What is carbon black ink?

The technical term for the substance is “ carbon black ,” and it is the powder that remains after burning coal or oil. The powder is mixed with a polymer and a solvent to turn it into smooth, flowing black rollerball ink. “So, if you can do it with soot, can we do the same with air pollution?”

What is tattoo ink made of?

For colors like yellow, orange, and shades of red, colorants were made from cadmium red and cadmium yellow. Nowadays, carbon is the main basis for tattoo ink, counting for 80% of all ink being carbon-based. However, cinnabar and cadmium compounds are still used to make ink colorants, but in a smaller percentage.

What is the binding agent in carbon ink?

Carbon inks were commonly made from lampblack or soot and a binding agent such as gum arabic or animal glue. The binding agent keeps carbon particles in suspension and adhered to paper. Carbon particles do not fade over time even when bleached or when in sunlight.

What is carbon black made of?

Typically, carbon black comprises more than 95 percent carbon, with traces of hydrogen, nitrogen, and oxygen. During the fabrication process, particles of carbon black form in sizes ranging from 10-500 nanometers.

How do you make carbon ink?

1:388:25Ink made of air pollution | Anirudh Sharma - YouTubeYouTubeStart of suggested clipEnd of suggested clipThere are factories around the world that are burning fossil fuels to produce carbon black to makeMoreThere are factories around the world that are burning fossil fuels to produce carbon black to make black inks that we use on everyday basis.

What is black carbon ink made from?

use in pen drawing One was black carbon ink, made from extremely fine particles of the soot of burnt oils or resins in a solution of glue or gum arabic. The finest type of black carbon ink was known as Chinese ink and was the prototype of the modern black India…

Who invented carbon ink?

30–50 minutes of car pollution can supply enough carbon to fill one AIR-INK pen....Air-Ink.TypePrivateIndustryMaterial Science, Industrial inksFounded2016FounderMIT Media LabHeadquartersCambridge , United States of America3 more rows

How do you make carbon black ink?

Black Ink Ingredients1/2 tsp. lamp black (You can buy lamp black or carbon black or you can make your own by completely burning paper or wood.)1 egg yolk.1 tsp. gum arabic.1/2 cup honey.

Is carbon black harmful?

The most likely effect of exposure to carbon black is lung disease. Inhaling carbon black particles can irritate the lungs and cause coughing. Carbon black can also irritate the eyes, nose and throat. When people are exposed to high levels of carbon black over many years, the particles may lodge deep in their lungs.

Is ink made from fossil fuels?

"The black ink we generally use is often produced by burning fossil fuels in factories. Given that millions of liters of fossil fuels are already being burned by fossil fuel sources cars, why not recycle their emissions?" said the founder of the start-up, Anirudh Sharma, during a TEDs talk, in October 2018.

Can you buy Air-Ink?

After rounds of prototyping, their first “Air-Ink” products are ready for market and currently being offered on Kickstarter. You can get Air-Ink in two forms: felt-tip pen markers ideal for calligraphy and lettering, and bottled silkscreen ink.

How do you make smoke ink?

The black ink we use in our pens or in inkjet printers is essentially made from soot. The technical term for the substance is “carbon black,” and it is the powder that remains after burning coal or oil. The powder is mixed with a polymer and a solvent to turn it into smooth, flowing black rollerball ink.

Is carbon black safe in tattoos?

Generally, black tattoo inks are safe for use on the human body. The black tattoo inks used in this study were found to consist of nano-sized particles with high carbon purity.

Why is carbon black used in ink?

Printing Systems Speciality carbon black are the most widely-used pigment for making black printing inks. Compared to other coloring and tinting materials, carbon black provides higher efficiency in combination with excellent fastness against light, temperature and various chemical substances.

Which tattoo ink is the safest?

BlackBlack remains safest. Blue and green inks with copper phthalocyanine pigments are safe too.

How do you make lampblack ink?

1:415:39How To Make Lampblack (Ancient Ink & Rare Firework Ingredient)YouTubeStart of suggested clipEnd of suggested clipWhen the pot is set on top the natural draft of the fire pulls air down the pipes to the base of theMoreWhen the pot is set on top the natural draft of the fire pulls air down the pipes to the base of the flame. And now we are starting to form lamp black as it collects on the bottom of the pot.

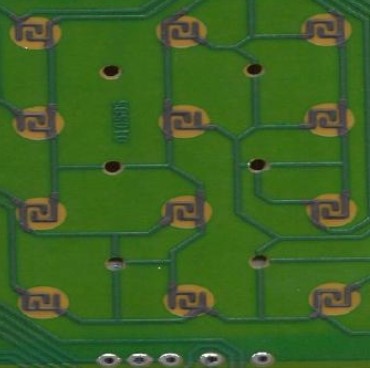

What is carbon ink?

Carbon ink PCB (printed circuit board) is coated on the PCB substrate with carbon-based conductive ink (referred to as carbon ink), cured to form a PCB with a carbon film conductive pattern. Now the market’s requirements for PCB board production costs have dropped repeatedly, and it is a general trend to use carbon oil keys to replace the current expensive gold keys. Carbon oil board is a relatively common surface treatment method for single and double PCBs. Through a series of inspections, tests and aging tests, and other technical processes, the PCB can work reliably for a long time.

What is the square resistance of carbon ink?

The carbon ink has strong adhesion, peeling resistance, and strong abrasion resistance, which can reach ≥ 1 million times, and the resistance change rate is ≤ 10%. The square resistance of conductive paste is relatively large compared to other metals. The square resistance of the current carbon oil board can generally be controlled at ≤ 20 ohms, but the cost is low with a high-performance cost ratio. The conductive paste is a crucial material for electronic component packaging, electrodes, and interconnection of electronic components. It mainly includes two types: burn-in conductive paste and curing conductive adhesive (conductive ink).

How big is the gap between the copper pad and the carbon oil window?

3. The size of the carbon oil window and the gap between the copper pattern: Due to the alignment tolerance and oil leakage and to ensure copper is not exposed, the carbon oil must be 6mil (HOZ bottom copper) or 8mil (1-3OZ bottom copper) larger than the copper pad on one side. Correspondingly, a gap of 6 mil (HOZ bottom copper) and 8 mil (1-3OZ bottom copper) between the carbon oil window and the surrounding copper pattern is required. This is to prevent carbon oil from covering the surrounding copper pattern, to avoid short circuits.

How big is the carbon oil pad?

The carbon oil contact pad is larger than the solder mask opening by 0.20mm on one side (min 0.15mm).

How long to bake carbon key board?

Generally, the thickness of the 1.2mm board is baked at 120℃ for 80 minutes, and the 1.6mm board is baked at 120℃ for 90 minutes. If shrinkage treatment is not conducted before printing, the board will shrink after etching, grinding, green solder mask, and carbon oil bridge process. If pre-shrinkage treatment is done in advance, the shrinkage will be minimal in production.

Why do you put silver oil in carbon oil?

Some suppliers add a little silver oil into the carbon oil to obtain lower resistance and higher conductivity.

What is carbon oil board used for?

Carbon oil board is mainly used in film circuits, mobile phone soft circuits, medical devices, communication equipment, automotive electronics, smart label RFID, and many other industries. In the circuit board industry, it is mainly used for calculators and remote controls. It can replace copper-plated holes, silver slurry hole fillings, and the copper slurry hole filling process. Environmental protection and the low cost of carbon slurry hole filling is the mainstream trend of the development of circuit boards. Currently, Microsoft uses carbon oil filling holes on the power supply board, which can completely replace the double-layer board with copper-plated holes.

What is black ink?

Black ink – generally carbon-based, contains iron oxide and potentially logwood. It is believed that black ink can contain bone back, powdered jet, wustite, and carbon soot as well. When it comes to carriers, there are generally isopropyl alcohol, witch hazel, and water.

What Is In Tattoo Ink?

To put it as simply as possible, tattoo inks of any kind comprise a tattoo colorant or pigment, and a carrier.

Are There Any Ink Alternatives?

So far, the most common alternative to the standard ink is the so-called vegan ink. This type of ink is believed to be more environmentally friendly since it supposedly doesn’t use animal-originating or carbon-based ingredients.

What is the main ink for tattoos?

Nowadays, carbon is the main basis for tattoo ink, counting for 80% of all ink being carbon-based. However, cinnabar and cadmium compounds are still used to make ink colorants, but in a smaller percentage. Since there is no direct insight into tattoo ink ingredients (and amount of ingredients used), we cannot say for sure how many tattoo ink colorants are cadmium- or cinnabar-based.

What are colorants made of?

For years, colorants were made from carbon and iron oxide primarily. These mineral sources were used to make black ink. For other colors, like red, ink colorants were made from cinnabar, which is a mercury sulfide compound. For colors like yellow, orange, and shades of red, colorants were made from cadmium red and cadmium yellow.

What is carrier ink?

Carriers, on the other hand, are fluid ink components that can be either glycerin, isopropyl alcohol, witch hazel, or distilled water. These components are responsible for transferring the colorant or pigment to the so-called ‘injection site’, which is the dermis of the skin. When the carriers are alcohol-based, they help carry more pigment into the skin, due to increased skin permeability. Carriers keep the pigments evenly mixed and free of pathogens as well.

Why is red ink bad for you?

Red ink, for example, is notoriously avoided because it is proven to contain cancer-causing ingredients. Red ink ingredients are even on the EPA list of common causes of allergies, infections, and cancer.

What Materials are used to Make Printer Ink?

They are derived from multiple sources which are rich in nitrogen compounds. Within printers, ink is utilized to create digital images or text copies.

What pigments are used to make ink?

Distinct color pigments will be applied to produce specific ink colors. While most white and black inks are derived from titanium dioxide or carbon black, they might be combined with various pigments to change their color.

Why Does Printer Ink Cost so Much?

However, the wiser course of action is to purchase the official toner or ink cartridges for your model, because they will last longer.

Why do pigments make ink opaque?

Sometimes the pigments will be mixed with opacifiers, which causes the ink to become opaque, or extenders that provide balance for the appearance of the pigment. The pigment might also be pulverized so it will displace in a more even manner within the fluids.

What is ink cartridge?

Ink cartridges are usually found in inkjet printers and are the container that holds the ink which is placed on the paper while printing. Every cartridge contains at least a single ink reservoir and some have multiple; manufacturers might also install chips or electronic contacts with which the printer communicates.

What is inkjet printer?

Inkjet-style printers will spray miniature ink droplets through small nozzles onto the paper to produce a digital copy of images or documents. Toner is different and consists of a powder that is very fine and comprised of polyester, which is a form of plastic.

What is the difference between black ink and white ink?

The ink consists of multiple ingredients such as resin, solvents, pigments, varnish, and additives like lubricants and wax. Black ink uses carbonized black pigments, while white pigments such as titanium dioxide are used for lighter ink colors.

What are the additives in tattoo ink?

These additives can include preservatives or binding agents that are designed to provide vibrant, long-lasting results . It would be best to talk with your tattoo artist about the ink they use, so they can give you as much information as they can on the brand. If for some reason they do not have the information you’re looking for they can contact the manufacturer directly.

How does tattoo ink work?

The tattoo artist has to inject the ink solution into the right layer of the skin to achieve permanent results. Ink needs to reach the skin’s dermis layer, which is the thickest layer between the epidermis and hypodermis. The ink needs to get to the dermis because it does not shed itself as quickly as the epidermis. Every person has a fresh epidermis layer every three to four weeks, and if the ink does not penetrate past the epidermis, the tattoo will fade away within a matter of weeks.

Why is carrier important for tattoo design?

When selecting a tattoo design, most individuals are focused on the color of the ink. However, the carrier plays a strong role that is equally important to the success of the overall design. The carrier component of the tattoo ink solution allows the color to be transported to the tattoo’s actual location. Carriers may contain a variety of ingredients, such as water, alcohol, or witch hazel. Most tattoo artists prefer alcohol-based carriers because these types are not only effective but also the safest. This is because the alcohol prevents bacteria from growing in the ink solution.

How long does tattoo ink last?

It takes more than just luck and skill to design a beautiful tattoo, be it an angel wings tattoo or anything else, that will last for years to come. Tattoo artists need to understand the science behind creating a tattoo, too.

Why do tattoos use pigments?

This is because pigments can provide concrete shades, and they do not rely on a chemical reaction to develop the correct color. Pigments are more reliable, and they stay in place within the design better than dyes would.

Is it safe to use ink for tattoos?

Depending on the ingredients included in the tattoo ink solution, you may be at risk for an allergic reaction. If you have any known allergies, you should work closely with your tattoo artist to ensure that the ink solution they use is safe for you. Ink Spread.

Is pigment better than dye?

Pigments are more reliable, and they stay in place within the design better than dyes would . It is important to be aware that every tattoo ink color is created with different ingredients. Previously, most tattoo ink solutions were made with mineral-based pigments.

How was carbon black made?

During the industrial revolution, the easy availability of coal tar made it possible to mass-produce carbon black. However, techniques were still virtually the same as those used in ancient Rome. In the mid-1800s, carbon black fabrication began to use filter systems, making the process more environmentally friendly. At the same time, in North America, a method that used natural gas as a feedstock was developed. Firing plants in the United States were designed to take advantage of the abundant supplies of natural gas produced through oil extraction, with firing plants becoming mobile operations that moved on to another well once gas from one was depleted.

How much carbon is in carbon black?

Typically, carbon black comprises more than 95 percent carbon, with traces of hydrogen, nitrogen, and oxygen. During the fabrication process, particles of carbon black form in sizes ranging from 10-500 nanometers. These particles then join into chains of aggregates, with the structure of these determining the carbon black grade, with the end product either powdered or granulated.

What is the History of Carbon Black?

Ancient people in China and Egypt mixed soot into tar, vegetable oils, or resins to create dyes and inks. The ancient Greeks, and later the Romans at a larger scale, used furnaces lined with bricks to make large quantities of carbon black, which they used to decorate walls. This was the precursor to the lamp black process for making carbon black.

What is carbon black used for?

Though used primarily for rubber reinforcement, carbon black has several visual properties, making it essential as a coating material and pigment. It is also still used in the printing industry and other specialized applications. Fine carbon black particles are used in paints, including as a key ingredient in jet-black colors for coloring polymers.

Why is rubber called carbon black?

Because of its importance within the rubber industry, it’s often referred to as rubber carbon black.

Why is carbon black used in rubber?

Carbon black is used with natural rubber and synthetic elastomers; carbon black acts as a reinforcer, strengthening the material. This involves mixing carbon black with elastomers and sulfur, along with multiple processing oils and chemicals. These are then heated to produce a wide variety of products.

What equipment is used to process carbon black?

The prime piece of equipment used for processing carbon black is the reactor in which it’s fired, with adjustments to conditions producing different grades. Temperatures, flow rates, time in the reactor , and reactor design all affect the physical characteristics of the end product.

What is air ink made of?

In 2013, Sharma and a few friends “hacked” an inkjet printer cartridge to print using ink made from soot from a candle at the Fluid Interfaces Group at MIT’s Media Lab. A year later, following the completion of his master's degree at MIT, Sharma returned to India to focus fully on developing what would become a product called AIR-INK, the first commercial ink made entirely from air pollution. It started as a small proof of concept experiment using soot from air pollution to make paint. When it worked, he and his team built a lab in a small garage in Bangalore to create a device that could capture air pollution at the source, in engines or factory machinery. In the six months they spent in India refining their technology, it wasn’t hard to find pollution sources for experimenting.

What is carbon black?

The technical term for the substance is “ carbon black ,” and it is the powder that remains after burning coal or oil. The powder is mixed with a polymer and a solvent to turn it into smooth, flowing black rollerball ink. “So, if you can do it with soot, can we do the same with air pollution?”.

Where is air ink on display?

About 45 minutes of diesel car pollution reaps 30 milliliters of AIR-INK, now on display at the Cooper Hewitt, Smithsonian Design Museum

How does Kaalink work?

Now, Kaalink can by scaled up to filter air pollution from just about any source, like a smokestack on small machinery or even straight out of the air, and turn it into soot, which is then hydrated to form ink that can be used in AIR-INK pens and markers . Each marker holds about 30 milliliters of AIR-INK, which is equivalent to approximately 45 ...

What was the first ink?

The earliest inks from all civilizations are believed to have been made with lampblack, a kind of soot, as this would have been easily collected as a by-product of fire. Ink was used in Ancient Egypt for writing and drawing on papyrus from at least the 26th century BC.

How many percent of ink is pigment?

Pigment molecules typically link together in crystalline structures that are 0.1–2 µm in size and comprise 5–30 percent of the ink volume. Qualities such as hue, saturation, and lightness vary depending on the source and type of pigment.

How long have Chinese inks been around?

Chinese inks may go back as far as three or maybe four millennia, to the Chinese Neolithic Period. These used plants, animal, and mineral inks based on such materials as graphite that were ground with water and applied with ink brushes. Direct evidence for the earliest Chinese inks, similar to modern inksticks, is around 256 BC in the end of the Warring States period and produced from soot and animal glue. The best inks for drawing or painting on paper or silk are produced from the resin of the pine tree. They must be between 50 and 100 years old. The Chinese inkstick is produced with a fish glue, whereas Japanese glue (膠 "nikawa") is from cow or stag.

Why is indelible ink so short?

Indelible means "unremovable". Some types of indelible ink have a very short shelf life because of the quickly evaporating solvents used. India, Mexico, Indonesia, Malaysia and other developing countries have used indelible ink in the form of electoral stain to prevent electoral fraud. Election ink based on silver nitrate was first applied in the 1962 Indian general election, after being developed at the National Physical Laboratory of India .

Why are pigments used more frequently than dyes?

Main article: Pigment. Pigment inks are used more frequently than dyes because they are more color-fast, but they are also more expensive, less consistent in color, and have less of a color range than dyes. Pigments are solid, opaque particles suspended in ink to provide color.

What is thicker ink used for?

Thicker inks, in paste form, are used extensively in letterpress and lithographic printing . Ink can be a complex medium, composed of solvents, pigments, dyes, resins, lubricants, solubilizers, surfactants, particulate matter, fluorescents, and other materials.

What is the difference between ink and quill?

Writing ink and a quill. Ink is a gel, sol, or solution that contains at least one colourant , such as a dye or pigment, and is used to color a surface to produce an image, text, or design. Ink is used for drawing or writing with a pen, brush, reed pen, or quill.

What is carbon black used for?

A good conductor of electricity, carbon black is used as a filler mixed in plastics, elastomer, films, adhesives, and paints. It is used as an antistatic additive agent in automobile fuel caps and pipes. Carbon black from vegetable origin is used as a food coloring, known in Europe as additive E153.

Who published Carbon Black?

Carbon Black: A users guide. Published by the International Carbon Black Association.

How much carbon black was produced in 2006?

Total production was around 8,100,000 metric tons (8,900,000 short tons) in 2006. Global consumption of carbon black, estimated at 13.2 million metric tons, valued at US$13.7 billion, in 2015, is expected to reach 13.9 million metric tons, valued at US$14.4 billion in 2016.

What is ivory black made of?

Ivory black was traditionally produced by charring ivory or bones (see bone char ).

What is the recommended exposure limit for carbon black?

The National Institute for Occupational Safety and Health (NIOSH) has set a Recommended exposure limit (REL) of 3.5 mg/m 3 over an 8-hour workday. At levels of 1750 mg/m 3, carbon black is immediately dangerous to life and health.

How much carbon black is inhaled?

The Occupational Safety and Health Administration (OSHA) has set the legal limit ( Permissible exposure limit) for carbon black exposure in the workplace at 3.5 mg/m 3 over an 8-hour workday.

What artists use carbon black?

Rembrandt, Vermeer, Van Dyck, and more recently, Cézanne, Picasso and Manet employed carbon black pigments in their paintings. A typical example is Manet's " Music in the Tuileries ", where the black dresses and the men's hats are painted in ivory black.