facts: All diamonds are at least 990,000,000 years old. Many are 3,200,000,000 years old (3.2 billion years)!!!

What is harder than a diamond?

The scientists found Q-carbon to be 60% harder than diamond-like carbon (a type of amorphous carbon with similar properties to diamond). This has led them to expect Q-carbon to be harder than diamond itself, although this still remains to be proven experimentally.

Can u break a diamond with a hammer?

To say something is “hard” is not the same as saying it is “strong”. As an example, you can scratch steel with a diamond, but you can easily shatter a diamond with a hammer. The diamond is hard, the hammer is strong. Whether something is hard or strong depends on its internal structure.

Why are diamonds so expensive?

Diamond production is falling as mines reach the end of their productive life. Diamonds are expensive because they cost a lot to bring to market, there's a limited supply of fine quality gems, and people around the world want to buy them. It's simply supply and demand.

How jewelers cut and polish diamonds?

Most of the carats of gem quality diamonds mined each year end up as dust, polished away during the cutting process. The five basic steps to cutting a diamond are: sorting the rough, planning for manufacturing, cleaving or sawing the rough into a preliminary shape, shaping the girdle, and polishing the facets.

How can you tell that a diamond is real?

Lay the stone onto the dot with the flat side down. Through the pointed end of the diamond, look down onto the paper. If you see a circular reflection inside the gemstone, the stone is fake. If you cannot see the dot or a reflection in the stone, then the diamond is real.

How can you tell real diamonds from eyes?

A sparkle test is quick and easy to do since all you need are your eyes. Simply hold your diamond under a normal lamp and observe the bright shimmers of light bouncing off the diamond. A real diamond provides an exceptional sparkle since it reflects white light extremely well.

How do you tell if a rock is a diamond?

The only hardness test that will identify a diamond is scratching corundum. Corundum, which includes all rubys and sapphires, is 9 on the hardiness scale. If your suspected diamond crystal can scratch corundum, then there is a good chance that you found a diamond. But NO OTHER HARDNESS TEST will identify a diamond.

HOW DO YOU CUT DIAMONDS?

For this reason, diamonds are always cut by trained professionals with expert knowledge and access to sophisticated equipment and tools. As a result of the diamond’s hardness, a stone can only be cut using another diamond, so a cutter’s tools usually consist of diamond-bladed edges or discs that are lined in diamond dust. Lasers are also used on occasion, but generally not until the later stages of the process.

What does poor cut diamond mean?

Poor: A poor cut grade diamond will mostly appear dark and dull. This is often the result of a thick girdle and angles that are too steep. Diamonds with this grade will usually have a diameter that is smaller than its carat weight would otherwise suggest.

What are the components of a diamond?

A diamond is comprised of the eight main components: 1 Diameter: The width of the diamond as measured from edge to edge. 2 Table: The largest polished facet as seen on the top of the diamond. 3 Crown: The angled top part of the diamond extending from the table to the girdle. It is comprised of bezel facets (sometimes known as crown mains), star facets, upper girdle facets (also known as upper halves), and the table. 4 Girdle: The widest edge of the diamond where the crown and pavilion meet. 5 Pavilion: The lower half of the diamond which extends from the girdle to the culet. 6 Depth: The depth is determined by the total height of the diamond as measured from the table to the culet. 7 Culet: The small point at the very bottom of the diamond.

What is the process of polishing diamonds?

Polishing. After the rounded shape of a diamond has been formed, the cutter must create the multiple facets that give a diamond its signature look and shine. Placing the rough on a rotating arm, they will use a spinning wheel to polish it and produce smooth, reflective facets.

What is the grade of a diamond?

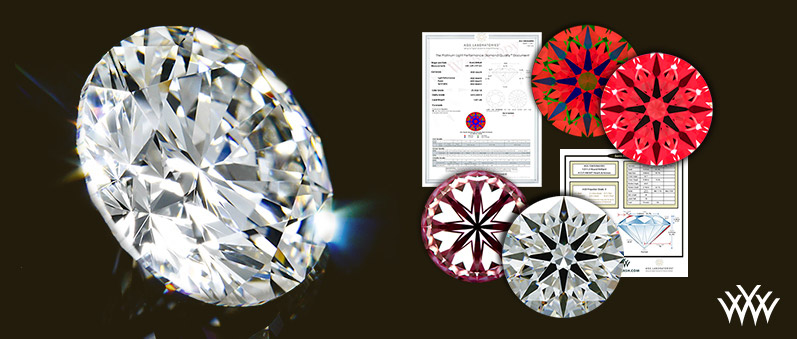

Once a diamond is cut and inspected, it will be graded. The widely accepted standard for cut grades was developed by the Gemological Institute of America (GIA) and takes into account the design and craftsmanship of each diamond. Using a precise calculation, the scale evaluates a diamond’s weight relative to its diameter, girdle thickness, the symmetry of its facet arrangement, and quality of the polish on those facets. The GIA scale is specifically designed to grade standard round diamonds, the most common shape, with color grades ranging from D to Z, though it can be used to assess other shapes as well.

What is the next step in diamond cutting?

All of this planning helps the cutter to ensure that the final diamond they produce is symmetrical and of the highest quality cut possible. Cleaving. This next step of the process splits the rough stone into separate pieces, allowing the cutter to fully utilize the rough.

What is the process of separating diamonds into rough stones?

Bruting. Once the large rough is split, bruting will further separate the pieces into rough stone rounds. Also known as girdling, this process involves placing the two diamond roughs next to each other on a spinning axle, then turning them in opposite directions to grind against one another.

How does a diamond get its facets?

A rough diamond being facetted on a polishing wheel. Once the rounded shape of the rough is formed, the next stage is to create and form the facets of the diamond. The cutter places the rough on a rotating arm and uses a spinning wheel to polish the rough. This creates the smooth and reflective facets on the diamond.

What happens when two diamonds are split?

What happens here is that two diamonds are placed on a spinning axle across each other. They will then turn in opposite directions and grind against each other to create a rough girdle finish.

What is diamond cutting?

Diamond cutting is the process that takes a rough diamond and changes it into a shaped and beautiful gem. The process must be undertaken by a professional with expert knowledge, equipment and tools for the job since every single decision made will affect the outcome of profitability. So, what are the main considerations a cutter take ...

How many facets does a brillianteer have?

The brillianteer will then finish up the job by adding in the remaining facets and bringing it to a total of 57 facets. He holds great responsibility as the fire and brilliance of the diamond is determined at this stage.

What are the main considerations a cutter take into account when planning to cut a diamond?

So, what are the main considerations a cutter take into account when planning to cut a diamond? The first choice to make is to decide on the shape itself; round, oval, pear etc. And secondly, the proportioning of facets and quality of the cut (i.e. symmetry and polish) are planned with computer simulations.

How many steps are there in diamond cutting?

The actual process of how diamonds are cut and polished can be broken down into five steps: planning, cleaving, bruting, polishing and inspecting.

What is the last stage of diamond polishing?

The last stage is the inspection process. This is where the diamond is checked to make sure it meets the specifications set out by the manufacturer. If need be, the stone would be sent back to the polishers for some touching up if it didn’t meet the quality control standards.

What is a round cut diamond?

Round cut diamond explained. Radiant Cut Diamonds. Diamonds with this cut have cut corners and square corners. They are about stones with between 62 and 70 facets. These diamonds have to be used as a central and unique stone in slopes and engagement rings. Radiant cut diamond explained. Princess Cut Diamonds.

What are the two stages of diamond polishing?

The polishing is divided into two stages: roughing and faceting. In the roughing, the stone is left next to the desired proportions. This is a very important step, if not the most important one, as it decides the appearance and brightness of the polished diamond.

What is diamond cut?

The diamond cut is the step in the production process that turns a rough diamond into an amazing jewel. This is a highly specialized art and requires the precision of an expert. An experienced cutter has the knowledge and tools to cut the diamond of your dreams. How does this work exactly?

How does diamond cutting work?

Currently, most cutting tools are partially mechanical, such as discs covered with diamond dust. Lasers, for example, are used for excision and turning or rounded. The entire process is divided into five stages: planning, splitting, grinding, polishing and inspection . It is a time-consuming process, as this will determine the final value of the rough stone.

How many facets does a princess cut diamond have?

These diamonds have 74 facets and a great luminosity for their vertical directions and their facets in the pavilion. It is undoubtedly one of the most desired in engagement rings. Princess cut diamonds explained.

How does a Sarin machine work?

A Sarin machine determines the dimensions of the rough stone to show the best cutting options in 3D. If you want to cut a rough stone in several smaller diamonds, then the rough stone needs to be divided into smaller parts. The diamond is divided with mechanical saws and lasers.

What is it called when two diamonds are rounded?

The separated pieces are rounded after the split; this is called turning or rounded. Two rough diamonds are placed in opposite directions of a turning axis. The friction generated between these two diamonds rounds both stones. At this point, it is already possible to create the facets.

How many carats are in a Koh I Noor diamond?

In the 18th century there was a trend for recutting Indian diamonds to suit English tastes. The Koh-i-Noor 's original cut weighed a little over 186.00 carats. When it was recut to an oval-shaped brilliant, almost 80 carats were lost.

How much weight does a diamond lose?

Even with modern techniques, the cutting and polishing of a diamond crystal always results in a dramatic loss of weight, about 50%. Sometimes the cutters compromise and accept lesser proportions and symmetry in order to avoid inclusions or to preserve the weight. Since the per-carat price of a diamond shifts around key milestones (such as 1.00 carat), many one-carat (200 mg) diamonds are the result of compromising cut quality for carat weight .

Why do diamonds fluctuate?

Due to changes in market desirability and popularity, the value of different styles of diamond fluctuates. All diamonds can be recut into new shapes that will increase value at that time in the market and desirability. An example of this is the marquise cut diamond which was popular in the 1970s to 1980s.

What is the process of cutting diamonds into pieces?

Sawing is the use of a diamond saw or laser to cut the diamond rough into separate pieces. Unlike cleaving, this step does not involve cleavage planes. This step gives diamonds their initial shape.

What is the other consideration of diamond planning?

The other consideration of diamond planning is how quickly a diamond will sell. This consideration is often unique to the type of manufacturer. While a certain cutting plan may yield a better value, a different plan may yield diamonds that will sell sooner, providing an earlier return on the investment.

What is diamond cutting?

Diamond cutting is the practice of shaping a diamond from a rough stone into a faceted gem. Cutting diamond requires specialized knowledge, tools, equipment, and techniques because of its extreme difficulty.

How do diamonds split?

Diamond manufacturers cut a groove in the diamond with a laser or saw, and then split the diamond with a steel blade.

How is a diamond inserted in cement?

The diamond is inserted in cement with just one corner exposed. Using one of these sticks in each hand, the cutter rubs the exposed diamond parts together to bruit them. In the mechanical process, the diamond is placed in a lathe, and another diamond in the lathe rubs against it to create the rough finish of the girdle.

How does a diamond cutter work?

The cutter places a steel blade in the groove and forcefully strikes it, cutting the rough diamond in two. Sawing - Sometimes, diamonds have to be cut where there is no plane of weakness, which cannot be done with cleaving. Instead, the cutter saws the diamond using a phosphor-bronze blade rotating at about 15,000 rpm.

What is it called when diamonds are cut by hand?

When diamonds are cut by hand, the technique is called bruiting -- cutting refers to bruiting by machine. When the cutter shapes diamonds by hand, he relies on the diamond's hardness as his tool -- he uses diamonds to cut diamonds.

What is the diamond sawing step?

During the sawing step, the cutter decides which parts of the diamond will become the table (the flat top of the stone with the greatest surface area) and the girdle (the outside rim of the diamond at the point of largest diameter). Then, he proceeds to cutting..

How to cut a diamond before it gets to the jewelry store?

There are special techniques that are used to cut and shape a diamond before it gets to the jewelry store. Diamond cutters use these four basic techniques: Cleaving - To cut a rough diamond down to a manageable size, the cutter must cleave it along the diamond's tetrahedral plane, where it is the weakest. A wax or cement mold holds the diamond in ...

How does polishing work?

Polishing - To create the diamond's finished look, the cutter places it onto the arm above a rotating polishing wheel. The wheel is coated with an abrasive diamond powder that smoothes the diamond as it is pressed against the wheel. Next, we'll learn what determines the beauty and worth of a diamond. 1 ….

What is the process of polishing diamonds?

Polishing of the diamond is the process of forming and shaping the facets of the diamond to achieve the optimum amount of reflection and refraction of the white light that brings sparkle and scintillation in the dia mond.

How is diamond marking done?

Diamond marking is done by examining and measuring the dimensions of the rough stone under a magnifying glass.

Why is planning important in diamond cutting?

Planning is a very important and critical step of diamond cutting, as the planning will determine the final value of your diamond.

What is the difference between cleaving and sawing?

The basic difference between cleaving and sawing is the tool used to cut the stone. In cleaving a tool like a hammer with the blade is used and in sawing the contactless tools like lasers are used. Normally, sawing is used for cutting the oddly-shaped rough stones.

Are Diamonds Cut by Hand or Machine?

The process of cutting diamonds. Upon arrival of a rough diamond in India, New York, Antwerp, or elsewhere, a highly trained diamond cutter either cuts it by hand or using a machine. Despite the fact that diamond cutting machines are highly accurate and useful, hand cutting a diamond is an incredible craft work.

How Long Does It Take To Cut a Diamond?

The saw can cut through a 1-carat rough diamond in 4 to 8 hours, but it can take much longer if it hits a knot.

What are Diamond Cutting Process Stages?

The following steps include a simplified round brilliant cutting process:

How is Diamond Polished?

The cutter places the rough on a rotating arm and the rough is polished using a spinning wheel. This creates the diamond’s smooth and reflective facets.

Why do diamonds have special coatings?

The second concerns the specific quality of cutting within the shape, and the quality and price will vary considerably depending on the quality of cutting. Because diamonds are one of the hardest materials, they use special diamond – coated surfaces to grind down the diamond.

How to cut a diamond?

Diamond cutting is done by cleaning or sawing the diamond with a steel blade or a laser like the Sarine Quazer 3. The rough diamond is usually placed in a wax or cement mold to hold it in place and then cleaved along its tetrahedral plane, its weakest point. If no point of weakness exists, instead sawing is used. As new and better technology has become available, the process of cutting a diamond has changed over time.

What is diamond cutting?

Diamond cutting is the practice of transforming a diamond into a faceted gem from a rough stone. Due to its extreme difficulty, cutting diamonds requires specialized knowledge, tools, equipment and techniques.

Overview

Diamond cutting process

The basic diamond cutting process includes these steps; planning, cleaving or sawing, bruting, polishing, and final inspection. A simplified round brilliant cut process includes the following stages:

• Planning – Modern day planning of a diamond is done using computer software.

Recutting

Due to changes in market desirability and popularity, the value of different styles of diamond fluctuates. All diamonds can be recut into new shapes that will increase value at that time in the market and desirability. An example of this is the marquise cut diamond which was popular in the 1970s to 1980s. In later decades, jewelers had little success in selling this shape in comparison to other shapes like the oval or pear shape. The marquise can be cut into an oval diamond by any d…

See also

• Cut (gems)

• Diamond

• Diamond cut

• Faceting machine

• Gemcutter

External links

• Antique Jewelry University – A History of Diamond Cutting

• Diamond Design, Marcel Tolkowsky. Web edition as edited by Jasper Paulsen.