What is the best air conditioning filter?

Types of Air Filters

- Fiberglass filter: Fiberglass filters are typically the least expensive option. ...

- Polyester / pleated filters: Pleated filters are available in different widths, but all of them are typically more effective at filtering airborne pollutants than standard fiberglass. ...

- Washable air filters: Washable filters are less common. ...

How to install a filter drier?

- Read the instructions thoroughly. ...

- The system must be pumped down and line depressurized before attempting to install. ...

- Extreme care should be used in handling contaminated refrigerant. ...

- Do not remove seal caps until ready for installation. ...

- Do not install access valve cores until all brazing is completed. ...

- The filter-drier may be installed in any position. ...

Do air filters also remove moisture from air?

While filters and separators are able to remove liquid moisture droplets from a system, they are unable to remove water vapor. In order remove water vapor, you must use a dryer. There are five techniques for removing moisture from compressed air: Cooling plus separation is exactly how it sounds.

Does a cold air intake replace the air filter?

Your cold air intake also makes for freer airflow and less hot air building up in the engine compartment. There are other benefits, too. An aftermarket cold air intake removes the need for a box to encompass the air filter, replacing it with smoother intake tubes. This allows the engine to have an uninterrupted air flow.

What is the purpose of a filter drier?

It is important to locate a filter-drier in a refrigeration system. Its role is to remove moisture from the refrigerant and lubricant by absorbing and retaining moisture deep within the desiccant granules.

Is a filter drier necessary?

A Filter Drier is an important part of an air conditioning system. A Filter Drier is so important that manufacturers normally supply one to install with a new home comfort system.

What are the two purposes of the filter dryer?

Filter driers are usually installed in the liquid line of a dry-expansion refrigeration system, where they have a dual function. First, they trap coarse particulate contamination and copper shavings, and second, they capture any moisture present in the system.

How often should a filter drier be changed?

every 2 yearsAll filter driers should be replaced every 2 years or by manufacturer's recommendation. The Receiver Drier's function in an automotive a/c system is to filter foreign material, remove moisture from refrigerant and to act as a reservoir to supply liquid refrigerant to the TX valve.

How much does it cost to replace AC filter drier?

Air Conditioning Receiver Drier Assembly Replacement Cost - RepairPal Estimate. The average cost for air conditioning receiver drier assembly replacement is between $321 and $403. Labor costs are estimated between $164 and $207 while parts are priced between $157 and $195.

Where is a filter drier located?

Standard driers are often installed directly ahead of the expansion device – one in the outdoor section and one in the indoor section. Another common design is to locate both driers in the outdoor section, where they are easier to service.

What is the difference between a strainer and a filter drier?

Strainers are commonly used to remove larger particles, those visible to the naked eye, so that equipment downstream can work at optimal functionality. Filters, on the other hand, are more typically used to remove smaller particles, those that can't be seen with the naked eye.

How can you tell when a filter drier is stopped up?

If the filter drier is partially clogged, there may be a few degree temp drop across it. However, if the filter drier is completely clogged, there will be a large temperature drop across it and likely frost due to the low temp of the refrigerant exiting the clogged filter drier.

How does a filter drier work HVAC?

A filter-drier in a refrigeration or air conditioning system has two essential functions: one, to adsorb system contaminants, such as water, which can create acids, and two, to provide physical filtration. Evaluation of each factor is necessary to ensure proper and economical drier design.

What happens if you don't replace filter drier?

Unwanted moisture will compromise the correct lubrication of a system and run the risk of internal corrosion. Any unfiltered particles allowed to freely circulate the loop will eventually clog up the system's components (condenser, expansion valve and evaporator) and/or cause the compressor to seize.

What does bubbles in the sight glass mean?

On startup of some refrigeration systems, when there is a large load on the system, bubbling and flashing could occur in the sight glass downstream of the receiver. This bubbling is caused by a pressure drop at the entrance of the outlet tube of the receiver. Bubbling could also occur during rapid increases in loads.

Do you have to replace the receiver drier?

The receiver dryer must be regularly replaced. It is recommended that the receiver dryer is replaced every second year or whenever the circuit has been opened. Always install a new receiver dryer any time the compressor is replaced and always when a serious leakage has been noticed and repaired.

What is the difference between a strainer and a filter drier?

Strainers are commonly used to remove larger particles, those visible to the naked eye, so that equipment downstream can work at optimal functionality. Filters, on the other hand, are more typically used to remove smaller particles, those that can't be seen with the naked eye.

What is a common symptom of a severely restricted filter drier?

What is a common symptom of a severely restricted filter drier? When the liquid line is restricted, the supply of refrigerant to the metering device is reduced.

What happens if you install a filter drier backwards?

When installing a new filter drier, an arrow on the filter drier's housing will indicate which direction refrigerant is designed to flow. If installed backwards, the filter drier will become useless.

Why should a filter drier be installed in a relatively cool location?

The colder the desiccant, the more moisture it can hold. Therefore, locating a filter-drier in a cooler location is an advantage. Removing a brazed filter-drier with a torch flame causes moisture to be driven out of the desiccant and into the system.

Absorbing Moisture, Preventing Acids

Water can come from many sources, such as trapped air from improper evacuation, system leaks, and motor windings, to name a few.Another source is d...

The Contractor's Truck: Types of Filter-Driers

Spun copper appliance driers are designed specifically for fractional-horsepower, low-vibration refrigeration systems. They are manufactured of ref...

Replaceable Drier Shells and Cores

Core formulations range from all activated alumina, blends of molecular sieve and activated alumina, to 100% molecular sieve. These cores provide r...

What is a filter drier?

Filter Driers. Filter driers are devices used in a HVAC system that are a combination of filter and dryer (or drier). A filter is used to remove any particle such as dirt, metal or chips from entering the refrigerant flow control.

Why is a drier used in a refrigerant system?

It can cause blockage to the passage flow of the refrigerant in the expansion valve and cause improper operation to the system. A drier as its name imply is used to remove the moisture from the refrigerant. Sometimes it is also referred to as dehydrator or dryer. It is necessary to remove moisture from the system otherwise it may freeze inside ...

Why is a suction line filter dryer important?

This device is used to protect the compressor especially after any failure that contaminates the system. Motor failure in the compressor usually cause acid and other contaminants to be introduced into the refrigerant system hence it is important to have the suction line filter dryer installed.

What are the two types of filters?

Types of Filter. There are basically two types in used today. Liquid Line Type. Suction Line Type. Liquid Line Type is placed after the condenser coil and before the expansion valve. The liquid refrigerant that flows from the condenser to the expansion valve is filtered from particles and moisture before entering it.

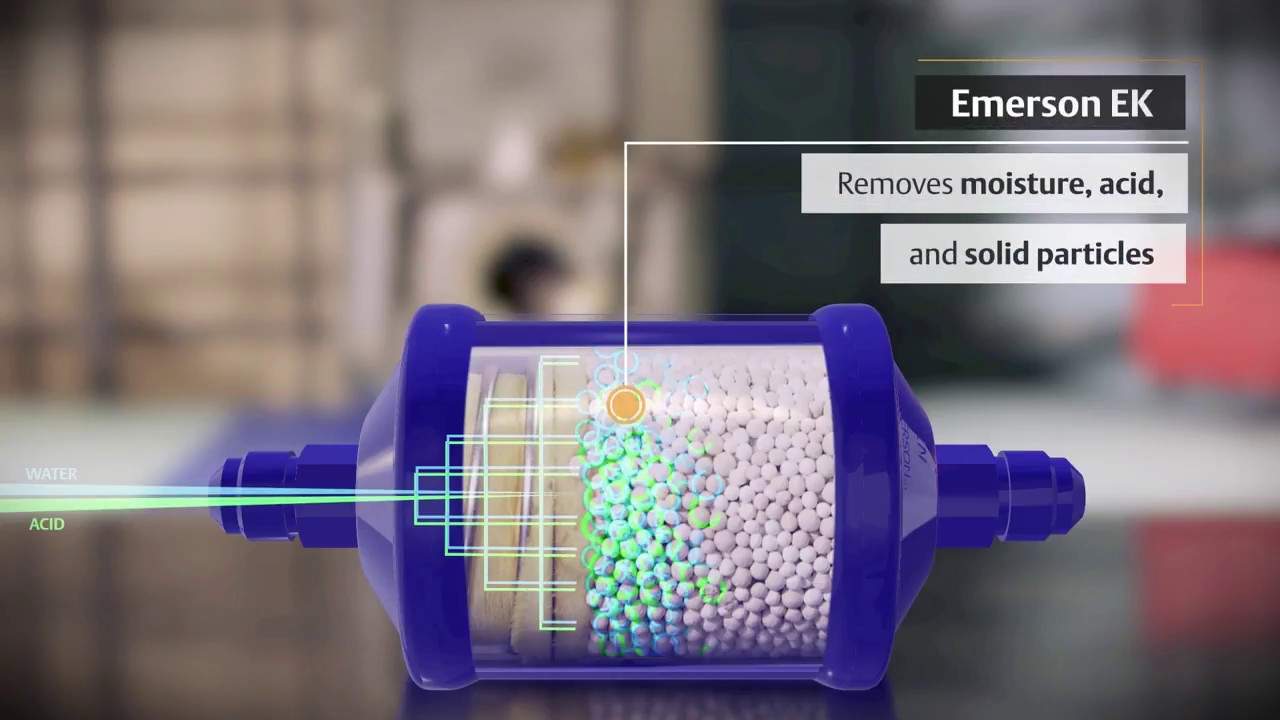

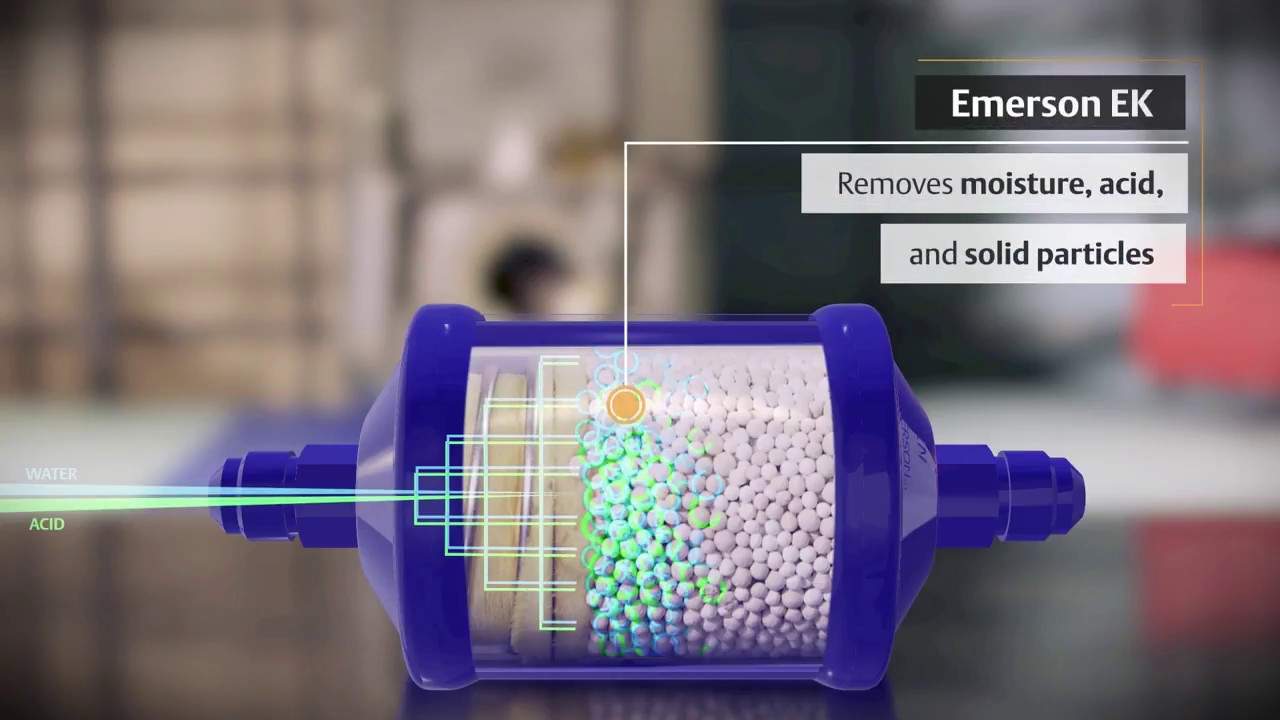

What is an EK 164 liquid line drier?

The Emerson EK-164 liquid line drier shown below is able to remove moisture and acid from the liquid refrigerant. It can also remove particles that are bigger than 20 micron from the refrigerant system.

What is a refrigerant flow control device?

The refrigerant flow control device could be thermostatic expansion valve or simply a capillary tube. The filter is sometimes also referred to as a strainer. It is critical that these particles are filtered out and prevented from going into the metering device. It can cause blockage to the passage flow of the refrigerant in ...

What is a filter dryer?

Filter-driers are a key component in any refrigeration or air conditioning system. This article offers acr technicians a description of the basic function of these devices and differences between the various types currently available.

What is the function of a filter drier?

A filter-drier in a refrigeration or air conditioning system has two essential functions: one, to adsorb system contaminants, such as water, which can create acids, and two, to provide physical filtration. Evaluation of each factor is necessary to ensure proper and economical drier design.

What is the purpose of a fiberglass drier?

These driers are physically sized to minimize pressure drop and provide adequate volume for filtration and drying. The molecular sieve desiccant has the highest weight percent water capacity so that water levels are kept to a minimum. The fiberglass filtration media allows the filter-drier to remove and retain large amounts of solid contaminant.

What is the role of desiccant in a filter drier?

Attrition occurs when the desiccant beads rub against one another when it is shaken or vibrated, yielding fine particles. Therefore, the method of retaining the desiccant in the filter-drier (based on drier size and location) plays a major role on the integrity of the desiccant.

Why does my SLD filter drop pressure?

In very dirty systems, enough contaminant will collect in the filter core causing an increase in pressure drop. The access valves on the SLD make it easy to measure the pressure drop to determine when the SLD should be replaced.

What is depth filter?

Depth filters force the fluid and contaminant to take an indirect route through the filter. Contaminants are trapped in the maze of openings that are spread throughout the filter. Depending on the type of filter, the openings will vary significantly.

What is a bi flow drier?

In a heat pump or reverse-cycle application, a liquid-line bi-flow drier is the best choice. Specifically designed for such applications, the steel shell filter-drier incorporates check valves within the shell so that external check valves are not required. These check valves allow flow through the drier in either direction without allowing the escape of contaminants already filtered out.

What is an AC Filter Drier?

If a compressor is the beating heart of an air conditioner’s sealed system, then the filter drier would be its liver. It’s used to protect the rest of the system from being contaminated by outside air, debris, or other materials. This is achieved through two functions:

Why is an AC filter drier important?

Air conditioners are able to cool your home thanks to a refrigeration system that’s similar to your home refrigerator, only much more powerful. These sealed systems are more dependable today than ever, but contamination still happens, which is why an AC filter drier is so important.

Is a filter drier expensive?

Fortunately though, compared to other sealed system parts, filter driers are not very expensive. When purchasing though, make sure to match the specifications from your AC with the part so you’ll know they’re compatible.

What is filter driver?

Filter Drivers. Filter drivers are optional drivers that add value to or modify the behavior of a device. A filter driver can service one or more devices.

What is a lower level filter driver?

Lower-level filter drivers typically modify the behavior of device hardware (see the Possible Driver Layer s figure). They are typically supplied by IHVs and are optional. There can be any number of lower-level filter drivers for a device.

What do we use a filter drier for?

Well these are found in refrigeration systems and as you might guess from their name, their job is to filter and dry the refrigerant. They protect the refrigeration system and its components by capturing and adsorbing water particles as well as harmful solid substances, and stopping these from cycling around the system and getting into the compressors, valves, sensors etc to keeping the system running at optimal conditions.

How does a filter drier work?

Filter drier perforated plate how filter driers work. The refrigerant then leaves the filter driver and heads to the expansion valve. So the refrigerant enters through the inlet, it passes across the spring, then surrounds the outside of the solid core. The refrigerant then passes through the solid core and as it does so the dirt, ...

What does the arrow on a heat pump filter mean?

On the side of the filter drier you’ll find an arrow, this indicates the direction of refrigerant flow. Some models for heat pumps might have a bi-directional filter and the arrow will point both left and right. But in this case we have a single direction, one way filter drier.

Why is aluminium oxide added to a filter drier?

The aluminium oxide is added in there to capture and retain acids. Not all filter driers will have activated alumina inside them it depends on the application. So the refrigerant enters and surrounds the outside of the core then is forced to pass through it.

Where is the filter drier located in a refrigeration system?

This is a very typical model filter drier and we’ll find these installed in the liquid line of the refrigeration system, between the condenser and the expansion valve.

What is the exterior of a refrigerator made of?

The casing is made from steel to give it a strong structure as this will be under some high internal pressure once connected into the refrigeration system.

What does a spring do at the refrigerant inlet end?

Now at the refrigerant inlet end we have a large spring, the spring just pushes against both the casing and the solid core, this is there just to keep the core in a fixed position inside the casing.

What is a filter drier?

The function of a filter-drier in a refriger - ation system is to remove contaminants that are harmful. If these contaminants remain at elevated levels, they will jeopardize the longevity of the system. Contaminants that are frequently found include moisture, acid, copper oxides, metal chips, wax-like compounds and others. Selecting a filter-drier for a particular application requires various technical factors to be considered. These factors include the type of system, connecting line size, water capacity, flow capacity (size of system), filtration capability, acid capacity, material of construction (steel vs. copper), and design pressures. Evaluation of each factor is necessary to ensure proper and economical filter- drier design. Parker has developed filter-drier recom- mendations based on current technical data, as well as many years of actual field experience. Products are tested for flow and water capacity using the American Society of Heating, Refrig- eration and Air Conditioning Engineers (ASHRAE) Standard 63.1 and are rated for use based on the Air Conditioning, Heating and Refrigeration Institute’s guideline AHRI-710. Data obtained from this testing is shown in the capaci- ties tables for liquid line filter-driers and can be used for comparison purposes. However, other factors must be consid- ered for various types of equipment.

How does a filter drier work?

Another source is due to improper handling of polyolester (POE) and poly-vinyl ether (PVE) lubricants, which are hygroscopic; that is, they readily absorb moisture. POEs and PVEs can pick up more moisture from their surround-ings and hold it much tighter than the mineral oils which have been used for many years. This moisture can cause freeze-ups and corrosion of metallic components. Moisture in the system can hydrolyze the POE lubricant, forming organic acids. These acids, if they exist in significant quantity, will react with materials within the system and can ad-versely affect component operation. To prevent the formation of these acids, the moisture must be minimized. This is ac-complished by the use of a filter-drier that utilizes molecular sieve and acti-vated alumina.

What is SLD filter?

The SLD Series is a solid core clean-up filter-drier for use in the suction line for both refrigeration and air conditioning systems. The compact design incorporates a large outside diameter shell, which results in a shorter lay-in length, and a larger core, which provides a greater filtration area for maximum operating efficiency. The core material has controlled porosity which effectively removes and holds a maximum amount of contaminants with a minimal pressure drop. In addition, the core material collects and holds acids and other harmful contaminants present after a motor burnout. Access valves make it easy to measure pressure accurately. The SLD-8 and SLD-27 each have one access fitting. The SLD-13 and SLD-15 each have two access fittings. Occasionally, enough contaminant matter may collect in the filter core to cause a slight pressure drop.

What is a Sahara filter dryer?

The new Sahara Series filter-driers are ideal for protecting air-conditioning sys- tems from the harmful effects of moisture, acid, and solid debris. The compact design reduces lay-in requirements. Multiple size products are available to opti- mize contaminant control. Replaced the existing Sahara Series Liquid Line Filter- Driers in a reduced size.

What is the difference between copper and steel filter driers?

Copper filter-driers are normally used in 5 ton and smaller, less complex applications, including systems with less pressure fluctuations and lower vibration tendencies. Some smaller sys-tems do not require high filtration capa-bilities; however, some of the smaller systems using the new refrigerants will require better filtration. In order to meet these requirements, a molded core construction and filter-driers with addi-tional fibrous media and screen should be considered. Also, copper is typically the most economical option for smaller systems. Because copper driers are used for smaller applications, the refriger-ant charge required will generally be smaller than in the steel filter-drier.

What is Parker filter shell?

Parker replaceable core filter-drier shells are designed to provide flexibility over a wide range of applications. All models are designed for use in both the liquid and suction line of air conditioning or refrigeration systems. In single or multiple-core applications, cores may be loaded individually for ease of installation in tight spots.

What is a gold label filter drier?

C B A The Gold Label bi-flow filter-drier is designed specifically for heat pump or reverse cycle applications. External check valves are not required since they are incorpo- rated within the filter-drier.