A Part 1 ball valve or Portsmouth ball valve is a ball valve made to British Standard specification 1212, Part 1. It consists of a piston inside a brass housing, with a float arm secured to the valve via a split pin. Inside the piston is a slot which accommodates the end of the float arm, and on one end of the piston is a washer.

What is the difference between Part 1 and Part 2 ball float valves?

It is very easy to spot the difference between a Part 1 and Part 2 ball float valve. A part 1 Valve has the water outlet spout on the underside of the float valve and a part 2 has it on top of the body with a plastic nozzle which directs the water downwards into the tank.

What is a one piece ball valve?

A one piece ball valve, can also be referred to as single piece ball valve, has a body and end connections formed from a single piece of material. This construction presents a comparatively reduced number of opportunities for leakage. The valve trim and seals are inserted through one of the end connections.

What are the components of a ball valve?

Ball valves are constructed with several crucial components: This is the main part of the valve and contains all of the components for on/off control. The ball is designed with a center bore (hole) that the media flows through. The direction of the ball is controlled by turning the stem.

What is a 1212 Part 1 ball valve?

A Part 1 ball valve or Portsmouth ball valve is a ball valve made to British Standard specification 1212, Part 1. It consists of a piston inside a brass housing, with a float arm secured to the valve via a split pin.

What Is A Part 1 valve?

A part 1 Valve has the water outlet spout on the underside of the float valve and a part 2 has it on top of the body with a plastic nozzle which directs the water downwards into the tank. Both types are typically found in loft cold water tanks or feed and expansion tanks.

What Is A Part 3 ball valve?

A Part 3 ball valve or diaphragm ball valve is a ball valve made to British Standard specification 1212, Part 3. It consists of a plunger and a diaphragm washer inside a plastic housing. The plunger is partly visible and protrudes from the face of the valve.

What are the parts of a ball valve?

Parts of a Ball ValveValve Body. This is the main part of the valve and contains all of the components for on/off control.Rotary Ball. The ball is designed with a center bore (hole) that the media flows through. ... Stem. This connects the ball to the external control mechanism. ... Seats. ... Power Source. ... Packing. ... Bonnet.

What is the difference between a one piece and two piece ball valve?

One piece ball valves are inexpensive and generally not repaired. Two piece ball valves consist of two separate pieces, with the connection between them being either threaded or a bolt and flange assembly. As you may have guessed, a 3 piece ball valve consists of three pieces, two end caps and a body.

What are the types of ball valves?

There are five general body styles of ball valves: single body, three-piece body, split body, top entry, and welded. The difference is based on how the pieces of the valve—especially the casing that contains the ball itself—are manufactured and assembled.

Can ball valves be repaired?

The only repair for a ball valve is replacing the packing washer. If the actual ball on the valve becomes deteriorated, it will leak. In that case, the entire valve must be replaced.

Can a ball valve fail?

Common Ball Valve Failures One of the most common types of ball valve failures involves a buildup of dirt and sediment within the valve, making it difficult to open and close. The use of solvent cement glue can also clog up the ball, causing it to stick to the inside of the valve and resist turning.

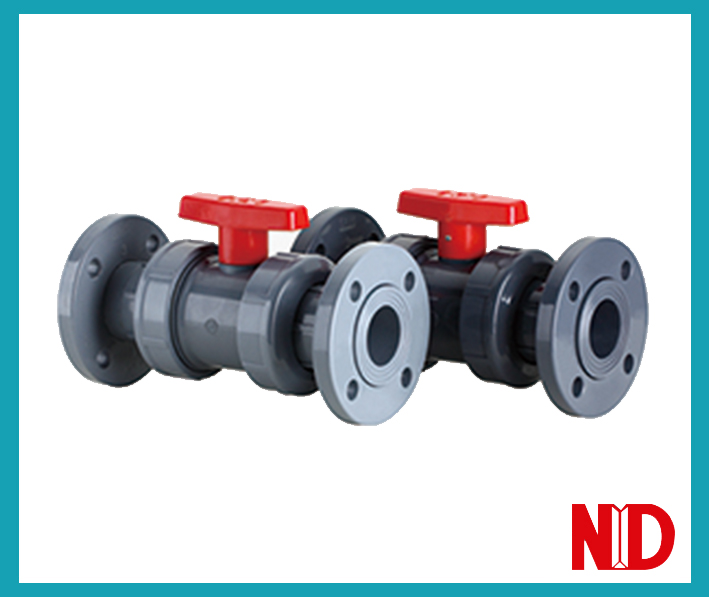

What is a 2 piece ball valve?

Two-piece ball valves are some of the most common ball valves used. As the name suggests, the two piece ball valve consists of two pieces, one piece that has one end connection and the body. The second piece fits into the first, holds the trim in place and includes the second end connection.

What is full bore ball valve?

Full bore ball valves have an oversized ball so that the hole in the ball is the same size as the pipe internal diameter which ensures straight-through flow and positive shut off with minimal pressure drop and very little resistance to the flow of liquid.

What is a top entry ball valve?

Top entry ball valves are used in piping systems where the top of the valve can be removed to gain access to the ball and seats without removing the entire valve from the piping system. Top entry ball valves are typically used in process systems where in-line maintenance is preferred over full valve removal.

What is the stem of a ball valve?

Components Of a Ball Valve. A ball valve is comprised of the following main components: Valve stem: The valve stem is a rotary shaft connecting the internal ball to the outside lever which when turned rotates the ball. O-ring: The o-ring is used to create a seal between the stem and housing of the valve.

What are the parts of a gate valve?

A gate valve has seven main parts, which can be seen in Figure 3, which are: handwheel (A), stem (B), gasket (C), bonnet (D), valve body (E), flange (F), and gate (G). A flanged gate valve or threaded gate valve is the most common connection type to connect the valve to an application.

What is the trim on a ball valve?

Trim. Different ball valve parts together create the Trim. These parts are Disk, Sleeves, Seat (also known as seals ring), and Stem. Trim enables the ball valve to perform basic motions as well as providing flow control.

How are ball valves assembled?

0:042:15Ball Valves | How It's Made - YouTubeYouTubeStart of suggested clipEnd of suggested clipTo assemble the ball valve the technician places two rubber o-rings on top of an end cap. Next is aMoreTo assemble the ball valve the technician places two rubber o-rings on top of an end cap. Next is a thick synthetic ring which will secure the ball in the valve.

How to repair a part 1 ball valve?

First, isolate the water supply. Then, while holding the valve body with a pair of grips, use an adjustable spanner to loosen the nut against the cistern wall. Undo the nut while holding the valve body in place with your hand, and the valve can then be removed. Take care to make sure that the washer doesn’t fall into the cistern as you remove the valve.

What is a Portsmouth ball valve?

A Part 1 ball valve or Portsmouth ball valve is a ball valve made to British Standard specification 1212, Part 1. It consists of a piston inside a brass housing, with a float arm secured to the valve via a split pin. Inside the piston is a slot which accommodates the end of the float arm, and on one end of the piston is a washer. When the water level in the cistern rises, the arm pushes the piston and its washer onto the valve seating, closing the valve.

Why are there no ball valves in cisterns?

For these reasons, Part 1 ball valves are no longer permitted on cold water storage cisterns due to non-compliance with water byelaws. They may be found on older installations, and should ideally be replaced with a Part 2 ball valve.

What is inside a float arm?

Inside the piston is a slot which accommodates the end of the float arm, and on one end of the piston is a washer. When the water level in the cistern rises, the arm pushes the piston and its washer onto the valve seating, closing the valve.

What is the difference between a Part 1 and Part 2 ball valve?

Part 1 and Part 2 ball valves – the main differences. The first difference concerns where on the valve the water comes out. On a Part 1 or ‘Portsmouth’ valve, the outlet is on the underside of the valve. However, on a Part 2 or ‘diaphragm’ valve, the outlet is on the top.

Why are Part 2 ball valves preferred?

If a Part 1 ball valve fails and the water level in the cistern reaches the pipe centre line, there will be no air gap between the valve and the water in the cistern. This means that the outlet on the valve will be completely submerged. More to the point, it means that the valve would fail a back-siphonage ...

How does a float work in a cistern?

They both work in roughly the same way. As the cistern fills and the water level rises, the float raises the arm. This in turn moves a rubber washer against the valve seat, closing the valve.

Why are Part 2 valves better than Part 1?

So, what’s the other reason why Part 2 valves are usually a better choice? They usually have a feature that allows you to adjust the water level. The position of the float on the arm can be raised or lowered via a wing nut. Unfortunately, you won’t see this feature on Part 1 ball valves: the only way to adjust the water level is to manually bend the float arm.

Can you adjust the water level on a Part 1 ball valve?

Unfortunately, you won’t see this feature on Part 1 ball valves : the only way to adjust the water level is to manually bend the float arm. So, the difference between a Part 1 and a Part 2 ball valve – or differences, to be more precise – are pretty straight-forward.

What is the ball valve?

The ball is another one of the ball valve parts that shapes like a sphere and contains a flow path (also known as hole or tunnel) at its center. The ball has a connection point for a shaft which permits the rotation of the ball.

How does a ball valve seat work?

In the Trim, the seat and the disk together help determining the performance of the ball valve system. The seat works like an interface, showing where the disk is seated and it is designed in two different ways. Manufacturers either forge the seat within the body, or welding it by machine. The seat shapes like a doughnut. This round unit contains discs that form a seal between the ball and the body.

What is the purpose of the ball valve trim?

These parts are Disk, Sleeves, Seat (also known as seals ring), and Stem. Trim enables the ball valve to perform basic motions as well as providing flow control. The disk separately is considered as a pressure boundary at the third stage in many designs, just like the body that was the first stage and the bonnet as the second stage. The disk has pressure-retaining capacity, enabling it to prohibit or permit fluid flow.

What is the best material to seal a ball valve?

These materials can fibrous materials such as flax or Teflon that can make the packing the best choice for sealing. Since leaks can cause damage to the ball valve system and its environment, it’s important for the packing to be properly placed at the right space. It shouldn’t be too loose or too tight.

How does a bonnet work?

Bonnet is used to cover this opening and just like the body, it serves as a pressure boundary at the second stage. Bonnet holds the ball and the stem assembly in place and its cap is fastened to the body to do the task. By the right adjustment of this unit, you can achieve the right compression of the packing to supply the stem seal. Manufacturers usually make the bonnet with the same material as the shell or the body. This makes the valve more strong and firm since the bonnet is bolted and screwed with the body in many cases.

Why do ball valves erode?

The conventional generations of ball valves have poor throttling characteristics and the seat quickly erodes due to the impingement of high velocity flow. So that was all there’s to know about ball valve parts and their application within the system.

Why are ball valves less expensive?

Ball valves are less expensive compared to other types of valves! Plus, they need less maintenance as well as low maintenance costs. Another advantage of the ball valves is that they are compact and provide tight sealing with low torque. Not to mention their quick quarter turn on / off operation.

What is the main part of a ball valve?

Valve Body: The main part of a ball valve is the valve body that contains all of the internal components for on/off control. Rotary Ball: A ball with a center hole through which the media flows is the main characteristic of ball valves that differentiate these valves from other valve types.

What is a Ball Valve?

A ball valve is a type of valve that uses a spherical perforated obstruction (a rotary ball) to stop and start the hydraulic flow. A ball valve is usually rotated 90° around its axis to open and close. It is one of the most widely used valve types. Ball Valves are suitable for both liquid and gas services. They are highly popular in the chemical, petrochemical, and oil and gas industry because of their long service life and reliable sealing throughout their service life. Ball valves can even be used for vacuum and cryogenic services. Developed around 1936, Ball valves are among the least expensive valves which are available in an extremely wide size ranges.

How many types of ball valves are there?

Depending on the body construction of valves, there are three types of ball valve designs; One-piece, Two-piece, and three-piece ball valves

How are side entry valves made?

Each part of the body is assembled by a bolt/stud similar to joining a two-piece of flanges. Side entry ball valves are usually made by forging the metal. Each piece of the body is forged separately and then assembled together to get the complete design.

What material is used in soft seated ball valves?

Soft seated ball valves use a thermoplastic material such as PTFE, NBR, etc. However, abrasive media, high pressure and temperature can severely stress the polymeric seals leading to damage. Because of this reason metal-seated ball valves are developed in the 1960s.

What is the purpose of the packing on an automatic actuator?

Automatic actuators use electric, pneumatic, or hydraulic power sources. Packing: Packing is a seal around the stem to prevent the media escape . Bonnet: The bonnet is the part of the ball valve body that contains the stem and packing.

When were ball valves invented?

Developed around 1936, Ball valves are among the least expensive valves which are available in an extremely wide size ranges. Ball valves are sometimes used as a control valve due to their cost-effectiveness but not preferred as they don’t provide precise control and adjustments.

What is a ball valve?

Ball valves are mechanical devices capable of controlling, guiding, directing, and modulating the flow of different substances such as gas, pressure, liquids, etc. There are different ball valve types with various designs for specific uses, but basic ball valve parts are the same among them. Different ball valves can be classified based on ...

What are the specifications of a ball valve?

You should consider different specifications such as pressure, size, temperature, number of ports, body materials, end connectors, and configurations.

What are the materials ball valves are made of?

There are different materials used to create different ball valve types. Some of the more popular materials are as follows:

What is the difference between a T valve and a L valve?

T valves can connect any pair of ports and the L valve can connect the center port to side ports. Inlet in a multi-port ball valve is usually orthogonal to the plane of the outlets. 4-way ball valves have 2 L-shaped ports in their ball known as X port.

How many ports does a ball valve have?

Number of Ports: Ball valves can be easily categorized based on the number of ports. A standard ball valve type has 2 ports (1 inlet and 1 outlet). A 3-way port has also been designed with 1 inlet and 2 outlets, or 2 inlets and 1 outlet. Design: Different designs such as floating, and trunnion mounted.

Why is a ball valve oversized?

The oversized ball in the full port ball valve lowers the friction loss because the hole in this ball valve is the same size as the pipeline. Though the valve is larger, the flow is unrestricted in full port ball valve size. Full bore ball valves are usually used for throttling applications in various systems with high flow coefficients ...

What is true union valve?

True union (Trunnion) True union ball valves have a pin in place which secures the ball in place and stops its movements. Two shafts at the opposite ends of the ball in Trunnion enable the supporting of a segmented ball by the valve and enable the system to cause less friction between different parts of the true union valve.

What is the difference between a ball float valve and a part 1 valve?

It is very easy to spot the difference between a Part 1 and Part 2 ball float valve. A part 1 Valve has the water outlet spout on the underside of the float valve and a part 2 has it on top of the body with a plastic nozzle which directs the water downwards into the tank. Both types are typically found in loft cold water tanks or feed and expansion tanks

What is the difference between a part 1 and part 2 float valve?

A Part 2 float valve has the float ball fixing on a lockable collar which allows it to be moved up or down to suit the water shut off level. A Part 1 float valve has no such adjustment and relies on bending the arm to adjust the water shut off level.

What happens if the float valve fails?

This is because if the float valve fails then the water level will submerge the outlet nozzle, and then if there is a pressure drop then the water in the tank can siphon back into the mains water system.

What is a one piece ball valve?

A one piece ball valve, can also be referred to as single piece ball valve, has a body and end connections formed from a single piece of material. This construction presents a comparatively reduced number of opportunities for leakage. The valve trim and seals are inserted through one of the end connections. This type of valve will not have a port size equal to the line size. The simplicity of the one piece body design tends to make their cost lower than the other versions. Once the valve is in place, it cannot be serviced without removing the entire valve assembly from the piping system. One piece ball valves are inexpensive and generally not repaired.

How many pieces are in a 3 piece ball valve?

As you may have guessed, a 3 piece ball valve consists of three pieces, two end caps and a body. Ball valves are employed throughout many commercial, institutional, and industrial venues where the need to isolate part of a system is necessary, or even just to regulate the on/off condition of system fluid flow.

What is SS ball valve?

SS ball valves are often used as shut off valves, the valve will include a rotatable ball with a bore. Stainless steel ball valves are a popular choice as they are both durable and cost efficient, they can also be used for a wide variety of purposes including water, air, corrosive chemicals, acids and bases.

Why are SS ball valves so popular?

When it comes to SS ball valves, there’s a number of reasons why they are a popular choice, this includes that they are lightweight, strong and long lasting. The material means that they are suitable for use in sanitary applications, and they are also resistant to chemicals and acids.

Can one piece valves be repaired?

One piece ball valves are inexpensive and generally not repaired. Buy One Piece Valves online here.