What is the difference between edge grain and end grain cutting boards?

Edge grain cutting boards are recognized for their durability and lower price, but they tend to dull your knives faster than end grain cutting boards. After prolonged usage, the wood cutting board will have cut marks, damaging the aesthetics of the board. However, this can be prevented by applying beeswax or mineral oil on a regular basis.

What are the different types of wood cutting boards?

There are two distinct models of wood cutting boards and those are the end grain cutting boards and edge grain cutting boards. The end grain cutting board is made from end pieces of wood. It usually comes in a checkerboard pattern, which is the main characteristic you’ll need to be able to recognize that it is indeed an end grain cutting board.

What type of cutting board is best for knives?

While these types of wood cutting board are a bit more expensive, some people deem it worthy, as it is better for the knives. End grain cutting boards have a “self-healing” factor, as the fibers close up after they have been cut by the knife. The edge grain cutting board is made from parallel pieces of wood that have been fused together.

How to take care of your wood cutting board?

After prolonged usage, the wood cutting board will have cut marks, damaging the aesthetics of the board. However, this can be prevented by applying beeswax or mineral oil on a regular basis.

Is end grain or edge grain better for cutting board?

Edge grain tops, while very good for chopping and food prep, will show signs of knife marks and wear over time quicker than end grain tops. The very durable wood surface acts like a wall and will also dull knives quicker than end grain tops.

Is end grain best for cutting board?

End Grain: End grain cutting boards are the most durable, have the ability to hide knife marks, and will not dull knives as quickly as plastic or glass cutting boards. But, end grain boards tend to come with a higher price tag as end grain boards require more steps to produce.

Why is an end grain better than a side grain cutting board?

On Long Grain, it's like the brush is lying left to right, and you're chopping those fibers in half. On End Grain, you're actually cutting between the wood fibers, keeping the board sharper longer and making it easier to clean and thus more sanitary.

Why do people like end grain cutting boards?

An end-grain cutting board has the benefits of being both attractive and easy on your knives. This cutting board construction creates a distinctive looking checkerboard pattern. An end-grain board also has a very fibrous cutting surface, so a knife's edge is likely to sink into the wood fibers while you are cutting.

What type of wood cutting board is best?

Maple. Maple — specifically, sugar maple or hard maple — is the most popular choice for cutting boards. Maple is a hard, closed-grain wood. This means that it's durable, able to resist bacteria, and features just the right amount of hardness.

What makes a cutting board expensive?

Why are some cutting board so expensive? Its the wood, maple wood are a lot more expensive than you think. Go to a home depot and try to buy a block of maple, it can easily cost ten dollar or more for a small strip. The boards arent even made of a single piece of maple, they are all glued together.

How long will an end grain cutting board last?

What Is the Average Lifespan of a Wood Board? When properly taken care of, the premium wooden cutting board can last between five and ten years. One of the main reasons why boards are replaced is because they become worn, warped, or miscolored. You can circumvent most of these with regular maintenance.

Is butcher block always end grain?

In our opinion, all butcher blocks should be made with end grain as opposed to edge grain. End grain means that the end of the wood fibers are exposed, whereas edge grain means that the grain is running along the outside.

How thick should end grain cutting board be?

How thick should end grain cutting board be? Keep end grain cutting board thickness between 2" and 2 ½" inches. Making the cutting board thinner than this might cause it to warp easily and crack. If it is made thicker than 2 ½ inches, the cutting board will become too heavy for everyday use and for moving it around.

Is Purple Heart a toxic wood?

As a finished project in your kitchen, purple heart wood is an excellent choice for a cutting board. The wood is food safe and safe in general, and once assembled and finished, will cause no allergies or adverse reactions.

What do you use to seal end grain?

Simply pre-seal the end grain. A light coat of a 2lb cut of shellac will work great for this. You can also use a solution of glue size.

What's the difference between end grain and edge grain?

It's usually made out of maple and walnut, although there are some that are made out of a different kind of wood such as pine and bamboo. Edge grain cutting boards are recognized for their durability and lower price, but they tend to dull your knives faster than end grain cutting boards.

How long does an end grain cutting board last?

What Is the Average Lifespan of a Wood Board? When properly taken care of, the premium wooden cutting board can last between five and ten years. One of the main reasons why boards are replaced is because they become worn, warped, or miscolored. You can circumvent most of these with regular maintenance.

Is butcher block always end grain?

In our opinion, all butcher blocks should be made with end grain as opposed to edge grain. End grain means that the end of the wood fibers are exposed, whereas edge grain means that the grain is running along the outside.

How thick should an end grain cutting board be?

Wessel says that for an end-grain cutting board he advocates for at least 2 inches of thickness.

What's the difference between end grain and edge grain?

It's usually made out of maple and walnut, although there are some that are made out of a different kind of wood such as pine and bamboo. Edge grain cutting boards are recognized for their durability and lower price, but they tend to dull your knives faster than end grain cutting boards.

Is end grain better for cutting boards?

End grain cutting boards are often thought to be the best type of cutting board. This is because they are made from the end of the wood, which is t...

Is end grain or edge grain better for a cutting board?

End grain cutting boards are often touted as being the best type of cutting board to use. But are they really better than other types of cutting bo...

Why should you never cut end grain?

End grain cutting boards are often thought to be better than edge grain or face grain cutting boards, but there are pros and cons to each type of b...

Are end grain cutting boards sanitary?

When it comes to cutting boards, there are two main types: end grain and edge grain. So, which one is better? End grain cutting boards are made fro...

What is an end grain cutting board?

The end grain cutting board is made from end pieces of wood. It usually comes in a checkerboard pattern, which is the main characteristic you’ll need to be able to recognize that it is indeed an end grain cutting board. While these types of wood cutting board are a bit more expensive, some people deem it worthy, as it is better for the knives. End grain cutting boards have a “self-healing” factor, as the fibers close up after they have been cut by the knife.

What is edge grain?

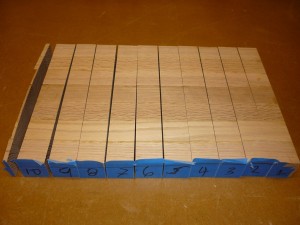

Edge Grain. The edge grain cutting board is made from parallel pieces of wood that have been fused together. This is the most common wood cutting board, which looks exactly like you imagined a wood cutting board would look. It’s usually made out of maple and walnut, although there are some that are made out of a different kind ...

Do end grain cutting boards have self healing?

You should consider the fact that end grain cutting boards have that “self-healing” factor in your decision-making process, as paying a bit more for that type of cutting board can yield better results in the long run .

Is a wood cutting board better for knives?

While these types of wood cutting board are a bit more expensive, some people deem it worthy, as it is better for the knives. End grain cutting boards have a “self-healing” factor, as the fibers close up after they have been cut by the knife.

Is a wood cutting board the same as a wood cutting board?

While many people consider all wood cutting boards to be the same, that’s not exactly the case, as there are many differences that affect not just how the wood cutting board looks, but also how durable they are. There are two distinct models of wood cutting boards and those are the end grain cutting boards and edge grain cutting boards.

Why are end grain cutting boards good for carving?

Due to the structure of wood fibers in end grain cutting boards, they have a sort of self-healing attribute to them. As the knife’s edge makes contact with the surface of the board, it goes in between the fibers, and they close right back in after you lift the blade. This characteristic makes them an excellent cutting board for butchering and carving.

What is end grain wood?

The end grain is the wood that’s cut along the direction of the tree’s growth. This is unique to end grain and different from face grain and edge grain. The wood fibers are exposed with a checkerboard pattern with end grain cutting boards, showing the growth rings. As the wood fibers stand vertically, they can take a beating quite well and make the most durable cutting boards.

What is face grain?

The face grain is the piece of wood with one side wider than the other. It’s where you see most of the grain of a tree and with different colors and patterns, sort of like the face of the wood, hence the name. This part of the wood is also softer and will absorb moisture faster than edge grain cutting boards. When taken as a cutting board, the wood fibers run horizontally, added with being on the softer side, these make face grain cutting boards susceptible to showing knife marks.

How do knife edges go through wood?

The knife’s edges go through the wood fibers when in contact with the surface, making edge grain cutting boards dull the blade faster.

Why are cutting boards so expensive?

As more pieces of wood are required to be put together to form a cutting board, they are generally more expensive.

How much does a cutting board cost?

You can find many sizable ones on the market for as little as $10.

Which cutting board has the most scratches?

Face grain cutting boards show the most amount of scratches and knife marks.

How much more expensive is an end grain cutting board?

An end grain cutting board is 4 to 15 times more costly than an edge grain block. They are usually thick, durable, and warp-resistant.

What is end grain wood?

The terms end grain wood and edge grain wood actually refers to the part where the wood is used to design the chopping board. Edge grain cutting boards are those boards where the edge grain is up. While end grain cutting boards are those at which the grain is perpendicular to the chopping surface. And each pattern has a different level ...

What is a butcher block made of?

Almost all the butcher blocks you can find on the market are made of end grain wood. The drawback about end grain cutting boards or butcher blocks is that they are heavyweight and absorb moisture easily. If you have an end grain butcher block or an end grain wooden board, make sure you always season and condition them.

What is face grain board?

Face grain term refers to the upper and most obvious part of the wood. A face grain board is usually made by using glue on the edges of narrow wood boards, and they are typically eye-catching and elegant. A face grain cutting board isn’t as durable as an edge grain cutting board or end grain wood board.

Why do you need to know what cutting boards to use?

First, to save your hard-earned money and stop spending it on useless cutting boards that will only ruin your precious knife set. And second to make sure you are protecting your food from bacteria ...

Do dents on end grain boards fade?

you need to know that while cutting or chopping your food, some tiny dents form on the surface of end grain boards. but later they will fade away, as the open wood-cell structure is self-healing. ( you may also like Forged Knives vs. Stamped Knives: What’s the Difference?)

Can you dull blades over time?

Dulling your blades over time is a problem you will face when dealing with an edge grain board.

What is wood made of?

Wood is made up of many fibers that run lengthwise. Think of wood for a minute as a paint brush. There is the very end of the paint brush (end grain), the wide flat side of the brush (face grain – also long grain) and the edge of the paint brush (edge grain – also long grain).

Do face grain cutting boards show knife marks?

Face grain cutting boards might show more knife marks than end grains. End grains are able to heal easier, especially with regular maintenance (See Cutting Board Care Tips). With any cutting board, you can always use one side and display the other. 😊