How are air hose fittings measured?

- Take your hose and a length of string

- Wrap the string around the hose

- Keep the string running around the diameter straight and true

- Mark the string across both ends

- Layout the sting next to a tape measure

- Read the length of the string from mark to mark

- This will give you the circumference of the hose

- Take this length and divide by PI (3.1416)

- Take your hose and a length of string.

- Wrap the string around the hose.

- Keep the string running around the diameter straight and true.

- Mark the string across both ends.

- Layout the sting next to a tape measure.

- Read the length of the string from mark to mark.

What sizes do air hoses come in?

North American Air hoses can be purchased in these main sizes: There are larger sizes, but those fall out of the scope of most people. NPT size (or other thread type size) does not give an indication of the inner diameter of the flow hole! There are different inner diameter “body sizes”: normally 1/4″, 3/8″ and 1/2″.

How to measure garden hose diameter?

How to Measure Garden Hose Diameter 1 Disconnect Hose. Disconnect your hose from the water source and remove any fittings that are not part of the original hose. 2 Check Opening. Turn the end of the hose upwards so you can see the opening inside the metal fitting that screws onto the spigot. 3 Measure Diameter. ... 4 Double Check Measurements. ...

What size coupler do I need for my hose?

If you're still unsure what size you need, it's simple, the circumference of your hose is the size coupler that you will need. You can use this quick trick to work out the circumference of your hose; There are many different types of air fittings but most air tools use one of just a few types of connector.

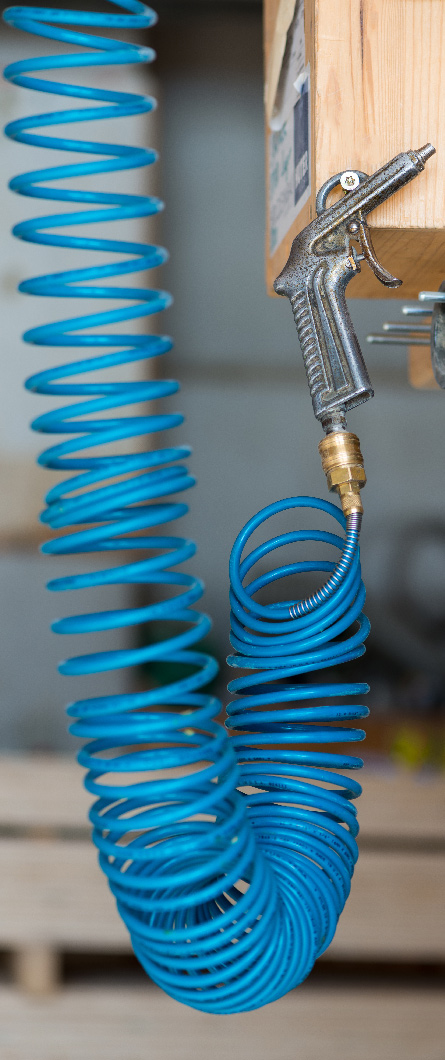

What is an air hose on an air compressor?

The air hose on an air compressor is simply a tube that carries pressurized air from the tank to a pneumatic tool or device. Air hoses come in many different sizesand are selected depending on the CFM requirements of each pneumatic tool. Air hose sizes are dictated by their inner diameter and are as follows (in order from smallest to largest):

How do I know what size air hose to buy?

The rule of thumb when picking your hose I.D is the higher the CFM requirement of your air tool, the larger the diameter hose you'll need. Hand held tools such as spray guns and nailers tend to require 1-3 CFM and will work perfectly well with a 6mm hose.

What is the difference between 1/4 inch and 3/8 inch air hose?

The most common inside diameters are 1/4- and 3/8-inch. Many people choose 1/4-inch hose because it's lighter than the 3/8-inch variety. It's easier to roll up, carry around and store. Of course, it doesn't hurt that the price tag for 1/4-inch hose is lower than its 3/8-inch counterpart.

What is 3/8 air hose diameter?

3/8"ID 300psi Blue Air Hose (Priced per Ft)Hose Inner Diameter3/8"Inner Tube MaterialPliovic™ApplicationAir/WaterHose Outer Diameter0.600"Product Weight489 more rows

What is the OD of 3/4 air hose?

1.15 INSPECIFICATIONSSub Brand:Maxecon™Type:General PurposeInside Diameter:3/4 INOutside Diameter:1.15 INLength:700 FT7 more rows

What is a 1/4 air hose used for?

Hose Diameter It is not difficult to understand that air hoses with a smaller diameter are lighter in weight. The most used sizes in practical application are 1/4 inch and 3/8 inch. Air hoses, with 1/4 inch diameter, are commonly used for air tools which don't require high pressure and a mass air transmission.

How many CFM can a 3/8 air hose handle?

3/8″ = 4.5 to 5 cfm.

Is air hose measured by ID or OD?

Air hoses are measured by their internal diameter (ID), and come in standard sizes of ¼”, ⅜” or ½” or metric sizes of 6mm, 8mm, or 10mm. Since higher ID correlates to higher air capacity, selecting your ideal air hose diameter requires an understanding of the CFM needs of your air tools.

What is the OD of 1/4 air hose?

6.35MMDIY AIR SYSTEMAir Line TubingAir Line TubingOD1/4 Inch (6.35MM)3/8” (9.52MM)Length32.8FT32.8FTMaterialPolyurethaneNylon1 more row

What is the ID of a 3/8 hose?

How to Interpret Hose, Tube & Fittings "Dash Sizes"HOSE I.D (Inches)All EXCEPT Transportation & Refrigerant Hoses-63/810-81/212,5-105/81611 more rows

How do you measure compressed air pipe?

The following is the fundamental formula for determining air compressor pipe size: A= 144*Q*Pa / V*60*(Pd+Pa). Such that: A = the area in square inches of a cross-section of the pipe bore (3.14 x diameter squared/4).

How much CFM can a 1/2 pipe flow?

Air pipe lines capacities at pressure 100 psi (6.9 bar).Recommended Pipe Size (inches)Free Air Flow (cfm)Length of Pipe (feet)251/21301/21353/4119 more rows

What type of air hose is best?

Read on to find out how to find the best air compressor hose for the job.BEST OVERALL: Flexzilla Air Hose, 3/8 in. ... BEST BANG FOR THE BUCK: WYNNsky 1/4 inch by 25 feet Polyurethane Hose.UPGRADE PICK: Goodyear 12709 Red Rubber Air Hose.BEST RUBBER: 25′ x 3/8″ Goodyear Rubber Air Hose.More items...•

What is the maximum pressure drop in compressed air?

This means the maximum pressure drop in our supply components can be no more than 15 psi or the tool pressure will be lower than the tool rating of 90 psi.

Why is my air tool getting sluggish?

This could be causing sluggish performance and a lack of power, leading to lower productivity. With a little bit of research you can fix the problem by matching the correct hose and connector to the tool.

How much pressure loss is needed for 18 cfm?

Then we might look up the pressure loss curve for our quick connect couplers and find that at 18 cfm flow the pressure loss of the two connections will be about 4 psi each, for a total of 8 psi. This hose sizing will cause a total pressure loss of 40 psi, resulting in a pressure of 65 psi at the tool, not the desired result.

How to measure air flow?

Turn on the anemometer and set it to measure air flow. If you just recently purchased your anemometer, insert batteries or plug it in to power it up. Once it’s on, change the measurement settings to CFM so you can measure air flow. A typical anemometer will have a button that reads “Unit” or “Units.”.

How to read air flow on a hood?

1. Set the balancing hood to read in exhaust mode. Your air balance hood will likely have several different modes that it can be set to. Follow the manufacturer’s instructions to make sure your hood is set to exhaust mode in order to ensure an accurate air flow measurement.

What is the CFM of a fan?

CFM stands for “cubic feet per minute,” which is how airflow is measured. Most exhaust fans should have an airflow reading of somewhere between 40 and 60 cfm to operate efficiently.

What does FPM mean in an anemometer?

Nearly all anemometers measure air speed in feet per minute (FPM), but they don’t always measure air flow specifically. Although you can technically convert FPM to cubic feet per minute (CFM), it’s much easier to use an anemometer that will do this for you.

How to pause anemometer reading?

Press “Hold” to pause the anemometer on a particular reading. The readings on your anemometer will constantly fluctuate as air flows past the vane wheel reader. Pressing “Hold” will allow you to freeze the meter on one specific airflow reading and record it.

What does the button on an anemometer mean?

A typical anemometer will have a button that reads “Unit” or “Units.” Toggle this button to switch the measurement settings of your anemometer.

Can you record your readings on an anemometer?

Some anemometers will also allow you to digitally save and record your reading to the device when you hit “Hold.”

How to measure hose size?

The most accurate way to measure is to use wooden dowels or metal drill bits if you have a good selection on hand. Since most hoses sold are 1/2, 5/8, and 3/4 inch in size, you probably only need three sizes of dowel or drill bit to measure this way.

How to measure a rubber hose?

Measure the diameter of the rubber hose opening using a measuring tape if possible. I know this can be difficult to get an exact dimension due to the fact the tape can’t lay flat against the hose opening due to the metal fitting.

What does GHT stand for on a hose?

Look for GHT on the label, which stands for “garden hose thread,” along with MHT or FHT for male and female hose thread fitting.

How to check a drill bit size?

Double-check the dowel or drill bit size by measuring diagonally across the end with your ruler.

Is thread on the outside a male or female fitting?

Threads on the outside is a male fitting, threads on the inside are female.

Is the end of a hose bigger than the diameter?

The metal ends of the hose tend to be a bit larger than the actual hose diameter, so don’t make the mistake of measuring the metal part.

How are air hose fittings measured?

Many of the hoses in our range will come already fitted with some type of end fitting so you can start connecting up to your air compressor and tools, any addition couplers you need will be the same size.

Why is a hose connection important?

The connection also allows the joint to move, meaning less kinking and twisting of the hose, better suited for a busy workplace, to keep the area safe.

What are Hose Tails?

Hose tails can be used to connect couplings to hoses, or (potentially), to connect two hoses together. It’s important to make sure that the correct hose tail size is chosen, based on the internal diameter of the hose, and then secured using a jubilee clip.

Why are air tool fittings important?

The fittings maintain a constant flow of air and pressure within the hoses so that the performance of the air tools is not compromised. Having durable and reliable air tool fittings and air tool couplers is hugely important for the safe and efficient operation of your air tools. Our superb air tool fittings and couplers can enable you to extend your air supply and/or help you create more complex air systems to suit your needs. To ensure the equipment is in its optimal working condition the fittings must be kept in good working shape.

Can you make a hose longer than a single hose?

By using couplings there is technically no limit to how long you can make the hose. As a general rule, it is always better to have a single, longer hose than to have multiple hoses connected together. The more connections present, the more likely it is you will experience pressure drop.

Can you connect two air hoses together?

Most hoses come supplied with either a thread fixing or quick release coupling. A male thread would screw into a female thread, whereas a male quick release would plug into a female quick release, so you may need a coupling to connect lines together. Fortunately, we supply a wide range of couplings, and any SGS air compressor or hose would use a ¼” BSP thread or quick release coupling to keep things simple.

What size threads are used in air tools?

Most air tools in North America have 1/4″ NPT threads in the tool.

How many lines are in a standard coupler?

Most every profile (standard) has its own coupler thats not interchangeable. The couplers normally have 1 line cut in indicating only 1 standard is applicable. There are universal couplers that have three lines indicated either in paint or by 3 groves indicating that 3 standards will interchange with the coupler.

Does NPT size give an indication of the inner diameter of the flow hole?

NPT size (or other thread type size) does not give an indication of the inner diameter of the flow hole!

Can a 3/8 NPT hose fit a 3/8 NPT?

If your fitting or coupler was 3/8 NPT and 3/8 Body size, your hose would need to have a 3/8 NPT fitting (or adapter) regardless of the hose size .

How to Measure Air Compressor Hose Size?

- Getting into the measuring air hoses, there are a few things that need to be clear before we get into detailed information;

Method of Measurement

- When measuring the hose size, you need to determine the internal size, or you can say inner measurement. The rule of thumb is used at first for taking the dimensions. Basically, it is a manual rule where it is thought that the total amount of the CFM level will be the hose dimension in a straightforward approach. To explain, indeed, this will be the dimension that your hose will n…

Steps to Measure The Hose Size

- You need a tape or a scale to do the measurement at first; measure from the inside and then move towards the outside measurement.

- Then, take a piece of paper and make a mark on it with the measurements you took from the inside of the hose. It will be the distance from the hose, and the measures come in inches; that can be any...

- You need a tape or a scale to do the measurement at first; measure from the inside and then move towards the outside measurement.

- Then, take a piece of paper and make a mark on it with the measurements you took from the inside of the hose. It will be the distance from the hose, and the measures come in inches; that can be any...

- The most common measurements are ¼ and 3/8 Inches of the hose.

Conclusion

- Air compressors are used widely with the tools and equipment to draw the air and build air pressure. When we talk about air hoses in an air compressor, there are multiple factors that come. One of the most basic is the measurement of an air hose for better fittings etc. After reading this article, I hope you are able to measure the air hose off an air compressor, as the use of hoses is …