Fractionating columns help to separate the mixture by allowing the mixed vapours to cool, condense, and vaporize again in accordance with Raoult's law. With each condensation -vapourization cycle, the vapors are enriched in a certain component. A larger surface area allows more cycles, improving separation.

What is a fractionating column?

Jump to navigation Jump to search. A fractionating column is an essential item used in distillation of liquid mixtures so as to separate the mixture into its component parts, or fractions, based on the differences in volatilities.

What is a fractional distillation column?

Fractional distillation is one of the unit operations of chemical engineering. Fractionating columns are widely used in the chemical process industries where large quantities of liquids have to be distilled.

Why does a fractionating column need more plates than a tray?

The efficiency of a tray or plate is typically lower than that of a theoretical 100% efficient equilibrium stage. Hence, a fractionating column almost always needs more actual, physical plates than the required number of theoretical vapor–liquid equilibrium stages.

What is reflux in industrial fractionating columns?

Industrial fractionating columns use external reflux to achieve better separation of products. Reflux refers to the portion of the condensed overhead liquid product that returns to the upper part of the fractionating column as shown in Figure 3.

How does fractional distillation work step by step?

Fractional distillation heated crude oil enters a tall fractionating column , which is hot at the bottom and gets cooler towards the top. vapours from the oil rise through the column. vapours condense when they become cool enough. liquids are led out of the column at different heights.

How does a fractionation tower work?

The tower acts as a heat exchanger, removing heat from the vapors as they rise. Some of them condense back into liquids and fall back down the column. The temperature gradually decreases as you go up the column.

How does a fractionating column work a level chemistry?

A fractionating column boils the mixture of hydrocarbons. The temperature decreases as you go up the levels of the column. The hydrocarbon with the lowest boiling point condenses lowest down and runs off. The hydrocarbon with the highest boiling point condenses closest to the top and runs out.

How does fractional column help in performing fractional distillation?

The fractionating column allows the vapours of the mixture to cool, condense and evaporate again by Raoult's law. The fractionating column allows the continuous condensation and vaporization of the mixture and enriches the separation of a component.

How fractionation is done?

Fractionation is a separation process in which a certain quantity of a mixture (of gases, solids, liquids, enzymes, or isotopes, or a suspension) is divided during a phase transition, into a number of smaller quantities (fractions) in which the composition varies according to a gradient.

How does an oil cracking tower work?

Refineries use large “cracking towers” as a part of their operations. These towers can be approximately 100 feet tall and are filled with a catalyst that assists the conversion of oil into lighter fuels. Periodically, the catalyst must be removed, the tower cleaned out, and new catalyst added.

How does a fractionating column separate liquids?

Fractionating columns help to separate the mixture by allowing the mixed vapors to cool, condense, and vaporize again in accordance with Raoult's law. With each condensation-vaporization cycle, the vapors are enriched in a certain component. A larger surface area allows more cycles, improving separation.

How does the fractionating column separate the crude oil mixture?

A tall fractionating column is fitted above the mixture, with several condensers coming off at different heights. The column is hot at the bottom and cool at the top. Substances with high boiling points condense at the bottom and substances with lower boiling points condense on the way to the top.

What are the 3 steps of fractional distillation?

Fractional Distillation ProcessEvaporation. Crude oil is heated until it evaporates. Crude oil vapour is put into a fractionating column at the bottom and rises upwards.Condensation. The temperature is highest at the bottom of the column. ... Collection. The fractions are collected.

What happens to the vapor in a fractionating column?

What happens to the vapor in a fractionating column? The vapor repeatedly condenses on and evaporates from the beads, allowing more volatile liquids to reach the top of the column faster.

How does fractional distillation work a level chemistry?

Fractional distillation works because the different liquids have different boiling points. When the mixture is heated: vapours rise through a column which is hot at the bottom, and cooler at the top. vapours condense when they reach a part of the column that is below the temperature of their boiling point.

What does a fractionating column do BBC Bitesize?

A tall fractionating column is fitted above the mixture, with several condensers coming off at different heights. The column is hot at the bottom and cool at the top. Substances with high boiling points condense at the bottom and substances with lower boiling points condense on the way to the top.

What is the principle of fractional distillation in chemistry?

Fractional distillation's basic process or principle is that different liquids evaporate and boil at various different temperatures. Therefore in fractional distillation during the heating of the mixture, the substance which has a lower boiling point, will start to boil first and hence convert into vapours.

What is in a fractionating column quizlet?

What is in a fractionating column? Glass or plastic beads. equivalent to one vaporization-condensation cycle, or one simple distillation. You just studied 5 terms!

What happens when the boiling point of a fractionating column is low?

Here, components with the highest boiling point will condense in the lower part of the column while substances with a low boiling point will condense at the top.

What is Fractional Distillation?

Fractional distillation is a type of distillation which involves the separation of miscible liquids. The process involves repeated distillations and condensations and the mixture is usually separated into component parts. The separation happens when the mixture is heated at a certain temperature where fractions of the mixture start to vaporize.

What is a distillation column?

Usually, huge vertical cylindrical columns are known as “distillation columns” or “distillation or fractionation towers” are used. These industrial towers use reflux which ensures complete separation of the mixtures.

Overview

Laboratory fractionating columns

A laboratory fractionating column is a piece of glassware used to separate vaporized mixtures of liquid compounds with close volatility. Most commonly used is either a Vigreux column or a straight column packed with glass beads or metal pieces such as Raschig rings. Fractionating columns help to separate the mixture by allowing the mixed vapors to cool, condense, and vaporize again in …

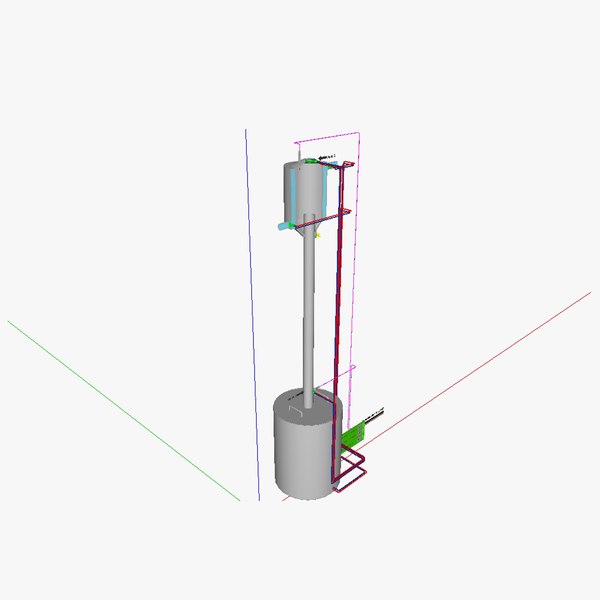

Industrial fractionating columns

Fractional distillation is one of the unit operations of chemical engineering. Fractionating columns are widely used in chemical process industries where large quantities of liquids have to be distilled. Such industries are petroleum processing, petrochemical production, natural gas processing, coal tar processing, brewing, liquefied air separation, and hydrocarbon solvents production. Fractiona…

See also

• Azeotropic distillation

• Batch distillation

• Continuous distillation

• Extractive distillation

• Laboratory glassware

External links

• Use of distillation columns in Oil & Gas

• More drawings of glassware including Vigreux columns

• Distillation Theory by Ivar J. Halvorsen and Sigurd Skogestad, Norwegian University of Science and Technology, Norway