What does 5s mean in workplace?

Quality Glossary Definition: Five S’s (5S) 5S is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. It’s designed to help build a quality work environment, both physically and mentally.

What does 5s stand for simplify stabalize scrub straighten sustain?

5S is an abbreviation for Sort, Straighten, Shine, Standardize, Sustain

What are the principles of 5s?

- Shine. Of all the principles of 5S, “shine” is perhaps the most self-explanatory: it means intensive cleaning of the work environment.

- Standardize. Standardization is key to continuous improvement. ...

- Sustain. Once standardization has been implemented, the last of the principles of 5S is ensuring the practices are sustained going forward.

What are the 5 steps of 5s?

What are the 5 steps?

- Sort, the first step. In the first step, Sort you go through all the materials, tools, and equipment on the area sorting between necessary and unnecessary items.

- Second S, Set in order. ...

- Shine, the third step. ...

- Standardize is the fourth S. ...

- Sustain, the most important step of 5S. ...

- Benefits of 5S. ...

What does 5S mean in lean?

The 5S pillars, Sort (Seiri), Set in Order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke), provide a methodology for organizing, cleaning, developing, and sustaining a productive work environment.

What is meant by 5S in the workplace?

5S is a five step methodology for creating a more organized and productive workspace: Sort, Straighten, Shine, Standardize, and Sustain. 5S serves as a foundation for deploying more advanced lean production tools and processes.

Where does the 5S term come from?

Called 5S after its alliterative core tenets—sort, set in order, shine, standardize, and sustain—the methodology originated on the Toyota assembly line, then went on to become a foundational element of the lean manufacturing wave that swept the world in the 1980s.

What is 5S quality?

Quality Glossary Definition: Five S's (5S) 5S is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. It's designed to help build a quality work environment, both physically and mentally.

Why is 5S important to safety?

Each S Helps with Safety Sort – Sorting an area out, removing any clutter, and ensuring the only items in an area are those that are strictly needed will eliminate obstacles. There are less items to run into, trip over, catch on fire, or cause other types of damage. A well-sorted workplace is a safer workplace.

What are the 5 principles of 5S?

What is 5S? 5S is a systematic way of organizing workplaces by eliminating waste, improving flow, and reducing the number of processes where possible. It applies the five principles: Sort (seiri), Set in order (seiton), Shine (seiso), Standardize (seiketsu), and Sustain (shitsuke).

How do I apply for 5S at work?

The Steps of 5SSort. Seiri (tidiness) Remove unnecessary items from each area.Set In Order. Seiton (orderliness) Organize and identify storage for efficient use.Shine. Seiso (cleanliness) Clean and inspect each area regularly.Standardize. Seiketsu (standardization) Incorporate 5S into standard operating procedures.Sustain.

How do you apply 5S in your everyday life?

Applying 5S to Everyday LifeRemove old clothes from your wardrobe that you no longer wear, to make it easier to choose from the clothes that you do wear (Sort)Always keep your keys in a standard place, preferably near the front door (Straighten)Wash the dishes regularly, rather than letting them pile up (Shine)More items...•

What are the 5 principles of 5S?

What is 5S? 5S is a systematic way of organizing workplaces by eliminating waste, improving flow, and reducing the number of processes where possible. It applies the five principles: Sort (seiri), Set in order (seiton), Shine (seiso), Standardize (seiketsu), and Sustain (shitsuke).

What are the 5 steps of 5S?

The Steps of 5SSort. Seiri (tidiness) Remove unnecessary items from each area.Set In Order. Seiton (orderliness) Organize and identify storage for efficient use.Shine. Seiso (cleanliness) Clean and inspect each area regularly.Standardize. Seiketsu (standardization) ... Sustain. Shitsuke (discipline)

What is 5S in health and safety?

5S involves the removal of unnecessary items in the workspace, thus improving productivity with minimal waste of time. The method promotes a clean working environment to reduce or totally eliminate work-related injuries. It helps ensure workplace safety.

How do you apply 5S in your everyday life?

Applying 5S to Everyday LifeRemove old clothes from your wardrobe that you no longer wear, to make it easier to choose from the clothes that you do wear (Sort)Always keep your keys in a standard place, preferably near the front door (Straighten)Wash the dishes regularly, rather than letting them pile up (Shine)More items...•

What are the benefits of 5S?

The results you can expect from a 5S program are: improved profitability, efficiency, service and safety. The principles underlying a 5S program at first appear to be simple and obvious common sense. However, when implemented in a disciplined manner the above benefits will accrue.

What is 5s in Kaizen?

What Is 5S? 5S is the foundation of all improvements and is the key component of establishing a Visual Workplace. Both are a part of Kaizen — a system of continual improvement which is a component of lean manufacturing. A 5S program focuses on having visual order, organisation, cleanliness and standardisation.

What Does 5S Stand For?

Originally, 5S comes from 5 Japanese terms starting with the letter S: Seiri, Seiton, Seiso, Seiketsu, and Shitsuke. Below is the 5S Japanese to English translation and their definitions.

Who Is Involved in 5S?

It’s true that employee involvement plays a critical role in the success of 5S, but so does the participation of company leaders (e.g., manager, supervisor) and business owners .

How Do You Use 5S in the Workplace?

It is a hands-on tool that establishes workplace organization to benefit both the company and the employees.

What Industries Can Benefit From 5S?

Popular industries that already implement the 5S system are manufacturing companies, factories, warehousing, and related industries . But of course, other industries can also significantly improve their work quality and efficiency by using the 5S. Some specific ventures include:

What Are The Benefits of Lean 5S?

Implementing the Lean 5S in the workplace allows both the company and its workers to reap several benefits, such as:

Origin of 5S

5S is an organization system in the workplace whose purpose is to make as easy and efficient as possible the tasks within the factory. The 5S origin comes from the Toyota ‘s Production System which was developed by Tahichi Ohno during the 60s in Japan. Its five S come from five Japanese words which are Seiri, Seiton, Seiso, Seiketsu and Shitsuke.

Steps of the 5S

But, Let´s review what each phase involves and what is particularly important in each step:

What does Lean manufacturing have to do with 5S?

As a matter of fact, the 5S system is a foundational part of the lean manufacturing. Only once the 5S system begins to be part of the organizational culture of the company, initiatives such as kanban or kaizen can be implemented successfully.

Benefits of the 5S

However, it is not all about the benefits of the 5S, it is more about the harm of not working with 5S in your shop floor and the main consequences. Maybe the most important is that your company will not be able to compete with modern companies as they will have a huge structural difference.

How to implement the 5S

When implementing a 5S work organization in your company’s shop floor, you are looking for a way to make the complex, just simple. And it can be done in several ways, but all of them need a tool to help you in this implementation process. mlean Production System® is a digital tool that brings you all what you are looking for.

Request a Demo

If you want to implement a 5S methodology, the best option is to use a specific tool such as our 5S digital Tool. Request a demo of our 5S software and define the state of reference of the workstation or line, following the 5S methodology. Launch the audit to maintain the standard.

What is 5S in healthcare?

Everything Is 5S: A Simple Yet Powerful Lean Improvement Approach Applied In A Preadmission Testing Center ( Quality Management Journal) A pre-admission testing center applied 5S to the patient flow process, streamlining steps and eliminating waste. Results show that the 5S framework is an effective and simple model for process design and improvement.

What is the 5S philosophy?

The 5S philosophy applies in any work area suited for visual control and lean production. The 5S condition of a work area is critical to employees and is the basis of customers' first impressions. The Five S's. 5S benefits.

What are the 5S tools?

The 5S quality tool is derived from five Japanese terms beginning with the letter "S" used to create a workplace suited for visual control and lean production. The pillars of 5S are simple to learn and important to implement: 1 Seiri: To separate needed tools, parts, and instructions from unneeded materials and to remove the unneeded ones. 2 Seiton: To neatly arrange and identify parts and tools for ease of use. 3 Seiso: To conduct a cleanup campaign. 4 Seiketsu: To conduct seiri, seiton, and seiso daily to maintain a workplace in perfect condition. 5 Shitsuke: To form the habit of always following the first four S’s.

What are the pillars of 5s?

The pillars of 5S are simple to learn and important to implement: Seiri: To separate needed tools, parts, and instructions from unneeded materials and to remove the unneeded ones. Seiton: To neatly arrange and identify parts and tools for ease of use. Seiso: To conduct a cleanup campaign.

What is the 5S lean method?

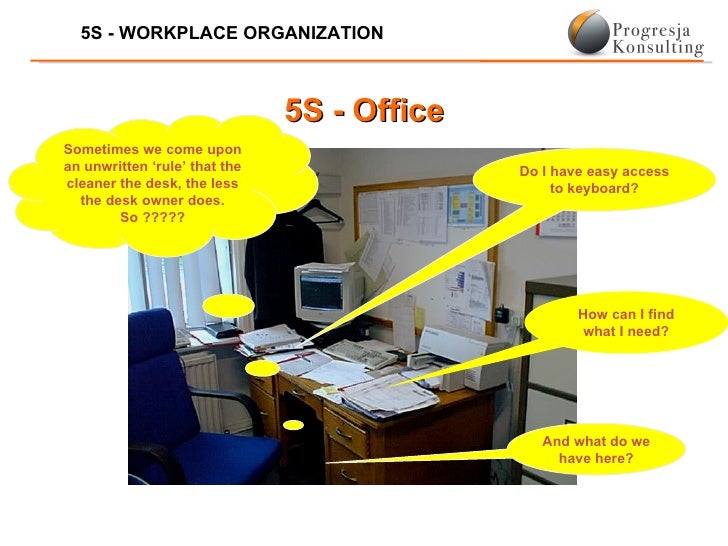

Office Efficiency ( Quality Progress) The 5S lean method is often used in manufacturing, but it can be adapted for office settings to make information workflows more efficient. Specifically, better organization and management of information flow allows knowledge workers to make better decisions about prioritizing and executing tasks.

What is the 5S tool used by Kaiser Permanente Colorado?

During meetings with internal and external stakeholders, Kaiser Permanente Colorado’s Medicaid Enrollment Project Team used the lean 5S tool to improve the enrollment template, as well as the template process. They implemented the 5S pillars as follows:

Who is using 5s in everyday life?

Utilizing 5S in Everyday Life ASQ member Alexander Tucker, a chemist at Capsugel, has been using the 5S tool in his home life. You won’t stop smiling as he humorously recounts the ways he has organized his bathroom, planned trips to the grocery store, and even trained his dog to be a quality canine.

What does the 5S stand for?

5S stands for the 5 steps of this methodology: Sort, Set in Order, Shine, Standardize, Sustain. These steps involve going through everything in a space, deciding what’s necessary and what isn’t, putting things in order, cleaning, and setting up procedures for performing these tasks on a regular basis.

What is Iskaizen?

What Is Kaizen? Kaizen is a Japanese term meaning “change for the better” or “continuous improvement.” It is a Japanese business philosophy regarding the processes that continuously improve operations and involve all employees.

What does 6 S mean?

Standardize, Sustain, Safety 6S, a modification of the 5S methodology which includes “Safety” as the 6th S. It is a lean process improvement tool that stands for Sort, Set in Order (aka Straighten or Stabilize), Shine (aka Scrub or Sweep), Standardize, Sustain, Safety. 6S can be the shortened form of Six Sigma.

What is 5s methodology?

Other Questions/Answers. 5S is a popular methodology that is focused on eliminating waste and improving organization. It is typically applied to workplace environments, especially manufacturing, warehousing, other related industries. It can be used in just about any field, or even in one’s personal life. The methodology gets its name ...

Where did the 5S come from?

The concept originated in Japan, so the actual words are in Japanese, but it has been translated into English, and has kept the 5S’s in place. The following are what each of the S’s stands for, and why it is important for any business.

What is the first step in the 5S process?

Sort, which is from the Japanese word ‘Seiri,’ is the first step in the 5S process. The purpose of this step is to make sure that every item in the facility has a place where it belongs. This will help ensure nothing is lost, and will also reduce the amount of time that is wasted looking for things that aren’t put back where they should go. Having a facility that is sorted properly also reduces the expenses associated with replacing tools and inventory that are either lost or stolen because they aren’t properly kept track of.

Who invented the 5S?

5S is based on the CANDO system developed by Henry Ford in the early 20th century. Watch this video, which explains the steps, and provides video time lapse of how a healthcare organization performed their 5S event. Here is a breakdown of each ‘S’. 1.

What are the other options to include with 5S?

The other options to include with 5S are Safety, Security and Spirit. Safety: Safety is often said that it is implied within 5S that everything should be done with safety as the number one priority, but to ensure that is the case, Safety is added as an additional S.

What is the 5 S methodology?

In simple terms, the five S methodology helps a workplace remove items that are no longer needed (sort), organize the items to optimize efficiency and flow (straighten), clean the area in order to more easily identify problems (shine), implement color coding and labels to stay consistent with other areas (standardize) and develop behaviors that keep the workplace organized over the long term (sustain).

Why is spirit added to 5s?

Spirit: To ensure that the focus of 5S is to make it easier for the workers, Spirit is added to remind people that it should be fun, and that creativity is key to coming up with new ideas and better ways to implement 5S. Without engaged workers, the 5S approach will not last or be successful.

Does Toyota use 5S?

However, Toyota and most other companies use the 5S as a standard. Other improvement experts like Paul Akers have promoted the use of 3S on a daily basis in his book “2 Second Lean,” to focus on Sort, Sweep and Standardize, and not focus as much on straighten or sustain.

Does 5S work?

5S also works well in the home. A popular method is the KonMari method, developed by Marie Kondo. Here are some resources about her.

What is 5S?

5S is a Lean tool that you can use to organize any workspace in order to make it clean, organized, and safe. The end goal of 5S is to limit any extra motion that people have to complete in the area. This includes bending or reaching to grab a tool or wasting time moving unneeded materials around to find something.

What does 5S stand for?

The first step of 5S is known as seiri in Japanese which loosely translates to sort. In this sorting step, you must identify what tools and materials you need for the task that the area is intended for. You should consider everything that is currently in the area. This includes:

What are the benefits of 5S?

If you are successfully able to implement 5S in a workspace, it can have tremendous benefits in many areas.

What are the challenges of 5S, and how can you overcome them?

At the surface level, 5S appears to be pretty simple and common sense. How difficult can organizing and cleaning really be, right? You may have gotten the sense already throughout this article, but the 5S process can definitely pose many challenges.

Conclusion

Overall, 5S is a very powerful tool to drive productivity through thoughtful organization. These concepts can be applied far beyond the typical manufacturing environment and in any area of your life. The next time that you are organizing a space in your home or office, you may want to consider questions such as: