Both variable speed and X13 motors are ECM or “electronically commutated motors,” which means that the DC power that drives them is electronically switched from positive to negative to spin the motor. Both are more efficient than the typical PSC motor, with ECM motors commonly being about 80% efficient and PSC being about 60%.

What is the difference between a PSC and ECM motor?

Additionally, the efficiency of a PSC motor may further decrease depending on its load and speed. The main benefit of using an ECM is reduced power consumption. One study found that the use of an ECM in an AHU consumed 23% less power during heating and 38% less power during cooling when compared to a PSC motor.

What is the difference between variable speed and X13 Motors?

The Difference Between Variable Speed and X13 Motors. Both are more efficient than the typical PSC motor with ECM motors commonly being about 80% efficient and PSC being about 60%. Both X13 and variable speed motors are DC, 3 phase, permanent magnet rotor motors that use back EMF to determine motor torque and adjust to load conditions.

What is the difference between an X13 motor and a PSC?

That means that while an X13 motor is more efficient than a PSC motor and does a better job of ramping up to overcome static pressure increase, it does not have the level of control that a variable speed has. It also does not produce an exact airflow output across the full range of static pressure.

What is an ECM and how does it work?

What is an ECM? An ECM (Electronically Commutated Motor) is an electric motor that is controlled by a microprocessor. In an ECM, power is provided to the controller, and the controller operates the motor at a specific speed and/or torque.

What is an ECM motor?

Why are EC motors used in air handlers?

How does a three phase motor work?

Is an EC motor more efficient than a PSC motor?

Is a three phase motor self starting?

Can a PSC motor be used in a fan?

Is the PSC motor good?

See 4 more

About this website

Which is better ECM or PSC motor?

ECM motors are around 30% more efficient than PSC motors, which is why there is such a big push for ECM motors. The energy usage doesn't come from when the motors are already on, but when they are starting up.

What is the differance between an EMC and a PSC motor?

PSC motor (permanent split capacitor) – Runs at a constant speed. ECM motor (electronically commuted motor) – Runs at a variable speed. This provides several benefits, including energy savings, lower need for maintenance, improved comfort and better airflow and indoor air quality.

What are the advantages of using a ECM over a PSC?

ECM motors do not use brushes, thereby reducing maintenance and extending service life. ECM fan and pump motors provide numerous performance gains over traditional PSC motors ranging from electrical savings, reduced starting current, modulating capability, and longer equipment lifespan.

Is an X13 motor an ECM motor?

The X13™ adjusts its speed (High, Medium High, Medium, Medium Low, Low) based on changes to static pressure by only monitoring changes in torque. This 'standard ECM' motor is much more efficient than PSC motors, but less efficient when compared to ECM variable speed motors.

What are the disadvantages of using a PSC motor?

The cost of the paper capacitor is higher, and the size is also large as compared to the electrolytic capacitor of the same ratings. It has low starting torque, less than full load torque.

How much more efficient is an ECM motor?

ECMs, in HVAC applications, can decrease energy usage by as much as 75%. ECMs require less maintenance and are not prone to overheating.

Do ECM engines last longer?

ECM motors are also quieter than traditional inefficient motors, have longer design life, and require less maintenance.

What causes ECM motors to fail?

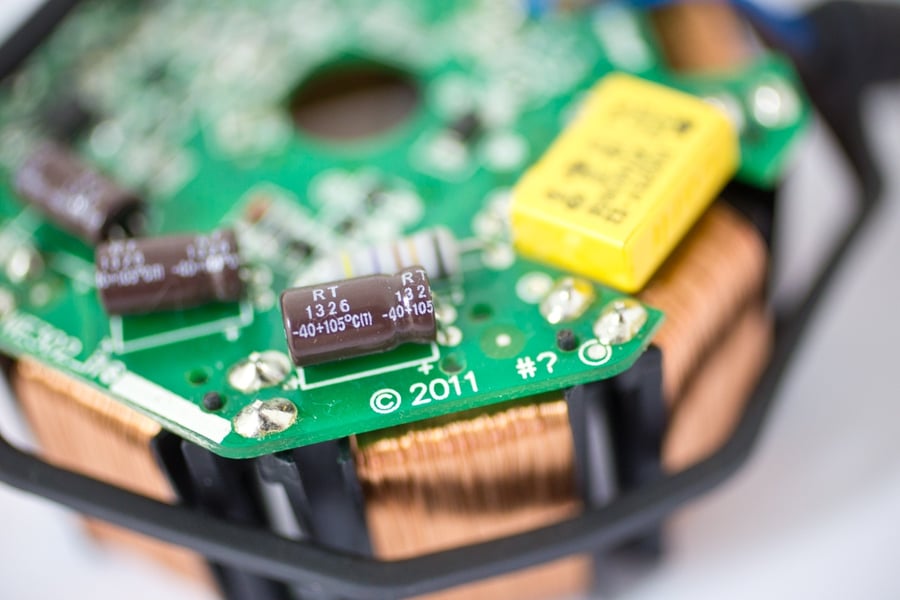

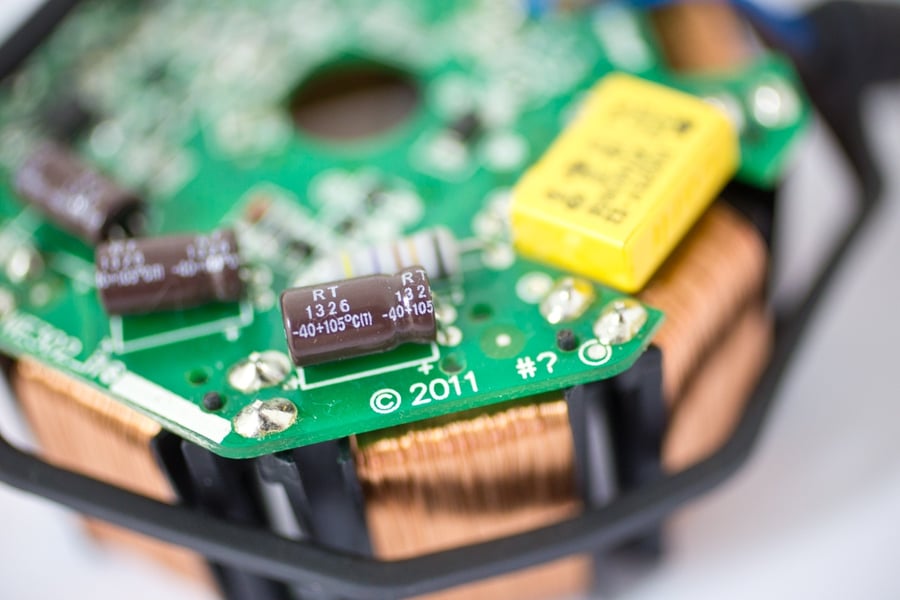

A major cause of failure occurs when a blower is applied to an application with static pressure above . 8” WG. This not only shortens the life of an ECM, but also a PSC. With an ECM this will cause a failure of the metal oxide varistor (MOV), a disk in the controller.

Can you put a speed control on a PSC motor?

If you have a PSC induction motor and fan as load, then U2008 would work. It is important to note that robust generalized speed control is not really possible with a single-phase induction motor. A three-phase induction motor can be controlled using a variable frequency drive (VFD).

Do X13 motors need to be programmed?

The X13 is constructed as one piece, with the two components of any ECM, the motor control and motor, housed inside one motor shell. It is programmed to provide a constant level of torque (power) to the motor.

What type of motor is X13?

The Genteq X13 motor is a high-efficiency motor that help manufacturers meet the 13 SEER mandate implemented by the federal government in 2006 (hence, the branding name of X13).

How do I know if my motor is X13?

Diagnosing ECM & X13 MotorsCheck for proper line voltage and 24v calls to the proper terminals in the equipment.Check for proper control signal entering the motor from the 24v field wiring or boards. ... Disconnect power and remove the blower housing.Check for abnormal sounds and side-to-side bearing play.More items...

Is a PSC motor an ECM?

The electronically commutated motor (ECM) is a permanent magnet motor while the permanent split capacitor (PSC) is an induction motor. To operate either motor, power is applied. The amount of power applied is measured in Watts. This is often referred to as “Watts In”.

What is EMC motor?

Electromagnetic compatibility is a way of monitoring and reducing the unwanted EMI out of the system. EMC performance is related to the final product and is therefore the responsibility of the OEM (original equipment manufacturer) and not of those who supply the components.

What is a PSC motor?

A Permanent Split Capacitor (PSC) Motor is a type of single-phase AC motor; more specifically, a type of split-phase induction motor in which the capacitor is permanently connected (as opposed to only being connected when starting).

What does EMC stand for in motors?

Electromagnetic compatibility (EMC) is the ability of electrical equipment and systems to function acceptably in their electromagnetic environment, by limiting the unintentional generation, propagation and reception of electromagnetic energy which may cause unwanted effects such as electromagnetic interference (EMI) or ...

Which universal ECM to replace my PSC blower motor?

Hey guys. So I moved into a house two years ago that had a brand new furnace. Single stage heat, PSC motor. It's an old house and the temperature on the three levels vary quite a bit. I'd like to run my furnace fan continuously but even at low speed, I find it too expensive, noisy and moves too much air in the winter (drafty).

ECM Motors: The Good, the Bad and the Ugly | Contracting Business

The Bad. In marginal systems with higher-than-design static pressures – for example, a 0.5-in. TESP rated furnace with ECM on a 0.8-in. TESP system – the motor still may be able to maintain airflow close to design. The tradeoff is higher velocities often cause a noisy system and some coil blow-off.

EEM Motor vs ECM Motor for Goodman - HVAC-Talk: Heating, Air ...

Hi everyone, Can anyone explain to me the difference between the two? Goodman offers them in some of their air handler models: AEPF is a V/S with ECM motor, while the ASPF is multispeed w/ EEM motor. When paired to the SSZ140361A*, the ARI performance is exactly the same: ARI#3068848, and ARI#3068856. The EMM motor is supposed to be “energy efficient”.

Swapping ECM for PSC fan motor - GreenBuildingAdvisor

I know a homeowner who runs the fan on his Ruud UBHC-17J11NFD air handler (2.5 ton heat pump) continuously in the summer to help keep the temperature a bit more consistent between the upstairs and downstairs, so he figures swapping the OEM PSC fan motor for an ECM motor, such as the Evergreen, might pay for itself. The Evergreen mfr/distributor says the following:

Your Furnace Replacement: The ECM Motor vs. the PSC

One of the primary energy consumers in your heating system is the furnace blower motor. The same holds true for the air conditioner blower located in the air handler. Yet, when published efficiency ratings for new furnaces and air conditioners are computed in the laboratory, the efficiency of the blower motor isn’t included in the… Continue Reading Your Furnace Replacement: The ECM Motor ...

What is the difference between X13 and variable speed motors?

Both X13 and variable-speed motors are DC (or alternating DC, if you prefer), three-phase, permanent-magnet rotor motors that use back EMF to determine motor torque and adjust to load conditions. The primary difference is the type of inputs to the motor control. A variable-speed motor is programmed for a specific piece of equipment ...

What is a PSC motor?

In residential and light commercial HVAC, we work primarily with PSC (permanent split capacitor) motors. However, it is good to be aware of some other types. PSC (Permanent Split Capacitor) A common medium torque single phase motor with a run capacitor always in the circuit. This type makes up the…

What is the difference between X13 and X13?

The Difference Between Variable Speed and X13 Motors. First, let's cover the basics. X13 is a brand name for the Regal Beloit/Genteq brand of constant torque motors; there are other manufacturers that make them, but the term “X13” has become pretty much synonymous with the fractional horsepower HVAC constant torque motor.

Is X13 more efficient than PSC?

That means that while an X13 motor is more efficient than a PSC motor and does a better job of ramping up to overcome static pressure increase, it does not have the level of control that a variable speed has.

Is X13 a PSC or ECM?

Both variable speed and X13 motors are ECM or “electronically commutated motors,” which means that the DC power that drives them is electronically switched from positive to negative to spin the motor. Both are more efficient than the typical PSC motor, with ECM motors commonly being about 80% efficient and PSC being about 60%.

Does CFM drop with static pressure?

That is why when you check the blower charts on a unit with a variable-speed motor, the CFM will remain the same over a wide range of static points, but when you look at an X13 system, the CFM will drop as the static pressure increases.

INTRO – PSC Motor vs Constant Torque Motor vs Variable Speed Motor

We have standard PSC motors that are found in the majority of homes today. I’d say 80 percent of the systems we work on today have PSC motors. They’re the ones that have capacitors strapped to them to help start the motor and help it run efficiently. I’ll explain more about them down below.

PSC Motors –

Ever heard of Nikola Tesla? I’m sure you have. He’s the inventor of the first practical design of these split-phase induction motors. He made them easy to use, low-cost, and compact in design, so well the industrial market started using them more and more.

ECM Constant Torque Motors (X-13 Motors)

Probably the most familiar name in ECM constant torque motors is the X-13 motor by Genteq. Genteq acquired General Electric’s motors and capacitors division in 2004, and in 2009 renamed themselves Genteq. I bring this up because the first high-efficiency residential HVAC ECM motors were made by GE back in the 1980s.

Variable Speed Motors –

GE, which I said before was acquired by Genteq (on the motors side), introduced the first variable-speed motors for use in HVAC systems in 1987. So, it’s not a new technology.

Conclusion –

PSC motors are simple, fairly inexpensive, moderately efficient motors with a reputation for being loud and not very dynamic. They also come hitched with the always unpredictable capacitor, which can go out due to overheating.

Does York sell modules?

York always sold just the module if that is what was wrong, along with several other brands did also.

Does Morrison Supply have drop in ECM?

Morrison Supply brought the Mars guy by our shop a couple weeks ago to demo the new ECM-PSC drop ins. The installation seemed pretty straightforward. Think its pretty slick to have a drop in ecm for a PSC application for the noise and consistent cfm's.

Can I touch PSC motors?

In existing equipment, I wouldn't touch the psc motors if they aren't broken.

Does a VS ECM motor go out?

A VS ECM motor seldom goes out. Its usually the cheaper module. But many techs don't know how to check them, so they just condemn the motor.

Is a mars motor the same as a x13?

The mars motor is the same as an x13 constant torque and is direct replacement for all x13 oem motors. It does have slight variable drive to try keep cfm up as static rises. I never want the overpriced variable ecm constant cfm because they are way to expensive. 10 years of electrical saving are gone when the motor needs replaced

What is an ECM motor?

Electrically commutated motors (ECMs, EC, or ECM motors) are simply a specific version of the popular brushless DC motor; it may, therefore, be useful to review this exciting new technology by reading our article all about brushless DC motors. To summarize, BLDC motors utilize a permanent magnet rotor and wound stator poles, and as such are “electrically” commutated (as opposed to mechanical or “brushed” commutation). The name “EC” motor is used to describe the low horsepower BLDC motors with integrated drives useful to HVAC applications. They have been separated from BLDC motors because designers do not want to confuse buyers, as the term “DC” usually refers to mechanically-commutated machines. ECMs are virtually identical to BLDC machines, except for the fact that they usually come with their own integrated microprocessor circuit that allows for speed and torque control. They are great for applications that do not have the budget for motor controllers such as variable frequency drives (VFDs) and provide all the efficiency, noise reduction, and controllability of the BLDC machine. These motors are quickly outpacing other common motors, as they are now dropping in price and can be used in hundreds of different applications. To learn more, read our article all about ECM motors.

Why are EC motors used in air handlers?

EC motors are quickly becoming the new industry standard for air handler fans and other applications because of their amazing efficiency. PSC motors dissipate heat due to their capacitors which reduces their overall efficiency to around 50%.

How does a three phase motor work?

Usually, three-phase motors use three separate currents to generate a rotating magnetic field (RMF) in their stator , which will electromagnetically induce current (and therefore magnetism) in the rotor. The torque produced from the RMF on the rotor is highest when it is at rest, so three-phase motors are inherently “self-starting”.

Is an EC motor more efficient than a PSC motor?

Since EC motors utilize micro-processing technology, they are naturally more advanced than the older PSC motor. Their design is structurally complex, as their stator contains many windings and requires accurate timing via some control module to pull the rotor around. However, this complexity is a double-edged sword; while allowing for more efficiency, less noise, and better working characteristics than PSC motors, maintenance on an EC motor takes longer and is more expensive.

Is a three phase motor self starting?

The torque produced from the RMF on the rotor is highest when it is at rest, so three-phase motors are inherently “self-starting”. Single-phase motors, while simpler in terms of their power source, cannot self-start like three-phase designs because a single phase cannot produce a true RMF.

Can a PSC motor be used in a fan?

PSC motors, therefore, cannot respond as fast (or sometimes at all) to dynamic situations as can ECMs. PSC motors produce a lot of vibrations and noise, which can deter some from using the design; however, since they are often used in fans, this is not a huge downside.

Is the PSC motor good?

The reliability of both motors is good, but the EC motor still wins in this category. The capacitors in PSC motors are prone to burning out after prolonged use which negatively affects their working lifespan. EC motors are brushless and are simple in design, lending them to long term use.