Is finger joint lumber worth it?

Finger jointing results in much higher quality and stronger pieces and components, while dramatically reducing waste in our industry where the cost of raw materials is rapidly increasing. The two most important advantages of finger jointed lumber are straightness and dimensional stability.

How to make finger joints in woodworking?

List of the Most Common Types of Joinery

- Butt Joint. The end of a timber board is called the “butt.” Woodworkers forming this joint are placing two ends together at a right angle to create a corner.

- Mitered Butt Joint (Miter Joint) This joinery option connects two butts that get cut at an angle. The advantage of using this approach involves the strength of the corner.

- Half-Lap Joint. ...

What are the different ways to join Wood?

Using a dowel joint

- Position the doweling jig over the top of the mark and start drilling your holes. The holes should be around 1/16 inch deeper than the half the dowels length.

- You now need to spread the glue over one piece within the holes and insert the dowels. ...

- Glue the end grain and house the other piece. ...

What is the strongest wooden joint?

One of the strongest woodworking joints is the mortise and tenon joint. This joint is simple and strong. Woodworkers have used it for many years. Normally you use it to join two pieces of wood at 90-degrees. You insert one end of a piece into a hole in the other piece.You call the end of the first piece a tenon.

Is finger joint wood good?

Finger Joint Performance It can work well, in larger pieces when there is ample gluing surface to help hold the pieces together, but it still has one fatal flaw. Wood moves. Wood expands and contracts in response to the conditions in the environment around it like heat, cold, and moisture.

Is finger joint same as dovetail joint?

A very simple alternative to the dovetail is called the box joint. As you can see from the image above, a box joint is very similar to a dovetail, with the difference being that the fingers in the box joint are rectangular rather than dovetail shaped.

What are the advantages and disadvantages of a finger joint?

Finger Joint Pros & ConsMakes a straighter joint.Less wood gets wasted during manufacturing.Cost Effective.Durable for a vertical load.Adhesives can be applied to create a stronger joint than mortise and tenon.

What are finger joint studs?

Finger-joint studs are a great product to use for framing walls, because they are straight and tend to stay straighter through the construction process, resulting in a straight, flat wall. Straight, flat walls result in walls with fewer drywall cracks, and make it easier to hang cabinets and millwork.

When would you use a finger joint?

Finger-joints are used to join short pieces of wood together to form units of greater length. The joint is composed of several meshing wedges or “fingers” of wood in two adjacent pieces and is held together with glue. Finger-joined lumber is used for both structural and non-structural products.

What's the difference between a box joint and a finger joint?

They don't mechanically interlock like dovetails, but box joints do have lots of surface area, so they're very strong when glued together. Finger joints are a thinner, more delicate cut than box joints, but work extremely well for long pieces like molding and boats.

Is finger-jointed wood strong?

Even under the most favorable con- ditions, strength of a finger joint will be lower than strength of clear wood.

Is finger joint timber strong?

Products : Finger-Jointed Timber The sides of each profile increases the surface area for gluing, resulting in a strong bond, stronger than a butt joint but not very visually appealing. Thus, it is commonly used for joinery and carpentry works that are concealed.

Can you stain finger-jointed wood?

Staining Finger Joint Pine Being a natural material, finger joint pine can be stained instead of primed and painted if having an exposed wood grain appeals to you.

What is finger joint pine?

The jointed pine is composed of pieces of pine glued end to end or side by side (laminated). This product is very popular when looking for a very stable pine because the risk of warping is almost none when using this type of product.

Can you use finger-jointed studs for framing?

Are finger jointed studs allowed in residential framing for exterior and interior load bearing walls.

Are finger-jointed studs structural?

That's why Universal offers structural finger jointed studs. Engineered for Construction. Finger jointed studs are made by bonding shorter sections of lumber into longer lumber using structural water resistant adhesives to give it added strength.

Is a dovetail joint stronger than a finger joint?

Frid wrote that finger (or box) joints are stronger than through dovetails because the fingers offer much more glue surface.

What is the difference between Picatinny and dovetail?

The Picatinny rail system is a more simply affair. It is a standard width and angle that manufacturers around the world all produce. The angle is 45 degrees as opposed to the 30 degrees that dovetails are regardless of their width. Some rifles come with an integral Picatinny rail machined into the receiver.

What is the strongest wood joint?

Mortise and Tenon Woodworking Joints One of the strongest woodworking joints is the mortise and tenon joint. This joint is simple and strong. Woodworkers have used it for many years.

Which is stronger box joint or dovetail?

For this test, the box joint proved stronger. Plus, the box joint is strong in both directions, whereas the dovetails are useful only for pulling from one piece, but not the other. So really, to use a dovetail joint for the sake of strength is obsolete, mostly on account of the strength of wood glues.

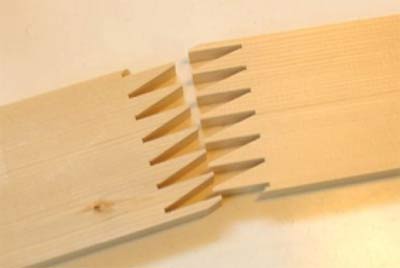

What is a finger joint?

1.1 What are finger joints? The finger joint is a joinery method in woodworking that is popular for woodworking joints in making boxes and other solid shapes. These joints help to join pieces of wood together so as to form greater length.

What is the purpose of a finger joint?

A finger joint’s ultimate purpose is to hold joints together by interlocking them and preventing them from coming apart. Finger joints are famous for making furniture as well as numerous woodworks that require a neat finish and appearance. However, there exist several important steps to pay attention to when making finger joints.

How to cut a board with your hands?

With your hands and fingers securely away from the cutting edge, make the main cut. Also, at that point, unclamp the board and slide the space that you slice on to the stop . Presently you can clasp the board set up and make your subsequent cut. Rehash this cycle until you arrive at the contrary edge of the board.

What to do after completing finger joint?

After completing your finger joint, the next action is to assemble the joints. However, it is essential to cut a tad bit higher than your board depth to ease the cutting process and cater to parallax error.

Is a box joint the same as a finger joint?

Most people regard the box joint and finger joint as the same. However, for specialists in woodworking, they believe there are intricate characteristics that make them different. Let’s take a look at how these joints differ.

Why is finger joint lumber so cheap?

Finger joint lumber is cheap because the manufacturers can use small lengths of leftover wood to assemble full length of moldings.

How to make a piece of wood extend to almost any length?

It’s a great way to make a piece of wood extend to almost any length by adding more and more pieces to the end. The finger joint is then glued with a wood glue or other adhesive and clamped together to cure.

Is finger joint lumber good for molding?

While it can save you a lot on your lumber and molding costs it may not be the best choice for your project. Finger joint lumber was the lumber industry’s way of creating the long pieces of wood that we need for non-structural things like trim and casings.

Brief History of Lumber

Wood is a critical building material, but to shape it into useful lumber is very difficult, making most types of wood costly. Pine, a plentiful wood throughout the United States, is a more cost-effective type of lumber. In addition, if you purchase pine that is rough cut, this may decrease its cost even more.

Why Finger Jointed Pine Was Invented

Finger jointed pine was a solution for selling wood that had issues. The bad parts of the wood could be removed and interlocked with other good wood parts. Finger jointed pine was invented to sell longer pieces of wood that fit together perfectly at a lower cost.

How is Finger Jointed Pine Created

You can purchase finger jointed pine from the store, buy it from a lumber supplier, or create it in your woodworking shop. Whatever way that you acquire it, the formation of it is the same.

How Finger Jointed Pine is Used

Finger jointed pine is very useful. Some furniture and woodworking are pieced together, and you may not even be aware that the finger jointed technique was used. This is because many projects use this method, but the finger-like shape is not exposed.

What is a finger joint?

Finger-joints are utilized to join short bits of wood together to frame units of more noteworthy length. The joint is made out of a few cross-section wedges or “fingers” of wood in two contiguous pieces and is held along with a stick. Finger-joined timber is utilized for both primary and non-underlying items.

What is straightness in wood?

Straightness: The bits of finger joint wood pieces are straight and valid. Any sort of forehead and hoodlum is caught up in the joint wood. Consistency: It is comprised of little bits of top-notch wood guaranteeing the finished result is consistent with premium quality. To sum it up finger joints: Makes a straighter joint.

Is finger joint wood strong?

Strength: The strength of finger joint wood is acceptable and finger joint wood is more grounded than regular measurement blunder. Stability: The odds of distorting and contorting is less on the finger joint. Straightness: The bits of finger joint wood pieces are straight and valid. Any sort of forehead and hoodlum is caught up in the joint wood.

Can finger joints be damaged by water?

Water-Damage: The finger joint wood can undoubtedly be harmed by water since it’s anything but a water-obstruction wood, so take great consideration of it. Moreover Finger Joints: Can come out crooked. Harder to achieve a smooth wall.

Is finger jointed wood flooring steady?

In any case, finger jointed wood flooring plank is substantially more steady in high rush hour gridlock zone. or on the other hand-warming ground in light of the fact that the flooring section. has less inward pack power contrasting and conventional single hardwood board.

What is woodworking joint?

Woodworking joints enable us to create items from multiple timber boards. Without the use of wood joinery techniques, everything we make using wood would end up coming from a single piece. Several woodworking joint styles are available to the woodworker to use, providing several creative options when putting together furniture, flooring, and more.

Why do woodworkers use joint?

Woodworkers use it to avoid having the connection visible from the front of the piece without compromising their work’s strength. This is one of those wood joints that require the hand of a skilled woodworker. But the end result is a beautiful, strong joint that is well worth the extra efforts. 12.

What is a rabbet joint?

Rabbet Joint. Woodworkers form this joint by forming a recess into the edge of the timber. It looks like the protruding edge from a tongue and groove joint, except it only has one side cut from it instead of two. While the rabbet joinery is a simple wood joint, it is much stronger than the butt joint.

What is dado joinery?

The dado joinery method is similar to a tongue and groove joint. The only difference is that the dado is cut across the woodgrain whereas a groove is cut in the grain direction which is usually along the length of the board. Moreover, there is no tongue carved on the edges, instead, the groove is cut wider to accept the thickness of the mating piece.

What is the difference between dovetail and box joinery?

On the other hand, box joinery is easy to create and works on most types of wood including plywood. You can easily cut the fingers of the box joint on a table saw with a set of dado blades. 14.

How to join wood to make a longer board?

This type of wood joinery technique is mainly used to join two pieces of wood to make a longer board. A lengthening joint usually has a larger gluing surface between the joined pieces.#N#First, you have to cut fingers similar to a box joint, but deeper. In the case of a box joint, you join two pieces of wood at 90 degrees to achieve a solid corner. Here you lay the mating wood pieces flat and assemble them with a thin layer of wood glue between the fingers.

What is a biscuit joiner?

Most tabletops and wooden counters use the biscuit joinery method to create a more reliable joint suitable for daily use. You can use the woodworking tool called biscuit joiner or plate joiner to make this type of edge joints accurately. A dowel joint is a modification of this option.