| Specifications | |

|---|---|

| Pallet Rack Height | 120 in |

| Pallet Rack Depth | 42 in |

| Pallet Rack Width | 108 in |

| Weight Capacity per Shelf | 4050 lb |

How to get your pallet rack upright capacity right?

That said, here’s how to get started:

- Start with the heaviest possible load you’d be storing in a given pallet position. For this example, we’ll say 2,500#.

- Multiply this number by the number of pallet positions per beam level. ...

- In most situations, you’ll only need steps 1 and 2. In a select few, you may also need to factor in upright frame capacity. ...

How to select pallet rack?

#2 Select Your Uprights – Height and Width

- Figure how tall your building’s ceiling is, or how high you want to go with your loads. ...

- The depth of your pallet rack upright is based on the depth of your pallet. ...

- You’ll need to determine what capacity upright you need by adding up the maximum weight for each pallet and multiplying it by the number of pallets in a pallet rack ...

What is the max weight load for a wooden pallet?

Pallet Type Edge Rackable Load Capacity Dynamic Load Capacity; Wood Stringer Pallet: 2,500 lbs: 2,200 to 2,500 lbs: Wood Block Pallet: 2,800 lbs: 4,600 lbs: Plastic Pallet: 2,800 lbs: 5,000 lbs

How do I Sell pallet racking?

Sell your used or surplus pallet racking & mezzanine floors. Get an immediate valuation of your used industrial racking by sending a message on WhatsApp calling us on 0800 1088883 Emailing [email protected] or via our form below. Surplus Pallet Racking. Give us a call with details of your racking, send us some photos via WhatsApp ...

How much does a pallet rack upright weight?

140.2 lbsAdditional informationWeight140.2 lbsDimensions240 × 3 × 42 inWarehouseMinnesota, Pennsylvania

How big is a pallet rack?

What are standard sizes for pallet rack uprights? Standard pallet rack depths are 36”, 42”, and 48”. Upright heights are generally standard as long as they are in even foot increments. The most common upright heights are 8', 10', 12', 16' & 20'.

How do you calculate rack load?

If you need to know how to calculate pallet rack load capacity or upright frame capacity, you need to first consider the estimated maximum load weight for each beam level. Then you multiply it by the number of levels in the racking section. The result is the required pallet rack upright capacity.

How strong are pallet rack beams?

Pallet Racking Beam Capacity A pair of 2.5” 16ga x 96” beams, for example, can hold up to 2,212 lbs., whereas, a pair of 4 1/2” 14ga x 96” beams can hold up to 6,944 lbs.

How much weight can pallet racks hold?

A typical pallet rack compartment or cell can hold two pallets, each weighing 2,000 lbs, on a pair of beams, for a total of 4,000 lbs.

What is standard racking?

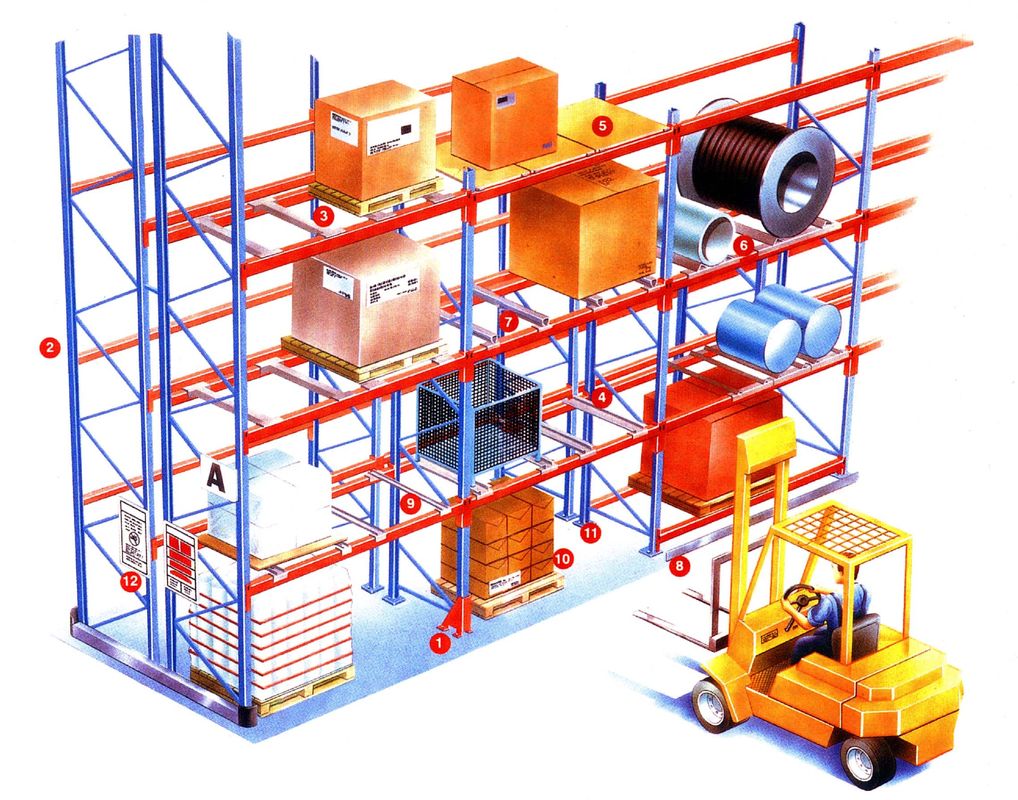

Standard Pallet racking is a system of warehouse storage. It uses racks to enable pallets, on which goods and materials are stored, to be stacked vertically and horizontally for efficient use of space and full selectivity.

What is OSHA requirements for warehouse racking?

Although OSHA has no specific warehouse racking safety guidelines, they are covered by the general clause of the Occupational Safety Health Act that created the agency, which states simply that each employer shall provide a workplace that is free from recognized hazards.

How strong is pallet racking?

Depending on the size and density of the pallet rack, standard duty pallet racking typically holds from 15,000-18,000 lbs. For heavy duty racking, typically the weight capacity can range from 25,000 to 30,000 lbs.

How do you measure a pallet rack?

Measure across the outside edge of the upright. This will give you the depth of the upright. Usually, the depth ranges from 3 to 4 feet but, as with cross beams, custom pallet racks may be a different size. Measure the outside face of the vertical column and then measure the inside face of the column.

What is used pallet racking?

Pallet racks are used throughout industry and distribution facilities for bulk storage of items. Generally, the items stored are boxed goods stacked on pallets which are placed on the rack. The pallets are accessed by some type of mechanized lifting and retrieval device.

How do you calculate metal shelf load capacity?

Count the number of brackets used to support the shelf that you're rating. Multiply the number of brackets by the safe load of the bracket to determine the safe load capacity for the entire shelf. For a shelf that has three brackets rated for 250 lbs.

What are pallet rack beams?

A pallet rack beam, sometimes called a cross beam, connects to pallet rack frames to form the shelf level of a pallet rack system. These heavy-duty steel rails have a standard 1 5/8” step, which makes them compatible with wire decking, pallet supports or wood supports.

What is standard pallet size?

48” x 40”When we talk about the standard pallet size in North America, we're generally talking about the 48” x 40” wooden pallet. The 48 x 40 wooden pallet was established as the standard-sized pallet by the Consumer Brand Association (CBA), but it took some time to get there.

How wide are standard racking?

The most common standard rack width is 19 inches. Most rack-mounted equipment, especially servers, have a mounting width of 19 inches measured from one hole to another. Thus, the rack must be 19 inches across in order to fit this technology. Many racks today come with a exterior width of 24 inches.

How tall is pallet racking?

The most common upright depth (front-to-back) is 42”, while 36” and 48” deep uprights are also standard sizes. Uprights come in a much greater variety of heights. The common height range is 8' to 24'. The vast majority of uprights are 3” wide (across the front face of the post).

What are pallet dimensions?

48" X 40"What is a standard pallet size? The standard pallet size is 48" X 40" with each deck board being 3 ½" wide 5/16" thick. There are other pallet sizes that are standard across different industries but the above described GMA pallet is the most common and makes up more than 30% of all pallets used in the USA.

How Much Weight Can a Pallet Rack Hold?

Your pallet racking system must be sufficient to support the maximum weight you’ll possibly put on it. It’s wise to extend your manufacturer’s rated capacity to one step beyond what you’ll conceivably store. Calculating rack capacity is clearly a case of being safe than sorry.

What is pallet rack?

Pallet racks, or pallet racking systems, form the interior skeleton of most American warehouses. Racks make your pallet storage and retrieval simple and safe. That’s provided you’ve determined your pallet rack weight capacity and never exceed it.

What is racking system braces?

Racking system braces: Braces give pallet rack uprights torsional rigidity. This structural insurance prevents loaded upright components from twisting and integrity loss that results in rack failure. Without diagonal and horizontal braces, a rack assembly would be highly prone to buckling and a disastrous collapse.

What is a racking beam?

Racking system beams: Beams are the rack’s horizontal members that connect the uprights at various intervals. Distances between beams depend on loaded pallets’ expected height. Beams are also called cross-members, and they’re under both compression and tension forces as they pick up pallet weight and laterally transfer it to the uprights.

How to determine rack capacity?

In theory, figuring out how to determine rack capacity is fairly straightforward. You calculate the maximum weight of your combined pallet loads, then size your decks, beams, uprights, bracing and baseplates so they’re above and beyond that anticipated limit. Sizing rack components always aims for a level beyond any practical possibility that you’ll ever exceed your rack system’s known weight capacity.

How to determine pallet rack load limits?

Engineers and designers determine pallet racking load limits by taking stock of the structural load-bearing capacity of each rack system component. Combined, each component contributes to your rack’s integrity, and this is how they determine rack capacity.

How many weight classifications does an upright have?

Uprights absorb and transfer two weight classifications. Each weight type adds to the overall capacity your uprights need to support. In engineering terms, these are the two loads happening in your pallet rack system that move along your uprights.

Why do pallet racks change capacity?

Remember that the capacity of pallet racks can change over time. This can be caused by damage done to the uprights as well as to the pallet shelves themselves. Shelves that have been bent from too much weight can be weakened and not able to hold as much weight in the future. The age of the racks can impact their maximum capacity, as well. That’s why it’s important to have your racking inspected regularly and address any damage done right away. Professional inspectors and repairmen will be able to help you adjust your maximum capacity and inform you when racking needs to be replaced.

Is pallet rack one size fits all?

Pallet racks certainly aren’t one-size-fits-all. There are a lot of different pallet racking options out there, and each one is going to have different weight limits. Some of the factors that will determine storage capacity include:

Why is pallet rack capacity important?

It is important to ensure that both the racking frames and beams are designed to hold the required weight to avoid a possible collapse. When calculating the pallet rack capacity, there are several elements to take into consideration.

How much weight can a rack beam support?

For example, if you have two pallet loads of 1500 lbs. each, your rack beam capacity will need to be at least 3000 lbs. per pair of beams to support the load. Beam capacities can vary by manufacturer.

How much weight is needed for a 16' frame?

For example, if you have a 16’ tall frame, with (4) beam levels rated at 3,000 lbs. each, the total frame capacity need will be 12,000 lbs. The spacing of the beams may impact the frame design. If the maximum distance between levels is 8’, then the gauge of the frame will most likely be increased as opposed to a configuration where the maximum distance is 4’.

What is the first element to consider when constructing a pallet?

The first element to consider is the load, or the pallet size, dimensions, contents and type of pallet. How much weight will be placed on each level? How tall and deep will each pallet be? Height, weight and depth are important factors in making sure the beams are being uniformly loaded. The beams must be able to support the weight.

What factors affect the capacity of a frame?

There are several factors that impact the capacity ratings for both frames and beams. The strength of the steel used to fabricate the racking components has a significant impact. Steel thickness, or gauge, will also impact the capacity of these components. Also, each manufacturer will have different section properties that affect their rated ...

How much weight can a GMA pallet hold?

GMA pallets can hold up to 4,600 lbs., that’s nearly as much as an average SUV! The weight can change depending upon how many deck boards it has and how thick those boards are. Coming in both block pallet and stringer pallet varieties, this pallet is versatile and multi-purpose.

How much does a GMA pallet weigh?

Measuring 48 inches long by 40 inches wide, this pallet is used in a variety of industries, including produce and grocery shipping. These pallets can weigh anywhere from 33-48 lbs. and is relatively lightweight for how much weight it can carry. GMA pallets can hold up to 4,600 lbs., that’s nearly as much as an average SUV! The weight can change depending upon how many deck boards it has and how thick those boards are. Coming in both block pallet and stringer pallet varieties, this pallet is versatile and multi-purpose.

What is pallet consultant?

Pallet Consultants is a national pallet manufacturer offering a wide variety of pallet products including recycled pallets, specialty pallets, custom-sized pallets, new pallets and more . We provide quality pallets and pallet retrieval services to industries around the country. Start a conversation with our expert team to see how we can meet the pallet needs of your operation.

Do pallets move the world?

Pallets move the world but have weight of their own. Read to find out the load performance of common wooden pallets and what they weigh themselves. There are many different types of pallets and pallet sizes. Each has a different weight and load bearing capacity depending on their construction material and pallet dimensions.

Can pallet weight change?

Remember however that pallet weight can change depending on how they’re constructed. Block pallets and stringer pallets weigh different amounts, and deckboards in mixed numbers or thicknesses will also alter weight. Pallet Consultants is a national pallet manufacturer offering a wide variety of pallet products including recycled pallets, ...

How much impact does a pallet have?

Capacities include 12.5% impact for two pallets side by side. For a three-pallet-wide shelf, the values should be multiplied by 0.95. For one pallet per shelf, the values should be multiplied by 0.90.

How much weight is required for a frame bracing?

Any application where the frame load exceeds 31,000 pounds. These situations may need heavier than standard frame bracing.

What is table value?

Any condition which creates uncertainty as to the proper use of these tables. Table values are column capacities based on gravity loading only. The table values are based on the assumption that the rack bracing is adequate (none of the above conditions apply), and all other aspects of the rack have been properly designed. All values are for undamaged racks.

What is the deflection limit for a beam?

The deflection limit for all beams is the length divided by 180. Roll-formed beams that are longer than 150” require lateral ties. Structural beams that are longer than 108″ can require lateral ties. Values in the table are for the beam bending only.

Pallet Rack

Pallet Rack Capacity varies according to manufacturer. Call Us for assistance or clarification. Capacity Chart for Interlake Mecalux Pallet Rack:

Cantilever rack

Cantilever Rack Capacity varies according to manufacturer. Call Us for assistance or clarification Capacity of "Rhino Rack" New Cantilever Rack

Make Sure All Components Have the Same Weight Limit

A rack consists of many parts that form a whole, and these parts come with different specifications and limits. Whether you’re ordering uprights, beams, decks, or braces, you must make sure they all have the same load capacity.

Determining the Capacity

The method on how to determine pallet rack capacity can be simple—it’s the construction that can be the difficult part. The first step is to know the weight of the heaviest load you’ll be storing. In this situation, it’s always good to overestimate a little than to underestimate.

What does the capacity rating on pallet racks mean?

This number represents the weight that a pair of beams can safely hold – not the strength of a single beam. Even if you’re quoted a single pallet rack beam, the capacity rating shown on the quote applies to a pair.

What is UDL in pallet rack?

A UDL is a load that is evenly-spread over the surface by which it’s supported. This is in contrast to, for example, a point load, in which the weight is concentrated in a smaller surface area. Because weight distribution affects capacity, pallet rack beam and wire deck capacities are usually rated for uniformly-distributed loads. ...

How much deflection is needed for a 96" beam?

To figure out what the allowable deflection is for your beams, take the beam’s length and divide it by 180. For a 96” beam, that comes to .53” of allowable deflection.

What is uniformly distributed load?

Uniformly-distributed loads, or UDLs, are loads that are spread evenly across the supporting surface.

Is beam capacity easier than upright frame capacity?

Beam capacities may be easier to understand than upright frame capacities, but it’s still helpful to take a closer look at how beam capacities work. Doing so will help to fully understand the underlying variables. Once you’re familiar with the basics of pallet rack beams and their capacities, you can apply this knowledge in future applications.