Common causes of incomplete combustion include:

- Fuel valve malfunction that leads to too much fuel in the combustion chamber

- Airflow restriction that limits the volume of air in the combustion chamber

- Ignition problems that lead to inefficient combustion

What are the causes of incomplete combustion?

In most cases, incomplete combustion is caused by inadequate mixing of the air and fuel, insufficient residence time, insufficient temperature, and a low total amount of surplus air present in the mixture. 1 How do you fix an incomplete combustion in a car? 2 What problems does incomplete combustion cause?

What causes a gas furnace to crack?

Airflow issues can also cause combustion problems in your furnace. If your gas furnace is operating with an incomplete combustion process, your burners will have to run hotter and longer. This excess heat puts more stress on your heat exchanger, which leads to cracking. Oversized furnace.

Why is there no air coming out of my furnace?

Obstructed air intake vent pipes in a direct-vent two-pipe system will cause serious combustion problems in a condensing furnace. Check to see if the furnace combustion problem is caused by an obstructed air supply pipe by removing the burner compartment cover. This will provide free airflow to the combustion chamber.

What happens if my gas furnace is not burning properly?

If your gas furnace is operating with an incomplete combustion process, your burners will have to run hotter and longer. This excess heat puts more stress on your heat exchanger, which leads to cracking.

What causes incomplete combustion to occur?

Incomplete combustion is generally due to poor mixing of the air and fuel, insufficient residence time, insufficient temperature and low total excess air.

What causes incomplete combustion on gas furnace?

The most common cause of incomplete combustion in gas furnaces is heat exchanger failure. As described earlier, combustion takes place within the steel tubes or drum. Air is drawn from the conditioned space, blown over the outside of these tubes and is sent back to the conditioned space after being warmed by the tubes.

How is incomplete combustion prevented?

After-burning: Prevent afterburning by introduction of multiple spark plugs so that the entire charge ignites simultaneously because there are chances that fuel exits the chamber unburnt. So make sure all the parts in the combustion chamber gets equal heat.

What are the signs of incomplete combustion?

A yellow flame, soot and excessive condensation are three physical signs of incomplete combustion.

Can too much air cause incomplete combustion?

Too much, or too little fuel with the available combustion air may potentially result in unburned fuel and carbon monoxide generation. A very specific amount of O2 is needed for perfect combustion and additional (excess) air is required for good combustion.

What happens when there is incomplete combustion?

Incomplete combustion occurs when the supply of air or oxygen is poor. Water is still produced, but carbon monoxide and carbon are produced instead of carbon dioxide. The carbon is released as soot . Carbon monoxide is a poisonous gas, which is one reason why complete combustion is preferred to incomplete combustion.

What is an example of incomplete combustion?

An example of incomplete combustion would be burning coal (a fossil fuel), during which quantities of soot and carbon monoxide are released. In fact, many fossil fuels—including coal—burn incompletely, releasing waste products into the environment.

Which is better between complete and incomplete combustion and why?

Combustion reactions are exothermic reactions that release energy when fuel is burnt. Complete combustion of a fuel yields a high amount of energy whereas incomplete combustion yields a less amount of energy. This is the main difference between complete combustion and incomplete combustion.

What are three necessary conditions for combustion?

For combustion to take place, the following conditions should be met:There should be a combustible substance.There should be a medium in which combustion can take place.The ignition temperature of the combustible substance should be attained.

How do you balance incomplete combustion?

9:2423:21√ The Incomplete Combustion Explained in Detail with Examples ...YouTubeStart of suggested clipEnd of suggested clipRight out the chemical reactants and the reactants and the products and there they are again. We donMoreRight out the chemical reactants and the reactants and the products and there they are again. We don't know how to balance them properly yet because we haven't gone through the balancing process but.

Is carbon monoxide produced by incomplete combustion?

During incomplete combustion part of the carbon is not completely oxidized producing soot or carbon monoxide (CO). Incomplete combustion uses fuel inefficiently and the carbon monoxide produced is a health hazard.

What leaks carbon monoxide in a house?

Clothes dryers. Water heaters. Furnaces or boilers. Fireplaces, both gas and wood burning.

What is an example of incomplete combustion?

An example of incomplete combustion would be burning coal (a fossil fuel), during which quantities of soot and carbon monoxide are released. In fact, many fossil fuels—including coal—burn incompletely, releasing waste products into the environment.

What are the symptoms of a shortage of primary air?

Insufficient primary burner air increases CO production. Restricted air inlets often produce a noticeable disruption of the flame and a change from blue to yellow. Another cause of insufficient primary air and incomplete combustion is excess gas flow to the burner.

What products are formed in incomplete combustion?

Incomplete combustion occurs when the supply of air or oxygen is poor. Water is still produced, but carbon monoxide and carbon are produced instead of carbon dioxide. The carbon is released as soot. Carbon monoxide is a poisonous gas, which is one reason why complete combustion is preferred to incomplete combustion.

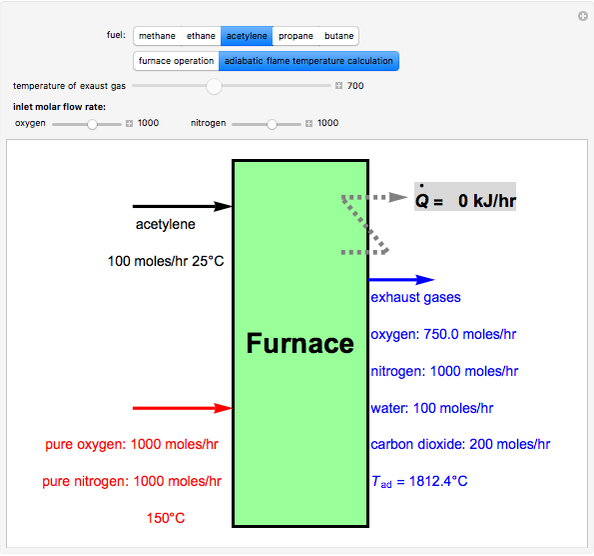

Where does combustion take place in a furnace?

The Combustion Chamber This is the area of the furnace where fuel and air mix. All combustion requires oxygen. Your furnace has a vent system so that it can “inhale” air to create clean and efficient combustion. This vent system is also where your furnace will “exhale” the combustion by-products.

What is incomplete combustion of oil?

Another form of incomplete combustion of oil is carbon buildup in the furnace. I recall looking in a burner observation port on one ship to see a complete arc of glowing carbon around the opening that the flame penetrated. Oil-fired furnaces are not equipped to remove carbon accumulations, so any carbon buildup is a serious problem. It also represents an accumulation of unburned fuel that could suddenly mix with air to form an explosive mixture. It’s a significant problem if it builds up on a furnace sidewall where it can fall off and fracture into thousands of bits of fuel. Most explosions from falling carbon buildups are not adequate to rupture a furnace setting, but there’s always a possibility of one being just enough.

Why is gas rich in a furnace dangerous?

It’s hazardous because the condition is intermittent. The quick variations from air-rich to fuel-rich provides an opportunity for the unburned fuel to mix with excess air to form an explosive mixture that is eventually ignited somewhere in your furnace or boiler. This condition is so prevalent I’m certain half of the readers will discover it exists in their plant. Even more dangerous is connecting these piping systems between multiple boilers.

Why is there black material around a boiler?

We’re familiar with carbon in many forms, including the pencils we write with, charcoal, etc. In every case it’s black. Therefore, any black material around a boiler is likely an indication of incomplete combustion. It’s an indication that there’s not enough combustion air at the burner.

How does CO increase exponentially?

As excess air is decreased, CO starts to form and increases exponentially as excess air approaches zero. This typical curve is not standard, as many people are willing to believe. Since oxygen is almost always 20.9% (by volume) of the combustion air, the oxygen curve is always as shown. The CO curve, however, is another story. Any extrapolation to the right would fail because CO will be produced and increase exponentially beginning somewhere between 100% and 400% excess air, it depends on the burner. Any burner with poor mixing will generate CO regardless of the amount of excess air so CO may never reach zero. And, the characteristic of the CO curve can vary from logarithmic (as shown) to a simpler or more complex form.

How to introduce natural gas to a burner?

More about incomplete combustion of gas. For most burners, the method of introducing natural gas is via a gas ring. It’s a pipe rolled to produce a donut shape with an internal diameter matching, or nearly so, the inside diameter of the burner throat.

Why do hydrocarbons burn?

Hydrogen, and some of the carbon, are burned to generate enough heat to crack (a petrochemical term that describes the process of breaking complex hydrocarbons down into less complex forms) remaining fuel leaving mostly carbon. Complex hydrocarbons are reduced to simple gases by the heat of the fire and they burn to release energy, part of which is used to crack more of the fuel. Since there’s proportionately more carbon in liquid and solid fuels the cracking process results in some raw carbon remaining. The source of the bright yellow color in liquid and solid fuel fires is the slower burning carbon. When there isn’t enough air to burn all the carbon, it leaves the furnace as unburned fuel, regardless of temperatures, and appears as black smoke in the flue gases.

What is the smoke that spews out of a furnace?

Most of us have observed the great clouds of black smoke spewing out a stack. That is the principal indication of incomplete combustion of oil. Incomplete combustion can also be detected in white smoke and, with heavier oils, accumulations of carbon deposits in the furnace.

Why is my furnace leaking?

This is the biggest issue. If black soot is found near where the furnace connects to the ducts, the heat exchanger may be leaking. This can cause combustion byproducts like soot to mix with the air in the house. Carbon monoxide can also be released in this fashion, which is highly toxic. If you see soot in this area of your house, turn the heat off and call a professional right away.

Where does soot come from in a furnace?

No matter where you find soot on or around your furnace, it always comes from the same place: the burners. As the furnace in your house burns fuel to create heat, especially natural gas, there are remnants left over after the process is completed.

What is the primary ingredient in black soot?

One of the combustion byproducts is carbon, the primary ingredient in black soot, which is sent up the heat exchanger and out of the house. However, if there is a problem with your furnace’s venting, you may start to find furnace soot in other places. This is where it can become a problem.

Why is my pilot light burning?

If you’re using a standing pilot light, this can be particularly troublesome, as it can prevent the light from igniting or staying lit . If your pilot light seems to be having trouble burning, especially if it is a primarily yellow flame instead of blue, you may want to check the pilot assembly.

Can you see soot on a furnace?

If you have a furnace, especially a gas-burning furnace, you may one day find soot visible on the outside of the unit. Though this may alarm you at first, don’t panic. Soot isn’t necessarily a bad sign, depending on where you find it. Let’s take a look at some of the places you’re likely to find furnace soot, and what it means.

Why is a high efficiency furnace called a condensing furnace?

High-efficiency furnaces are often known as condensing furnaces because they have a second heat exchanger that extracts additional heat from the air ...

How to tell if a furnace is condensing or conventional?

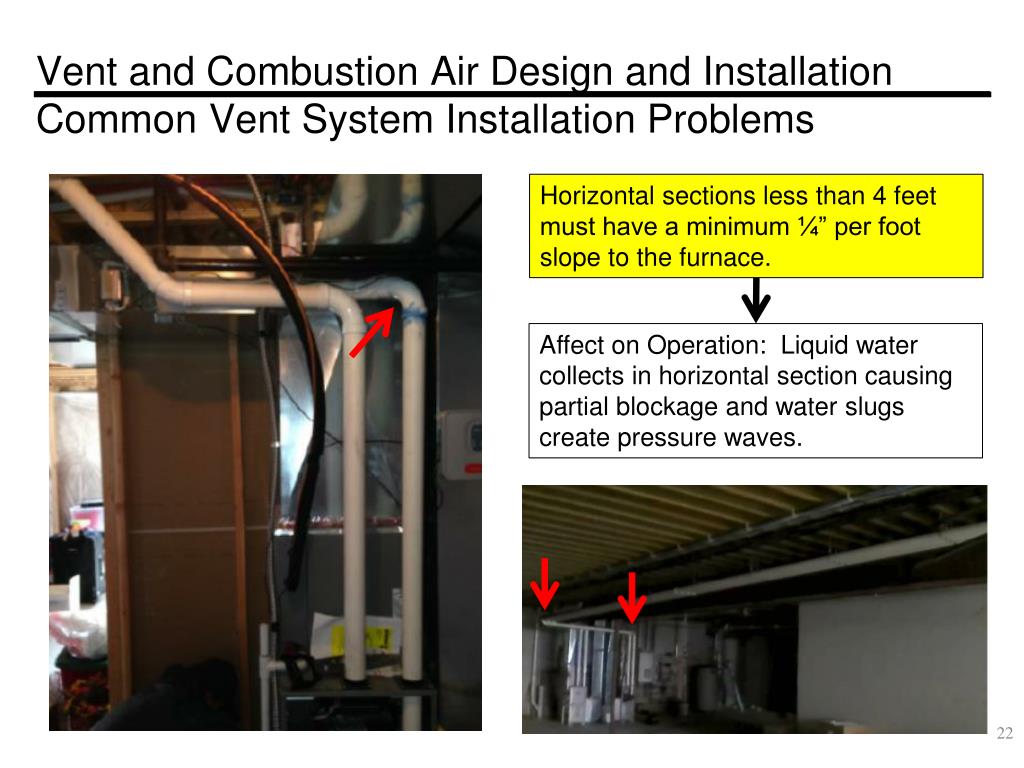

The main difference between a conventional furnace and a condensing furnace is the heat exchanger technology used to extract heat from the combustion process and exhaust the combustion gases. Visually, you can usually identify a condensing furnace because the exhaust gases will exit your home through a relatively small PVC pipe, rather than the large metal exhaust flue found in conventional furnaces. Often, you will see two PVC pipes extending from the furnace through the sidewall or roof of your home—one is the air intake vent, the other the exhaust vent. This indicates a direct-vent system.

What happens if you have an obstructed air intake vent pipe?

An obstructed air intake vent pipe in a direct-vent two-pipe system will cause serious combustion problems in a condensing furnace.

What is a high efficiency condensing furnace?

High-efficiency furnaces are often known as condensing furnaces because they have a second heat exchanger that extracts additional heat from the air that passes through the first heat exchanger. This heat-extraction processes caused water vapor to condense out of the air, which is drained away through a tube that is usually placed in a floor drain. Thus, a high-efficiency condensing furnace can be identified by the presence of this drainage tube.

What happens when the exhaust vents are too close together?

This can happen when the air intake and exhaust vents are too close together and the exhaust vent gases—which consist mostly of water vapor, carbon dioxide, and carbon monoxide—are drawn back into the combustion air intake vent. The result is that air reaching the furnace does not have enough oxygen for proper combustion.

What happens when you install a direct vent system?

When a direct-vent system has its air intake and exhaust vents improperly installed on the outside of the home, it can create a problem of "short-circuiting," which allows exhaust gases to flow back into the combustion air intake pipe.

Why does my furnace pressure switch open?

A partially clogged condensate line, or a clog at the condensate collector box near the inducer fan, will often trip the furnace’s pressure switch . If the condensate drain is blocked by debris or frozen condensate, or if it simply drains improperly, the pressure switch may open, preventing ignition.

What causes a furnace to overheat?

Poor airflow. Dirty air filters and closed or blocked air registers are a few examples of problems that can slow airflow to your heating system. If your furnace isn’t receiving proper airflow, it can overheat and put extra stress on your heat exchanger. This extra stress often leads to premature cracks.

Why is my furnace cracking?

If your gas furnace is operating with an incomplete combustion process, your burners will have to run hotter and longer. This excess heat puts more stress on your heat exchanger, which leads to cracking. Oversized furnace.

What happens if a heat exchanger cracks?

If a crack makes its way through the walls of your heat exchanger, dangerous carbon monoxide fumes can leak into your home’s air. One of the best ways you can protect your home from the dangers of a cracked heat exchanger is to know how those cracks develop in the first place.

Does condensation evaporate in a furnace?

This condensation eventually evaporates after a few minutes of use. In an oversized furnace, however, that condensation doesn’t have enough time to evaporate.