How to Splice Wires

- STEP 1 : Prepare and install the junction box. ...

- STEP 2 : Prepare wire splice connectors. ...

- STEP 3: Ground the junction box. ...

- STEP 4: Strip and ground the wires. ...

- STEP 5: Use a twist-on wire cap. ...

- STEP 6: Twist wires together. ...

- STEP 7: Secure the junction box. ...

Full Answer

How to splice a 12/2 wire?

How to secure wires to junction box?

What is a Romex wire?

What is the name of the wire used to connect a 12 gauge wire to a ground wire?

How to use Romex connector?

How to tie a 12/2 romex wire?

How many amps can a 12 gauge wire handle?

See 4 more

About this website

How do you splice and join wires?

How to Splice WiresCut a piece of heat shrink to cover the exposed wires. ... Face the wire terminals toward each other and touch the exposed ends together.Hold the wires together by using tape to hold the wires in place against a soldering mat.More items...

How do you splice a joint?

You can take the easy way and butt two pieces together, or you could make a splice joint. To make a splice joint, cut a 45 degree angle at the end of each piece. Simply slide them together and drive one fixing through the face to secure the pieces together to create a nice, flush joint.

What are the types of splices and joints?

There are four main types of splice joints: half lap, bevel lap, tabled, and tapered finger.Half lap splice joint. ... Bevel lap splice joint. ... Tabled splice joint. ... Tapered finger splice joint.

What are the three ways to splice a wire?

When splicing wires, you'll usually incorporate one of three kinds of splices: the butt splice, where the two wires are joined to form one, continuous wire; the pigtail splice, where the wires lie next to each other; and the three-way splice, which brings a second wire into the middle of another wire.

What is the best way to splice wires?

1:566:38Together slide on a wire nut and twist until even the insulated part of the wires get twisted.MoreTogether slide on a wire nut and twist until even the insulated part of the wires get twisted. Together pre-twisting the wire nuts before putting on the wire nut is optional.

What are the three most common wire splices and joints?

Common Electrical Wire splices and JointsKnotted tap. ... Plain tap joint. ... Aerial Tap. ... Duplex cross joint. ... Western Union Short-tie Splice. ... Western Union Long-tie Splice. ... Cross Joint. ... Wrapped tap or Tee joint. This is used on large solid conductors where it is difficult to wrap the heavy tap wire around the main wire.More items...•

What are the 3 types of splicing tools?

Splicing tools include Splicing Needles, Splicers in a range of sizes, Splicing Kits, Swedish fids and Whipping Needles.

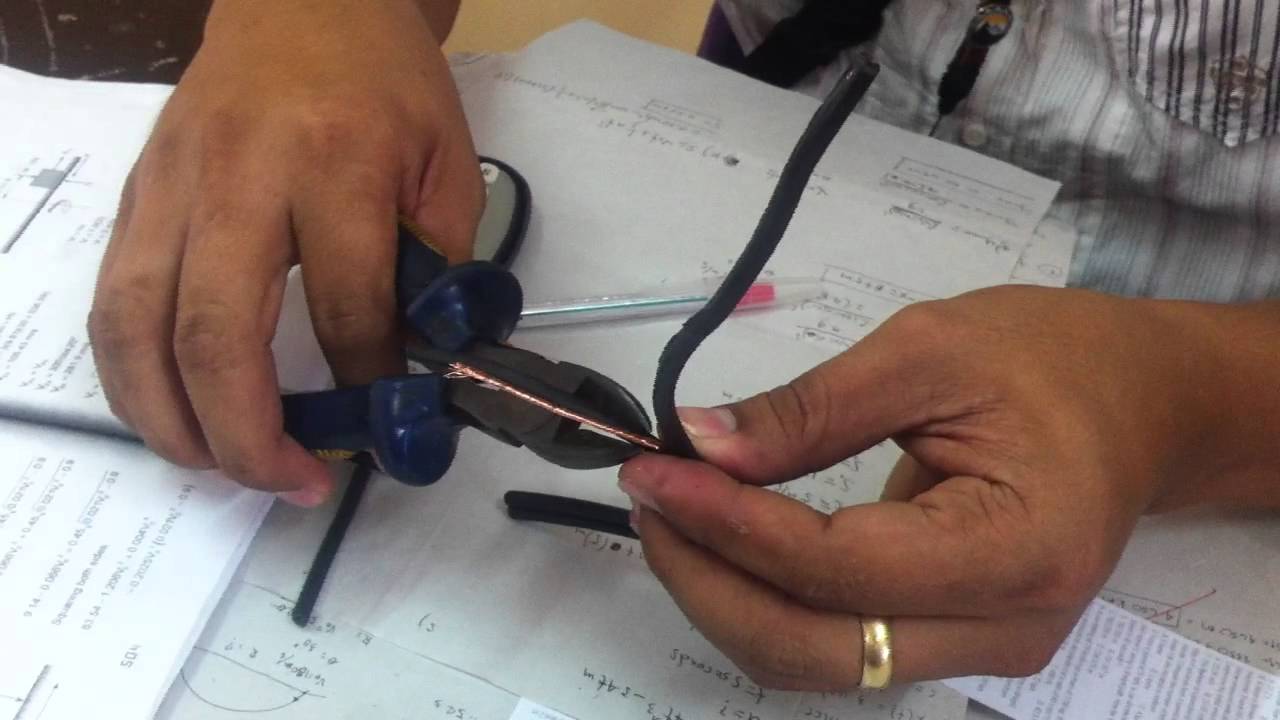

What are the tools used in splicing and joint?

Tools. Splice kits can include many different tools to ensure a safe joint between cables. These tools include a wire cutter, needle nose pliers, wire strippers, and electrical tape. Wire cutters, also called diagonal cutters, are intended for cutting wire instead of grabbing or turning anything.

What is the most common electrical splice or joint?

Western Union Splice Joint For Wire This is the most common type of wire splice. It's a straight splice between two small solid conductors. You'll need to remove above 5 inches of wire cover on each wire.

How do you join wires together?

1:584:25You're going to press them into the connector as shown. And then when you insert the second wire youMoreYou're going to press them into the connector as shown. And then when you insert the second wire you're actually going to push that wire into the other.

What are the different methods of joining wires?

Let's take a look at my 'Top 5' ways to create a cable joint:1: Crimp Splice. The In-Line Crimp Splice is simple and requires minimal tools. ... 2: Solder Sleeve. ... 3: Terminal Block. ... 4: Ultrasonic Weld. ... 5: Solder.

How do you splice wires at home?

2:146:01And my dad always taught me that the wire nuts job. The wire nuts job is to cover the splice. It'sMoreAnd my dad always taught me that the wire nuts job. The wire nuts job is to cover the splice. It's not to make the splice. So in this case.

Can you splice with just electrical tape?

Don't Use Electrical Tape to Repair / Splice Cords However, Federal OSHA electrical safety standards actually do not allow us to make a repair to a frayed or damaged electrical cord using electrical tape, nor can we use electrical tape to splice two cords together .

Can you splice with tape?

Single-coated splicing tape is suitable for butt splicing. Double-coated splicing tapes are suitable for use with laminators, coaters, and other converting operations. Double-sided tapes are commonly used in flying splices, manual splices, core starting, and roll finishing applications.

What tools do you need to make a halving joint?

0:213:27With each other the center lap. Half the thickness is removed from both pieces to make sockets intoMoreWith each other the center lap. Half the thickness is removed from both pieces to make sockets into which the end grain of the opposite piece is locked. The tools you will need are a ruler a tri

What does it mean to splice tape?

Splicing tape is easy. It is simply a matter of rearranging sounds. You physically cut out unwanted words, phrases or sounds and rejoin the remaining pieces with adhesive (splice) tape.

How to splice a 12/2 wire?

Thread the end of each 12/2 Romex wire—the existing wire and the wire you’re splicing to it—through one of the Romex wire connectors attached to the box. Tighten the screws on the sides of the wire connector designed to hold it in place, using the appropriate type of screwdriver.

How to secure wires to junction box?

Secure the connector to the junction box using its threaded locknut and tightening with needle-nose pliers and/or a screwdriver. The connectors act as protective guides that also secure the wires to the junction box. Without them, the wires could be damaged by the sharp edges of the knockout holes.

What is a Romex wire?

Romex is a brand name of wire preferred by many electricians that is commonly used in residential applications. The markings stamped on the outer insulation, “12/2 NMC with ground,” indicate the size and type of wire—in other words, a 12-gauge wire with two inner insulated conductors (a black “common” and white “neutral”) as well as ...

What is the name of the wire used to connect a 12 gauge wire to a ground wire?

The following instructions assume that you’re splicing together two Romex wires of the same type. (In this example, we’re connecting a 12/2 NMC with ground to the same type and size of wire.) Romex is a brand name of wire preferred by many electricians that is commonly used in residential applications. The markings stamped on the outer insulation, “12/2 NMC with ground,” indicate the size and type of wire—in other words, a 12-gauge wire with two inner insulated conductors (a black “common” and white “neutral”) as well as a non-insulated grounding wire.

How to use Romex connector?

Insert a Romex connector in each knockout hole in the junction box. Be sure to purchase a connector that fits the knockout holes you’re using on the junction box and is suited for the diameter of wire you are splicing.

How to tie a 12/2 romex wire?

Using the electrician’s pliers, twist together the stripped ends of the corresponding wires from each strand of 12/2 Romex, white wire to white, and black to black. Twist them until they are tightly joined, and secure each joint with a threaded wire cap/nut. Fold both sets of wires neatly into the junction box.

How many amps can a 12 gauge wire handle?

For example, a 12-gauge wire is capable of handling approximately 20 amperes, while a 10-gauge wire is capable of handling 30 amperes. Overloading a wire with more than its intended amperage could cause it to overheat, melt, and possibly catch fire.

What is splicing wire?

This article has been viewed 403,925 times. Splicing is the process of combining 2 lengths of wires so they can carry a current. Before you splice your wires together, you need to prepare the wires by stripping them and turning off the power.

How to splice a wire with a soldering iron?

Heat up your soldering iron and hold it near your wire coils with your dominant hand. Hold a rod of silver solder with your non-dominant hand next to the tip of your soldering iron. Melt the silver onto your coils so it drips between your wires and coats your entire splice.

How to shrink wires?

Heat the shrink tube with a heat gun. Turn on your heat gun and point the nozzle toward the shrink tubing. Rotate the wire in your hands so the tube shrinks evenly around the splice to insulate the wires. If you don’t have access to a heat gun, you can use a small torch or a lighter to heat the tubing.

What to do if you forgot to use shrink tube?

If you forgot to use shrink tube before you spliced your wires, you can wrap the entire splice and any exposed wires with electrical tape.

How to keep wires from slipping?

Twist a wire cap clockwise onto the exposed wires. Set a wire cap on top of the expose d wires and start twisting it on with your fingers. Turn it clockwise for about 5 seconds so the wires wrap and coil inside of the cap. Lightly tug on the wires to see if they stay in place. If not, tighten the wire cap more.

How to crimp a butt splice?

Place the jaws of the crimper 1⁄4 – 1⁄2 in (0.64–1.27 cm) from the edge of the butt splice. Squeeze the crimper handles all the way so the wire is held in place. Don’t use a hole that’s too small or else you may cut through your wire.

How to secure wires in a wire cap?

Hold the wir e ends so they’re touching one another. Press the exposed ends of the wires together so they’re right next to each other. Don’t twist or coil the wires together or else they won’t stay as secure in the wire cap.

How to hold two wires together?

However, some wire nut manufacturers instruct to simply hold the two parallel wires together, then twist the wire nut over the bare ends of the wires in a clockwise direction. However you do it, the wires should be connected securely enough that they don't come free from the wire nut when you tug on them.

How to expose wires in plastic jacket?

First, expose the individual conducting wires within the tough outer plastic jacket by using a cable ripper to slice through the sheathing. Do not use a utility knife, as you risk cutting into the individual wires. Insert the cable into the hole on the cable ripper until it is about 6 inches from the end of the cable.

How to install a junction box?

The cable sheathing should extend past the clamp into the box by 1/4 to 1/2 inch. Tighten the screws on the clamp until the cable is securely gripped .

What is push fit connector?

This is the method approved by the National Electrical Code (NEC). The old, informal method of splicing wires together with electrical tape should never be used.

How to remove severed sheathing?

Trim away the severed portion of the sheathing and paper filler with the cutting jaws on a wire stripper or with a utility knife.

How to remove knockout disks from junction box?

With a screwdriver and hammer, loosen two opposing knockout disks from the junction box. Use pliers to pry off and completely remove the discs. Often, you have to rock the disk back and forth several times before it will come free. Dispose of the disks.

Can you splice wires with UL approved wire connectors?

The method demonstrated here is the correct way to splice electrical wires using UL-approved wir e connectors joined inside an approved electrical box. These connectors can be the familiar twist-on wire nuts or newer style push-fit connectors. This is the method approved by the National Electrical Code (NEC). The old, informal method of splicing wires together with electrical tape should never be used.

How does a fixture splice work?

A fixture splice can connect wires of differing sizes. It begins in a similar way to the rat tail joint. However, rather than the two wires being twisted together, the smaller wire, called the fixture wire, is wrapped around the bigger wire, called the branch wire. Once the full extent of the fixture wire is wrapped, the top of the branch wire should be bent over the top to hold it in place. Then, the joint should be soldered and taped up.

What is Western Union splice?

Western Union Splice Joint For Wire. This is the most common type of wire splice. It's a straight splice between two small solid conductors. You'll need to remove above 5 inches of wire cover on each wire.

How to make a wire ring?

Cross the exposed wires, first wrapping one side around the other six times, then repeating the process with the other wire. Cut off any excess with a wire cutter, then solder and cover with electrical tape.

What is a Y splice?

Y Splice Joint For Wire. A Y splice joint, also known as a tap splice, connects a conductor to a running wire. You'll need to remove about 1.5 inches of insulation from the running wire. Take the connecting wire and tie it in a knot onto the running wire to create a knotted tap splice.

What is a rat tail splice?

A rat tail splice, sometimes also called a pigtail, is another method of joining two conductors. It's more suitable for circuits where there's no physical tension. You'll need to strip the insulation from two ends of the two wires and then twist them together. They can then be soldered and covered with tape.

Do you need to cover splices in solid wire?

Splices and joints in solid wire should also be covered with electrical tape for safety. Advertisement. Types of Wire Joints & Splices. Image Credit: energyy/E+/GettyImages. When working with electricity, it's important to be extremely careful.

Is a splice or joint secure?

There are a variety of kinds of splices and joints in wire. A good wire splice or joint will be secure even before soldering. The soldering can act as an extra securing method and also prevents corrosion in the joint. Splices and joints in solid wire should also be covered with electrical tape for safety. Advertisement.

How to splice a 12/2 wire?

Thread the end of each 12/2 Romex wire—the existing wire and the wire you’re splicing to it—through one of the Romex wire connectors attached to the box. Tighten the screws on the sides of the wire connector designed to hold it in place, using the appropriate type of screwdriver.

How to secure wires to junction box?

Secure the connector to the junction box using its threaded locknut and tightening with needle-nose pliers and/or a screwdriver. The connectors act as protective guides that also secure the wires to the junction box. Without them, the wires could be damaged by the sharp edges of the knockout holes.

What is a Romex wire?

Romex is a brand name of wire preferred by many electricians that is commonly used in residential applications. The markings stamped on the outer insulation, “12/2 NMC with ground,” indicate the size and type of wire—in other words, a 12-gauge wire with two inner insulated conductors (a black “common” and white “neutral”) as well as ...

What is the name of the wire used to connect a 12 gauge wire to a ground wire?

The following instructions assume that you’re splicing together two Romex wires of the same type. (In this example, we’re connecting a 12/2 NMC with ground to the same type and size of wire.) Romex is a brand name of wire preferred by many electricians that is commonly used in residential applications. The markings stamped on the outer insulation, “12/2 NMC with ground,” indicate the size and type of wire—in other words, a 12-gauge wire with two inner insulated conductors (a black “common” and white “neutral”) as well as a non-insulated grounding wire.

How to use Romex connector?

Insert a Romex connector in each knockout hole in the junction box. Be sure to purchase a connector that fits the knockout holes you’re using on the junction box and is suited for the diameter of wire you are splicing.

How to tie a 12/2 romex wire?

Using the electrician’s pliers, twist together the stripped ends of the corresponding wires from each strand of 12/2 Romex, white wire to white, and black to black. Twist them until they are tightly joined, and secure each joint with a threaded wire cap/nut. Fold both sets of wires neatly into the junction box.

How many amps can a 12 gauge wire handle?

For example, a 12-gauge wire is capable of handling approximately 20 amperes, while a 10-gauge wire is capable of handling 30 amperes. Overloading a wire with more than its intended amperage could cause it to overheat, melt, and possibly catch fire.