What are the different sizes of pitch chains?

Since chains are used as a drive and as part of a conveyor system, the range of sizes can be quite significant. Smaller pitch chains are often found in light to moderate load applications while larger pitch chains are used in heavier load applications.

What are the chain dimensions for roller chains?

The three charts below list complete chain dimensions for single, double & triple metric roller chains. Quick Tip: The 3 most important dimensions to measure first is the Pitch (P), Roller Diameter (d1) & Inner Width (b1). Anything labeled special order is available on a per quote basis for resellers & OEM's - Larger MOQ are required.

What is the pitch of a bike chain link?

The bike chain link pitch (distance between pin centers) is standardized and equals 1/2 inch or 12.7 millimeters. Historically there were also other pitch sizes but the 0.5-inch pitch is standard these days. The total length of the bike chain is calculated by multiplying the number of links with a 1/2 inch link pitch.

Is the pitch of the drive sprocket the same as the chain?

Additionally, the pitch of the chain, drive sprocket and nose sprocket ought to be the same. Which are the best brands and their pitch sizes? Different brands come with different chainsaw pitches.

What does the pitch mean on a chainsaw chain?

Chain pitch is the size of the chain and is defined as the distance between any three consecutive rivets divided by two. Oregon chain is made in several pitches - 1/4" is the smallest, 3/8" is the most popular, and 3/4” is the largest.

What does 3/8 mean on a chainsaw chain?

If you decide to measure the pitch yourself, just remember to measure between the middle points of 3 rivets on the chain, and then divide the number by 2. So, for a 3/8" pitch chain, the measurement between three links would be 3/4" (. 75"), which is 3/8" (. 375") when divided by 2.

What chainsaw pitch is best?

Experts say the best chainsaw chain for cutting firewood is the Husqvarna High Performance 18 inches, 0.05 gauge, 0.325 pitch chain.

How do I know what pitch my chain is?

To determine the pitch (chain size), you'll need to measure the distance between any three consecutive rivets, then divide the result by 2. The rivets are the small, round pegs/studs that hold the chain segments together. Measure from the first to the third, then divide that number in half to get your chain pitch.

What is the most common chainsaw chain size?

Most chainsaws use 0.050" (1.3 mm) and 0.058" (1.5 mm) gauge chains. 0.043" (1.1 mm) and 0.063" (1.6mm) gauge chains are less common.

What is the difference of 3/8 and 325 in chainsaw chain?

The three-eighths chain is a beefier saw and better suited to one that has more horsepower. It has larger teeth and a heavier duty chain, so it requires more horsepower to operate correctly. Older saws tend to have a three-eighths chain and tends to be less expensive than its newer cousin.

Why do Loggers Run chainsaw bars upside down?

Every chainsaw bar has been designed to be mounted right-side up or upside down. The reason for this is that it allows the user to extend the life of his chainsaw bar by 50%. Flipping the bar will give the heavily-used areas some relief from wear and tear.

What chainsaw chain cuts the fastest?

full chisel chainA full chisel chain is a chain with square cornered teeth, and they're known for being the fastest cutting blade shape available. A full chisel chain also has a higher number of teeth than other chain options(full chisel is also known as a standard chisel chain).

What chainsaw chain stays sharp the longest?

The x-Cut line of Husqvarna chains is also designed to stay sharp longer, so you can cut for a longer amount of time before the chain needs sharpening. The SP33G features semi-chisel cutters, a . 325 pitch, and a . 050 gauge.

What size file do you use on a 3/8 chainsaw chain?

File sizesChain pitchRound file diameter1/4"4.0mm.3254.8mm3/8"5.2mm.4045.5mm

What does 91 mean on chainsaw chain?

0:002:45How To Identify Your Chainsaw Chain - YouTubeYouTubeStart of suggested clipEnd of suggested clipThe first bit of information is a type of chain that you have this chain in front of you is a typeMoreThe first bit of information is a type of chain that you have this chain in front of you is a type 91 typical example has 91 stamped into the drive links. This makes it a type 91 chain.

How do I know what chainsaw chain to buy?

When choosing a chainsaw chain, you first need to know the pitch, the gauge and the number of drive links. Once you have these, everything else about the choice is basically about what you prefer. Pitch is the average distance between two rivets on the saw chain.

What is the best size chainsaw for cutting firewood?

Many homeowners find that a 14- to 16-inch chainsaw is a good length for them. That's long enough to limb-up trees, cut down small trees, and cut most firewood, but it's also short enough that it's easy to control the saw.

What size chainsaw do loggers use?

Professional loggers usually go for chainsaws with engine power ranging from 40cc and above, with a guide bar length of 14 inches and more.

Does skip tooth chain cut faster?

A skip chain has fewer cutting teeth than a conventional chain which means it won't be dragging as many teeth through the wood you're cutting. Less drag on the chain means less power is needed to cut through the log. That means the motor on your saw runs faster which keeps it in a more efficient power curve.

What chainsaw chain do professionals use?

full chisel chainsaw chainsTypically only professionals and experienced chainsaw users use full chisel chainsaw chains. They are typically used to cut through hardwood such as oak as their square-cornered cutting teeth are more geared up to power through the wood.

What is double pitch carrier chain?

Double pitch carrier type chains are also referred to as oversized roller double pitch chains because the roller extending past the sidebars. This creates a chain that is capable of conveying product from one point to the next with the use of the rollers. Chain Size.

What is double strand heavy chain?

Double-strand heavy roller chains are also commonly referred to as duplex heavy chains and offer superior strength and shock load resistance when compared to their simplex counterpart. Having double the side plates and double the number of rollers that come into contact with each sprocket tooth-pitch means that these chains have nearly double the strength!

What is double pitch conveyor?

Double-pitch conveyor type roller chains are designed with a flat surface on top of the chain for optimal conveying. These chains can be found in a wide range of conveying applications as well as chains for belt and crossbar conveyor systems.

What is single strand chain?

Single strand roller chains are also commonly called simplex roller chains, unlike the other guys who supply chains that are just hot-dipped and heat-treated we offer roller chains with additional performance-driven features such as solid bushings and solid rollers, shot-peened components, and factory pre-loading to dramatically reduce chain stretch.

What is the tensile strength of a roller chain?

Sizing the right roller chain for your application comes down to a few key factors: Tensile Strength - The tensile strength of a roller chain is the rating that represents the force required for breaking the chain. There are three different tensile strength values; minimum, average, and ultimate.

What is the purpose of a roller chain?

The core function of a roller chain is to transfer energy from one point to another to the highest degree. A Roller chain is especially useful in applications that require the transfer of energy to be consistent over a long period of time, or where a shift in direction from linear to rotary is needed, and simply for moving objects from one point to another. Our chains offer superior transmission of energy and function with features such as solid bushings, solid rollers, heat-treated components, and factory pre-loading. View our premium roller chain selection to learn more about our chains or watch the below video.

What are the conditions for roller chains?

Application Conditions - It is important to take a look at certain conditions such as temperature, corrosion, abrasion, and hours in operation . Standard roller chains are manufactured from carbon steel, meaning that their temperature range is limited and they will corrode in abrasive and corrosive applications.

What is a chain pitch?

It is the distance between 3 consecutive rivets on the chain dived by two. Luckily, most chainsaw manufacturers display the measurement on the tool or in the manual.

Which chainsaw brands produce state of the art chainsaws?

However, if you are looking for quality, Oregon, Husqvarna and Carlton produce state of the art chainsaws. Let’s have a look at their respective chain pitch. The above drive link markings can be used to identify the gauge and pitch of the chainsaw.

What is the gauge of a chain?

Chain gauge is the thickness of the Drive link at a point where it fits into the groove while the drive link amount is basically the length of the chain loop.

Why use a 3/8" saw?

The 3/8” is widely used by professionals saw users due to its agility, cutting speed when used with powerful motors, low weight, and flexibility to make accurate and precise cuts.

What is the pitch of a chainsaw?

There are two types of chains and they do two different types of jobs. The .325 and three-eighths pitch pertains to the spacing between the rivets. That spacing is important when you are cutting.

Which chain is better for a small saw?

It tends to work better with small saws that have a high RPM because it causes less drag. The three-eighths chain is a beefier saw and better suited to one that has more horsepower. It has larger teeth and a heavier duty chain, so it requires more horsepower to operate correctly.

Why is it important to have the right chain on your blade?

The right chain on your blade in the right hands can save energy and hours. Consider the chain size when you are purchasing a chainsaw. If the chain you have on your saw isn't cutting it, you might be able to switch it out for a different size with little trouble and maximum payoff. Advertisement.

Is a 325 chainsaw chain faster?

The .325 may be smaller and faster, but it may not be your best bet for your everyday needs. The three-eighths-inch chain is durable and lasts longer than its smaller cousin. This makes it one of the more popular switches for chainsaw users who want to get more out of their saw.

What is the pitch of a bike chain?

The bike chain link pitch (distance between pin centers) is standardized and equals 1/2 inch or 12.7 millimeters. Historically there were also other pitch sizes, but the 0.5-inch pitch is standard these days.

What size chain is used for a motorized bike?

A motorized bike also uses a second chain as a drive. The size #415 drive chain, e.g., King PRO COMPANY bike chain, is thicker and heavier and is explicitly designed for motorized bikes. Coming with a durable and versatile design, it can be used in 2 stroke bikes.

How To Find The Proper Length Of the Chain?

If your old chain still holds a great shape with proper length, you can use it for comprising when buying your new chain .

How to put chain in 5 o'clock?

Take the chain and pass it through the front derailleur cog and keep it put in the 5 o’clock position.

What to use to measure bike chain size?

On the contrary, if you don’t have your old chain, you can also use the largest cog and largest chainring method to measure your bike’s chain size.

How to determine the width of a chain for a bike?

The proper width is determined by the number of rear sprockets your bike has – the more rear sprockets are spaced close together, the narrower chain should be used.

What size chain for a bike?

There are 4 sizes of the internal width of bike chain – 1/8″, 3/32″, 11/128″, and 5/32″: 1/8″ (3.2mm) – some of the bikes with a single rear spro cket. 3/32″ (2.4mm) – some of the bikes with a single rear sprocket, bikes with 5-8 rear sprockets, and derailleurs.

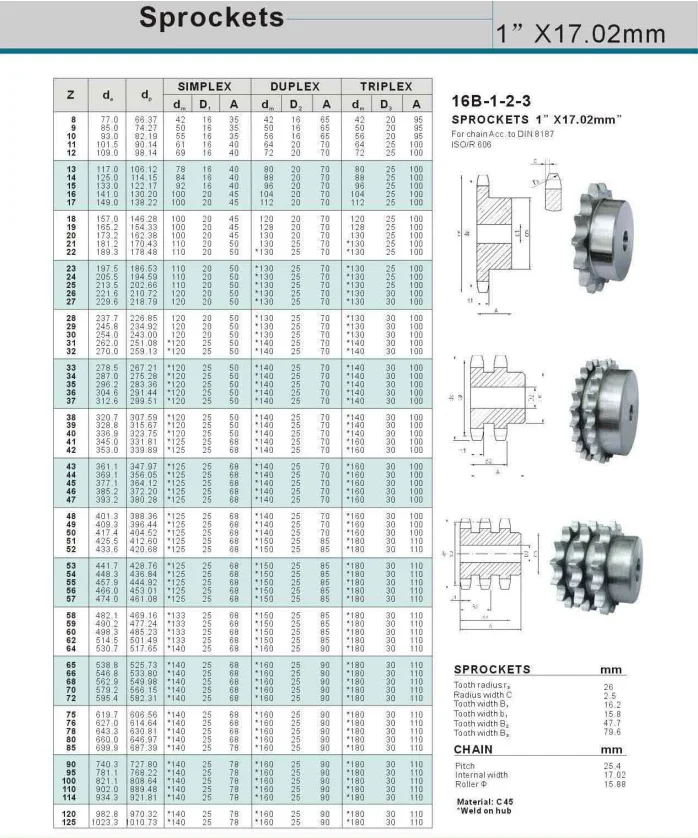

What is pitch diameter?

Pitch Diameter: The pitch diameter is the theoretical circle measured from the center of one roller chain pin to the center of another roller chain pin 180 degrees across when the chain is wrapped around a sprocket.

What is the length thru bore?

Length Thru Bore (LTB): The Length thru Bore or LTB is the distance measured from one face of the sprocket to the opposite face thru the center bore.

How Are Sprockets Measured?

Pitch Diameter: The pitch diameter is the theoretical circle measured from the center of one roller chain pin to the center of another roller chain pin 180 degrees across when the chain is wrapped around a sprocket.

How to contact PEER Chain?

Contact PEER Chain at 800-523-4567 or fill out our contact form. You can also drop us a message at [email protected], and we'll work with you to ensure that we provide you with the exact roller chain sprockets or conveyor chain sprockets that you need. You can even reach our Product Management Department at 847-775-4600 or via email ...

How to tell sprocket size?

Sprocket Teeth: The sprocket Outside Diameter, Pitch Diameter, and Caliper diameter are all derived from the number of teeth. When the chain pitch is known, the most efficient and easiest method for identifying a sprocket size is to count the number of teeth.

What is the most common standard for chainsaws?

The most common standard in the United States is ANSI. Chains are identified by what is called their “pitch,” which refers to the distance from one roller-pin center to the next roller-pin center of a given chain. Chain pitch is always measured in 1/8” increments for ANSI standard chains.

What is a hub type?

Hub Type: All sprockets come in several different configurations to be affixed to a shaft. no hub (A-style); a hub projection from one side (B-style); hub projections from both sides of the sprocket (C-style); or sprocket hubs that accept bushings.

What is the pitch of a chainsaw?

There are several basic parameters for choosing a chainsaw, one of them is the pitch of the saw headset. The pitch depends on the power of the chainsaw, and greatly affects the cutting speed.

What is chain drive?

Chain drives are widely used in many areas of mechanical engineering, structures of agricultural and road machines, machine tool construction , etc. They are used in machine tools, motorcycles, bicycles, industrial robots, drilling equipment, lifting and transport, road construction, agricultural, printing and others. machines for transferring motion between parallel shafts over long distances, when the use of gear drives is impractical, and belt drives are impossible.

When and how to change the chain?

Excessive stretching of the mowing chain over the links is considered a major sign of critical wear. Both the main row and the sprocket with the tire undergo deformation, so the update should be considered comprehensively. If you only plan to replace the chain, then you should resort to trick, since it is not so easy to install new equipment of the same size on an old tire. For regular work, it is advisable to purchase a headset in three sizes. The main parameter will be the step and length. For the medium size, a format should be chosen that directly matches the characteristics of the tire and sprocket. The alternating use of multi-format chains will correct the interaction between the working bodies and the cutting teeth. This is a kind of running-in of the chain teeth by tension. The chainsaw, in turn, should be used in different modes in terms of engine speed, if such an option is provided in principle.

What is Oregon cutting chain?

Chains from Oregon Cutting Systems , which is the representative of a larger company called BlountIncorporation. The latter is considered the leader among manufacturers of saw chains, guide sets, and other accessories (not only for gasoline tools, but also for electric ones). Oregon Cutting Systems is renowned for its patented steel alloy, which, due to its high toughness, is guaranteed to be wear resistant.

What is chain transmission?

Chain transmission refers to gearing transmissions with flexible coupling. The power in the chain drive is transmitted by means of a multi-link pivot chain from the drive to the driven sprocket, located on parallel shafts.

Where are Stihl saw chains made?

This company develops the bulk of the replacement equipment on a production line in Switzerland, using the highest quality raw materials, including high alloy chromium-nickel steel, which allows Stihl products to be as strong and reliable as possible. It is interesting that even with intensive use of the chain of this brand, the carved element will not stretch (and this usually leads to the loss of all standard features), since saw chains are riveted on heated metal.

What is a guide bar on a chainsaw?

A chain with a guide bar is a removable equipment, which means, for example, when deciding which chain is better for a budget-class Stihl chainsaw, you can also consider carved elements of a different class. In other words, owners of budget gasoline chainsaws can choose a durable saw set for their tools, which is more wear-resistant.