What is scheduling and controlling in production?

At its best, scheduling and controlling, production refers to creating a scheduled (or prioritized) list of tasks for every machine. The list should maximize the output of each tool while keeping cycle time as low as possible for the whole production flow. I will refer to 3 types of an organization from the easiest to the most complex:

What is horizontal loading in a scheduling system?

This process is referred to as horizontal loading. The scheduler using finite loading can then project the number of hours each work center will operate. A drawback of horizontal loading is that jobs may be kept waiting at a work center, even though the work center is idle.

Why do you need production planning and scheduling software?

You need effective production planning software to track your flow and find production scheduling issues to get to the root of a problem. Understanding production planning and scheduling allow you to oversee your manufacturing methodically to overcome production issues easily.

What is a finite loading scheduler?

Finite loading considers the capacity of each work center and compares the processing time so that process time does not exceed capacity. With finite loading the scheduler loads the job that has the highest priority on all work centers it will require.

What is loading and scheduling?

Loading The next step is the execution of the schedule plan as per the route chalked out it includes the assignment of the work to the operators at their machines or work places. So loading determines who will do the work as routing determines where and scheduling determines when it shall be done.

What is scheduling in the production process?

Scheduling is the process of arranging, controlling and optimizing work and workloads in a production process or manufacturing process. Scheduling is used to allocate plant and machinery resources, plan human resources, plan production processes and purchase materials.

What is production control scheduling?

Scheduling is essentially the short-term execution plan of a production planning model. Production scheduling consists of the activities performed in a manufacturing company in order to manage and control the execution of a production process.

What is loading in operation?

Loading means the assignment of Jobs to work or processing centers. Operations Managers assign jobs to work centers so that cost and completion times are kept to a minimum. Work centers are areas in a business in which productive resources are organized and work is completed.

What is scheduling and types of scheduling?

Comparison between SchedulerS.N.Long Term Scheduler2Speed is lesser than short term scheduler3It controls the degree of multiprogramming4It is almost absent or minimal in time sharing system5It selects processes from pool and loads them into memory for execution1 more row

What are the two types of scheduling?

An operating system uses two types of scheduling processes execution, preemptive and non - preemptive.Preemptive process: In preemptive scheduling policy, a low priority process has to be suspend its execution if high priority process is waiting in the same queue for its execution.Non - Preemptive process:

What is loading in production management?

Loading. A load means the quantity of work, and allocating the quantity of work to the processes necessary to manufacture each item is called loading. It is performed in the CRP (Capacity Requirements Planning) of the manufacturing planning.

What is the purpose of scheduling?

The Importance of Scheduling Scheduling is the art of planning your activities so that you can achieve your goals and priorities in the time you have available. When it's done effectively, it helps you: Understand what you can realistically achieve with your time. Make sure you have enough time for essential tasks.

What are the 4 components of production scheduling?

Five Components of Production Scheduling1) Planning2) Routing.3) Scheduling4) Dispatching5) Execution

What is scheduling and sequencing?

Scheduling involves the determination of two types of decisions: Allocation decisions – which resources (here called machines) will be assigned to perform each of a given set of jobs; and. Sequencing decisions – in what order and when are each of these jobs performed.

What is scheduling in an organization?

Scheduling pertains to establishing both the timing and use of resources within an organization. Under the operations function (both manufacturing and services), scheduling relates to use of equipment and facilities, the scheduling of human activities, and receipt of materials.

What is a scheduling service?

Scheduling Service is the utility which helps you to schedule jobs or tasks for execution at a future point of time. The 'time' can range from a few seconds in the immediate future to some other date in the distant future. The task is executed at the scheduled time by worker threads.

What is the difference between loading and sequencing?

Loading involves assigning jobs to work centers or machines in the work centers while sequencing is concerned with determining the order in which j...

What is scheduling and sequencing?

SCHEDULING AND SEQUENCING -Presented by Akanksha Gupta 2. Scheduling • Scheduling: The allocation of resources over time to accomplish specific tasks.

What is loading and scheduling in production control?

What is loading and scheduling in production control? Loading. A load means the quantity of work, and allocating the quantity of work to the proces...

What is operations scheduling?

• Operations scheduling: A type of scheduling in which jobs are assigned to workstations or employees are assigned to jobs for specified time perio...

Get professional help and free up your time for more important courses

Scheduling, loading and sequencing. (2018, Jan 04). Retrieved from https://phdessay.com/scheduling-loading-and-sequencing/

Cite this page

Scheduling, loading and sequencing. (2018, Jan 04). Retrieved from https://phdessay.com/scheduling-loading-and-sequencing/

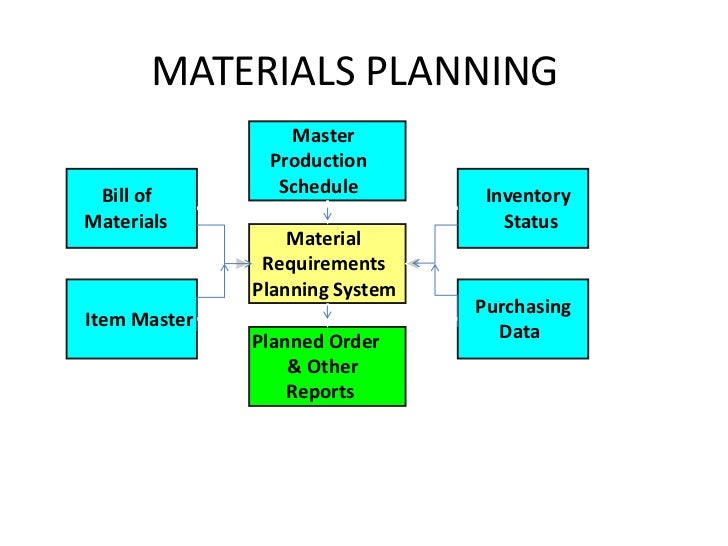

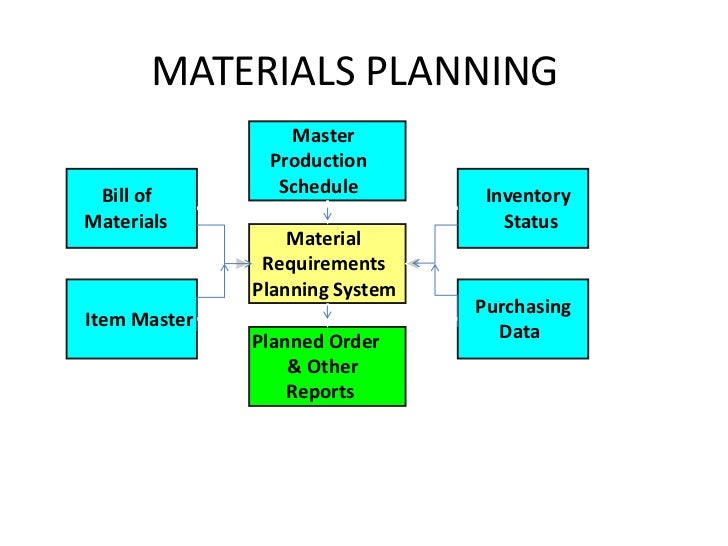

What is a master production schedule?

Master Production Scheduling (MPS) is a scheduling strategy that dictates when and how much of each product is going to be produced based on criteria such as demand, capacity, and inventory availability.

When does the third stage of production control start?

The third stage of production control starts when production is initiated. That is, when the scheduling plan is implemented, materials and work orders are released, and work is flowing down the production line.

What is the first stage of production planning?

The first stage of production planning is to determine the path of production from raw materials to finished goods. Here, you will determine the equipment, resources, materials and sequence to be used. 2. Scheduling. The second stage of production planning is to determine when operations are scheduled.

What is PPC in manufacturing?

Production planning and control (PPC) is a term that combines two strategies: production planning and production control. In the manufacturing world, production planning and control are defined by four stages: Routing, Scheduling, Dispatching, and Follow-Up. The first two stages relate to production planning while the second two relate ...

What are the benefits of production planning and control?

The benefits of production planning and control include: Improved organization for regular and timely delivery. Better supplier communication for raw materials procurement.

What is production planning?

Production planning and control refers to two strategies that work cohesively throughout the manufacturing process. Production planning involves what to produce, when to produce it, how much to produce, and more. A long-term view of production planning is necessary to fully optimize the production flow.

What is infinite loading?

With infinite loading jobs are assigned to work centers without regard for capacity of the work center. Priority rules are appropriate for use under the infinite loading approach. Jobs are loaded at work centers according to the chosen priority rule. This is known as vertical loading.

What is the drawback of horizontal loading?

A drawback of horizontal loading is that jobs may be kept waiting at a work center, even though the work center is idle. This happens when a higher priority job is expected to arrive shortly.

Why is the work center idle?

The work center is kept idle so that it will be ready to process the higher priority job as soon as it arrives. With vertical loading the work center would be fully loaded. Of course, this would mean that a higher priority job would then have to wait to be processed since the work center was already busy.

What is dispatching in construction?

In particular, dispatching refers to: (i) Procurement of necessary tools, jigs and fixtures etc.; before they are actually required by the workmen. (ii) Giving workers the necessary work orders, instructions, drawings etc. for initiating the work. Follow-Up (or Checking the Progress)

What is the purpose of routing?

The objective of routing is to. find out the best and the cheapest sequence of operations.

What is inspection in manufacturing?

Inspection is the quality control aspect of production planning and control. It ensures that goods produced are of the right quality. The inspectors may inspect materials, semi-finished and finished products either at the work bench or in special laboratories or testing rooms. To ensure maintenance of high standards of quality, ...

Can a job be processed on only one machine?

If a job can be processed on only one machine, no difficulty is presented. However, if a job can be loaded on multiple work centers or machines, and there are multiple jobs to process, the assignment process becomes more complicated.

What is production planning?

Production planning is the process in manufacturing that ensures you have sufficient raw materials, labor and resources in order to produce finished products to schedule. It is a crucial step in production management and scheduling. Complete production planning involves the accurate tracking of:

Why is production planning important?

Production planning is vital for any manufacturing or craft business. Even basic products need a clear and defined flow to turn them from raw materials into quality goods. If this is not followed, your products are sure to drop in quality. Without a proper process, your standardized practices are sure to be forgotten.

What is manufacturing route?

Routing is the route or path, to be followed during each step of the manufacturing process. The manufacturing route defines the path from raw materials through to the production of a finished product. If done correctly you’ll know at what stage your item is at and which machine, tool, or work center it needs to travel to next.

What is production planning?

Production planning for an organization that has tools (machines) that basically load raw material, process it and create a product. There might be other steps in the production process, but there is no other production process that competes for the same resources.

What are the parameters to prioritize batches?

Decide how to prioritize the batches. There can be one or more of the following parameters: earlier promise dates, FIFO, sales priority, customer priority , or any other relevant parameters. Of course, we can use more than one parameter.

Can scheduling software be integrated with ERP?

The scheduling software can be integrated with the organizational ERP so that it will read, process, and write data back to the ERP. It can also be a standalone software that only reads data from the ERP and creates a standalone production plan for each tool.

Can you use more than one tool in a production flow?

Many tools can be used for more than one phase in the production flow (the material runs on a machine and gets back to a similar machine after a dozen steps). There is always a conflict between running more batches an hour on each tool or running the “right” batches so that we will not have WIP bubbles.

What is scheduling in manufacturing?

Scheduling can be defined as “prescribing of when and where each operation necessary to manufacture the product is to be performed.”. It is also defined as “establishing of times at which to begin and complete each event or operation comprising a procedure”.

What is the principle of scheduling?

The principle aim of scheduling is to plan the sequence of work so that production can be systematically arranged towards the end of completion of all products by due date. The principle of optimum task size: Scheduling tends to achieve maximum efficiency when the task sizes are small, and all tasks of same order of magnitude.

What is backward scheduling?

Backward scheduling. is often used in assembly type industries and commit in advance to specific delivery dates. Backward scheduling determines the start and finish times for waiting jobs by assigning them to the latest available time slot that will enable each job to be completed just when it is due, but done before.