A few of the most familiar uses of styrene include:

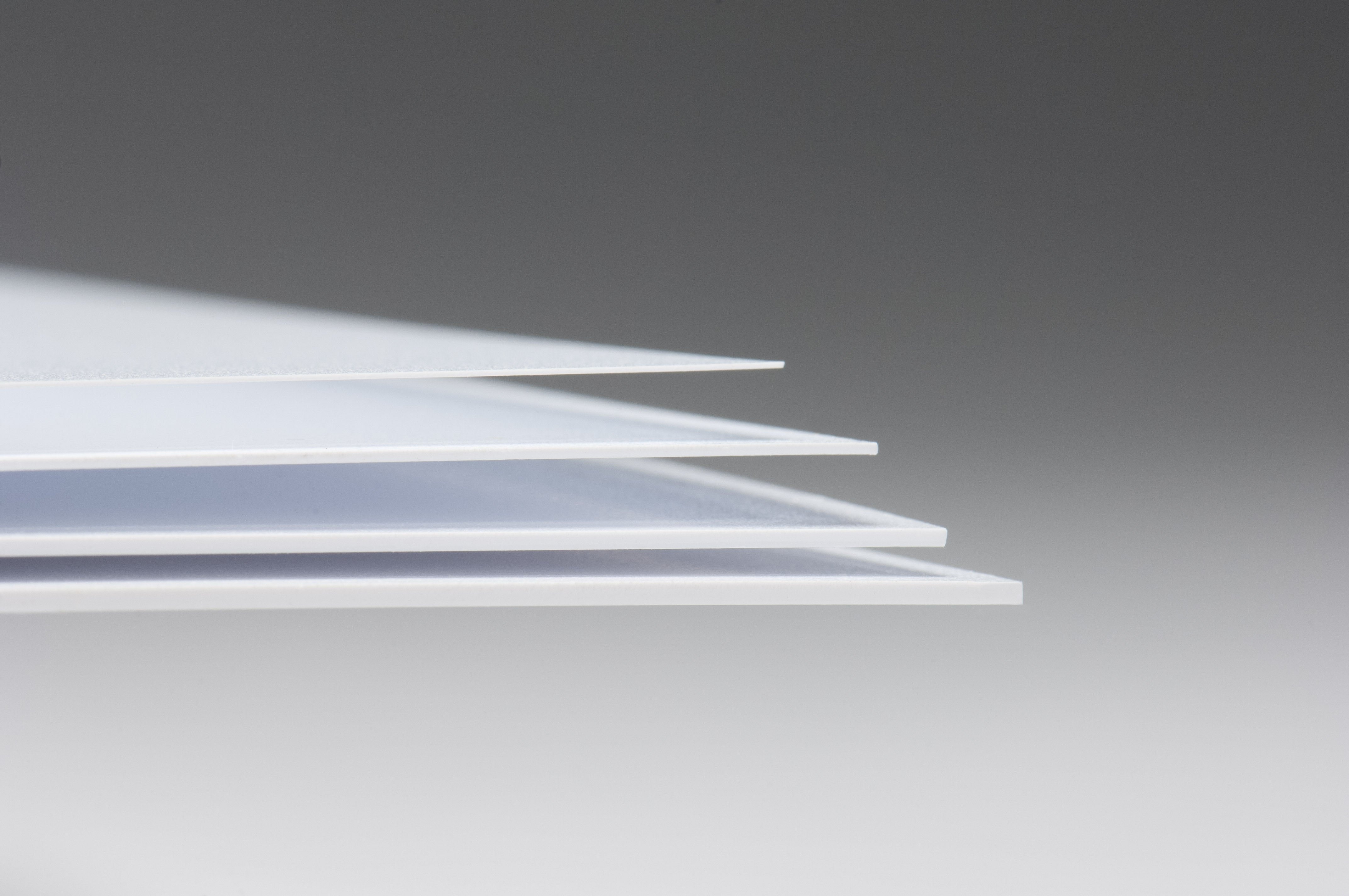

- Solid and film polystyrene, used in rigid foodservice containers, CD cases, appliance housings, envelope windows and many other products.

- Polystyrene foam, used in food service products and building insulation.

- Composite products, used in tub and shower enclosures, automobile body panels, wind turbine parts, boats and many other applications.

What are the different uses of polystyrene?

few of the places that you’ve probably seen polystyrene:

- Plastic cutlery

- Shipping and packing materials

- Insulation in buildings

- Food packaging

- Libraries

What is polystyrene, and what is it used for?

Polystyrene is prepared by free radical addition polymerization of styrene in the presence of benzoyl peroxide as a catalyst. It is used for making polystyrene products like polystyrene sheets, polystyrene foam, brush handles, and combs. It is used for making talcum powder.

What can you do with polystyrene?

- Use as drainage in the base of plant pots.

- Create your own presentation mounts.

- Make your own superglue.

- Use as insulation (with caution)

Why is polystyrene used for packaging so commonly?

Polystyrene sheets are an ideal packaging material. They are lightweight, easy to cut, and they provide the ideal protective barrier between delicate and fragile items during transportation. Polystyrene sheets are cost effective and safe to use. In addition, they do not contain any CFCs or HCFCs so they are extremely environmentally friendly.

What are the advantages of using polystyrene?

Benefits of Polystyrene PackagingSuperior insulation which protects produce from temperature changes.Dimensional stability and recovery.Light weight and easy to stack.Water resistant.Ideal for hydro cooling.Excellent shock absorption qualities.Resistant to bacterial growth.More visually appealing to customers.More items...

What plastic is used in polystyrene?

Polystyrene (PS) is a polymer made from the monomer styrene, a liquid hydrocarbon that is commercially manufactured from petroleum. At room temperature, PS is normally a solid thermoplastic but can be melted at higher temperature for moulding or extrusion, then resolidified.

Is polystyrene eco friendly?

Despite what you may have heard, expanded polystyrene (EPS) is environmentally friendly. Made from 98% air, no toxic substances are used in the manufacture of EPS and it is 100% recyclable.

What is an example of polystyrene?

Three major types of polystyrene include polystyrene foam, regular polystyrene plastic, and polystyrene film. Amongst the different types of foam are expanded polystyrene (EPS) and extruded polystyrene (XPS). EPS includes the most well-known and common types of polystyrene to include styrofoam and packing peanuts.

Is polystyrene plastic toxic?

Why ban polystyrene foam? Studies show that styrene, a likely carcinogen, can leach from polystyrene foam cups and containers when heated. Never put hot food/drink into polystyrene foam containers, and never microwave these (or any plastic) products!

Is polystyrene plastic safe?

Regulatory bodies around the world, such as the US Food and Drug Administration and The European Commission/European Food Safety Authority, who undertake rigorous studies to evaluate a product's safety, have not changed their view that polystyrene is safe for foodservice packaging.

Is PVC and polystyrene the same?

In fact, they are different kinds of boards (Polystyrene board, PVC foam board). Firstly, the price, material and weight of the two kinds of plates of Polystyrene board and PVC foam board are obviously several times worse.

Is polystyrene the same as polypropylene?

The key difference between polystyrene and polypropylene is that the monomer for polystyrene is styrene, while the monomer for polypropylene is propylene. Polymers are large molecules, which have the same structural unit repeating over and over. These repeating units are “monomers”.

WHAT IS POLYSTYRENE (EPS/XPS)?

There are two types of polystyrene foam best suited for processing with the Hot wire foam cutters and Hot knife cutters: extruded polystyrene (XPS foam), and expanded polystyrene (EPS foam). Although both types of insulation are comprised of polystyrene, the two types of manufacturing processes produce finished products with very different performance properties. XPS is manufactured in a continuous extrusion process that produces a homogeneous closed cell crossed section, whereas EPS is manufactured by expanding spherical beads in a mold, using heat and pressure to fuse the beads together.

What is EPS foam used for?

Other Uses. Polystyrene foam – EPS can be used in manufacture of sliders, model planes and even surfboards because of its positive strength to weight ratio. The strength of EPS foam along with its shock absorbing properties makes it effective for use in children’s seats and cycling helmets.

What is XPS foam?

Insulation foam – EPS, XPS are used for a variety of applications because of its excellent set of properties including good thermal insulation, good damping properties and being extremely light weight. From being used as building materials to white foam packaging, expanded polystyrene has a wide range of end use applications. In fact, many surfboards now use EPS as the foam core.

What is the best material for building a house?

A resilient and robust construction material boasting a high compressive strength and a superior thermal performance, Extruded polystyrene is the number one choice for home builders, specifiers, architects and engineers. The high-density cell structure of XPS styrofoam also makes it practically impervious to water.

What is EPS insulation?

EPS insulation material also has applications in horticulture in seedling trays to promote aeration of soil.

How are XPS and EPS made?

XPS is manufactured in a continuous extrusion process that produces a homogeneous closed cell crossed section, whereas EPS is manufactured by expanding spherical beads in a mold, using heat and pressure to fuse the beads together.

What are the properties of polystyrene?

Answer: Five properties of polystyrene are given below: 1 polystyrene has a good optical property like it is transparent polymer allowing high transmission of all wavelengths. Moreover, its high refractive index gives it a particularly high brilliance. 2 Due to the chain stiffening effect of the benzene ring, polystyrene is hard but brittle. It emits a characteristic metallic sound when dropped. 3 Being a non-polar amorphous polymer, its softening temperature is low. It cannot withstand the temperature of boiling water. 4 polystyrene has a low tendency for moisture absorption. Moreover, it has good electrical insulation characteristics. Therefore, used in making polystyrene insulation products. 5 polystyrene has reasonable chemical resistance but mediocre oil resistance

How is polystyrene prepared?

Polystyrene is prepared by free radicle addition polymerization of styrene in the presence of benzoyl peroxide as a catalyst.

Why is polystyrene hard?

Answer: Due to chain stiffening effect of the benzene ring, polystyrene is hard but brittle in nature. It emits a characteristics metallic sound when dropped.

Why is polystyrene an amorphous state?

polystyrene exists in an amorphous state because of the presence of bulky phenyl groups, packing of polystyrene chains is not efficient.

Is polystyrene good for insulation?

polystyrene has a low tendency for moisture absorption. Moreover, it has good electrical insulation characteristics. Therefore, used in making polystyrene insulation products.

Is polystyrene a light material?

Polystyrene is very light in weight, as it is composed of 95% air.

What is Polystyrene?

Polystyrene, also known as poly-phenylethene, is a polymer made up of repeating molecules called styrene. It is a thermoplastic polymer, meaning it softens and melts when heated and can be reused. It is an excellent electrical insulator and is resistant to chemicals such as acids and bases.

What Are the Uses of Polystyrene?

Polystyrene is used across all industries, from toys and parts of consumer goods to insulation and packaging materials. It is also the ingredient for the synthesis of new plastics. Polystyrene is used in its solid, film, and foam form, forms the polymer matrix in composites, and works as the basis for co-polymerized plastics.

How Does Polystyrene Affect Human Health?

Polystyrene affects human health by releasing styrene when it starts leaching after long periods, which can affect the central nervous system. However, if accidentally ingested, the material will only cause someone to choke if the piece is big enough.

Conclusion

Polystyrene is a popular material in many applications, from parts of consumer goods to insulation and packaging solutions. Its moldability and low shrinkage make polystyrene suitable for injection molding. Moreover, polystyrene is the base material for various co-polymerization processes to produce better plastics with unique properties.

Why is polystyrene used in packaging?

Food packaging: Polystyrene is extensively used in packaging of food products. It helps keep the food clean and fresh. It also costs less to use polystyrene and being transparent, it is great in terms of appearance that is so critical in retail.

Why is polystyrene used in vacuum cleaners?

It is also used in vacuum cleaners and blenders because it is inert and does not react with other materials. Electronics: The rigid and hard type of polystyrene is used in the making of television and computer housings. Other IT equipment also uses polystyrene because it can give the right kind of finish and shape.

How is polystyrene made?

Polystyrene is made via distillation of hydrocarbon fuels which results in the formation of lighter groups called fractions. These fractions are then combined with catalysts to allow a chemical reaction. The result of this reaction is the creation of the plastic that is known as polystyrene. The entire process is considered to be a polymerization process.

What is the most popular material used in insulation?

Foam – As mentioned above, polystyrene as a foam is one of the most popular applications of the material. It is made by blowing special agents and foam is actually 95% to 98% air. These foams are good thermal insulators and are used in the construction of homes and buildings. They are also used in packaging.

What is bulk polymerization?

Bulk polymerization is great when good clarity of material and a high-quality of colored resin is needed. Polystyrene foam is produced by blowing agents into the plastic, which expand and form a foam, which basically consists of trapped air.

What is a PS plastic?

Polystyrene or “PS” is a thermoplastic polymer that is naturally transparent . Interestingly, there are certain types of Polystyrene that could be classified as a thermoset polymer as well.

What was the first styrofoam?

After all of this, the Americans entered. In 1941, Dow Chemical made the world’s first styrofoam.

What is polystyrene polymer?

Polystyrene is an addition polymer that results when styrene monomers interconnect ( polymerization ). In the polymerization, the carbon-carbon π bond of the vinyl group is broken and a new carbon-carbon σ bond is formed, attaching to the carbon of another styrene monomer to the chain.

When was polystyrene discovered?

Polystyrene was discovered in 1839 by Eduard Simon, an apothecary from Berlin. From storax, the resin of the Oriental sweetgum tree Liquidambar orientalis, he distilled an oily substance, a monomer that he named styrol.

How is styrene butadiene rubber made?

Styrene-butadiene rubber (SBR) is produced like PS-I by graft copolymerization, but with a lower styrene content. Styrene-butadiene rubber thus consists of a rubber matrix with a polystyrene phase dispersed therein. Unlike PS-I and SBC, it is not a thermoplastic, but an elastomer. Within the rubber phase, the polystyrene phase is assembled into domains. This causes physical cross-linking on a microscopic level. When the material is heated above the glass transition point, the domains disintegrate, the cross-linking is temporarily suspended and the material can be processed like a thermoplastic.

Why is polystyrene not recycled?

Most polystyrene products are currently not recycled due to the lack of incentive to invest in the compactors and logistical systems required . Due to the low density of polystyrene foam, it is not economical to collect. However, if the waste material goes through an initial compaction process, the material changes density from typically 30 kg/m 3 to 330 kg/m 3 and becomes a recyclable commodity of high value for producers of recycled plastic pellets. Expanded polystyrene scrap can be easily added to products such as EPS insulation sheets and other EPS materials for construction applications; many manufacturers cannot obtain sufficient scrap because of collection issues. When it is not used to make more EPS, foam scrap can be turned into products such as clothes hangers, park benches, flower pots, toys, rulers, stapler bodies, seedling containers, picture frames, and architectural molding from recycled PS. As of 2016, around 100 tonnes of EPS are recycled every month in the UK.

How long does it take for polystyrene to biodegrade?

Waste polystyrene takes hundreds of years to biodegrade and is resistant to photo-oxidation.

Which is stronger, acrylonitrile or polystyrene?

Acrylonitrile butadiene styrene (ABS) is a material that is stronger than pure polystyrene.

What is the name of the substance that is heated with styrol?

This eventually led to the substance receiving its present name, polystyrene.