Definition: Potential failure mode is defined as the manner in which the process could potentially fail to meet the process requirements and/or design intent as decribed in the process function/requirements column. (Page 39) So, when performing a Process FMEA

Failure mode and effects analysis

Failure mode and effects analysis (FMEA)—also "failure modes", plural, in many publications—was one of the first highly structured, systematic techniques for failure analysis. It was developed by reliability engineers in the late 1950s to study problems that might arise from malfunctions of military systems. An FMEA is often the first step of a system reliability study.

What is potential failure mode in process management?

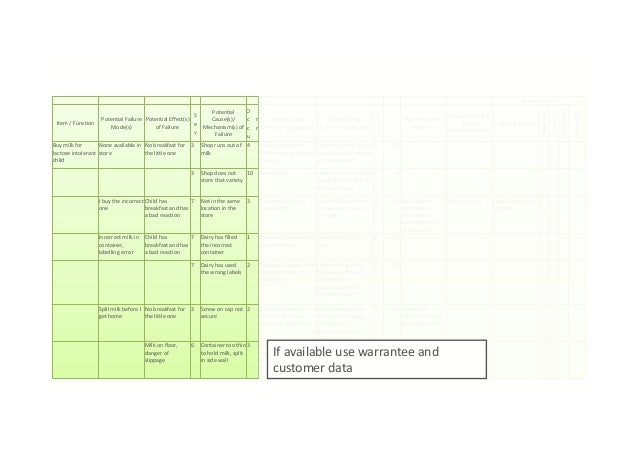

Definition: Potential failure mode is defined as the manner in which the process could potentially fail to meet the process requirements and/or design intent as decribed in the process function/requirements column. (Page 39) So, when performing a Process FMEA, a failure mode can be a process failure and/or a product failure.

What is potential failure mode in FMEA?

I use the AIAG FMEA manual as my reference here... Definition: Potential failure mode is defined as the manner in which the process could potentially fail to meet the process requirements and/or design intent as decribed in the process function/requirements column. (Page 39)

What is failure modes and effects analysis?

Failure modes and effects analysis ( FMEA) is a step-by-step approach for identifying all possible failures in a design, a manufacturing or assembly process, or a product or service. “Failure modes” means the ways, or modes, in which something might fail.

What is the meaning of failure mode?

Something goes wrong in the process resulting in the "Failure Mode" : Improperly installed wheel nut. In this example (appropriate in most examples) the "Failure Mode" is the opposite of the intent "requirement/step". Now while the car is being driven, the wheel falls off.

How do you identify potential failure modes?

Step 1: Identify potential failures and effects. The first FMEA step is to analyze functional requirements and their effects to identify all failure modes. ... Step 2: Determine severity. Severity is the seriousness of failure consequences of failure. ... Step 3: Gauge likelihood of occurrence. ... Step 4: Failure detection.

How do you describe failure mode?

A failure mode is a cause of failure or one possible way a system can fail. When a system has many potential ways of failing, it has multiple failure modes or competing risks. The more complex a system is, the more failure modes there are.

What is failure mode example?

Failure mode – common ones Premature operation. The user did not operate the machine, for example, at the right time. The user did not cease operation at the right time. Something went wrong while the machine was in operation.

What is meant by failure mode analysis?

Failure Modes and Effects Analysis (FMEA) is a systematic, proactive method for evaluating a process to identify where and how it might fail and to assess the relative impact of different failures, in order to identify the parts of the process that are most in need of change.

What are the 4 modes of failure?

For mechanical devices, there are four Failure Mechanisms: corrosion, erosion, fatigue and overload. While those Failure mechanisms exists many places in nature, they may or may not be present in the specific working environment of an asset.

What are types of failure?

4 Types of Failure We Have all Experienced and Will AgainAbject Failure.Glorious Failure.Common Failure.Predicted failure.

What are the 3 types of FMEA?

Types of FMEA: Process FMEA (PFMEA) Functional FMEA (FFMEA) / System FMEA (SFMEA) Software FMEA.

What is the difference between failure mode and failure effect?

Failure Mode and Effects Analysis (FMEA) is a structured approach to discovering potential failures that may exist within the design of a product or process. Failure modes are the ways in which a process can fail. Effects are the ways that these failures can lead to waste, defects or harmful outcomes for the customer.

What is the difference between failure mode and failure mechanism?

Failure Modes are associated with deviant function or behaviour. Failure Mechanisms are associated with deviant physical condition or physical state. A Failure Mechanism is a direct cause of a Failure Mode.

What is process failure mode and effect analysis?

A Process Failure Mode Effects Analysis (PFMEA) is a structured analytical tool used by an organization, business unit or cross-functional team to identify and evaluate the potential failures of a process.

What is failure effect?

A Failure Effect documents the consequence of a failure occurring. Most FMEA methodologies use Failure Effects to capture the safety, environmental, and economic (or production) impacts associated with a failure.

What are the 5 steps of the FMEA process?

Here's an overview of the 10 steps to a Process FMEA.STEP 1: Review the process. ... STEP 2: Brainstorm potential failure modes. ... STEP 3: List potential effects of each failure. ... STEP 4: Assign Severity rankings. ... STEP 5: Assign Occurrence rankings. ... STEP 6: Assign Detection rankings. ... STEP 7: Calculate the RPN.More items...•

What is failure effect?

A Failure Effect documents the consequence of a failure occurring. Most FMEA methodologies use Failure Effects to capture the safety, environmental, and economic (or production) impacts associated with a failure.

What is the difference between failure mode and failure mechanism?

Failure Modes are associated with deviant function or behaviour. Failure Mechanisms are associated with deviant physical condition or physical state. A Failure Mechanism is a direct cause of a Failure Mode.

How do you perform failure mode and maintenance analysis?

How to perform FMECA analysisStep 1: Perform FMEA. ... Step 2: Determine your parameters. ... Step 3: Adjust failure rate for redundancy. ... Step 4: Calculate criticality number or RPN. ... Step 5: Create a criticality matrix. ... Step 6: Determine critical items and take appropriate action.

What is process failure mode and effect analysis?

A Process Failure Mode Effects Analysis (PFMEA) is a structured analytical tool used by an organization, business unit or cross-functional team to identify and evaluate the potential failures of a process.

What is potential failure mode?

Definition: Potential failure mode is defined as the manner in which the process could potentially fail to meet the process requirements and/or design intent as decribed in the process function/requirements column. (Page 39)

What is failure mode and effects analysis?

Failure modes and effects analysis ( FMEA) is a step-by-step approach for identifying all possible failures in a design, a manufacturing or assembly process, or a product or service.

Why keep FMEA to 3?

The reason I try to keep the causes to no more than 3 is the fact that your FMEA can become really large. Let's say someone stated a potential cause was "Martians did it". The occurence rating would be say a 1. Would I keep this in my process FMEA? No, I would discard it. The number keeping no more than 3 is not solid but not too many have more than 3 potential causes with occurence rating over 5 or 6.

What is process FMEA?

Process FMEA focuses on manufacturing and assembly processes. Refer to this website for more info - http://www.npd-solutions.com/fmea.html

What is failure mode in FMEA?

So, when performing a Process FMEA, a failure mode can be a process failure and/or a product failure.

What does "capable of being but not yet in existence" mean?

Capable of being but not yet in existence; latent: a potential problem.

Is there confusion over failure modes in a Process FMEA mixing a potential cause with a potential failure?

There is a lot of confusion over failure modes in a Process FMEA mixing a potential cause with a potential failure mode.

What is failure mode?

It is a common process analysis tool. "Failure modes" means the ways, or modes, in which something might fail. Failures are any errors or defects, especially ones that affect the customer, and can be potential or actual. "Effects analysis" refers to studying the consequences of those failures.

What is failure mode analysis?

military, failure modes and effects analysis (FMEA) is a step-by-step approach for identifying all possible failures in a design, a manufacturing or assembly process, or a product or service.

What to know before undertaking an FMEA process?

Before undertaking an FMEA process, learn more about standards and specific methods in your organization and industry through other references and training.

How to calculate risk priority number?

Calculate the risk priority number, or RPN, which equals S × O × D. Also calculate Criticality by multiplying severity by occurrence, S × O . These numbers provide guidance for ranking potential failures in the order they should be addressed.

Why is failure prioritized?

Failures are prioritized according to how serious their consequences are, how frequently they occur, and how easily they can be detected. The purpose of the FMEA is to take actions to eliminate or reduce failures, starting with the highest-priority ones.

What is critical characteristic?

Optional for most industries: Ask, "Is this failure mode associated with a critical characteristic?" (Critical characteristics are measurements or indicators that reflect safety or compliance with government regulations and need special controls.) If so, a column labeled "Classification" receives a Y or N to show whether special controls are needed. Usually, critical characteristics have a severity of 9 or 10 and occurrence and detection ratings above 3.

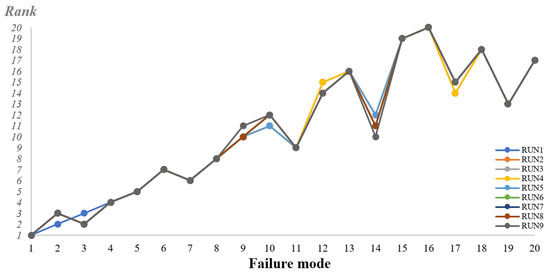

What are the first and second highest risks of RPN?

Notice that RPN and criticality prioritize causes differently. According to the RPN, "machine jams" and "heavy computer network traffic" are the first and second highest risks.

Why is failure mode important?

In the following example, Failure Mode A is important because it is likely to escape to the customer. Failure Modes B and C, are critical because they could be costly. Failure Modes.

What is failure mode and effect analysis?

What is a Failure Mode and Effect Analysis (FMEA)? Failure Mode and Effect Analysis (FMEA), also known as “Potential Failure Modes and Effects Analysis” as well as “Failure Modes, Effects and Criticality Analysis (FMECA)” is a systematic method for identifying possible failures that pose the greatest overall risk for a process, product, ...

How Does FMEA Work?

Once each failure mode is identified , the data is analyzed, and three factors are quantified:

What is the RPN of failure mode?

The failure mode “data entered incorrectly” with a potential cause of “data entry error within a single field” has the highest RPN, and warrants further review since it has been identified that there are no controls in place, and a detectability score of 10 has been assigned. The failure mode for “application filled out incorrectly” has a lower RPN of 96 , but may also deserve further investigation since the severity rating is high at 8.

Why is FMEA important?

It is important to document and assess all changes that occur which affect quality or reliability.

What is FMEA in process control?

FMEA provides a structured approach to identifying and prioritizing potential failure modes, taking action to prevent and detect failure modes and making sure mechanisms are in place to ensure ongoing process control.

What is the potential failure for successful electronic transmission of a prepared tax return to the IRS?

For example, the potential failure for successful electronic transmission of a prepared tax return to the IRS would have a high Severity rating (due to an unfiled return), but if the filing system automatically checks for successful transmission then the Detection score is low. Ignoring the excellent detectability and pursuing designs to reduce the occurrence may be an unproductive use of team resources.

What is failure mode in a process?

a) the failure mode is a nonconforming output [i.e. "...fails to meet process requirements..."] (I would assume in context of your question that output is PRODUCT), which is potentially allowed to occur if the process fails.

What is a failure mode wheel nut?

The controls include torque and torque angle. Something goes wrong in the process resulting in the "Failure Mode" : Improperly installed wheel nut.

What is PFMEA in process management?

The PFMEA is simply a tool to help us see what might occur if our process fails, and then apply risk based thinking to determine what actions, if any, are necessary to prevent that process failure from happening .

What is PFMEA in business?

The PFMEA is simply a tool to help us see what might occur if our process fails, and then apply risk based thinking to determine what actions, if any, are necessary to prevent that process failure from happening . Specific to your question... , ...

What is failure mode?

The Concise Oxford English Dictionary defines “failure” as the act of ceasing to function or the state of not functioning. “Mode” is defined as a way in which something occurs.

What is an example of a mode of failure?

It goes beyond the antithesis, and provides more information. An example is “leak.”. If the container leaks, that describes the manner in which the container does not contain the fluid. By describing the mode of failure, we are one step closer to the cause. It also helps describe the effect of failure.

What is the definition of “Failure Mode” in an FMEA?

A “failure mode” is the manner in which an item or operation potentially fails to meet or deliver the intended function and associated requirements. Depending on the definition of failure established by the analysis team, failure modes may include failure to perform a function within defined limits, inadequate or poor performance of the function, intermittent performance of a function, and/or performing an unintended or undesired function. There may be many failure modes for each function.

How are Failure Modes identified in FMEAs?

The FMEA team can be asked a question, such as, “what is the manner in which the item does not accomplish its intended function ?” or similar questions.

What is an example of a Design FMEA failure mode?

Function: Delivers hydraulic power for steering by transforming oil pressure at inlet (xx psi) into higher oil pressure at outlet [yy psi] during engine idle speed

Why not merely fail?

Why not merely “failure”? The answer lies in the progression to root cause. FMEA is in part a journey from what an item is intended to do all the way to the root cause of why it does not accomplish its intention. Some practitioners identify “failure” as the antithesis of the function.

Is FMEA good practice?

Therefore, provided the FMEA team has the correct membership and is led by a skilled facilitator, it is good practice to limit FMEA entries to areas of genuine concern to one or more of the team members.

What is failure mode?

Failure modes are the ways in which a process can fail. Effects are the ways that these failures can lead to waste, defects or harmful outcomes for the customer. Failure Mode and Effects Analysis is designed to identify, prioritize and limit these failure modes.

What is failure mode and effect analysis?

Failure Mode and Effects Analysis, or FMEA, is a methodology aimed at allowing organizations to anticipate failure during the design stage by identifying all of the possible failures in a design or manufacturing process.

How does FMEA reconcile failure?

The FMEA and Problem Solving reconcile each failure and cause by cross documenting failure modes, problem statements and possible causes.

What are the two categories of FMEA?

There are two broad categories of FMEA, Design FMEA (DFMEA) and Process FMEA (PFMEA).

What are the causes of failure in a FMEA?

Causes in a FMEA are equivalent to potential root causes in Problem Solving. Effects of failure in a FMEA are Problem Symptoms in Problem Solving. More examples of this relationship are: The problem statements and descriptions are linked between both documents.

What is process FMEA?

Process FMEA (PFMEA) discovers failure that impacts product quality, reduced reliability of the process, customer dissatisfaction, and safety or environmental hazards derived from:

What is path 1 in FMEA?

Path 1 consists of inserting the functions, failure modes, effects of failure and Severity rankings. The pre-work documents assist in this task by taking information previously captured to populate the first few columns (depending on the worksheet selected) of the FMEA.

What are the effects of failure?

These consequences could include user injury, machine or process malfunction, or poor product quality. The system failure could also affect other systems directly related to it. Effects analysis studies how failures impact different system components.

What is the probability of occurrence of a failure?

The probability of occurrence is how often this failure or problem happens. These are also ranked 1–10, so a failure happening every 3rd time a machine turns on could be rated a 10, while a failure happening every 500,000 times a machine turns on could be a 1 or 2.

What is FMEA?

FMEA (Failure Mode and Effects Analysis, also known as Failure Modes and Effects Analysis or Failure Mode Effects Analysis), is a procedure used to pinpoint where certain systems or machinery might fail. That way, your team can set up a plan to proactively fix those systems. By reviewing as many components and subsystems as possible, you can identify the system’s potential failure modes and their root causes.

How does FMEA work?

Your team can use FMEA to evaluate and prevent possible failures by correcting early, rather than reactively—after failures have occurred. FMEA enables you to identify and prioritize failures according to how serious their consequences are, how often they happen, and how easy they are to find.

Why is FMEA important?

FMEA was created to study potential problems caused by malfunctioning military systems, and continues to be effective at discovering potential failures and evaluating system reliability. This allows you to correct and limit process failures early so you can avoid their negative impacts on your system.

What is FMEA in design?

FMEA has two broad categories: Design FMEA (DFMEA) and Process FMEA (PFMEA). Failures are errors or defects, and can be potential or actual. Failure modes are the ways a product or process fails. (In other words, what went wrong, and how.) Failure effects are the ways these failures can lead to waste, defects, or harmful outcomes.

What is FMEA safety?

FMEA helps lower risk of injuries through improved design and proactive repair.

Failure Mode, Cause, Effect

Physical/Abstract Failure Modes

- Not only do we use the term for physical things, i.e., things we can touch, but also abstract things. We cannot touch abstract things because they have no physical form, i.e., we can only think about them. Systems, such as management or computer software systems, for example, are abstract When we say ‘a failure mode,’ we are talking about one cause of failure. In other words, one poss…

Failure Mode – Common Ones

- Below is a list of some of the most common failure modes: 1. Premature operation. 2. The user did not operate the machine, for example, at the right time. 3. The user did not cease operation at the right time. 4. Something went wrong while the machine was in operation. 5. There was a degradation in the machine’s capability. 6. It is also possible that somebody overused it, i.e., pus…

Failure Mode and Effects Analysis

- FMEA-FMECA.com says “failure modes are a key ingredient to aFailure Mode and Effects Analysis (FMEA).” Reliability engineers in the late 1950s developed FMEA. It was one of the first highly structured systematic techniques for failure analysis. They developed FMEA to study problemsthat military systems might have. Failure analysis is the investigation into how somethi…

Video – Failure Mode and Effects Analysis

- This QIO Programvideo explains that FMEA is a proactive process that allows us to anticipate potential problems. This gives us a chance to take action to prevent potential problems from occurring. The video focuses on healthcare safety.