Types of Check Valves

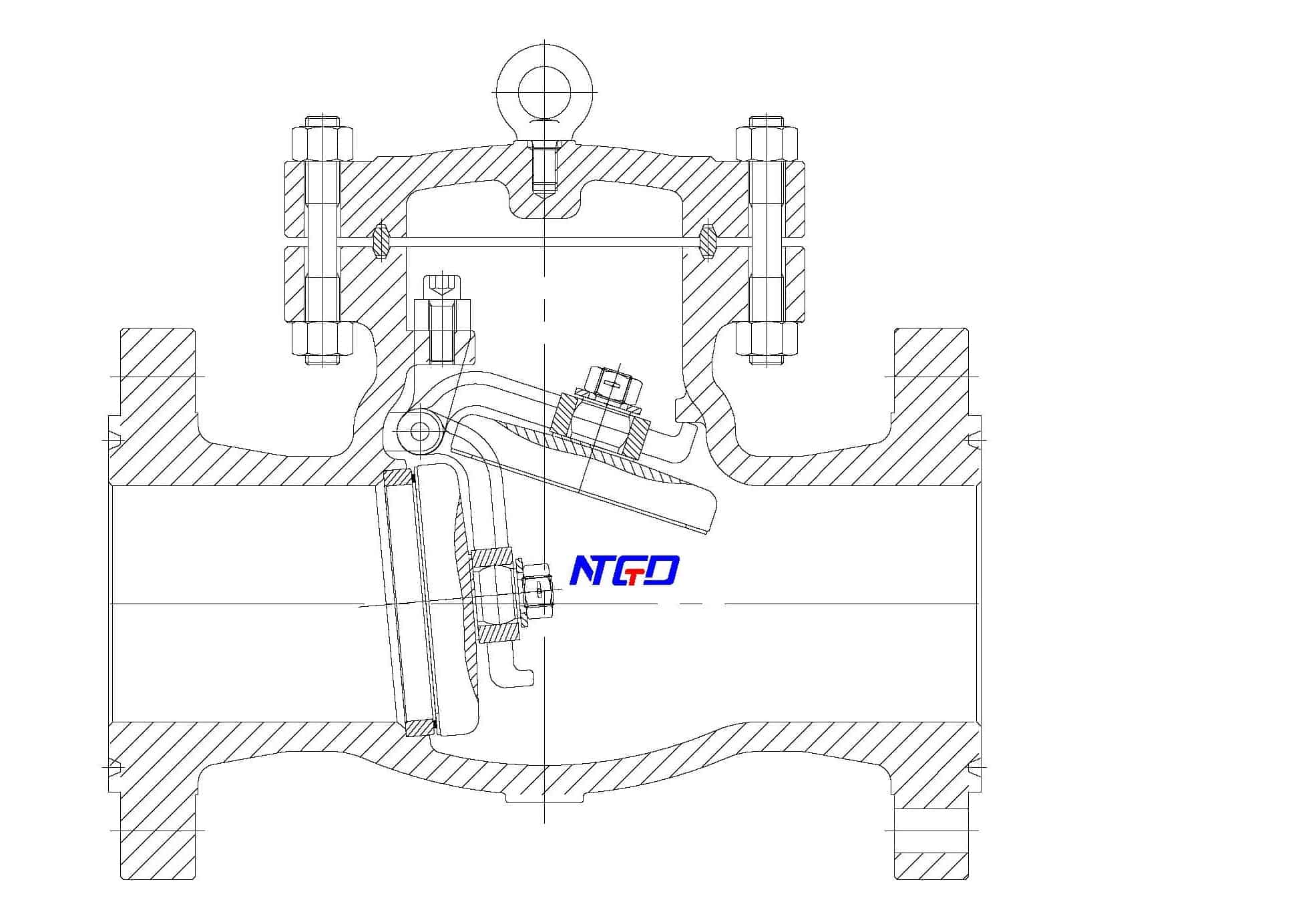

- Swing Check Valve. A swing check valve is the most widely used check valve. ...

- Wafer Check Valve. Wafer check valves are very slim and compact in design and use a swinging disc to allow or block flow.

- Spring Loaded Check Valves. ...

- Ball Check Valves. ...

- Diaphragm check valves. ...

- Lift check valve. ...

- Stop check valve. ...

- Foot Valve. ...

- Duckbill Valve. ...

How to install swing check valves?

verify compatibility with the Swing Check Valve and associated equipment. Prior to installing the valve, thoroughly flush the water supply piping to verify that no foreign matter is present. The Swing Check Valve may be installed in vertical position with direction of flow up, or in horizontal position with the access cover up.

What are the different types of check valves?

Types of Check Valves

- Types of Check Valves

- SWING CHECK VALVE. Swing Check Valves are available in straight body design and y-pattern design. ...

- TILTING DISK CHECK VALVE. ...

- WAFER TYPE CHECK VALVE. ...

- DISC CHECK VALVE. ...

- PISTON CHECK VALVE. ...

- BALL CHECK VALVE. ...

- DUAL PLATE WAFER CHECK VALVE. ...

- NON-SLAM CHECK VALVE. ...

How to check and adjust valves?

Check all 4 valves on #1, the intake valves on #2, and the exhaust valves on #3. For each valve needing adjustment, remove the shim, measure it, make a note, and put it back in. NEVER TURN THE ENGINE WITH A SHIM OUT. Okay, next rotate the engine (clockwise only) 360 degrees (the cam rotates 180 degrees).

How to check a stuck engine valve?

How to Cure a Sticky Lifter or Stuck Valve

- Set the vehicle in park and engage the emergency brake. Start the engine and raise the hood. ...

- Shut the engine off. Check the level of the engine oil, and fill the crankcase with the proper level of oil as marked on the dip stick scale, ...

- Check the dip stick for a too high reading of the oil level. ...

Why is it important to check a swing valve?

Fault and Troubleshooting. Swing check valves are very critical components in many situations, as the reverse flow is very damaging sometimes. So, it is required that the symptoms of the check valves should be detected as early as possible to prevent shut down of the line and costly repairs.

Why do swing check valves shut off?

As pressure reaches zero, the valve shuts fully to prevent backflow. Swing check valves belong to the group of automatic valves, which are used mostly in pipelines where the medium flows in one direction and allow only the medium to flow in one direction to avoid accidents. The pressure drops and turbulence in these types of valves are very low.

How to prevent a swing check valve from leaking?

1. To prevent swing check valve from damage, just keep the valve clean by wiping off dust and dirt regularly. 2. Always carry out regular inspections of the valve.

What makes a water hammer pressure small?

2. As the medium pressure of a swing check valve falls below its cracking pressure the valve flap closes quickly which makes the water hammer pressure very small. 3.

Why do we use swing valves?

Summary: Like all check valves, Swing check valves are used to avoid reverse flow in the pipe. The fluid pressure that passes through a system opens the valve, whereas the valve is closed by any flow reversal.

How to prevent premature valve failure?

Another effective way of reducing premature valve failure is to lubricate the valves. Check valves consist of several moving parts; thus, reducing friction between these components by lubrication can extend valve component life, improve overall efficiency, and ensure efficient operation.

What is the key to preventing check valve failure and ensuring valve longevity?

Proper and regular preventive maintenance is the key to preventing check valve failure and ensuring valve longevity.

How Does a Swing Check Valve Work?

Swing check valves work a little like a butterfly valve. They have a disc inside that covers the opening of the valve. That opening has to be clear in order for anything to pass through. The disc is attached to a hinge , so the disc can swing open or closed when liquid hits the disk. It's kind of like a circular door. The direction of the flow is the most important thing when using these valves.

What is a swing valve?

One iteration of the swing check valve is a spring check valve. These valves function in the same way as swing check valves, but they have a spring to stay closed when there is no flow in the correct direction. That means that as soon as fluid stops flowing through, the valve claps shut.

How does a liquid disc work?

The disc is attached to a hinge, so the disc can swing open or closed when liquid hits the disk. It's kind of like a circular door. The direction of the flow is the most important thing when using these valves. When liquid is traveling in the desired direction, the pressure of the flow pushes the door open, allowing liquid to pass through.

Can a swing check valve be removed from a pipeline?

If your swing check valve has a true union design, it can easily be removed from the pipeline. These valves are available in many different forms. Metal swing check valves are often seen in heavy industrial use. However, a PVC swing check valve can often handle the same jobs and will be much less expensive.

Is a swing valve the same as a spring valve?

It is easy to get swing and spring check valves confused, but they do serve different purposes. Swing check valves are forced close by backflow and spring check valves are closed by default, requiring more pressure to open their door and allow fluid through. Make sure you get the one you need! Many online forums debate on which are best for certain jobs. Checking those could help you decide which you need.

What is a Swing Check Valve?

A swing check valve is a type of check valve that ‘swings’ open to allow water to pass then closes to prevent backflow. The disk inside is responsible for swinging open when water is exiting and then closing once all the water has passed. The lip will seal water tight when closed by closing up against a rubber pad.

What happens when a new check valve is installed?

Potential problems to keep an eye out for while testing include: water leaks, a noise every time the swing opens and closes, no water exiting the line and water flooding back into the sump basin.

Can a swing valve be installed horizontally?

Most swing valve models can be installed horizontally or vertically.

How Does a Swing Check Valve Work?

Swing check valves are among the most common types of check valves and are frequently used to manage a high horizontal flow. The fluid’s pressure opens the disc to allow the water or gas through. After the flow stops, the disc swings back into its closed position, resting against the valve’s seat and preventing backflow.

Applications of Swing Check Valves

Made of metal or PVC, swing check valves best suit pipes that receive a steady flow of fluid. Repeated instances of sudden pressure changes may damage swing check valves and result in leaking (referred to as passing) because the valve cannot seal correctly against the seat.

Introduction

Swing check valves allow flow in one direction, but not both. Swing check valves are also referred to as clack, non-return, stop, check and one-way valves. Other common check valve designs include the tilting disc (a variation of the swing check design), piston, butterfly and stop valve designs.

Operation

Flow is allowed through the valve in only one direction, inlet to outlet. If there is flow in the opposite direction, the valve disc will be pressed against the seat and all flow will stop (the valve is now closed).

What is a swing check valve?

A swing check valve is the most widely used check valve. The closing member or the disc swings on a hinge or shaft. To allow the flow, the disc swings off the seat and it swings back onto the seat to block the reverse flow. In an open position, a swing check valve offers very little resistance to the flow. To achieve optimum performance, often a lever and weight or a lever and spring are mounted. The disc weight and the return flow has an impact on the shut-off characteristics of the valve. Swing Check Valve is also known as the Tilting Disc Check valve.

What are the characteristics of check valves?

Check valves have “Dynamic Characteristics”, ie different speeds of response, which determines the maximum reverse velocity, Vr max, and, hence, the degree of “check valve slam”.

Why use a diaphragm check valve?

Due to very low cracking pressure, Diaphragm check valves finds its use in low pressure and vacuum applications.

How does a water hammer work?

Now, during operation if someone shuts the quarter turn ball valve abruptly, a pressure wave will be generated which will flow through the piping. This phenomenon is known as water hammer. If the check valve is a a swing check valve, the flapper will remain open until that pressure wave returns back to the swing check. The pressure wave causes the flapper to slam shut making an audible sound, and causing excessive wear within the swing check valve and other piping system components. However, if a spring loaded check valve is installed, the spring will close the valve before the pressure wave gets there. So, a spring check valve can effectively reduce the effects of water hammer. Spring check valves are also known as “silent check valves”. A spring is utilized in spring check valve to assist the poppet in silent closing of the check valve prior to fluid flow reversal.

What is the minimum upstream pressure required for a check valve to open?

For a check valve to open, it must attain a minimum upstream pressure known as cracking pressure. Depending on the check valve design and size, the cracking pressure changes.

What does it mean when a check valve is closed?

In situations, if downstream pressure is more, the valve will close preventing back-flow. Closure can also be accomplished by the weight of the check mechanism, by a spring, or by a combination of all these means.

What is an in line valve?

In-line valves are also known as Nozzle Check Valves or Silent Check Valves. These valves employ a centrally guided stem-disc assembly along with a compression spring. To open the valve, the flow pressure must be more than the spring force and cracking pressure. In that case, the flow pushes the disc allowing the flow.

What is a swing check valve?

Swing check valves are by far the most common check valve in any industry. They are often a lower-cost solution and effective most of the time; however, it’s important to understand the differences between a swing check valve and a spring check valve. Don’t get confused! In this article, we’ll cover some basic differences between these two types of inline check valves as well as some of the advantages of using a spring check valve over a swing check valve.

What is the difference between a swing check valve and a spring check valve?

The flapper in a swing check valve ‘swings’ off the seat to allow forward flow and then swings back onto the seat when the flow is stopped. In contrast, a spring loaded check valve incorporates a spring to assist in closing the check valve.

What is a water hammer valve?

Let’s say water is flowing and someone shuts the quarter turn ball valve abruptly. This can produce a pressure wave flowing through the piping – this is what is known as water hammer. With a swing check valve specifically, the flapper on that valve will be open until that pressure wave returns back to the swing check.

Do swing valves fit in existing piping?

While swing check valves do offer a larger flow capacity (larger CV value assuming the valve is fully open), they do not always fit in existing piping configurations. On the other hand, spring loaded check valves can be mounted in any flow orientation with the right spring selections.

Can a swing valve be installed in horizontal flow?

Learn more about spring check valves! Swing check valves are limited in the orientation in which they can be installed. Swing check valves can only be installed in horizontal flow applications, which greatly limits the installation orientation.

Does a spring loaded check valve eliminate water hammer?

Conversely, a spring loaded check valve will help minimize, and in some cases, eliminate the effects of water hammer. How? When we think about that same pressure wave that closed the swing check valve, the spring in the spring check closes before the pressure wave gets there.

What is a check valve?

Check valves are an automatic safety device that prevents backflow, ensures gases or liquids are flowing in the right direction, and creates a tight seal to prevent leaks. By controlling the flow of liquids, check valves protect pumps and compressors from serious damage. Flange Insert from Check-All-Valve.

How does a ball check valve work?

Ball check valves use a ball to block fluid flow and can be spring loaded. Reverse flow moves the ball back to seal off the flow. When there is enough pressure in the flow, the ball is lifted away from the flow. When the pressure decreases, it comes down to close the opening.

What is the difference between a foot valve and a pump?

The opening of the valve is larger than the opening of the line. Foot valves keep the pump primed. When the pump is operating, suction pulls water up through the pipe and foot valve. When the pump is turned off, the water in the pipe is pulled back by the force of gravity.

What is duckbill valve?

Duckbill check valves are made of rubber or synthetic elastomer and have the shape of a duck’s beak. The open end of the valve is stretched over the outlet to the supply line. The other end retains its normal shape. Upstream pressure forces the duckbill lips open allowing the flow. As the pressure increases, the lips open wider. As the pressure gets lower, the lips return to a flatten and close.

Why does my check valve keep chattering?

Some check valve systems have chattering caused by repeated opening and closing of the valve. This is caused by oversizing of the check valve. When installing a check valve, it has to be sized to fit the application. The disk has to be stable in the open position and make a complete seal when closed, which can prevent repeated opening and closing, fluttering, and failure of the check valve.

What is a butterfly check valve?

A butterfly check valve is also known as a dual, folding disk, double disk, or splits check valve. The halves of the disk open toward the centerline, as seen in the diagram, during the forward flow of the fluid. With reverse flow, the halves open and seal the pipe. The short distance that the halves have to travel lessens the slamming effect on the disks. Butterfly check valves operate very quietly making them ideal for heating, ventilation, and air conditioning systems.

How does a tilting disk valve work?

A tilting disk check valve has its pivot point at the center of the disk so that the fluid flows over the top and bottom of the disk. They are often used where there is frequent flow reversal. When the disk is open, the flow keeps it open, which is different from a swing check valve where the velocity of the flow keeps it open. The disk is small and light with a center of gravity that is close to its pivot point. It has a low pressure drop with low flow rates and a higher pressure drop with high flow rates.