What is JIT practice?

What is JIT management?

What is the role of front line employees in JIT?

What is the enemy of JIT?

What is push system in manufacturing?

How to pursue JIT goals?

What is just in time manufacturing?

See 4 more

About this website

Is JIT pull or push?

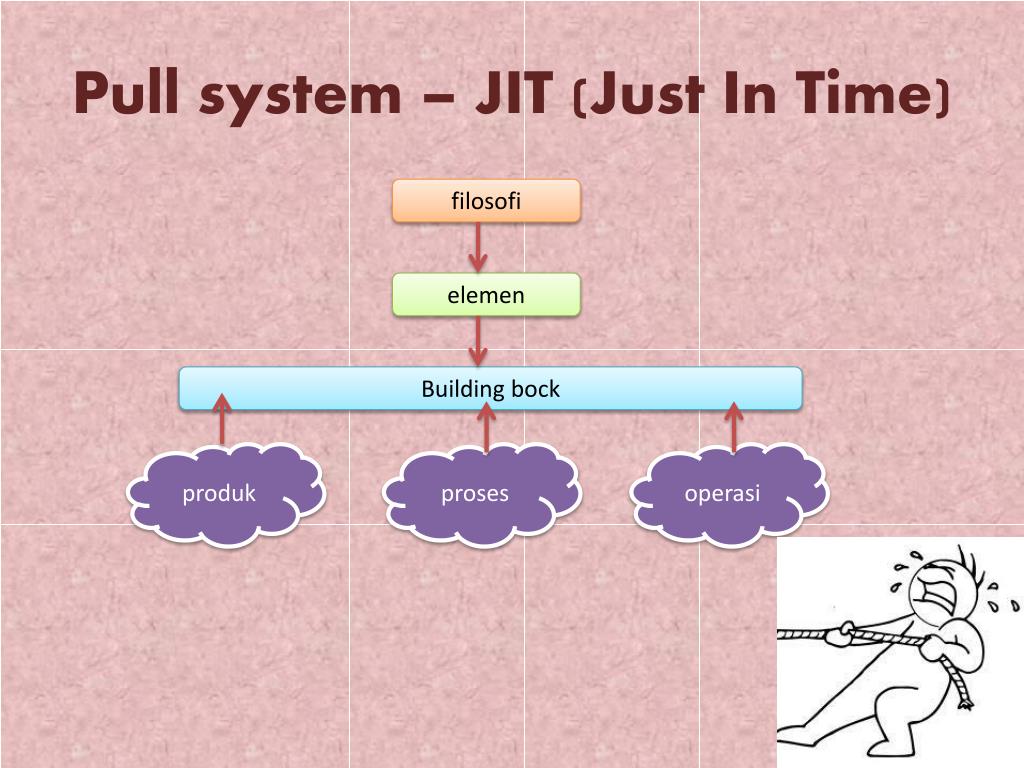

In contrast to the push system, JIT espouses a “demand-pull” system that operates on the rule that work should flow to a work center only if that work center needs more work.

Is JIT a pull system?

When the just-in-time concept is applied to an industrial material management system, it is called a pull system, which means that the amount and time of material flow are determined by the rate and time of the actual stock consumption.

What kind of system is JIT?

Just-in-time, or JIT, is an inventory management method in which goods are received from suppliers only as they are needed. The main objective of this method is to reduce inventory holding costs and increase inventory turnover.

Is Kanban a push or pull system?

Kanban is a pull-based process, meaning, team members pull work to themselves when they have the bandwidth – work is not pushed or assigned by someone else- and god! that makes a significant difference.

What is an example of a pull system?

A great example of a pull system is just-in-time manufacturing. The core idea of JIT is to schedule the process so that materials would reach the facility exactly when production is scheduled to start, and production is scheduled so that it would be finished just as the goods should be dispatched to the customer.

Is Kanban a pull system?

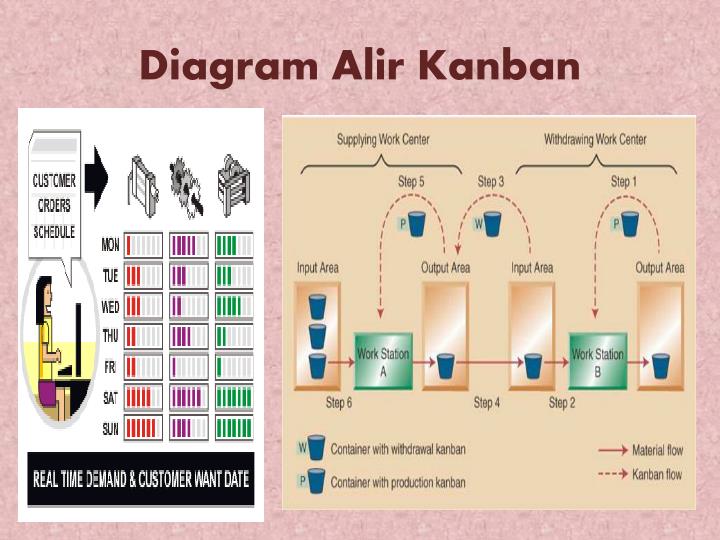

Kanban pull systems are an essential Lean implementation tool. The Kanban pull system is a way of synchronizing the material and information flow of disconnected processes to enable Just in Time production. A Pull System itself is a method for controlling the flow of resources through a system.

Is JIT Lean or Agile?

JIT manufacturing is very similar to Lean manufacturing, and the terms are often used synonymously.

What is JIT and its types?

Just-In-Time compiler(JIT) is a part of Common Language Runtime (CLR) in . NET which is responsible for managing the execution of . NET programs regardless of any . NET programming language. A language-specific compiler converts the source code to the intermediate language.

What is difference between JIT and kanban?

Summary. 1) JIT is an inventory management strategy; one of its elements is Kanban. 2) Kanban is a pull or demand type of scheduling system, usually in the form of cards, bins, palettes, or boxes. 3) JIT uses Kanban as a means to prevent inventory-related costs.

Is ERP a push system?

In inventory, push systems are those where the business orders products with the aim of selling. In other words, the business pushes its existing stock on the consumer. Push systems are like Enterprise Resource Planning (ERP) or Material Resource Planning (MRP) systems.

Is Amazon push or pull?

Amazon's warehouses are strategically placed, moving closer and closer to main metropolitan areas and city centers. As a result, it uses a pure push strategy for the products it stores in its warehouses based on the downstream demand forecast.

Is Mcdonalds a push or pull system?

The basic difference between pull and push is that a pull system initiates production as a reaction to present demand, while push initiates production in anticipation of future demand. Thus a fast food restaurant like McDonald's runs on a pull system, while a catering service operates a push system.

What is a pull system in inventory?

A pull inventory system prioritizes current demand. The supplier orders or manufactures goods in the quantity and timeframe needed, based on existing customer sales orders. In contrast, the push inventory system uses demand forecasting.

What are the three basic types of pull systems?

There are three basic types of pull production systems:Supermarket Pull System. The most basic and widespread type, also known as a fill-up or replenishment or a-type pull system. ... Sequential Pull System. ... Mixed Supermarket and Sequential Pull System. ... See: Just-in-Time Production; Overproduction.Compare: Push Production.

What is a pull based system?

What Is a Pull System? A pull system is a lean manufacturing strategy used to reduce waste in the production process. In this type of system, components used in the manufacturing process are only replaced once they have been consumed so companies only make enough products to meet customer demand.

What is pull production system?

In pull production systems, the product is manufactured in response to a specific demand. The order is used to trigger a pulling action from the end of the production line (e.g., from the last workstation). If that workstation cannot fill the order, it requests additional units from the preceding workstation.

The Four Key Elements of Just In Time System | JIT System

For example, all of the granulation machines are ordinarily in one location and all of the compression machines in another. As a result, work-in-process must move lengthy distances between operations.

Just-In-Time (JIT) Method: Definition and Objectives - Your Article Library

ADVERTISEMENTS: Just-In-Time (JIT) Method: Definition and Objectives (With Example)! Definition of Just-In-Time (JIT) Method: Just-In-Time (JIT) is a purchasing and inventory control method in which materials are obtained just-in-time for production to provide finished goods just-in-time for sale. JIT is a demand-pull system. Demand for customer output (not plans for using input resources ...

What is JIT practice?

The successful practice of JIT means having the right quantities of the right products in the right place at the right time. Driving down setup times enables the company to produce the product mix and quantities that are demanded in the present time period.

What is JIT management?

The JIT philosophy has evolved from a manufacturing-focused management approach to a set of management principles that can be applied to any organization . “Lean operations” is a term that is replacing JIT, especially in service environments. “Lean operations” captures the true essence and power of how a culture built around continuous improvement and the pursuit of value-added activities leads directly to competitive advantage in the marketplace. Lean operations is a management philosophy for any organization to achieve higher quality, increased productivity, improved delivery speed, greater responsiveness to changing markets, and increased customer satisfaction.

What is the role of front line employees in JIT?

Front-line employees play a critical role in successful JIT practice. They work in partnership with management and each other in the continuous pursuit of excellence. There are several ways in which front-line employees contribute to JIT success:

What is the enemy of JIT?

The enemy of JIT is uncertainty. A JIT environment thrives on predictability in customer demand, production processes, suppliers, and workers. Of course, uncertainty cannot be completely eliminated in most organizational environments.

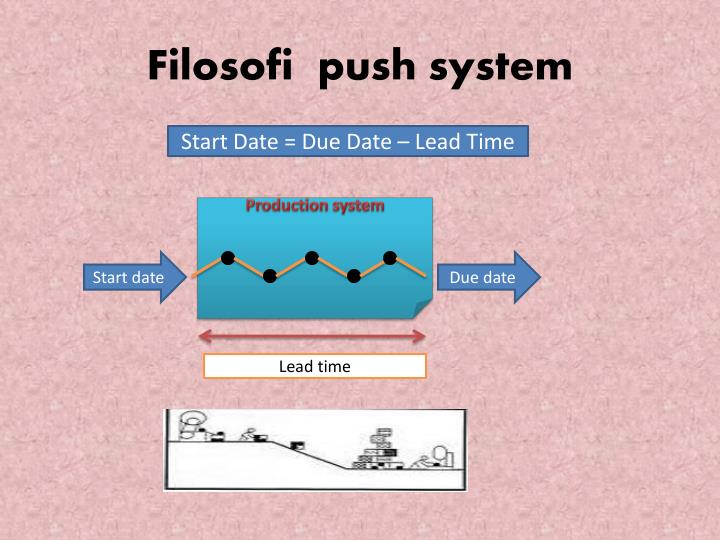

What is push system in manufacturing?

The traditional approach to manufacturing management promotes a strong focus on machine and labor utilization. The view was that if managers make sure that workers and machines are always busy, then surely the factory will be productive and efficient. This approach is called the “push” system of manufacturing, where raw material and work-in-process is continuously pushed through the factory in the pursuit of high utilization. The problem with this approach is that it usually produces high levels of inventories, long lead times, overtime costs, high levels of potential rework, and workers who are competing with one another rather than working cooperatively.

How to pursue JIT goals?

In a manufacturing setting, there are six major ways to pursue JIT goals: inventory reduction to expose waste, use of a “demand-pull” production system, quick setups to reduce lot sizes, uniform plant loading, flexible resources, and cellular flow layouts.

What is just in time manufacturing?

Just-in-time inventory principle is designed to reduce waste associated to maintaining inventory or inputs. Consider the impact of a just-in-time approach to the reduction of waste in your inventory system.

What is a Push System?

In manufacturing, a push system means that a company produces goods according to a demand forecast. This is also called make-to-stock manufacturing and it is often used to produce goods that have a low chance of unforeseeable demand fluctuations, e.g. food, pharmaceuticals, household chemicals, electronic devices, etc.

What is a Pull System?

The pull system is a lean manufacturing strategy where goods are produced according to actual demand as opposed to forecasts. In this kind of system, companies only keep as much inventory and produce as much as is needed to respond to existing customer orders.

Push System vs. Pull System

The main difference between push and pull systems is that in a push system, production dictates how much of the product will reach the market while in a pull system, current demand dictates how much to produce. This key factor of what triggers activities in the supply chain leads to an array of distinctions between the two systems.

Push-Pull System

Push and pull systems can work well together, bringing forth benefits from both systems. In this case, manufacturers use demand forecasting to determine the quantity of goods to be used as the base inventory but use customer orders to trigger further production.

Push, Pull, and MRP

Although traditional material requirements planning (MRP I) can be regarded as a push system that acts according to a master production schedule that is based on forecasts, today’s manufacturing resource planning systems (MRP II) can also complement pull systems.

Key takeaways

A push system (also called make-to-stock) means that a company produces goods according to a demand forecast. It is often used to produce goods with a low chance of unforeseeable demand fluctuations, e.g. food, pharmaceuticals, household chemicals, etc.

Why is the pull system called a JIT system?

The pull system is also called a JIT system because it operates Just in time in delivering finish goods, materials or WIP when it is needed instead of just to accumulate inventory.

What is push pull inventory?

Push-pull is also known as lean inventory strategy. It demands a more accurate forecast of sales and adjusts inventory levels based upon actual sale of goods.

Why do we use pull systems?

The purpose of implementing a pull system is to build products based on actual demand and not on forecasts. Just because you have spare capacity at any given point in the system, does not mean you should produce more. In the end, this leads to excess inventory, which is just another form of waste.

What is the difference between push and pull?

The main difference between push and pull systems is the WIP limit in your production line. In the case of an explicit limit on WIP , the process has a pull system and hence has access to all its benefits. If there is no explicit limit on WIP, then it is a push system.

What is push system?

It is the common way to organize production and is widely extended throughout organizations

What are some examples of pull systems?

One of the best examples of a pull system is a supermarket. Every time a customer buys an item, there is a signal that goes to the supermarket’s inventory control center detailing which items the customer is purchasing and in which quantity. Then, the exact items that were sold are replenished.

Is it hard for push system companies to eliminate all these expenses?

But, as soon as they reduce inventory, they will find several improvement opportunities to overcome all this waste.

Should batching and queuing parts between processes be avoided?

Batching and queuing parts between processes should be avoided if possible. Having WIP (work in progress) waiting between process stages add inventory and cost. The extra resources needed to manage this in-between inventory work may damage the product itself as it is waiting for a buyer.

What is push pull system?

On the other hand, pull systems are perfect for smaller entities with limited budgets that are still establishing themselves. Most businesses, however, use a hybrid approach called a push-pull system that features key elements from both strategies. Let’s dig in to understand the best choice for your business.

What is push pull inventory management?

Push-pull systems (or lean inventory management) aim to strike a balance between having enough product on hand to meet demand while also minimizing storage and production costs.

How does push inventory work?

Basically, your business predicts how many units of a product you’ll need for the next month, quarter, or year. You then order all the units you’ll need at once. Optimistically, you’ll always be well-stocked without needing to constantly reorder.

Is a push inventory system good for small businesses?

In our opinion, a pure push inventory system is probably best for larger small businesses that have a good handle on how inventory turns within their business.

Is pull inventory management right for my business?

A pull inventory management system may be right for your business if any of the following apply: You don’t have a lot of storage space: A pull system minimizes warehousing since you order less product. You have minimal working capital: Upfront costs are low since you pay as you go.

Can a pull system be time sensitive?

You work with a local manufacturer: International shipping costs and cross-country transit times could prohibit a pull system’s time-sensitive nature.

Can you use EOQ for push pull?

Indeed, this can be complicated. Using EOQ requires some advanced math skills—not to mention time. So if you’re thinking a push-pull system is right for you, we highly recommend you consider using an inventory management software that can run the numbers for you.

What is push system?

A company using the push system will forecast demand and employ the Material Requirements Planning (MRP) process to produce goods and services ahead of time. This is related to the Just-in-Case concept.

Why is the push system important?

The push system is particularly useful for products with low demand uncertainty or with high importance of economies of scale in reducing costs.

What is push based supply chain?

In a push-based supply chain, products are pushed through the channel from production up to the retailers. This means that production happens based on demand forecast. In a pull-based supply chain, procurement, production, and distribution are demand-driven rather than based on predictions. Goods are produced in the amount and time needed.

Is Push vs Pull black and white?

As with Just-in-Time vs Just-in-Case, Push vs Pull is not black and white. Most companies have some sort of a hybrid of the two, on a spectrum between the two ends.

Why use JIT in manufacturing?

A system using JIT manufacturing and following the principles of Lean with a pull system will find their system is much more flexible. If demand fluctuates or market conditions shift unexpectedly, you will have an easier time adapting production accordingly. It ensures production is only happening effectively eliminating overproduction and over-processing, which can hide defects and cause a whole bevy of other wastes.

What is push system?

In a push system, production is scheduled to meet the forecasted rate of demand. Also known as mass production, the push method has been around for centuries and while there are instances in which it might be beneficial, this kind of system can easily become a wasteful strategy. There are no limits on WIP and products are processed in large batches before moved down the production line or into storage. An inaccurate prediction can have a major impact on inventory levels or cycle times, and many organizations find themselves producing excessive inventory,

What are the elements of a JIT system?

16. Three basic elements work together to complete a JIT system: just-in-time manufacturing, total quality management, and

What is the ultimate goal of JIT?

24. The ultimate goal of JIT is to produce products in a lot size of

When did the JIT philosophy start?

3. JIT can be traced back to the early 1900's but no one can argue that the philosophy gained worldwide prominence

What is a Kanban card used for in JIT?

38. In JIT a Kanban card is used to signal

What is JIT practice?

The successful practice of JIT means having the right quantities of the right products in the right place at the right time. Driving down setup times enables the company to produce the product mix and quantities that are demanded in the present time period.

What is JIT management?

The JIT philosophy has evolved from a manufacturing-focused management approach to a set of management principles that can be applied to any organization . “Lean operations” is a term that is replacing JIT, especially in service environments. “Lean operations” captures the true essence and power of how a culture built around continuous improvement and the pursuit of value-added activities leads directly to competitive advantage in the marketplace. Lean operations is a management philosophy for any organization to achieve higher quality, increased productivity, improved delivery speed, greater responsiveness to changing markets, and increased customer satisfaction.

What is the role of front line employees in JIT?

Front-line employees play a critical role in successful JIT practice. They work in partnership with management and each other in the continuous pursuit of excellence. There are several ways in which front-line employees contribute to JIT success:

What is the enemy of JIT?

The enemy of JIT is uncertainty. A JIT environment thrives on predictability in customer demand, production processes, suppliers, and workers. Of course, uncertainty cannot be completely eliminated in most organizational environments.

What is push system in manufacturing?

The traditional approach to manufacturing management promotes a strong focus on machine and labor utilization. The view was that if managers make sure that workers and machines are always busy, then surely the factory will be productive and efficient. This approach is called the “push” system of manufacturing, where raw material and work-in-process is continuously pushed through the factory in the pursuit of high utilization. The problem with this approach is that it usually produces high levels of inventories, long lead times, overtime costs, high levels of potential rework, and workers who are competing with one another rather than working cooperatively.

How to pursue JIT goals?

In a manufacturing setting, there are six major ways to pursue JIT goals: inventory reduction to expose waste, use of a “demand-pull” production system, quick setups to reduce lot sizes, uniform plant loading, flexible resources, and cellular flow layouts.

What is just in time manufacturing?

Just-in-time inventory principle is designed to reduce waste associated to maintaining inventory or inputs. Consider the impact of a just-in-time approach to the reduction of waste in your inventory system.