Different Grades of Copper

- Oxygen Free Coppers Oxygen free coppers are the purest coppers available. They contain 99.99% copper at a minimum with the lowest level of volatile impurities. ...

- Electrolytic Coppers Electrolytic tough pitch copper is made from copper that has been refined using electrolysis. ...

- Free-Machining Coppers Free-machining coppers has sulfur and telluride added to increase its machinability. ...

Full Answer

What's the difference between #1 and #2 copper?

0:114:35#1 or #2 Copper? - YouTubeYouTubeStart of suggested clipEnd of suggested clipThe difference between number one and number two copper is very simple number one copper is free ofMoreThe difference between number one and number two copper is very simple number one copper is free of any paint party oil solder joints or solder of any kind of heavy oxidation.

What is the best grade of copper?

Bare Bright Copper Also referred to as “bright & shiny copper,” it is the most valuable and high-paying grade around. It refers exclusively to bare, uncoated and unalloyed wire or cable – no thinner than 16 gauge in thickness – which is of #1 copper quality.

What is the difference between #1 and #2 scrap copper?

0:061:49Copper Scrap Differences: #1, #2 & #3 - YouTubeYouTubeStart of suggested clipEnd of suggested clipTubing it's clean there's no solder on it i take a smell in there sniffle there's no gas no oil thatMoreTubing it's clean there's no solder on it i take a smell in there sniffle there's no gas no oil that means it's clean that makes it number one.

What is considered dirty copper?

Scrap copper that has a dirty appearance falls under the #2 copper grade. To qualify for this category, the material's copper content should be 94 to 96 per cent. Any unalloyed wire or pipe that has solder, paint, coating and other types of tarnishing falls are classified as #2 copper.

What are the 3 grades of copper?

The three most common types of copper pipe used in residential and commercial construction are Type K, Type L, and Type M.

What is better L or M copper?

When to use Type L and Type M copper pipe sizes. Type L copper pipe is recommended where you need strength and protection. But for normal “in the wall” household plumbing, Type M copper pipe is just fine.

What is classed as clean copper for scrapping?

Bare bright copper wireNarrowing in on copper There are four primary categories of copper scrap: Bare bright copper wire is defined as clean, bare, uncoated, unalloyed copper wire, not smaller than No. 16 gauge wire. Bare bright also should be free of copper tubing, burnt copper wire and nonmetallics.

Is it worth stripping copper wire?

So is stripping copper wire worth it? Yes, absolutely if you have a wire stripper. If not, then sometimes, but most likely only if you have wires you're sure have a high copper recovery rate.

What is the best thing to scrap for copper?

Copper can be found in wires, pipes, kitchen sinks, and fixtures. It's a great item to scrap for those who are just starting their re-model project or ripping down their home since it's likely you have some lying around the house.

Does wd40 clean copper?

Use of the Day: WD-40 helps to remove oxidation from copper pots. Clean with soap and water after.

Can you burn copper wire to strip it?

Copper wire stripping warnings First things first, the one piece of information we want to you take away from this article is that you should never strip the insulation off scrap wire by burning it or excessively heating up the insulation to remove it from the copper.

What is the blue stuff on copper?

Blue or green staining occurs exclusively with copper pipe and fittings (including brass, which is copper + zinc), and is caused by the corrosion and dissolution of the metal itself.

What is the strongest copper?

Beryllium copperBeryllium copper has the highest tensile strength and hardness among all of the copper alloys.

Which copper is harder L or M?

Type K is the heaviest. Type L is medium weight and used most often for water lines in homes. Type M is thinner and is used underground or for light domestic water lines if local codes allow.

What is high purity copper?

High purity (6N) 99,9999% copper metal is produced in wire, rods, shot, pellets, sputtering targets, wafers, and many other shapes. 6N copper wires are widely used for superconducting MR magnets in medical devices, synchrotrons, cryogenic systems, and in the high-voltage cable electronics industry.

Which brand copper is best?

Copper bottles offer so many health benefits....Prestige TATTVA Copper Bottle. ... NORMAN JR, HAT Collection - Exotic Water Bottle. ... AYURVEDACOPPER 100% Pure Copper Water Bottle. ... Signoraware Urja Copper Bottle.More items...•

What is #2 copper?

Number 2 copper has a minimum of 94% copper content and may come in the form of bare bright with contamination and be tin-plated. Common examples of # 2 copper include piping, tubing, bus bar and some grades of thin gauge wire. It should be free of attachments such as brass, steel, die-cast, stainless steel, aluminum, Lead, etc., or other solid non-metallics such as insulation, foam, excessive oil & heavy sediment. Scrap dealers receive # 2 copper as plumbing scrap with solder, paint, a small percentage of grease or dirt, as well as enameled wire, oxidized copper, electric motor windings, copper-bearing, and tin-plated solids. It is common that # 2 copper is often supplied by plumbers, do-it-yourselfers, demolition contractors, electricians & mechanical & HVAC contractors.

What is bare bright copper?

This type of copper is typically supplied by electricians and utility companies. Also known as bright & shiny copper, bare bright is 99.9% copper and is a highly targeted item for scrap dealers and their customers due to its high value. Additionally, it should not be thinner than 16-gauge in thickness size and be free of tarnish, oxidation, insulation, rubber or cloth residual, burnt wire, tinned, coated, plated, copper-clad (steel with copper exterior plating) and any other non-copper attachments. It’s useful to note that this type of copper is used to make power cables that deliver heavy voltage electricity into a building. Because Bare Bright comes from power cables, you will need to remove the insulation to generate bare bright copper.

What is copper used for?

It has innumerable applications & uses such as in electric motors, construction, industrial & everyday household products. If you collect copper scrap due to your profession, for example, a contractor, ...

What is recovery of copper?

Recovery pertains to the amount of copper that solidifies after it’s been melted in a furnace. If 10,000 lbs. of copper scrap is added to a fur nace of which 5% percent of the weight is solder or dirt & 5% of the copper evaporates while melting after the copper cools into solid material again, its recovery equates to 90%.

What is number one cooper?

It is bare copper in the form of a tube, pipe, bus bar or some grades of wire that are not less than 1/16 of an inch in thickness. For example, the bus bar is used in transformers within large industrial buildings for transferring large amounts of electricity. Number one cooper should not have other metals attached to it, & be un-plated, un-coated & free of any contaminants. It is most commonly sold to H&C Metals in the form of a clean plumbing tube or pipe.

Is copper unalloyed?

Regarding the purity of copper collected by scrap yards, copper can be free of other metals (unalloyed), or either chemically combined (alloyed) or plated with other metals, including Tin, Lead, Beryllium, Phosphorus & Silicon, etc., or contaminated by the presence of dirt, solder, paint, grease, oil, tape, enamel or fiber, etc.

How much copper is high yield?

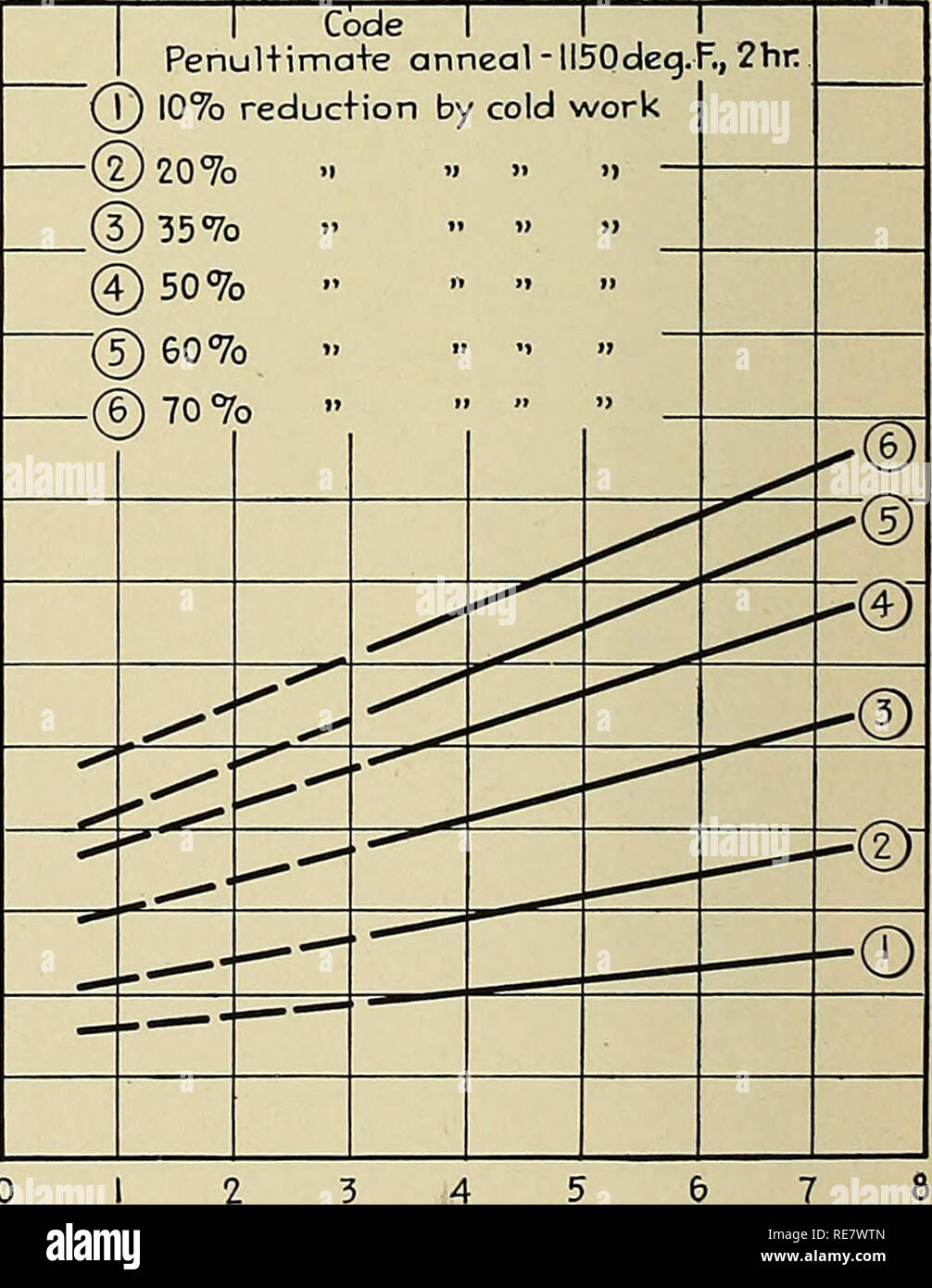

The yield strength of cold-rolled high yield (H01) copper is significantly higher than standard cold rolled (H00) copper, up to 33,000 p.s.i. This allows the use of 12 ounce high yield copper in many applications where 16 ounce cold rolled copper is normally used.

Why is soft temper copper not recommended?

It was historically used in building construction. Because of its low strength, heavy gauge material was required. As a result, the use of soft temper copper is not recommended for most building applications.

What is the best temper for roofing?

In general, cold rolled 1/8 hard temper (H00) copper is recommended for most roofing and flashing installations. Soft copper may be used where extreme forming is required such as in complicated thru-wall flashing conditions. However, it should be noted that cold rolled copper offers far more resistance than does soft to the stresses induced by expansion and contraction. Copper roof sheet of higher temper should be specified only if indicated for specific and engineering applications requiring such higher tempers.

What is high yield copper used for?

The major use for high yield copper is flashing products, where malleability and strength are both important. Good resistance to corrosion, good electrical and thermal conductivity, ease of fabrication coupled with strength and resistance to fatigue are criteria by which copper or one of its alloys is selected.

Why is copper resistant to corrosion?

Its high resistance to corrosion is due to its ability to react to its environment and reach weathering equilibrium.

What is the process of joining copper?

Copper and its alloys are readily assembled by any of the various mechanical or bonding processes commonly used to join metal components. Crimping, staking, riveting, and bolting are mechanical means of maintaining joint integrity. Soldering, brazing and welding are the most widely used processes for bonding copper metals.

Is cold rolled copper stronger than soft copper?

Cold rolled temper is less malleable than soft temper copper, but is much stronger. It is by far the most popular copper temper currently used in construction. The properties of cold rolled copper are summarized in Table 1.1A. Table 1.1A. Properties of Cold Rolled Copper.

What is grade #2 copper?

#2 grade insulated copper consists of unalloyed wire – thinner than 16 gauge – which includes heavy, double or plastic insulation. The grade generally covers many common types of telecommunications wiring as well as electronics such as outlet and extension cords. Some coatings on the scrap, such as tin and nickel for example, as well as some degree of corrosion will also meet classification.

What is the minimum copper content?

Additionally, its minimum copper content should be 94-96%. In order to qualify for this grade, wire must be bare of insulation and be thinner than a 16th of an inch in diameter. The ends and fittings of #2 copper are generally accepted at dealerships, and oxidation of some wire, pipe or tubing is allowed as long as damage is not excessive.

What is copper scrap?

Understanding Grades of Copper Scrap. Copper is among the most valuable metals available when it comes to scrap collection and recycling. With an infinite recyclable life, copper is used and reused in motors, computers, construction, industrial machinery and more.

What is #1 copper?

#1 copper is the second most profitable type to trade in. To be classified as #1, the copper should be comprised of bus bars, clippings, commutator segments and wire of at least 1/16th of an inch in diameter. It should also be clean in appearance, unalloyed and uncoated.

Does copper have to be stripped?

As its name implies, samples must be stripped of insulation and other materials. Furthermore the metal must be free from any paint, impurities or signs of tarnishing. This includes any visible oxidation, and very negligible amounts of patina on the copper are allowable.

Is #2 copper good for oxidation?

The ends and fittings of #2 copper are generally accepted at dealerships, and oxidation of some wire, pipe or tubing is allowed as long as damage is not excessive. #2 copper is the third most valuable grade available.

Is copper tubing clean?

It should also be clean in appearance, unalloyed and uncoated. The most valuable type of copper pipe – clean copper tubing – may qualify as #1 copper as long as it is free of fittings, insulation, paint, solder and other materials.

What is type M copper pipe?

Type M Copper Pipe: Type M copper pipe is thinner than both type K and L copper pipe. Sold in both rigid and flexible forms, Type M is used most commonly for heating water services and vacuum systems. It can be used with sweat, compression, and flare fittings. Type M tubing is favored for residential work for its relatively low price; a thinner wall means less copper and thus a lower price. Type M copper is not always allowed by plumbing codes in all areas and applications. Always check with the local building authority for restrictions on its use.

What type of copper pipe is used in commercial construction?

The three most common types of copper pipe used in residential and commercial construction are Type K, Type L, and Type M. A fourth type, used for drain-waste-vent, or DWV, piping, can be found in some older homes.

What is copper pipe used for?

Copper pipes are commonly used in the construction industry for water supply lines and refrigerant lines in HVAC (heating, cooling, and air-conditioning) systems . Copper pipes can be manufactured as soft or rigid copper and offer excellent corrosion-resistance and reliable connections.

What type of copper pipe is used for sweat?

It is available in rigid and flexible forms and can be used with sweat, compression, and flare fittings. Type L is considered the most common type of copper piping, as it can be used in many more applications than Type K. Flexible Type L copper can be used to repair or replace old water lines, although rigid tubing is more durable.

What is type K pipe?

Type K pipe is available in a rigid and flexible form and can be used with flared and compression fittings. It is recommended for main water lines and underground installations because its thickness helps it withstand the pressure from backfilled earth in trenches.

Is copper pipe type L or M?

Type L copper is thinner than Type K but thicker than type M. Type M Copper Pipe: Copper pipe type M wall is thinner than both type K and L copper. Sold in both rigid and flexible forms, Type M is used most commonly for heating water services and vacuum systems. It can be used with sweat, compression, and flare fittings.

What is the thickest type of copper pipe?

Of all copper pipe types, Type K has the thickest walls and is the most durable. Pipe wall thickness varies according to the pipe diameter. ½-inch Type K pipe has a wall thickness of .049 inches, while ¾-inch has a thickness of .065 inches. Its thickness also makes Type K the heaviest and most expensive type of copper pipe. You won’t find Type K copper pipes under your sink or connected to other plumbing fixtures; partly because they aren’t as easy to work with as other types of copper but mostly due to the prohibitive cost. Type K’s thickness lends itself to use in commercial plumbing, HVAC, and sprinkler systems but most commonly found in underground water main installations. A thinner pipe can crimp or collapse underground, but Type K’s durability will allow it to last longer, meaning it doesn’t need to be dug up every few years.

What is the difference between Type M and Type M copper pipe?

Best of all, it costs less than the other copper pipe types! Advertisement. Type M has red markings and comes in flexible rolls and rigid tubing. While it isn’t often used in outdoor underground applications, Type M copper pipe is a perfect fit and plenty durable if you are looking to run a water system in your home.

What type of copper pipe is used for underground water lines?

2. Type L Copper Pipe. While not quite as thick as Type K, with a wall thickness of .045 inches for a ¾-inch diameter pipe, it is still quite durable and can be used in many more ways. Type L is beefy enough to be used in underground applications but is often used to replace or repair water lines.

What type of copper pipe is best for a home?

1. Type K Copper Pipe. Of all copper pipe types, Type K has the thickest walls and is the most durable.

What is copper pipe used for?

Photo: depositphotos.com. Copper pipes have been used as water supply lines in homes for decades, and you’ve probably seen them under your cabinets or overhead in your basement. Most people know that pipes come in different diameters, but what you may not realize is that some types of copper pipes are thicker than others, too.

What is a K pipe?

Distinguished by green markings, Type K pipe is available in both rigid form and in flexible rolls. You’ll often find flexible rolls of Type K used for underground water mains because they are easier to run in a trench, require no fittings, and can be used with compression and flared fittings.

What is type L water pipe?

Marked with blue and equipped for interior water supply systems, hot water heating systems, and fire protection such as sprinkler systems, Type L is the most commonly used of the copper pipe types. It comes in both flexible rolls and rigid tubing, with the rigid tubing usually used for internal water piping and the flexible rolls used underground and outside the home.

What is the minimum copper content for ASTM?

All tube supplied to these ASTM standards is a minimum of 99.9 percent pure copper. The copper customarily used for tube supplied to these specifications is deoxidized with phosphorus and referred to as UNS C12200 or DHP 1 Copper. Other coppers may also be used.

What is standard copper tube?

Standard Tubes: Types of Copper Tube. Long lasting copper tube is a favorite choice for plumbing, heating, cooling and other systems. In the United States, it is manufactured to meet the requirements of specifications established by ASTM International. All tube supplied to these ASTM standards is a minimum of 99.9 percent pure copper.

What is the difference between a K and L gas tube?

Each type represents a series of sizes with different wall thicknesses. Type K tube has thicker walls than Type L tube, and Type L walls are thicker than Type M, for any given diameter. All inside diameters depend on tube size and wall thickness.

How to join a tube in a hard temper?

Tube in the hard temper condition is usually joined by soldering or brazing, using capillary fittings or by welding. Tube in the soft temper can be joined by the same techniques and is also commonly joined by the use of flare-type and compression fittings.