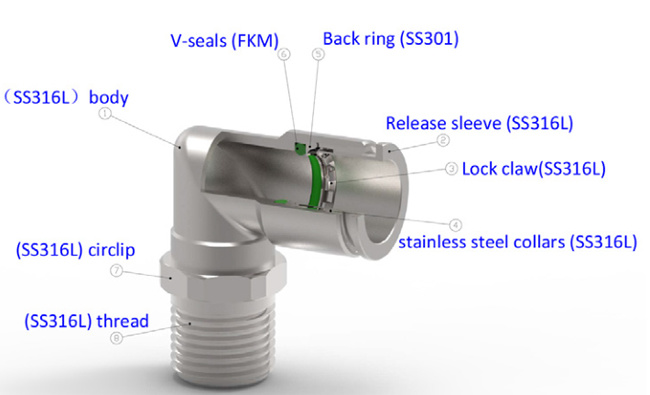

Push-to-connect fittings are universal pipe fittings that can be installed without the use of special tools. A mechanism inside the fitting locks the pipe using pressure inside the plumbing system. There is no need for soldering, crimping, or gluing. This type of fitting is also called a push-fit, push-in, or push-fit connector.

What are push-to-connect fittings?

“Push-to-connect”, “push-fit”, “push-in” and simply “push fittings” all refer to the same type of universal pipe fittings which are installed without use of special tools and which lock the pipe by means of counter-forces produced by the mechanism inside the fitting and by pressure inside the plumbing system. No more soldering, crimping or gluing.

How do you install a push-to-connect junction?

Create a push-to-connect junction in equipment with these fittings. To install, drill a stepped hole in your surface, push the fitting components into place, then insert your tubing. An all -metal body and built-in tube support or dual seals allow these fittings to handle the highest pressure ratings of all our push-to-connect tube fittings.

What are push to connect tube fittings made of?

Push-to-Connect Tube Fittings for Air and Water Made of nickel-plated brass, these tube fittings resist corrosion better than plain brass fittings. The male threaded ends connect to NPT, NPTF, BSPP, BSPT, and other universal threads, so you don’t have to bother matching exact thread types.

How do you install push to Connect plumbing fittings?

Create a push-to-connect junction in equipment with these fittings. To install, drill a stepped hole in your surface, push the fitting components into place, then insert your tubing. Connect these fittings to Schedule 40 plastic pipe— they are the industry standard for residential and commercial low-pressure plumbing and water supply applications.

What does push to connect mean?

Push-to-pull, push-to-connect, push-in, push-fit, or instant fittings are a type of easily removed compression fitting or quick connect fitting that allows an air (or water) line to be attached, nominally without the use of tools (a tool is still usually required for cutting tubing to length and removal).

Are push connect fittings reliable?

And they are more practical than permanent solvent-gluing CPVC and PVC pipes or sweat-soldering brass pipes with a torch in general plumbing applications. These fittings have proven to provide highly reliable connections even when they are hidden behind panels or other enclosed areas.

What is a push to connect coupling?

Push to Connect couplings allow for a fast and easy way to repeatedly connect and disconnect air or fluid lines. If a tube or hose in a fluid or air system needs to be disconnected and reconnected on a frequent basis the best solution is a Push to Connect fitting.

Do push to connect fittings leak?

While it's rare for quick-connects fittings to be defective, leaks are common because of improper installation, damage, or forceful pressure.

Do push-to-connect fittings last?

Most plumbers still prefer soldering over push-fit fittings as it provides a more secure and permanent connection. However push-fit may be a good option for your project and can be used as a permanent installation, especially in a pipe that poses less risk to future water damage.

What is the biggest advantage of push-to-connect fittings?

The speed of making a connection with push-fit fittings is perhaps the biggest advantage. In an emergency, you can quickly cap or repair a pipe by simply slipping on a push-fit fitting. Push-fit fittings are a great way to make pipe connections without having to solder or use clamps, unions, or glue.

Can you use push-to-connect on PVC?

SharkBite Push-to-connect PVC transition fittings are the fastest way to transition from PVC or IPS (iron pipe size) pipe to PEX, copper, CPVC, PE-RT, or HDPE pipe. No soldering, clamps, unions, glue, or special tools are required.

How do you stop a push fit joint from leaking?

Using wire wool or similar, clean around copper pipe fitting by stop end/cap to remove dirt. Using pair of pliers or a wrench, push/force push end further into pipe. If leak does not stop, drain down, and replace.

Can you use push fit without inserts?

Do I need to use an insert every time I connect Speedfit pipes to a fitting, and why are there two types of insert? The simple answer is yes, always use an insert when installing Speedfit pipes as it supports the shape of the pipe.

Can you use push fit on mains water?

Connecting water to the mains MDPE is the most common material used for robust, heavy-duty requirements, making our MDPE push fit fittings perfect for underground trenches and connecting mains water supplies to homes.

How long do SharkBite push to connect fittings last?

25 yearsHow long do SharkBite fittings last? SharkBite fittings last a long time. In fact, SharkBite warrants the fittings for 25 years when used with SharkBite tubing.

Are compression fittings better than push fit?

Solder fittings are the gold standard in copper, however compression fittings are generally the next level down and very reliable. I would stick with those over push fit as these can pop off.

How reliable are copper push-fit fittings?

Push fit fittings and pipes, like copper, can safely withstand heat and pressure so they're suitable for water and heating systems. Many joints are pressure tested to standards in excess of those usually required in domestic situations – 10 bar (100 psi) is common.

Do SharkBite fittings fail?

I had some sharkbite fittings installed in my basement about 2.5 years also and 2 of them have failed (pictures linked) and 2 more seem to be on their way to fail. The ones that are on the way to fail when touching the green substance feels oily.

Why are push fit fittings so popular?

Push-fit fittings are becoming more and more readily available in home improvement centers and hardware stores, mostly because consumers find them so easy to use. Compared to solvent-gluing CPVC and PVC pipes, or sweat-soldering copper pipes with a torch, push-fit fittings are remarkably easy to use and require no particular skill ...

What is a Neoprene O-ring?

Neoprene O-rings inside the fittings form tight, waterproof seals against the pipes. According to the American Society of Plumbing Engineers, these connections are dependable and secure even when hidden inside finished walls and ceilings. 1. When you are making joints for CPVC, PEX, or copper pipes, push-fit fittings are by far ...

What is gatorbite and sharkbite?

Sharkbite and Gatorbite are two well-known brand names. Regardless of the brand, push-fit fittings all have a similar internal structure that allows them to create a watertight seal when they are pushed onto a pipe. 3:17.

What should the package labels tell you?

The package labels should tell you the accepted usage of the fittings. Follow the manufacturer’s directions and recommendations to ensure that your connections are watertight and safe. There is a tool designed to remove certain types of push-fit fittings.

Can you cap a pipe with a push fit fitting?

In an emergency, you can quickly cap or repair a pipe by simply slipping on a push-fit fitting. Push-fit fittings are a great way to make pipe connections without having to solder or use clamps, unions, or glue. Pipes need not be perfectly dry when using push-fit fittings.

Do you need to dry pipe before soldering?

Pipes need not be perfectly dry when using push-fit fittings. This is in contrast with CPVC and PVC, which must be bone-dry before solvent gluing; or copper pipes, which also must be dry before soldering with a torch. Push-fit fittings are available in various materials for different kinds of applications.

Who is Aaron Stickley?

Aaron Stickley is a licensed plumber with first-hand knowledge in solving home plumbing problems.

What is a tube fitting made of?

Made of nickel-plated brass, these tube fittings resist corrosion better than plain brass fittings. The male threaded ends connect to NPT, NPTF, BSPP, BSPT, and other universal threads, so you don’t have to bother matching exact thread types.

How do ball bearings work?

Ball bearings allow these fittings to rotate 360°, even after they are tightened. They have a special seal that reduces friction to allow for continuous rotation.

What is a built in shut off valve?

A built -in shut-off valve stops airflow when the fittings are disconnected from tubing.

Why do tubing supports slip inside tubing?

Tube supports slip inside tubing to prevent the walls from collapsing.

What is an instant fitting?

Also known as instant fittings, they connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. Use in applications up to 150 psi.

What is Schedule 40 pipe?

Connect these fittings to Schedule 40 plastic pipe— they are the industry standard for residential and commercial low-pressure plumbing and water supply applications. They are plastic for good corrosion resistance.

What pressure is standard for a water pipe fitting?

Connect these fittings to standard-wall plastic pipe for use in low- to medium-pressure applications up to 810 psi. They are the industry standard for residential and commercial plumbing and water supply applications.

How to remove a sharkbite fitting?

Once pipe is secured inside the fitting, it can only be removed by pressing down on the fitting's collet or "release collar" (SharkBite): this is the small plastic ring that just barely sticks out of the fitting end. This "ring" is just the outer edge of a larger piece, whose other end features the metal teeth that grip onto the pipe. John Guest collets need only fingertips to push in; SharkBite and ProBite release collars call for a special disconnect tool (or careful use of an adjustable crescent wrench: slide over pipe, adjust to size, and push the collar firmly into the fitting while gently pulling the pipe out).

How long is the warranty on Sharkbite?

Something to think about... Still not sure if you should trust push-fit? Consider this: SharkBite and John Guest fittings have a 25-year warranty; ProBite fittings carry a whopping 75-year warranty.

What is a push fit?

All push-fits work using three primary elements: a collet featuring a ring of metal teeth that firmly grasps the pipe, one or more O-rings that create a watertight seal, and a locking mechanism that keeps everything together. The fittings are designed to work with CPVC, PEX, and hard drawn copper pipe (types K, L, M). Most are not compatible with soft copper tubing, with the exception of John Guest fittings (soft copper easily deforms and does not return to shape, making it difficult to achieve a good seal). Smaller John Guest fittings can also be used with vinyl or polyethylene tubing for things like water filters and refrigerator icemakers.

How much does a 1/2" push fit cost?

Note: The convenience of push-fit does come at a premium: push-fit fittings will cost significantly more per piece than other options: a 1/2" push-fit coupling will run between $4-$8, while its copper or CPVC counterpart will be less than a dollar.

How to keep push fit fittings from leaking?

The most important thing you can do to guarantee leak-free performance out of a push-fit fitting is to have a clean, smooth cut that's free of burrs and maintains the shape of the pipe. This keeps the O-rings from getting damaged, ensuring a tight seal.

Do you need inserts for PEX?

When working with PEX, you'll need to make sure a special insert is used that keeps the tubing from col lapsing. SharkBite and ProBite come with an insert already inside the fitting; all you need to do is push the tubing in. With John Guest fittings, inserts will need to be purchased separately and manually placed in the tube end (s).

Can you reuse Sharkbite caps?

SharkBite recommends reuse only for testing purposes (e.g. reusing caps to check leaks, test pressure), never permanent installation. When burying push-fit fittings, make sure they're prevented from making direct contact with soil/backfill by wrapping them with chloride-free tape, insulation, or some other barrier.

What is a tubing 61?

This tubing has hard walls like copper tubing, but is lighter in weight and easier to install. It connects to fittings with no heat or soldering required. Tubing meets NSF/ANSI Standard 61 for drinking water.

Why is hard tubing bagged?

Designed for high-purity applications, this hard tubing is cleaned and bagged to prevent dirt and moisture from contaminating the inside. It is free of plasticizers like DEHP, so it won’t impart tastes or odors to the fluid running through it.

How much pressure can a tubing handle?

Excellent strength and durability allow this tubing to handle high-pressure air and water applications up to 950 psi.

Why do tubing supports slip inside tubing?

Tube supports slip inside tubing to prevent the walls from collapsing.

What is an instant fitting?

Also known as instant fittings, they connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. Use in applications up to 150 psi.

What is a built in shut off valve?

A built -in shut-off valve stops airflow when the fittings are disconnected from tubing.

What is air brake tubing?

FMVSS 106 or D.O.T. FMVSS 49 specifications for testing and performance requirements in motor vehicle brake systems.