The probable causes of pin floc or stragglers in effluent include the onset of de-nitrification or excessive grease amounts in the mixed-liquor suspended solid. An industrial waste monitoring and enforcement program can at least minimize grease going into the aeration system.

What causes pin floc?

Pin floc occurs most commonly at starvation conditions -- a very low F/M and long sludge age. Chronic toxicity can also cause a pin floc condition. Free floating filaments can, at times, cause a dispersed growth problem.

Why is my activated sludge not settling?

Dominance of filamentous bacteria in activated sludge can cause problems with sludge settling. At times excessive numbers of filamentous microorganisms interfere with floc settling and the sludge becomes bulky. This bulking sludge settles poorly and leaves behind a turbid effluent.

What is floc forming bacteria?

Floc is a collection of smaller particles agglomerating into larger particles containing particulate matter, debris, bacteria and Bio-polymers. Some of the positive aspects of floc forming bacteria is that they settle out easily as solids, reduce the need for polymers in clarifiers and reduce consumption in dewatering applications.

What are the negative effects of floc forming bacteria on sludge?

They can reduce the amount of "pin" floc. Some of the negative aspects are that they can interfere with separation and compaction of activated sludge and cause bulking when predominant. They can affect the sludge volume index (SVI) and they can cause poor settling if dominant. Floc forming bacteria are usually desired.

What is the significance of the presence of pin or straggler floc?

What are the positive aspects of floc forming bacteria?

What are filamentous bacteria?

What does the color of a floc mean?

What are the negative aspects of activated sludge?

Can chlorination cause filaments to grow back?

Is a floc a good or bad structure?

See 2 more

What causes pin floc?

Pin floc occurs most commonly at starvation conditions -- a very low F/M and long sludge age. Chronic toxicity can also cause a pin floc condition. Free floating filaments can, at times, cause a dispersed growth problem. Here, the cause is filament-specific and is the same as for filamentous bulking (discussed below).

What causes pin floc in water treatment?

Pin-floc also occurs in systems where solids are unintentionally being returned from solids processing. Excessive solids in anaerobic or aerobic digester supernatant or improper solids capture from sludge dewatering systems can all cause excessive loads of tiny sludge particles that will show up as pin-floc.

What causes floating sludge?

And more importantly, what can be done to control it. First floating sludge is most often caused by: Denitrification – small nitrogen gas bubbles float the sludge in the clarifier creating floating sludge chunks with small bubbles entrapped. Fats, Oils & Grease – simply put, FOG floats on water.

How do I reduce pin floc?

Pin floc leads to a more turbid effluent. It is most commonly the result of exceedingly high sludge age. Reducing sludge age often minimizes the occurrences of pin floc. Algae growth within secondary clarifiers is common for uncovered secondary clarifiers.

Why is my floc not settling?

The water needs to be still and not moving for the floc to work. Otherwise, the floc may not effectively clump together. And if the debris has already sunk to the bottom after using floc, you will stir the debris back up which will mean you'll need to wait for it to settle again before you can vacuum it out.

What chemical causes flocculation?

alumChemicals (coagulants) are added to the water to bring the nonsettling particles together into larger, heavier masses of solids called floc. Aluminum sulfate (alum) is the most common coagulant used for water purification. Other chemicals, such as ferric sulfate or sodium aluminate, may also be used.

How do you get rid of floating sludge?

Floating-sludge clumping due to septicity may be remedied by maintaining dissolved oxygen at a minimum level of 1.0 Mg/L, along with making sure adequate mixing is occurring in the aeration tank.

What happens if MLSS is high?

If the MLSS concentration is above the desired concentration, the wasting of the excess solids will have to be started or increased. If the MLSS concentration is below the desired concentration level, wasting should be decreased or stopped.

How do I stop sludge bulking?

To avoid sludge bulking some of the flow that enters the reactor can be bypassed, recycle ratio can be increased, lime or soda can be added to the reactor or the re-aeration rate increased.

How are flocs removed?

After flocculation is complete, the large solid masses can be removed from the wastewater stream. This is done either through settling where the floc drops to the bottom for removal or through the use of filters which capture the floc in the filter material.

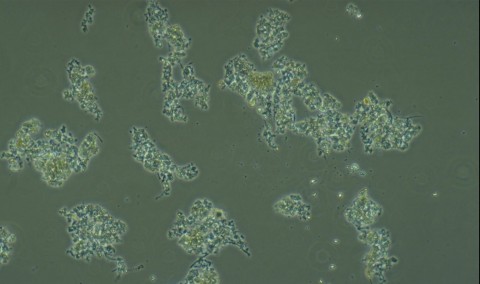

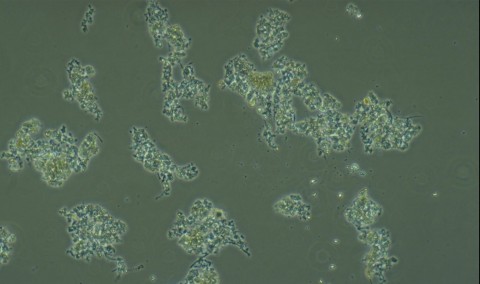

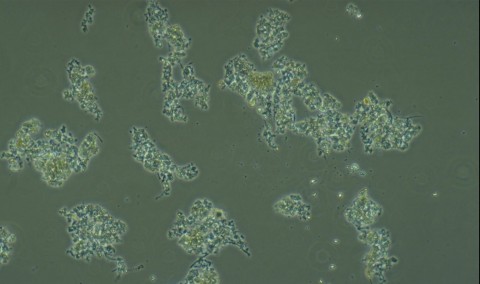

What is pinpoint floc?

Very small floc (the size of a pin point) that does not settle out of the water in a sedimentation tank or clarifier.

What happens if MLSS is low?

However, an MLSS concentration that is too low can reduce BOD removal rates and disrupt settling during secondary clarification as a critical mass is essential in order to form a dense, uniform sludge blanket.

What is pinpoint floc?

Very small floc (the size of a pin point) that does not settle out of the water in a sedimentation tank or clarifier.

How can flocculation be prevented?

Nonionic surfactants prevent flocculation by steric repulsion. Hydrophilic nonionic surfactants such as alcohol ethoxylates can be considered as low molecular weight polymeric surfactants, the longer the length of the hydrophilic part the better the stabilization against flocculation of o/w emulsions.

What factors influence coagulation and flocculation?

The factors that influence coagulation–flocculation are, among others, temperature, pH, effluent quality, dosage and coagulant type (Nnaji 2012; Jin 2005; Ma et al. 2001). The suspended particles vary considerably in source, composition charge, particle size, shape, and density.

During which process floc is formed?

Floc is formed in secondary treatment of sewage. Floc formation is the aggregation of bacteria and fungal filaments in a mesh like structure. This aggregation is known as floc. When BOD and hence pollution is reduced, effluent is passed into a settling tank.

What are the factors that affect sludge settling?

Changes in temperature, pH, DO and sludge age, or even amounts of available nutrients such as nitrogen, phosphorus, oils and grease, can affect these bacteria. Dominance of filamentous bacteria in activated sludge can cause problems with sludge settling.

What causes foaming in aeration basin?

Some filamentous microorganisms may cause foaming in the aeration basin and clarifiers. Algae and fungi are photosynthetic organisms and generally do not cause problems in activated sludge, their presence in the treatment system usually indicate the kinds of problems associated with pH changes and older sludge.

What is activated sludge?

Activated sludge isn’t a thing, it’s a process. As a sewage and industrial wastewater treatment, it makes use of air and a biological floc composed of bacteria and protozoa. The idea in controlling activated sludge is to keep the wastewater biomass-to-food ratio in balance. To control activated sludge, you need to "have a handle" ...

How to control activated sludge?

To control activated sludge, you need to "have a handle" either on aeration, sludge-wasting or return-sludge flow. Aeration-rate adjustment is probably the simplest way to go. It involves, however, more than measuring aeration-basin dissolved oxygen (DO) concentration once each day.

Why does my diffuser header boil?

The probable causes of equipment issues often include leaks in the aeration-system piping, plugged diffusers or air discharging from diffuser-header blow-off pipes, causing local boiling to occur on surfaces near the diffuser-header pipe or insufficient or inadequate oxygen transfer.

What happens when sludge is not wasted?

If sludge is not wasted, the secondary clarifier eventually fills up with solids.

What causes cloudy effluent?

For any conventional activated-sludge process , the probable causes of cloudy effluent include that mixed-liquor suspended solid ...

Why does my diffuser header boil?

The probable causes of equipment issues often include leaks in the aeration-system piping, plugged diffusers, air discharging from diffuser-header blow-off pipes, causing local boiling to occur on surfaces near the diffuser-header pipe or insufficient or inadequate oxygen transfer.

Why does sludge foam?

Old sludge conditions usually cause a dark brown, thick, scummy foam. It is usually caused by the growth of Nocardia or Microthrix parvicella, both of which grow at the high MCRT/low F/M condition associated with old sludge. A treatment pressure is required to decrease the total sludge units in the system. Thus, one must increase wasting and try to remove foam from the system. Once Nocardia has started to grow profusely, it is difficult to eliminate through increased wasting. Therefore, removal of foam from the system becomes more important. Foaming due to M. parvicella appears to occur more during colder temperature conditions while Nocardia can bloom profusely under higher temperature conditions. Both also appear to like oils and grease in their diets.

What causes high effluent suspended solids?

High effluent suspended solids are usually caused by one of two conditions: either individual particles that will not settle are discharged or the sludge blanket in the clarifier washes out. Either of these can cause conditions 6 through 24 to occur. Look first at clarifier blanket washout related to conditions 6 through 17. In this situation, the sludge blanket in the clarifier actually rises close enough to the surface so that it washes over the effluent weir. To learn the reason for the clarifier-blanket washout, the first thing to do is to look at the sludge settleability. If the problem is not a blanket wash-out, it is individualparticle washout. The individual particles may be tiny pin-floc, large straggler-floc or individual, dispersed cells. Physical observation of the effluent and microscopic observation of the mixed liquor or effluent will show which type or combination of types of individual particles is involved.

What bacteria grow well under low oxygen?

Type 1701, Sphaerotilus natans, and Haliscomenobacter hydrossis have all been known to grow profusely under low dissolved oxygen conditions. In recent years, it came to light that Microthrix parvicella also grew well under low DO conditions at high MCRT. Also, it was not known until recently that as the food-to-microorganism ratio increases, aeration basin dissolved oxygen also needs to increase, otherwise low DO bulking can occur. For instance, to protect a system with an F/M of approximately 1.0, almost 5 mg/L DO is required (watch potential denitrification problems). That F/M is defined as pounds of COD removed per pound of ML VSS in the aeration tank (Jenkins, et aI., 1993).

Why is white foam in aeration tanks?

White billowy foam is caused by high concentrations of surfactants such as detergents. It is not nearly the problem today that it was before biodegradable detergents were used. Condition 4 occurs at start-up of a system where a young sludge exists due to low mixed liquor suspended solids concentrations. In this condition there are just not enough solids present to break the surface tension of the surfactant bubbles that form. Thus, billowy white foam can accumulate on the aeration tank and can even be blown around by the wind. The condition is usually short-lived since at start-up the operator is usually applying oxidative pressure by increasing the total sludge units in the system. If the condition occurs due to previous excessive wasting, the solution is still to decrease wasting and increase the total sludge units in the system.

What causes slime bulking?

Slime bulking (Jenkins, et al., 1993) is usually caused by a nutrient deficiency. As in Condition 2, ammonia or nitrate must be added if the ammonia plus nitrite plus nitrate is less than 1 mg/L. Phosphate must be added if the phosphate is less than 0.5 mgIL in the effluent. Slime bulking is usually associated with industrial waste, but may be found in municipal systems that have high concentrations of industrial wastes discharged to them. Even higher concentrations of N & P may be required with certain industrial wastes. This is true if the organic loading comes from easily metabolized materials, such as simple sugars, short-chain organic acids, or alcohols. These may be metabolized so rapidly that excess N and P are required in the system to ensure that the local concentrations are high enough. Complete mixing may also help in this situation.

Why is my slime thick?

A grayish slimy foam that is very thick is commonly caused by nutrient deficiencies. It is often noted with a slime bulking condition. Those deficiencies may be either nitrogen or phosphorus. The solution usually involves addition of the limiting nutrient, such as ammonia to provide nitrogen, or phosphoric acid to provide phosphorus. There is usually enough nutrient if the ammonia plus nitrate in filtered (0.45 μm) effluent is greater than 1 mg/L and the soluble orthophosphate is greater than 0.5 mg/L (Jenkins, et al., 1993). However, in certain cases where easily degradable, soluble BOD is available, higher N and P concentrations may be necessary.

Does 0041 grow well on aeration?

Types 0041, 0675, and 0092 along with M. parvicellaare known to grow well on slowly metabolized food. There are no real answers to controlling this growth to date, but it appears that maintaining good mixing and proper dissolved oxygen throughout the aeration process helps. These are also associated with older sludges. Therefore, reducing MCRT often reduces their growth.

What is the formation of a floc?

Floc-forming species share the characteristic of the formation of an extracellular polysaccharide ("slime") layer, also termed a glycocalyx. This material, which consists of polysaccharide, protein and sometimes cellulose fibrils, "cements" the bacteria together to form a floc. Floc formation occurs at lower growth rates and at lower nutrient levels, essentially starvation or stationary growth conditions.

What causes activated sludge?

Most activated sludge upsets and loss of process control are caused by one of several microbiological problems which include poor floc formation, pin floc, dispersed growth, filamentous and slime bulking, filamentous foaming, zoogloeal bulking, nitrification and denitrification problems and toxicity. Use of the microscopic examination and the OUR test are invaluable tools in troubleshooting the activated sludge process. Once the cause of the problem or upset is known, specific remedies appropriate for the problem can be used. Short term control methods such as chlorination are often used to quickly stop a bulking problem. However, the best approach is to investigate the long-term control methods suitable for the problem that is occurring to achieve trouble free operation.

What causes foaming in wastewater?

Three filaments cause foaming: Nocardia, M. parvicella and type 1863. All of these filaments grow on grease and oil, and these can become a problem when grease and oil are high in amount in the influent wastewater. Systems that lack primary clarification (the main grease and oil removal mechanism) appear to suffer more foaming problems. Communities with enforced grease and fat ordinances appear to suffer less from foaming problems. Also, disposal of septage, which contains substantial grease and oil content, to small activated sludge systems has been associated with foaming problems.

What are the short term measures of sludge juggling?

Short term measures include: "sludge juggling" - changes in return activated sludge (RAS) rates and in waste feeding points; polymer and coagulant addition to aid sludge settling; and chlorination.

How to improve activated sludge settling?

There exist several methods of chemical addition to enhance activated sludge settling. Most used are synthetic, high molecular weight, anionic polymers alone or in combination with cationic polymers that serve to overcome the physical effects of filaments on sludge settling. These are usually added to the MLSS as it leaves the aeration basin or to the secondary clarifier center well. Use of polymer does not significantly increase waste sludge production but can be quite expensive, up to $450. per million gallons treated (obviously this is only used if absolutely necessary). A polymer supply company should be consulted for advice on selection of a polymer and its dosage (the chemical composition of most polymers is a trade secret). Jar testing should be performed to determine the type of polymer needed and its dosage, which is quite plant specific. Further, this jar testing needs to be repeated often, as the needed polymer and its dosage can change, particularly if the filament type(s) change.

What are some methods of intermittent bulking?

Several methods useful for intermittent bulking problems, but which will not solve a chronic problem, are manipulation of RAS flow rate and manipulation of waste feed points to the aeration basin to minimize the adverse effects of a bulking sludge.

What causes a floc to not separate from liquid?

The growth of excessive numbers of filamentous bacteria results in a floc that cannot separate from liquid due to the hair-like projections of the filaments. This condition is know as “sludge bulking”, and it can lead to the total loss of the solids inventory in the treatment system as the sludge is washed out of the secondary clarifier. ...

What is activated sludge?

When an activated sludge process is operating well, it will primarily contain a mixture of simple round and rod shaped bacteria, an assortment of higher life forms known as protozoa, and a few long, hair-like filamentous bacteria that add strength to the bio-flocculated structure (known as floc).

What is old sludge?

Old sludge tends to settle very rapidly but leaves pin floc in the supernatant and a surface material known as “ashing”. Ashing appears just as though ashes were scattered on the surface of a settleometer test or secondary clarifier.

Why is mixed liquor not always the case?

The reason has to do with the fact that the type of microorganisms in the mixed liquor has more to do with how the sludge will settle and compact than the concentration does.

Does a settleometer test show MLSS?

The settleometer test yields a great deal of information about how well sludge will settle and compact, but it does not reveal the MLSS concentration. It would seem obvious that if the MLSS concentration increases, the settling rate would slow down. (That is; thicker mixed liquor should settle more slowly). To some extent, this holds true, but it is not always the case. The reason has to do with the fact that the type of microorganisms in the mixed liquor has more to do with how the sludge will settle and compact than the concentration does.

What is the significance of the presence of pin or straggler floc?

The presence or absence of pin or straggler floc, which can be responsible for high-suspended solids (TSS) in wastewater, is also an important observation when examining floc structure. The presence of many filamentous bacteria is also examined to determine if filamentous bulking is responsible for poor settling.

What are the positive aspects of floc forming bacteria?

Some of the positive aspects of floc forming bacteria is that they settle out easily as solids, reduce the need for polymers in clarifiers and reduce consumption in dewatering applications. If the right type of biomass is developed, a reduction in solids handling can also be found.

What are filamentous bacteria?

Filamentous Bacteria are bacteria that grow in long thread-like strands or colonies. Some of the positive attributes of filaments are that they are very good BOD removers. They add a backbone or rigid support network to the floc structure. They help the floc structure to filter out fine particulate matter that will improve clarifier efficiency. They help the floc to settle if in small amounts. They can reduce the amount of "pin" floc.

What does the color of a floc mean?

Clear indicates a very young biomass. Golden brown indicated a healthy floc. Black indicates the floc is turning anaerobic and running out of air or is older. Sometimes floc can be colored if the influent contains dyes. Usually this does not impact anything unless there are heavy metals or toxic compounds that will not pass a leach test when disposing of the solids.

What are the negative aspects of activated sludge?

Some of the negative aspects are that they can interfere with separation and compaction of activated sludge and cause bulking when predominant. They can affect the sludge volume index (SVI) and they can cause poor settling if dominant. Floc forming bacteria are usually desired.

Can chlorination cause filaments to grow back?

Chlorination is only a quick fix. Without process changes, filaments will grow back after chlorination. Wastewater Biomass Analyses and Cooling Tower Analyses also available.

Is a floc a good or bad structure?

What may be considered good floc structures in one system may be poor floc structures in another wastewater treatment plant. Nonetheless, some characteristics can be examined to determine relative floc condition. Generally, the more firm and compact a floc is, the better it will settle.