The decrease in the height of the center of the slumped concrete is called slump. The slump is measured by placing the cone just besides the slump concrete and the temping rod is placed over the cone so that it should also come over the area of slumped concrete.

Is slump test a good test for measuring workability?

Slump test is not considered as a measure of workability because: (i) There is no connection between the test results of slump test and workability; (ii) The test results exhibit large random variations which is greater than that due to observed differences in workability; (iii) Concrete of different workability may have the same slump.

What are the disadvantages of slump test?

Limitations/ Disadvantages of Concrete Slump Test

- It is unreliable for lean mixes. ...

- It is not exact measurement because slump bears no unique relation to workability. ...

- For a specimen, more than one shape can be resulted confusing the correct result. ...

- It cannot differentiate in workability of stiff mixes as it shows zero slumps. ...

- It is not suitable for concrete formed of aggregate higher than 40 mm.

What are the limitations of the slump test?

Limitations of the Slump Test. The slump test is acceptable for slumps with a medium to low workability, with a slump of between 5 and 260 mm. However, the test is incapable of determining the difference in workability between stiff mixes with no slump and wet mixes with a collapsing slump. It is restricted to concrete composed of particles no ...

What is the ideal value of slump?

What is the ideal value of slump? Answer 1 In case of a dry sample, slump will be in the range of 25-50 mm that is 1-2 inches. But in case of a wet concrete, the slump may vary from 150-175 mm or say 6-7 inches. So the value of slump is specifically mentioned along the mix design and thus it should be checked as per your location.

How is a slump measured?

The slump of the concrete is measured by measuring the distance from the top of the slumped concrete to the level of the top of the slump cone.

What is slump explain?

: to drop or slide down suddenly : collapse. : to assume a drooping posture or carriage : slouch. 3. : to go into a slump. sales slumped.

What does 5 inch slump mean?

The 4- to 5-inch slump for decorative concrete is a relatively stiff mixture, but not quite as stiff as the 2- to 3-inch slump seen here. A higher slumped concrete is more more fluid and will flow some distance on its own.

Why do we measure slump?

The concrete slump test measures the consistency of fresh concrete before it sets. It is performed to check the workability of freshly made concrete, and therefore the ease with which concrete flows. It can also be used as an indicator of an improperly mixed batch.

What is a good slump value?

What is the ideal value of slump? Answer 1 In case of a dry sample, slump will be in the range of 25-50 mm that is 1-2 inches. But in case of a wet concrete, the slump may vary from 150-175 mm or say 6-7 inches.

What does 4 inch slump mean?

Slump is the measure of concrete consistency and fluidity. It shows the flow and overall workability of freshly mixed concrete. Simply put, the higher the slump, the wetter the mix. Four-inch (4”) slump is very common with normal weight concrete and is a good for pumping.

What are the 4 types of slump?

There are three types of slump that may occur in a slumps test, namely, true slump, shear slump and collapse slump.

What is normal slump?

In case of a dry sample, slump will be in the range of 25-50 mm that is 1-2 inches. But in case of a wet concrete, the slump may vary from 150-175 mm or say 6-7 inches. So the value of slump is specifically mentioned along the mix design and thus it should be checked as per your location.

What happens if slump is too high?

High slump value means the water-cement ratio of concrete is high. Hence, both the strength and durability of concrete may get reduced.

What causes high slump?

Causes of slumping include earthquake shocks, thorough wetting, freezing and thawing, undercutting, and loading of a slope.

What is the minimum slump for concrete?

Explanation: According to IS 456-2000, the slump value (in mm) of the concrete used in ordinary RCC work for beams and slabs, etc. is 50 to 100 mm. For concrete work, low workable concrete is preferred.

What increases slump?

Adding just 1 gallon of water per cubic yard can: Increase slump 1 inch, decrease compressive strength 150 to 200 psi, waste about 1/4 bag of cement, and increase shrinkage by 10%. But water isn't the only way to adjust slump. Consider adding a superplasticizer at the site to increase slump.

What is slump and its types?

There are three types of slump that may occur in a slumps test, namely, true slump, shear slump and collapse slump. True slump refers to general drop of the concrete mass evenly all around without disintegration. Shear slump indicates that the concrete lacks cohesion.

What is called slumping?

When the weathered materials do not move downward but sink "in situ", this is called slumping. Such rapid mass movements may also occur beccause of earthquakes.

What causes a slump?

Slumps often happen when a slope is undercut, with no support for the overlying materials, or when too much weight is added to an unstable slope. Figure 1. Slump material moves as a whole unit, leaving behind a crescent shaped scar.

What slump means in concrete?

The 'slump' of concrete refers to the consistency of fresh concrete before it sets – the higher the slump, the more fluid the concrete is. It's a fairly confusing term for a complex-sounding process, but it really is quite simple when it all boils down.

What are the properties of concrete?

Actually, the ease with which concrete is mixed, transported, placed, compacted and finished depends upon its two basic rheological properties and they are: Homogeneity. Consistency. The behaviour of concrete as a rheological fluid is such that if its homogeneity is increased its consistency decreases and vice versa.

What is workability of concrete?

Hence, workability of the concrete is defined as the ease with which the concrete may be mixed, transported, placed, compacted and finished. In other words, workability of concrete is a property combining the properties of mixability, transportability, placebility, compactability and finishability.

What is concrete slump?

Concrete slump is the measurement technique of concrete workability and an indirect measurement of concrete consistency.

Does less water speed up concrete cure times?

Also, less water can speed up cure times in some types of concrete with the understanding that the strength profile will continue to increase over time. Indication of lateral loads imposed by concrete. Low or zero slump concrete is more self-supporting than high slump concrete. Therefore, i.

Is concrete a complete test?

Different tests that measure workability of concrete measure some of the specific parts of workability such as its consistency or compactability and hence no test is a complete test as such. Some of the tests are:

Can a physical test measure concrete?

As the workability of concrete is a property involving many different properties that have conflicting nature, no physical test can actually measure workability of concrete it the truest sense of its definition.

What is the slump range for bagged concrete?

This standard stipulates the slump range of bagged concrete (without water-reducing admixtures) to be between 2 and 3 inches.

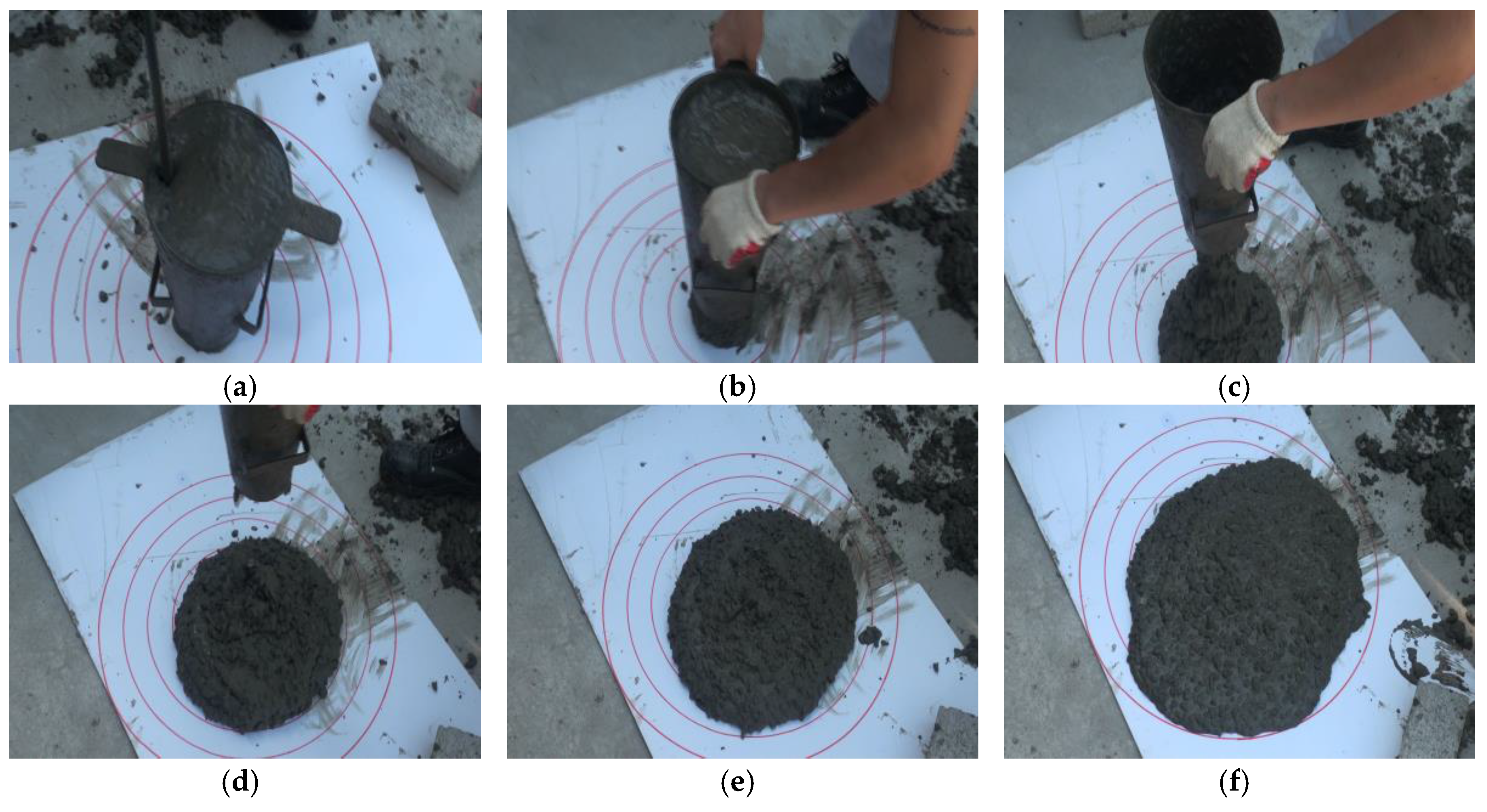

How to remove concrete from cone?

Strike off the excess concrete from the top of the cone, using the tamping rod as a screed in a rolling or sawing motion.

How tall is a slump cone mold?

Slump Cone Mold —The mold is 12-in. in height and known as an Abrams cone.

How much slump is needed for concrete?

Unless otherwise specified, ready-mixed concrete is delivered to the job-site at a slump of 4 ±1 in. but can be batched to meet exact specifications for the job.

What happens if you mix concrete with excess water?

If standard concrete is mixed to a higher-than-specified slump using excess water the set time will be substantially delayed, and—even worse–the end strength of the concrete will be adversely affected. Make sure to follow procedures to the letter when working with concrete.

What is concrete slump?

In technical terms, slump is a measured indication of the workability, or flow, of a mix. The drier the mix, the lower or “tighter” the slump. Conversely, the wetter or “looser” the mix, the higher the slump.

How many times do you rod the second layer?

Rod the second layer 25 times, making sure to penetrate the previous layer by about an inch. Continue rodding in a circular fashion, working to the middle —the same pattern as discussed in step 3.

What Is Concrete Slump and How Is It Measured?

The concrete slump test is used to determine the consistency and fluidity of concrete. It demonstrates the flow of freshly mixed concrete and its overall workability.

What is the maximum size of a concrete slab for a slump test?

It is restricted to concrete composed of particles no larger than 38 mm in diameter (1.5 inch)

What is high workability concrete?

High workability concrete with a slump of >100 mm is typically used where reinforcing bars are closely spaced and/or the concrete must flow a significant distance.

How much droop is needed for concrete?

Simply put, the greater the droop, the more liquid the mixture. Slump of four inches (4”) is quite frequent with average weight concrete and is ideal for pumping.

What does "slump" mean in concrete?

Slump demonstrates the flow of freshly mixed concrete and its general workability. Simply put, the greater the droop, the more liquid the mixture. Slump of four inches (4”) is quite frequent with average weight concrete and is ideal for pumping.

What is the shape of a slump cone?

The test is conducted using a metal mould in the shape of a conical frustum, also known as a slump cone or Abram’s cone, that is open on both ends and equipped with handles.

Why is the slump test used?

The slump test is used to check that different loads of concrete perform consistently under field conditions. A specialized test, referred to as the flow table or slump-flow test, is used to determine the slump of concrete that is too fluid ...

What does collapsed slump mean?

True Slump. . If the cone crumbles completely, it is termed as Collapsed Slump and indicates that the mix is too wet. In such cases, a fresh sample is taken again and the test is repeated. It also implies that the mixture is of high workability and is not suitable for the test.

Why is concrete mix test important?

It is also critical in measuring the workability of the concrete and lets you know the composition of the mix. The reasons why this test is preferred is its simplicity and effectiveness. The use of simple tools to perform the test is also a reason for its popularity.

What is shear slump?

If the cone’s top crumbles and slips to the sideways , it is termed as Shear Slump. These are typically found to have a workability, which is medium, of 50-90mm and is usually used in reinforced concrete ...

What is concrete used for?

Concrete is widely used in building and construction of buildings, road, and repair works and in other works of the foundation. We all tend to ignore once we provide the contractor a specific quality or standard of constitute. It will all depend on him to decide the mix and strength of the concrete without understanding the need of the type ...

What happens when you mix Portland cement and water?

When a course is mixed with Portland cement and water, it produces a slurry which can be easily poured and molded into required shapes. As soon as the mixture becomes dry, it hardens and gives strength to the structure. The standard of the mixture should be appropriate to provide the following to the structure:

Is concrete good for road construction?

If at all the workability is found to be between 0-25mm, then the concrete is best suited for road construction. And in such cases, the worth of the test cannot be determined and is not taken as valid. You may say that this is the limitation of the test.

Is concrete good for stripping?

Examine that the strength of concrete is appropriate for the needs of the project and is suitable for stripping, stressing, and opening to traffic. The concrete takes the required shape and the workability is as per the set standards.

What does a concrete slump test tell you?

The concrete slump test measures the consistency of fresh concrete before it sets. It is performed to check the workability of freshly made concrete, and therefore the ease with which concrete flows. It can also be used as an indicator of an improperly mixed batch.

What is the ideal value of slump?

What is the ideal value of slump? Answer 1 In case of a dry sample, slump will be in the range of 25-50 mm that is 1-2 inches. But in case of a wet concrete, the slump may vary from 150-175 mm or say 6-7 inches.

What is the slump test used for?

Purpose. The Slump Test is a neural tension test used to detect altered neurodynamics or neural tissue sensitivity.

What is the maximum concrete slump?

Concrete Slump Reinforced foundation wall and footings: Slump shall be between 2 and 5 inches. Footings, caissons : 1-inch minimum, 4-inch maximum. Slabs, beams, building columns, and reinforced walls: 3-inch minimum and 6-inch maximum. Pavements: 2-inch minimum and 3-inch maximum.

How is Slump value calculated?

Place the cone next to the mound of wet concrete and put the steel bar level on top of it, extending over the top of the mound. Immediately measure the distance between the bottom of the steel bar and the top of the concrete mound. The distance, measured to the nearest 1/4 inch is the concrete slump.

What is slump and its types?

There are three types of slump that may occur in a slumps test, namely, true slump, shear slump and collapse slump. True slump refers to general drop of the concrete mass evenly all around without disintegration. Shear slump indicates that the concrete lacks cohesion.

What does a high slump test indicate?

Accordingly, its slump rating indicates what construction application the concrete is good for. The higher the slump, the more workable the concrete.

What is the purpose of the slump test?

This test is also known as the slump cone test. The slump test measures the consistency or workability of concrete. It is used to check the workability of freshly made concrete for the easy placement of concrete. In addition, this test indicates the ...

What is the shape of a mold called?

The mold shape is in a cone. The cone is known as the Abrams cone or slump cone.

How to make a concrete mold?

Step 1. Place all the apparatus parts together. By using a trowel, but the first layer of concrete into the mold. Then done tamping on the first layer (25 times) with the help of the rod. Step 2. The second layer of concrete is added to the mold. Again the (25 times) tamping was done with the rod. Step 3.

What is a slump test?

In addition, this test can be used to measures consistency between the individual batches. It is a simple and low-cost test prepared at the laboratory or the site during work. It can be carried out from batch to batch to check the workability ...

What happens to concrete during a slump?

In true slumps, the concrete subsides shortly and maintains its cone shape.

How to do a concrete slump test?

First, you have to clean all the apparatus that will be used with water and then apply the oil on the surface to make then friction-free.

What is the purpose of a brush on a mold?

We use the brush to clear the last remaining concrete left on the mold.