How do you check a shaft and coupling alignment?

- Insert the feeler gauge between the coupling faces of the shafts.

- After the feeler gauge is put, both couplings are rotated half way simultaneously.

- The readings on the feeler gauge are checked at four points on the shaft coupling.

How to check the alignment of a flexible coupling?

In the absence of a laser alignment system, users can check the alignment with some simple tools. The necessary tools used for checking the alignment of a flexible coupling are a straightedge and a taper gauge or a set of feeler gauges, or by use of dial indicators.

How do I check for angular alignment of the coupling?

A rough check for angular alignment is made by inserting the taper gauge or feelers between the coupling faces at 90 degree intervals (see Image 2). Checks for angular and parallel alignment by this method can only be done if the face and outside diameters of the coupling halves are square and concentric with the coupling bores.

How do you check if a coupling is parallel?

A rough check for parallel alignment is made by placing a straightedge across both coupling rims at the top, bottom and at both sides (see Image 3). After rough alignment, fasten the indicator to the pump half of the coupling, with the indicator button resting on the other half coupling periphery (see Image 4).

How do I adjust the coupling on my drive shafts?

Set the dial to zero, and mark the coupling half beside where the button rests. Rotate both shafts by the same amount, i.e., all readings on the dial must be made with the button beside the mark. The dial readings will indicate whether the driver has to be raised, lowered or moved to either side. Image 2 (left). Angular misalignment.

How do you ensure a shaft alignment?

Shaft Alignment Procedures ( Rim and Face Alignment Method )Rotate the dial indicators to 12:00.Set the face dial indicator to zero.Record the setting of both dials at 12:00.Rotate the dial indicators to 3:00.Determine and record the reading on both dials.Rotate the dial indicators to 6:00.More items...•

How do you check a shaft misalignment?

Measuring different sections along the horizontal and vertical planes will help determine shaft misalignment and whether the misalignment is angular, parallel, or often both. Phase analysis offers the most precises diagnose of misalignment.

How do I check my pump coupling alignment?

Measuring Misalignment With the motor and pump shaft flanges close to each other, but disconnected, mark a spot on each shaft, then measure the separation between them with a feeler or taper gauge. Rotate both shafts by about 90 degrees, keeping the marks close to each other.

What is the most accurate means of checking coupling alignment?

For most of us, laser alignment is considered the most accurate and effective. But shaft alignment can be done with reverse dial indicator sets, or dial indicators and chain-type brackets, or a straightedge, feeler gauge, and an outside caliper.

How do you check a shaft?

1:293:50Basics of Measuring GD&T Runout on a Shaft - YouTubeYouTubeStart of suggested clipEnd of suggested clipMake sure you rotate in only one direction find the greatest distance from zero in either positiveMoreMake sure you rotate in only one direction find the greatest distance from zero in either positive or negative direction stop rotating the shafts and reset the dial to zero.

What causes shaft misalignment?

Following are some of the causes of the Shafts Misalignment. Over time, foundations or base-plates can settle to lower positions, causing settling misalignment gradually. Thermal expansion can cause one piece of equipment to move proportionately to another, causing relative movement misalignment.

How do you align a fluid coupling?

AlignmentThe driving machine must be mounted in its final position. The foundation bolts must be firmly tightened.Fit the flexible element in the connecting coupling.Push the motor up to the driven machine. To allow the motor to be correctly aligned, the feet should be adjusted by means of shims or foil plates.

How do you do shaft alignment with dial indicator?

2:094:41Shaft Alignment Training: Faster Alignment With Dials | ACOEMYouTubeStart of suggested clipEnd of suggested clipWith the bolts still loose rotate the dials to the three o'clock position and make the horizontalMoreWith the bolts still loose rotate the dials to the three o'clock position and make the horizontal Corrections.

How is pump alignment done?

The tool is held in place on a pump shaft by a clamp and jig system. A laser shaft alignment tool performs measurements by means of two sensors mounted on two connected shafts. The sensors fire and receive laser beams from each other simultaneously to show whether the shafts are aligned within a certain tolerance.

Which instrument is used for shaft alignment?

Micrometers. Another precision measuring instrument used for coupling alignment is the outside micrometer caliper, shown below.

How is misalignment calculated?

To determine angular misalignment, divide the coupling gap difference by the diameter of face dial indicator travel. Example: The face indicator is set to zero at 3:00. The indicator is rotated 180 degrees to 9:00. The face indicator reads 10 mils (.

Which instrument is used for checking the alignment of machine?

An autocollimator is an optical instrument for non-contact measurement of angles. They are typically used to align components and measure deflections in optical or mechanical systems.

How is an alignment done ?

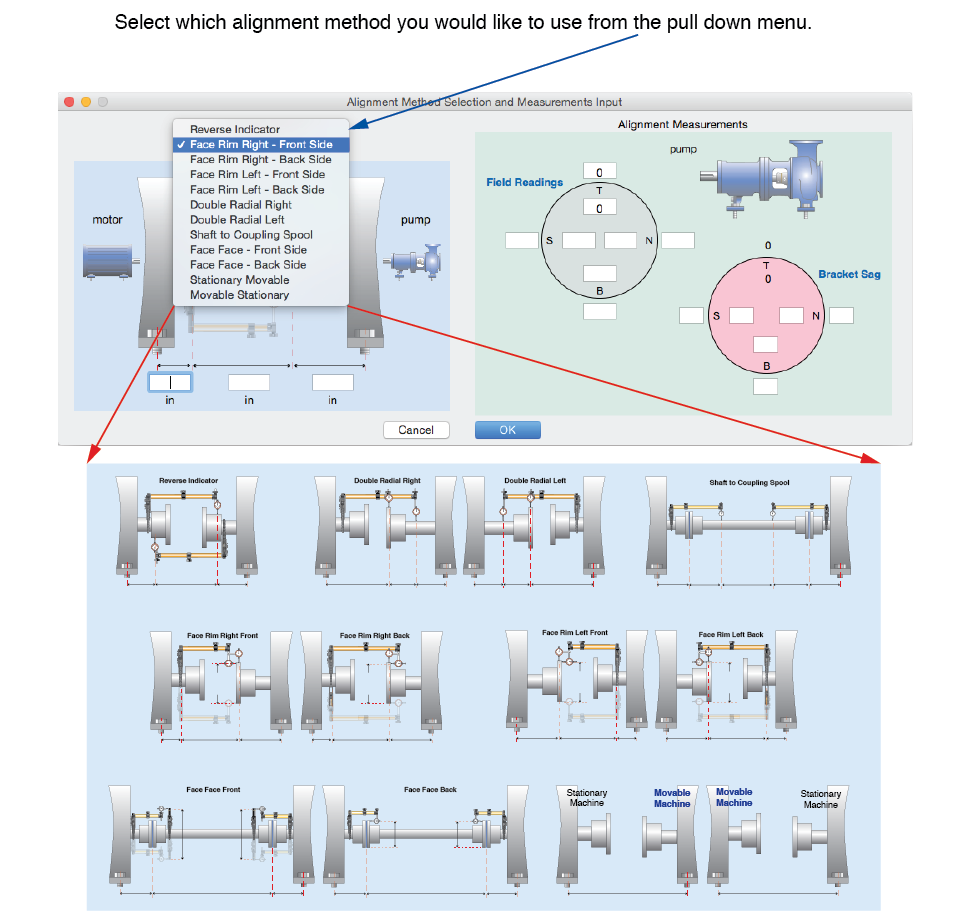

The alignment of misaligned shaft are done by using different types of shaft alignment methods which are mention below :

Rim and Face Alignment Method

Rim and Face alignment method are oldest method used for shaft alignment of misaligned equipment/shaft. In this method two dial indicator ( rim and face dial ) are used to determine the relative position of movable shaft with respect to stationary shaft.

Shaft Alignment Procedures ( Rim and Face Alignment Method )

The step by step procedure of rim and face alignment method is explained below :