Engineering controls can reduce harm by:

- Isolating workers from chemicals (eg, Using a self-contained lube station)

- Enclosing high risk operations in sealed areas (eg, Sealing off an area that is only opened during maintenance and cleaning)

- Extracting contaminants from the breathing zone of workers (eg, Installing a Local Exhaust Ventilation (LEV) system)

What are engineering controls?

Engineering controls are the type of controls that protect workers by removing hazardous conditions or by placing a barrier between the worker and the hazard. These controls focus on the source of the hazard, unlike other types of controls that generally focus on the employee exposed to the hazard.

How are engineering controls used to isolate workers from hazards?

The three basic methods of engineering controls used to isolate these hazards are: Process control is an attempt to isolate the worker from hazards by changing the way a process is done or altering the machinery, tools, and equipment used in the process.

Why are engineering controls preferred over administrative and personal protective equipment?

Engineering controls are favored over administrative and personal protective equipment (PPE) for controlling existing worker exposures in the workplace because they are designed to remove the hazard at the source, before it comes in contact with the worker.

What are the engineering controls for Psychosocial hazards?

Psychosocial hazards. Engineering controls for psychosocial hazards include workplace design to affect the amount, type, and level of personal control of work, as well as access controls and alarms. The risk of workplace violence can be reduced through physical design of the workplace or by cameras.

Which is an example of an engineering control?

Examples of engineering controls include installing guardrails to prevent falls, limiting exposure to hazardous chemicals via ventilation, using portable air conditioners to combat heat stress and installing noise absorption panels to dampen high noise levels.

What are the 4 engineering controls?

Engineering controls consist of a variety of methods for minimizing hazards, including process control, enclosure and isolation, and ventilation. Process controls involve changing the way that a job activity is performed in order to reduce risk.

How does the OSHA define and engineering control?

Engineering controls do this, unlike other controls that generally focus on the employee exposed to the hazard. The basic concept behind engineering controls is that, to the extent feasible, the work environment and the job itself should be designed to eliminate hazards or reduce exposure to hazards.

What are engineering controls in the workplace?

Engineering controls reduce or prevent hazards from coming into contact with workers. Engineering controls can include modifying equipment or the workspace, using protective barriers, ventilation, and more. The NIOSH Engineering Controls Database has examples of published engineering control research findings.

What are 5 engineering controls?

Safeopedia Explains Engineering Controls These include fall hazards, noise, aerosols, fumes, gasses, potentially harmful drugs, contaminated materials such as used needles, and hazardous building materials such as asbestos.

What are the 5 types of controlling hazards?

There are five general categories of control measures: elimination, substitution, engineering controls, administrative controls and personal protective equipment.

What are the three engineering controls?

A. The engineering control methods that can be used to reduce or eliminate lead exposures can be grouped into three main categories: (1) substitution; (2) isolation; and (3) ventilation. Engineering controls are the first line of defense in protecting workers from hazardous exposures.

What are the engineering controls in the SDS?

Two of the most common engineering controls found on an SDS are local exhaust and general ventilation.

Is a fire extinguisher an engineering control?

Appropriate and mandated engineering controls include ventilation, fume hoods, fire extinguishers, eyewash stations, and safety showers.

Is Loto an engineering control?

The traditional electrical LOTO process is an administrative control that is inherently manual and relies on detail-oriented workers.

What are the 4 levels of PPE?

Levels of PPEFull-face or half-mask, air-purifying respirator (NIOSH approved).Chemical resistant clothing (one piece coverall, hooded two piece chemical splash suit, chemical resistant hood and apron, disposable chemical resistant coveralls.)Gloves, outer, chemical resistant.Gloves, inner, chemical resistant.More items...

What is the difference between engineering controls and administrative controls?

Engineering controls might include changing the weight of objects, changing work surface heights, or purchasing lifting aids. Administrative controls are workplace policy, procedures, and practices that minimize the exposure of workers to risk conditions.

What are examples of engineering controls for safety?

Engineering controls protect workers by removing hazardous conditions or by placing a barrier between the worker and the hazard. Examples include local exhaust ventilation to capture and remove airborne emissions or machine guards to shield the worker.

Is Loto an engineering control?

The traditional electrical LOTO process is an administrative control that is inherently manual and relies on detail-oriented workers.

What are engineering controls quizlet?

Engineering controls. objects used in the workplace that isolate or remove a hazard, thereby reducing the risk of exposure. Engineering controls include. Biohazard bags and labels. PPE.

What are examples of work practice controls?

Prohibiting recapping, removing or bending needles unless no other exists; enforcing hand washing procedures following the removal of gloves, restricting eating and drinking in work areas; and decontaminating equipment before servicing are all examples of work practice controls.

How are engineering controls used?

Engineering controls are physical changes to the workplace that isolate workers from hazards by containing them in an enclosure, or removing contaminated air from the workplace through ventilation and filtering. Well-designed engineering controls are typically passive, in the sense of being independent of worker interactions, which reduces the potential for worker behavior to impact exposure levels. They also ideally do not interfere with productivity and ease of processing for the worker, because otherwise the operator may be motivated to circumvent the controls. The initial cost of engineering controls can be higher than administrative controls or personal protective equipment, but the long-term operating costs are frequently lower, and can sometimes provide cost savings in other areas of the process. : 10–11

What is a well designed engineering control?

Well-designed engineering controls are typically passive, in the sense of being independent of worker interactions, which reduces the potential for worker behavior to impact exposure levels.

What is the National Institute for Occupational Safety and Health?

National Institute for Occupational Safety and Health researches engineering control technologies, and provides information on their details and effectiveness in the NIOSH Engineering Controls Database.

How can engineering control be used to reduce inhalation exposure?

Engineering control approaches are often oriented towards reducing inhalation exposure through ventilation and isolation of the toxic material. However, isolation can also be useful for preventing skin and eye contact as well, reducing reliance on personal protective equipment which should be the control of last resort.

What are non-ventilation engineering controls?

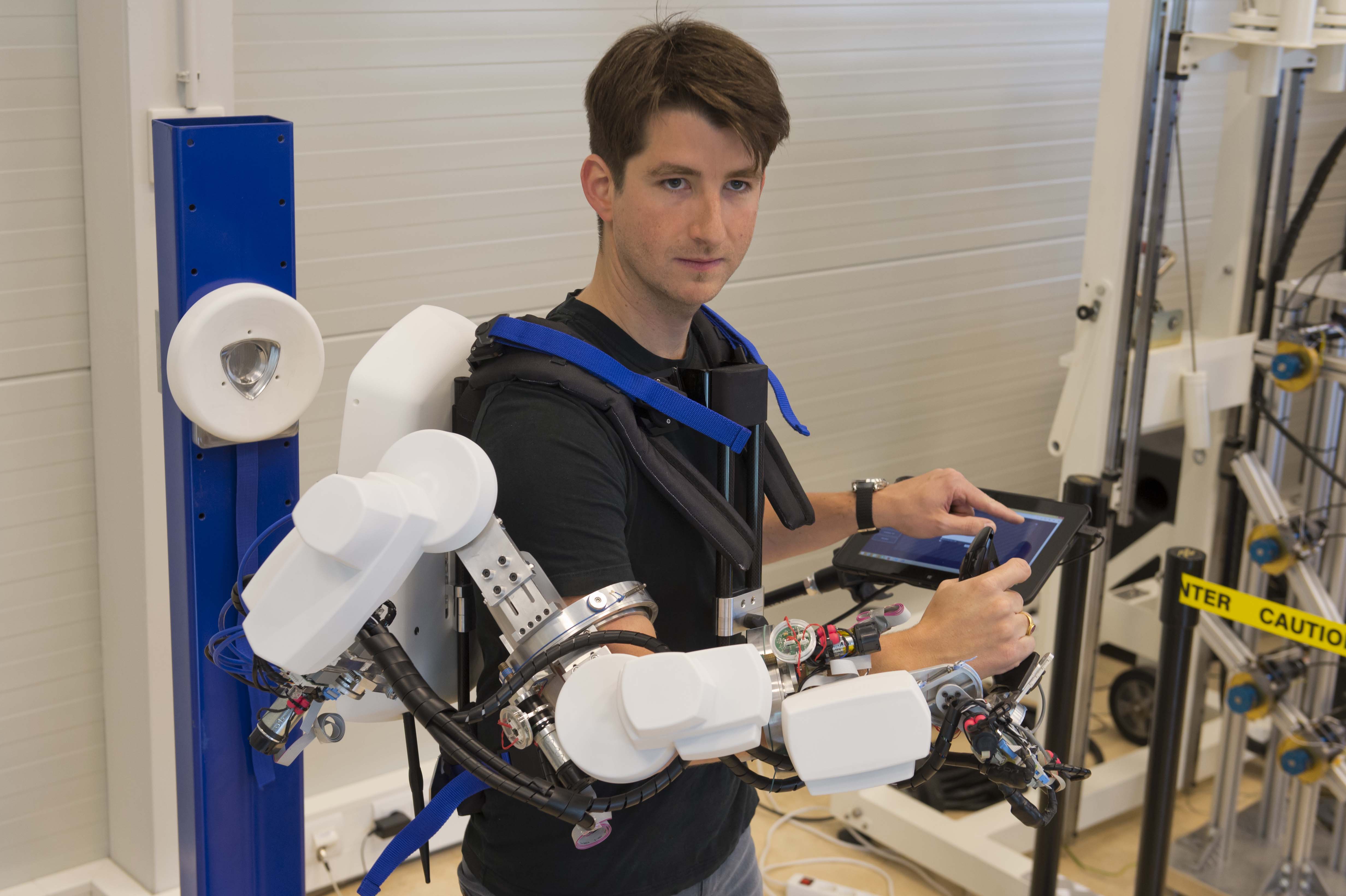

Non-ventilation engineering controls can also include devices developed for the pharmaceutical industry, including isolation containment systems. One of the most common flexible isolation systems is glovebox containment, which can be used as an enclosure around small-scale powder processes, such as mixing and drying. Rigid glovebox isolation units also provide a method for isolating the worker from the process and are often used for medium-scale operations involving transfer of powders. Glovebags are similar to rigid gloveboxes, but they are flexible and disposable. They are used for small operations for containment or protection from contamination. Gloveboxes are sealed systems that provide a high degree of operator protection, but are more difficult to use due to limited mobility and size of operation. Transferring materials into and out of the enclosure also is an exposure risk. In addition, some gloveboxes are configured to use positive pressure, which can increase the risk of leaks. : 24–28

Why are engineering controls preferred over administrative controls and personal protective equipment (PPE)?

Engineering controls are preferred over administrative controls and personal protective equipment (PPE) because they are designed to remove the hazard at the source, before it comes in contact with the worker.

Which is the third most effective member of the hierarchy of hazard controls?

Engineering controls are the third most effective member of the hierarchy of hazard controls. They are preferred over administrative controls and personal protective equipment, but are less preferred than elimination or substitution of the hazards.

When can engineering controls be used?

When hazards can't be eliminated from a work process, engineering controls can be used in conjunction with other control methods to isolate workers from the hazards.

What are the three methods of engineering controls used to isolate hazards?

Chemical fumes and other air contaminants. The three basic methods of engineering controls used to isolate these hazards are: Process control. Isolation and containment. Ventilation.

Why are engineering controls more effective than administrative controls?

Engineering controls are more effective than administrative and PPE controls because they modify the work environment and equipment to reduce or isolate the worker from the source of the exposure to a hazard. There are a variety of engineering controls used for different types of exposure.

What is process control?

Process control is an attempt to isolate the worker from hazards by changing the way a process is done or altering the machinery, tools, and equipment used in the process.

How does process control isolate hazards?

The three basic methods of engineering controls used to isolate these hazards are: Process control is an attempt to isolate the worker from hazards by changing the way a process is done or altering the machinery, tools, and equipment used in the process.

What is a control measure?

Control measures are those measures designed to protect workers by preventing and controlling hazards in the workplace. Both The National Institute for Occupational Safety and Health (NIOSH) and the Occupational Safety and Health Administration (OSHA) recognize the following Hierarchy of Controls for controlling workplace hazards.

Which is more effective, PPE or engineering controls?

Engineering controls. Administrative controls. Personal protective equipment (PPE) Engineering controls are more effective than administrative and PPE controls because they modify the work environment and equipment to reduce or isolate the worker from the source of the exposure to a hazard.

What Does Engineering Controls Mean?

Engineering controls are designs or modifications to equipment, industrial plants, processes, or systems that reduce the risk of worker exposure to a hazard. They operate on a “hazard isolation principle”, either by removing a hazardous workplace condition (such as through ventilation) or by placing a barrier between the worker and the hazard (such as through machine guards). These methods control hazards either at the source of the hazard or in transmission, rather than protecting the worker at the point of exposure to the hazard. Engineering controls offer a uniform standard of protection to all workers and function continuously without human supervision or intervention.

Why are engineering controls more reliable than personal protective equipment?

Because engineering controls operate independently of human action, they are considered to be more reliable than the use of personal protective equipment or behaviour guidelines (administrative controls), which may fail upon use due to individual human error.

What is OSHA 1910.1000?

OSHA regulations for certain types of exposure require the use of engineering controls. For instance, OSHA’s standard for exposure to air contaminants (no. 1910.1000) requires the use of engineering controls where practicable. Advertisement. Advertisement.

What are engineering controls?

The term ‘Engineering Controls’ covers a broad spectrum of possible interventions that are intended to reduce worker exposure, to chemical, physical and biological agents. This article will explain what ‘Engineering Controls’ are with respect to chemical and biological agents and how they fit into the hierarchy of controls. Examples are given of engineering controls along with some advantages and limitations. The importance of matching the control measure to the health risk and its reliability is also discussed along with commissioning. Once control has been achieved the article will explain why maintenance and checks are vital in order to maintain good control and therefore reduce worker exposure.

Why are engineering controls important?

Clearly engineering controls are designed to reduce exposure and to assist companies in complying with health and safety regulations and occupational exposure limits. However, it is possible that they may help to reduce environmental pollution and, importantly can make an economic impact by reducing company expenditure on such items as product consumables. Two examples of this are given in .

How to control chemical risk?

This principal of priority is often referred to as the ‘Hierarchy of Control’. The European Control Hierarchy, as stipulated by Council Directive 98/24/EC gives the priority order and is summarised below: 1. Elimination of hazardous substances 2. Substitution by a substance less hazardous 3. Design of appropriate work processes and engineering controls and use of adequate equipment and materials, so as to avoid or minimise the release of hazardous chemical agents which may present a risk to workers' safety and health at the place of work 4. Application of collective protection measures at the source of the risk, such as adequate ventilation and appropriate organisational measures 5. Where exposure cannot be prevented by other means, the application of individual protection measures including personal protective equipment (PPE). The directive goes on to state that hazardous chemical agents shall be eliminated or reduced to a minimum by: • the design and organisation of systems of work at the workplace, • the provision of suitable equipment for work with chemical agents and maintenance procedures which ensure the health and safety of workers at work, • reducing to a minimum the number of workers exposed or likely to be exposed, • reducing to a minimum the duration and intensity of exposure, • appropriate hygiene measures, • reducing the quantity of chemical agents present at the workplace to the minimum required for the type of work concerned. It should be noted that this hierarchical approach is not unique to Europe and is adopted by safety professionals worldwide . From the above list it can be seen that engineering controls are integrated into steps 1 to 4. For example it can be argued that modifying a manufacturing process so as to eliminate the hazardous substance is a form of engineering control. However, it is common practice to associate engineering controls with steps 3 and 4: i.e. once elimination and substitution of chemical hazards have been considered. At times engineering controls may not offer adequate control and may need to be supplemented with other measures. Often this will take the form of PPE, which includes respiratory protection equipment (RPE). As can been seen from the priority list, PPE is the last step if all other interventions fail to offer sufficient protection. The problem with PPE is that it only protects the wearer. For RPE this is of particular concern as whilst the process operator may be protected from an airborne hazard, once it is released into the air it will inevitably pervade the workplace and therefore expose others who are likely to be unprotected. Furthermore for RPE to be effective it needs to be properly selected and correctly fitted, making training and user cooperation essential.

What is required to be considered before engineering controls can be contemplated?

Before engineering controls can be contemplated it is necessary to understand how the contaminant is being released into the workplace. This requires a full understanding of how the process works and how workers interact with the process. Ideally workers should be involved in the design and selection of the controls, as they will be using them on a daily basis. Failure to do this often results in engineering controls that are unworkable resulting in poor exposure control. Depending on the process, other disciplines may also need to be consulted, in particular the engineering function, as their input may be required to ensure the more intricate nuances of the process are considered and understood (for example quality of the final product is not affected by the introduction of the control measure).

What is commissioning in engineering?

Once a control measure is designed and installed it needs to be commissioned. ‘Commissioning’ is proving that the engineering control is capable of providing adequate exposure control. The type of commissioning and the complexity depends upon the control measure. Probably the most complex commissioning process is that of LEV systems. Unfortunately LEV commissioning is frequently carried out incompletely or is inadequate. LEV commissioning tends to focus on the engineering parameters, such as system pressures and air velocities. Whilst this is an essential part of the commissioning process, a judgement on the effectiveness of the controls and the worker exposure needs to be taken. There are a number of qualitative and quantitative tools available to help the assessor judge control. An example of a qualitative assessment is the use of smoke tubes to visualise the air flow in and around an LEV hood in order to assess LEV performance. An example of a quantitative control is personal sampling to quantify worker exposure to a particular substance (s).

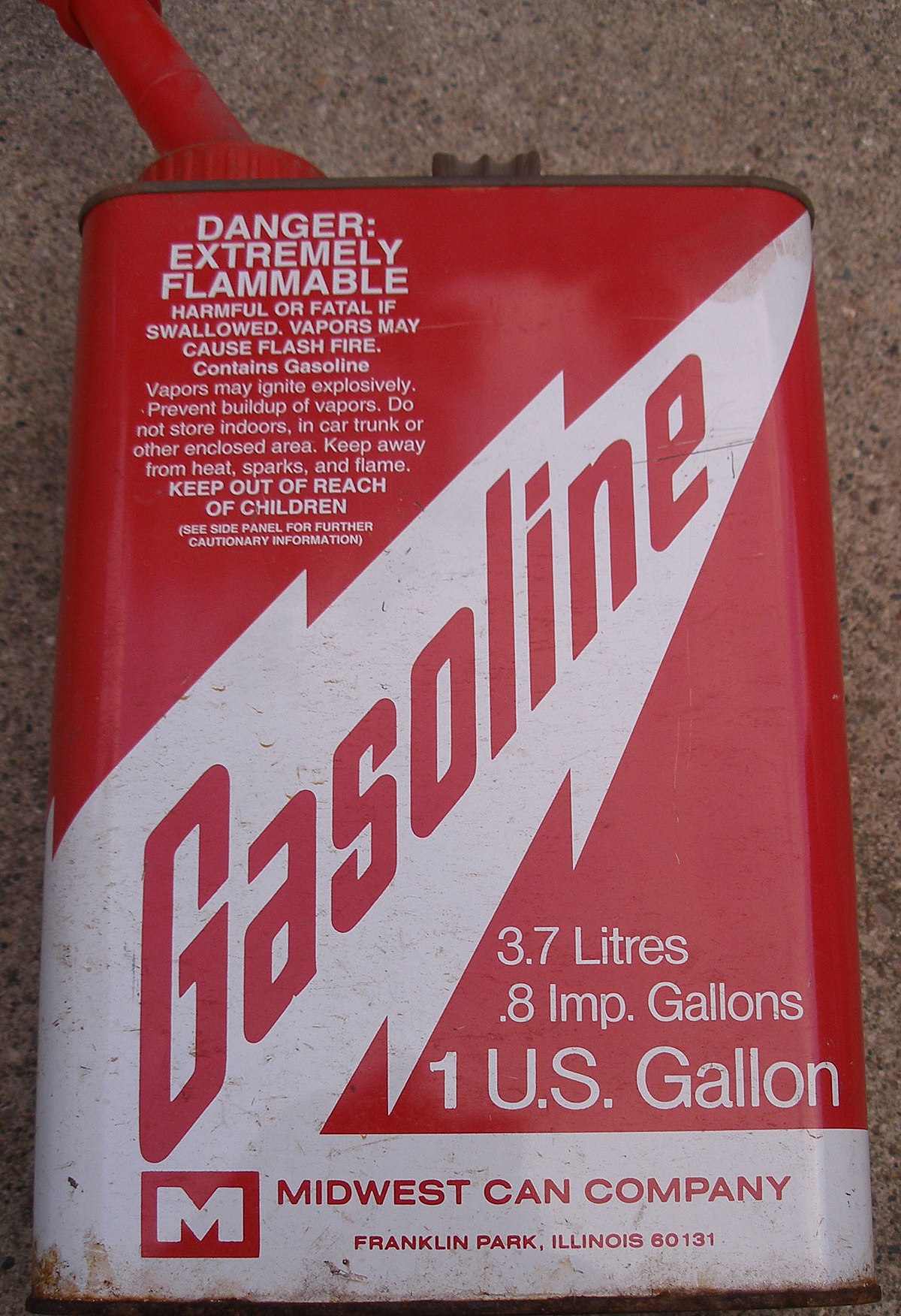

What is non ventilation control?

Non-ventilation controls have the capability to reduce or eliminate process emission rate, for example the use of well fitting lids to liquid containers. They can range from enclosures, seals, jigs and handling aids. However, engineering controls are frequently assumed to involve some form of ventilation control.

What is the problem with PPE?

The problem with PPE is that it only protects the wearer.

What is the purpose of engineering controls?

Purpose. Engineering controls reduce or eliminate exposure to chemical or physical hazards through the use of equipment or devices. Engineering controls function with minimum user input and do not rely on the skill or vigilance of individuals. If a hazard cannot be eliminated or a safer substitute cannot be found, ...

When should a safety shield be used?

Whenever a potentially explosive reaction is being carried out (such as generation of diazomethane) or the use of pressurized equipment is involved, a safety shield should be used to provide added protection against an implosion.

What can impair the effectiveness of a local exhaust system?

Drafts, traffic, and heating sources can impair the effectiveness of a local exhaust system. Chemical fume hoods contain hazardous dusts, gases, vapors, and fumes that are generated within them and remove them via the building's ventilation system.

Why is a vacuum line important?

Vacuum line protection. Vacuum systems (both centralized and stand-alone pumps) are commonly used to help researchers filter reagents and dispose of waste. It is very important to protect your vacuum system from chemical; and biohazards routinely used in research.

How do vacuums protect against chemicals?

House vacuum systems must be protected from chemicals by filters.

Why do laboratories have emergency override buttons?

Some laboratories install emergency override buttons (see image at right) to provide maximum room ventilation in the event of a chemical emergency that impacts laboratory air. Only activate this button if you feel laboratory air has been impacted by a chemical emergency.

What is the best approach to keep a hazard from a laboratory worker?

If a hazard cannot be eliminated or a safer substitute cannot be found, the next best approach is to use engineering controls to keep the hazard from a laboratory worker. Engineering controls are often used with administrative controls* and personal protective equipment. Read about engineering controls at UC San Diego:

What are engineering controls?

Engineering controls are considered the first line of defense in the laboratory for the reduction or elimination of the potential exposure to hazardous chemicals. Examples of engineering controls used in laboratories at Cornell include dilution ventilation, local exhaust ventilation, chemical fume hoods, glove boxes and other containment ...

Why do laboratories need to consider available engineering controls?

Laboratory personnel need to consider available engineering controls to protect themselves against chemical exposures before beginning any new experiment (s) involving the use of hazardous chemicals.

Who is responsible for reporting malfunctioning protective equipment?

However, it is the responsibility of laboratory personnel to immediately report malfunctioning protective equipment, such as fume hoods, or mechanical problems to their Building Coordinator as soon as any malfunctions are discovered. American Glove Box Society.

Why are engineering controls important?

Engineering controls are favored over administrative and personal protective equipment (PPE) for controlling existing worker exposures in the workplace because they are designed to remove the hazard at the source, before it comes in contact with the worker. Well-designed engineering controls can be highly effective in protecting workers and will typically be independent of worker interactions to provide this high level of protection. The initial cost of engineering controls can be higher than the cost of administrative controls or PPE, but over the longer term, operating costs are frequently lower, and in some instances, can provide a cost savings in other areas of the process.

What is administrative control?

Administrative controls and PPE are frequently used with existing processes where hazards are not particularly well controlled. Administrative controls and PPE programs may be relatively inexpensive to establish but, over the long term, can be very costly to sustain. These methods for protecting workers have also proven to be less effective than other measures, requiring significant effort by the affected workers.

What is the hierarchy of controls?

Traditionally, a hierarchy of controls has been used as a means of determining how to implement feasible and effective control solutions.

Overview

Engineering controls are strategies designed to protect workers from hazardous conditions by placing a barrier between the worker and the hazard or by removing a hazardous substance through air ventilation. Engineering controls involve a physical change to the workplace itself, rather than relying on workers' behavior or requiring workers to wear protective clothing.

Engineering controls is the third of five members of the hierarchy of hazard controls, which order…

Background

Controlling exposures to occupational hazards is considered the fundamental method of protecting workers. Traditionally, a hierarchy of controls has been used as a means of determining how to implement feasible and effective controls, which typically include elimination, substitution, engineering controls, administrative controls, and personal protective equipment. Methods earlier in …

Chemical and biological hazards

Various chemical hazards and biological hazards are known to cause disease. Engineering control approaches are often oriented towards reducing inhalation exposure through ventilation and isolation of the toxic material. However, isolation can also be useful for preventing skin and eye contact as well, reducing reliance on personal protective equipment which should be the control of last r…

Physical hazards

Ergonomics is the study of how employees relate to their work environments. Ergonomists and industrial hygienists aim to prevent musculoskeletal disorders and soft tissue injuries by fitting the workers to their work space. Tools, lighting, tasks, controls, displays, and equipment as well as the employee's capabilities and limitations must all be considered to create an ergonomically appropriate workplace.

Psychosocial hazards

Engineering controls for psychosocial hazards include workplace design to affect the amount, type, and level of personal control of work, as well as access controls and alarms. The risk of workplace violence can be reduced through physical design of the workplace or by cameras.

See also

• Engineering controls for nanomaterials

Further reading

• Harold E. Roland; Brian Moriarty (10 October 1990). System Safety Engineering and Management. John Wiley & Sons. pp. 73–. ISBN 978-0-471-61816-4.

• Jeanne Mager Stellman (1 January 1998). Encyclopaedia of Occupational Health and Safety: Chemical, industries and occupations. International Labour Organization. pp. 871–. ISBN 978-92-2-109816-4.

Relation Between Engineering Controls and Osha

- Occupational Safety and Health Administration (OSHA) is a body charged with ensuring employees' safety in the workplace. OSHA has three lines of defense, including personal protective equipment, administrative and work practice, and engineering control. Therefore, it relies on engineering controls to set the standards needed to create a healthy wor...

Importance of Engineering Controls in Construction

- Engineering controls in construction work minimize the employees' risks and creates a barrier between them and the threats they are exposed to. The construction site employees are exposed to dangerous fumes like silica and asphalt. Silica dust is found in the earth's crust, and its dust particles clog the lung tissues, reducing lung capacity. On the other hand, inhaling asphalt can c…

Common Engineering Controls

- There are different types of engineering controls, and the common engineering control examplesinclude process controls, isolation, containment, and ventilation. They are explained as follows.

Engineering Controls Examples

- Engineering control examples include inventing rag holders for solvent rags, pumping volatile liquids instead of pouring, and installing a fence with a locked gate to isolate workers from an electrical hazard. The engineering control examples are discussed below.