How to Create a Maintenance Checklist in 3 Steps

- Step 1: Create a plan. Establish the specifics of your maintenance program such as, determining who will be involved in the maintenance project and what the goal is (e.g., decreasing equipment downtime or reducing maintenance costs)

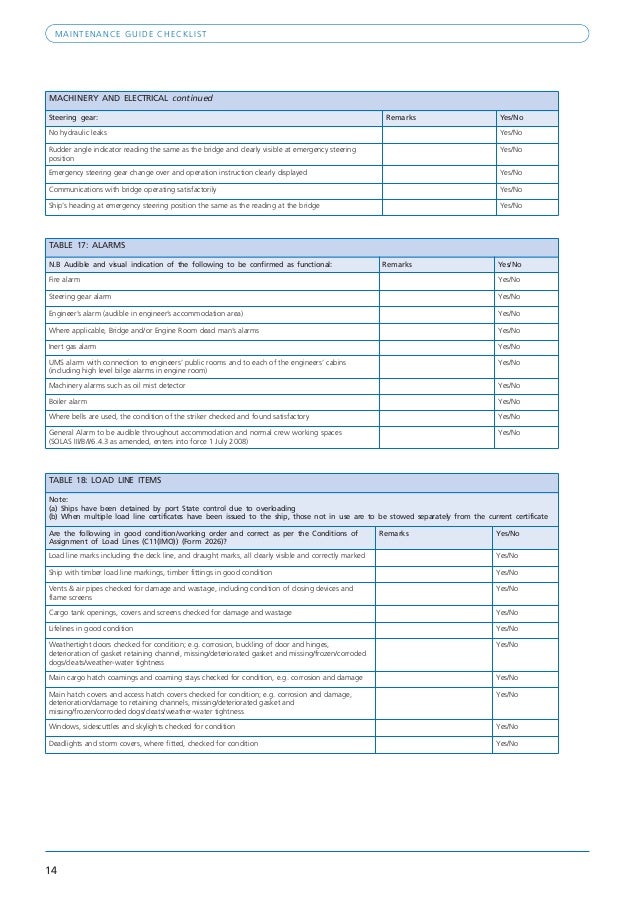

- Step 2: Determine items or areas to cover. ...

- Step 3: Draft your checklist.

- Involve the Right People in the Process. When planning the assets to maintain and creating PMs for each one, it helps to have the right types of expertise on board. ...

- Be Detailed, but Concise. ...

- Include Pictures. ...

- Include Safety Measures. ...

- Make Your Checklists Mobile. ...

- Update as Needed.

What is a maintenance checklist?

What are Maintenance Checklists? Maintenance checklists and logbooks are tools used by technicians to document equipment maintenance inspections. Equipment maintenance involves the continuous process of checking, repairing, and servicing operating equipment to ensure businesses can operate without interruption.

Which should be included on your daily maintenance checklist?

For proper vehicle maintenance, inspect the following:OIL AND COOLANT LEVELS. ... AIR FILTER. ... TIRE PRESSURE AND TREAD DEPTH. ... HEADLIGHTS, TURN SIGNALS, BRAKE, AND PARKING LIGHTS. ... OIL & FILTER. ... ROTATE TIRES. ... WAX VEHICLE. ... TRANSMISSION FLUID.More items...•

What are the 5 routine maintenance?

Examples of routine maintenance Lubricating, cleaning, or adjusting machinery. Inspecting equipment to ensure proper operation and safety. Replacing parts that show deterioration. Checking, testing, and maintaining safety equipment, such as safety barriers, fire extinguishers, or alarm systems.

What are the 4 types of maintenance?

4 types of maintenance strategy, which one to chose?Corrective maintenance.Preventive maintenance.Risk-based maintenance.Condition-based maintenance.

What is basic maintenance?

uncountable noun. The maintenance of a building, vehicle, road, or machine is the process of keeping it in good condition by regularly checking it and repairing it when necessary.

What is the recommended maintenance schedule?

Routine maintenance services are often done on a 30-60-90 interval, meaning you should perform essential preventative maintenance about every 30,000 miles. Every vehicle is unique, and various parts can wear out at irregular intervals depending on your driving habits.

What does general maintenance include?

General maintenance and repair workers fix and maintain machines, mechanical equipment, and buildings. They paint, repair flooring, and work on plumbing, electrical, and air-conditioning and heating systems.

What is maintenance task?

Maintenance tasks indicate which action—or set of actions—a maintenance technician is supposed to perform to complete a work order. Different maintenance tasks are assigned based on the type of equipment that needs maintained.

What is daily maintenance report?

A maintenance report is a detailed document that covers any routine or emergency maintenance services performed on a specific vehicle, piece of equipment, or machine. It serves as a guide outlining the proper care of the equipment in your workplace and can help your company avoid duplicate service requests.

What is a good maintenance strategy?

An effective maintenance strategy is concerned with maximizing equipment uptime and facility performance while balancing the associated resources expended and ultimately the cost. We need to ensure that we are getting sufficient return on our investment.

What is the best maintenance strategy?

Preventive maintenance is probably the most popular maintenance management strategy…at least it gets the most buzz in the industry. When the quality of production is impacted due to unreliable equipment and costs skyrocket because of unplanned servicing, it's probably time to consider a preventive maintenance program.

What is a maintenance plan?

A maintenance plan covers all routine servicing (again, according to the manufacturer's schedule), as well as cover for mechanical failures, and wear and tear. Many maintenance plans are included in manufacturer's new car sales but these can also be bought separately.

What is the importance of maintenance checklist?

A preventive maintenance plan can save a company money because it will managers and staff to focus on preventing equipment failure rather than reacting in case of emergencies. Preventive maintenance checklists can help you to monitor your assets based on maintenance goals, expected needs and past performance.

What does a PM include?

In practice, a preventive maintenance schedule may include things such as cleaning, lubrication, oil changes, adjustments, repairs, inspecting and replacing parts, and partial or complete overhauls that are regularly scheduled.

What is a PM checklist?

A preventive maintenance checklist is a set of tasks that the technician needs to complete in order to close a preventive maintenance work order. A checklist gets all the steps and information out of a manual and into the hands of experienced technicians by standardizing PMs in your CMMS.

What are the types of maintenance?

What Are the Different Types of Maintenance? The 6 different types are; Predetermined Maintenance, Preventive Maintenance, Corrective Maintenance, Condition-based Maintenance, Predictive Maintenance and Reactive Maintenance.

What are Maintenance Checklists?

Maintenance checklists and logbooks are tools used by technicians to document equipment maintenance inspections. Equipment maintenance involves the continuous process of checking, repairing, and servicing operating equipment to ensure businesses can operate without interruption. Maintenance checklists can be used to better track records of actions performed for safety and quality purposes.

Why are maintenance checklists and logs important?

Paper-based maintenance checklists and logs can be a hassle to use and maintain for data gathering and record-keeping purposes. Producing defect reports can be challenging without the ability to easily include photo evidence. Losing paper documents can create unresolved issues that may not be addressed in a timely manner.

What is a fire extinguisher maintenance schedule?

A fire extinguisher maintenance schedule template is used to conduct a monthly fire extinguisher inspection to determine if the equipment meets the standards and safety measures for any emergency purposes. Trained professionals can follow this template as a guide when performing inspections:

What is a heavy vehicle maintenance checklist?

A heavy vehicle maintenance checklist is used to identify problems and mechanical issues of heavy vehicles. It is used by certified technicians to prepare for the DOT annual vehicle inspection. The template has been built to guide the inspector to perform the following:

What is HVAC maintenance?

HVAC Maintenance template is used to ensure building heating and air conditioning systems are running efficiently. HVAC contractors and property managers can follow these template instructions when performing their inspection:

What is equipment maintenance audit checklist?

Use this equipment maintenance audit checklist to assess tools and equipment used for operations. Ensure that all equipment is in good working condition to avoid accidents and costly repairs. You can customize this checklist according to your needs.

What is a CCTV maintenance log?

A CCTV Maintenance log template is used to ensure surveillance equipment are operational. This template can be used by security teams to document any defects identified. The template has been built to guide the inspector to perform the following:

Identify maintenance goals

To begin with, you must identify your goals for which you can skim through the maintenance data. Some of the goals should include minimizing the maintenance costs, improving compliance, reducing production rejects, reducing the chances of errors, improving uptime, and enhancing safety standards.

Audit assets

Once you’ve outlined your maintenance goals, the next step is documenting the equipment and the current operational state. When a piece of equipment breaks down, it is common for maintenance teams to lose track of installed spare parts on the equipment. For this reason, it is essential to audit the equipment to streamline the repair process.

Focus on regulations & standardization

The majority of facilities need to comply with stringent safety and health requirements. In some cases, it means keeping the specific equipment pieces in good form. Both state and federal regulations have certain laws and rules that demand specific maintenance processes and tasks.

Choose assets

Some maintenance checklists cover several assets, while some are applicable for specific equipment. In either case, you need to choose the high-priority systems and assets where the checklist has the most significant impact.

Identify preventive maintenance tasks

Now that you have the list of your systems and assets identifying the preventive maintenance tasks is your next step. Everyday PM tasks include lubrication, metering, tuning, adjustments, parts replacement, condition monitoring, and inspection. Moreover, you must note the priority, critical equipment, and frequency for every asset.

Creating checklist items

Once you’ve outlined the tasks for every asset, it’s time to accumulate the information and create a list. Every item on the PM checklist should have instructions to help technicians understand the inspection process and be aligned logically. Moreover, you must leave blanks for responses (keeping it open-ended is better).

Training

Ensuring that the maintenance team is correctly implementing them is essential. Usually, maintenance teams are hesitant towards adopting such checklists, but proper discussions can ease the transition. You can discuss the importance of the checklists and share how it could ease their job as well.

How Do I Start a Maintenance Checklist?

Starting your home maintenance checklist can be difficult, but once you leave the starting block you’ll begin to notice just how much there is you’d like to get done. Our advice is to start with small, day-to-day tasks, and build toward larger undertakings.

What Regular Maintenance Should I Do On My House?

Home maintenance may be fundamentally similar across all properties (in every climate,) but the finer details of your home may be unique to even those of your neighbors in the same subdivision.

What Parts of My House Need Regular Maintenance?

While each part of your home won’t need regular maintenance, your home maintenance checklist can be broken down by seasonal tasks and further divided according to each part of your home.

Funding Costly Repairs

As you scroll through our ultimate home maintenance checklist and begin to assemble your own, you might begin to see dollar signs appear over each new task. We admit, seeing these tasks all on the same page can be daunting — but having a plan in place will help you budget for some of the more costly repairs revealed by your checklist.

What Are Maintenance Checklists?

A maintenance checklist is like a strategy map of how a maintenance program should play out. It is a document that contains the itemized list of maintenance tasks that are prepared by experts or whoever is in charge of maintenance. And whoever is expected to carry out every maintenance task should follow the checklist’s instructions rigidly.

Why Should You Have a Maintenance Checklist?

A well-made maintenance checklist gives you plenty of advantages. And here are some of the best reasons why you should prepare a maintenance checklist:

Parts of a Maintenance Checklist

Maintenance checklists may differ in purpose so it only makes sense that their content would be different from one example to another. However, there are standard parts that are naturally seen in most maintenance checklists. And these are the following:

How to Create an Excellent Maintenance Checklist

You already know what a maintenance checklist is, why it is important, and what its building blocks are. Now for the main course, apply everything you learned so far into making the maintenance checklist itself. And these are the only steps you need to ace the process:

How much money should you budget for maintenance?

The amount of money you allocate for the maintenance budget depends on the value of the asset itself. A common practice in home maintenance is to set aside around 1%–4% of the house’s value for the home maintenance budget.

How can you arrange the maintenance checklist?

You can organize or arrange the action items in the maintenance checklist according to their similar elements. Examples include arranging by asset, system, year, interval, season, contractor, skill level, priority level, and urgency level.

What are the two main formats of a maintenance checklist?

Maintenance checklists have two primary formats: (1) condition-based maintenance and (2) time-based maintenance.

What is maintenance checklist?

The maintenance checklist is a checklist designed to track the maintenance of buildings, vehicles, equipment, and places. Regular maintenance is needed to ensure a 100% efficiency in operation at all times. It is highly required by most companies especially the vehicle and residential property to conduct a maintenance check annually, monthly, or even daily. With the help of a maintenance checklist, redundancy and maintenance misses are prevented and maintenance costs are as is.

What are the different types of maintenance checklists?

There is a maintenance checklist for car, home maintenance checklist, preventative maintenance checklist, maintenance hotel checklists, maintenance apartments checklist, maintenance equipment checklist, maintenance restaurant checklists, and many more. What you need to figure out is the type of maintenance that you have. Here are the steps in making a maintenance checklist.

Can you put a maintenance checklist on a letterhead?

If you have any company letterhead, you can put it as your header. If none, you can directly put a label of what type of maintenance checklist you are making. Afterward, put the list of the needed maintenance action. This is the actual checklist already.

What is a preventive maintenance checklist?

A preventive maintenance checklist is a set of written tasks that guide the technician through a PM before it can be closed.

What should a PM checklist include?

Provide photos and/or diagrams – PM checklists should include visual representations of the instructions to make the task easier and clarify any ambiguity. Be as concise as possible – Every task on a PM checklist should have a clear action and goal associated with it so you can ensure maximum efficiency.

Why are checklists important in PM?

Preventive maintenance checklists are an essential part of an effective PM program. They eliminate miscommunication and reduce the chance of human error. Checklists make everyone’s life easier and allow your maintenance to focus on tasks that optimize their skills and time.

What is a step by step checklist?

Step-by-step checklist. There are also asset parts that require preventive maintenance based on the usage of that asset. For example, a motor might be changed every 500 hours. A step-by-step preventive maintenance checklist outlines instructions for changing the motor, from beginning to end. These checklists ensure no critical steps are missed ...

What should maintenance managers do?

The maintenance manager should be the one reviewing checklists and making sure they’re doing the job they’re supposed to be doing and that there are no instances of pencil-whipping occurring. “You always want to be proactive to ensure your PMs are still relevant and leading to better maintenance,” says Afara.

What is PM checklist?

PM checklists create a standard way to do tasks, which leads to reliable outcomes. There’s no guesswork or miscommunication, reducing the chances of error. For example, if you need to replace an engine, a good checklist will tell you what kind of engine, so you don’t use the wrong part.

What is a pass or fail checklist?

For example, a compressor has an ideal operating temperature. A checklist might include instructions to measure the actual temperature of the compressor and compare it to acceptable standards. The compressor can either meet this standard or not.

Table Of Contents On Building Maintenance Services

Keeping tabs on what needs to be done and the condition of all rental properties can seem impossible, but it’s essential to your business’s success. Follow along as we cover what should be monitored and how to do that efficiently:

What Is Building Maintenance?

Building maintenance is the process of maintaining the condition of all parts of a building to ensure that it is safe, habitable, and not in need of any repairs.

How To Use Your Checklist

Once you have a general checklist in place, it’s time to implement it. These four steps are essential to the success of implementing your maintenance checklist.

Create Your Facility Maintenance Checklist Now

Are you ready to dive in and create your own facility maintenance checklist?

What is a chiller preventive maintenance checklist?

A chiller preventive maintenance checklist is used by manufacturing facility chiller operators and maintenance personnel to daily inspect different types of industrial chillers such as centrifugal, screw, reciprocating, and scroll. Easily check an unlimited number of industrial chillers and take photos of detected defects or done repairs with this intuitive checklist. If critical repairs cannot be done on the spot, you can use this checklist to create an action and assign it to key personnel with a priority level and due date.

What is a chiller commissioning checklist?

A chiller commissioning checklist is used to thoroughly record observations before and after the start-up of chiller systems. Accurately capture suction, discharge, oil, and brine temperatures using iAuditor temperature sensors. Automate temperature monitoring of chiller systems, easily manage risks through proactive alerts to the right people when something goes wrong, and stay in control of your day-to-day operations.

What is Chiller Maintenance?

Chiller maintenance is the process of regularly inspecting commercial or industrial chillers to extend equipment life and maintain optimum efficiency. While chiller maintenance vary per type of chiller—reciprocating, centrifugal, screw, and scroll—preventive chiller maintenance should also be carried out. Maintaining the good working condition of air-cooled chillers and water-cooled chillers is crucial to prevent substandard output and avoid increased costs.

Why Is It Important?

How to Create A Maintenance Checklist in 3 Steps

- Regular maintenance checks partnered with an effective maintenancechecklist can help avoid further equipment failure and prolong their lifespan. Below are the 3 steps to building an effective maintenance checklist.

Using Mobile Applications For Your Maintenance Inspections

- Paper-based maintenance checklists and logs can be a hassle to use and maintain for data gathering and record-keeping purposes. Producing defect reports can be challenging without the ability to easily include photo evidence. Losing paper documents can create unresolved issues that may not be addressed in a timely manner. iAuditor by SafetyCulture, can replace all of your …