The primary goal of acceptance sampling plans is to make sure units or raw materials to be used in the manufacturing process are of good quality. Acceptance sampling plans are typically classified into three broad categories: sampling plans for attributes, sampling plans for variables, and special sampling plans.

What is acceptance sampling and why is it important?

The history of acceptance sampling dates back to a time before mass production. In fact, it was developed as a way for manufacturers to check their work as they created products manually. It is a form of quality control and is used to ensure that each batch is of high quality before it is sold.

What is'acceptance sampling'?

What is 'Acceptance Sampling'. Acceptance sampling is a statistical measure used in quality control that allows a company to measure the quality of a batch of products by selecting a specified number of products for testing. The quality of these products will be viewed as the quality level for the group of products.

What are the different types of acceptance sampling?

There are three main types of acceptance sampling: single sampling plan, double sampling plan, and sequential sampling plan. 1. Single Sampling Plan A single sampling plan involves choosing a sample from each lot and testing it to see if it meets a certain quality threshold.

How do I use acceptance sampling to evaluate a batch of products?

If you want to use acceptance sampling to evaluate a batch of products, you first need to decide which method is best for your situation: acceptance sampling by attributes, or by variables. Acceptance sampling by attributes assesses either the number of defects or the number of defective items in a sample.

Why do we need acceptance sampling?

Acceptance sampling is a quality-control measure that lets a company determine the quality of an entire product lot by testing randomly selected samples and using statistical analysis. When done correctly, acceptance sampling is effective for quality control.

When Should acceptance sampling be used?

In general, acceptance sampling is employed when one or several of the following hold: testing is destructive; the cost of 100% inspection is very high; and. 100% inspection takes too long.

How is acceptance sampling plan used in industry?

Acceptance Sampling is a method used in the industry for quality control. This method uses statistical sampling to inspect or test a random sample for determining whether the quality of a batch of product or service is acceptable or not.

What is meant by acceptance sampling plan?

Acceptance sampling is a quality control procedure, which uses the inspection of small samples instead of 100 percent inspection in making the decision to accept or reject much larger quantities, called a lot.

What is acceptance sampling give its advantages and disadvantages?

Advantages and disadvantages of Acceptance Sampling Compared to 100% inspectionAdvantagesUsually less expensive because there is less inspectionLess handling of the product, hence reduced damageIf inspection/testing of the product destroys the product, you cannot do 100% inspectionFewer personnel are involved in ...

What are the advantages of acceptance sampling over 100% inspection?

Advantages of Acceptance Sampling Over 100% Inspection 1. It is usually less expensive because there is less inspection. 2. There is less handling of the product, hence reduced damage.

How does AQL sampling work?

Acceptable Quality Limit (AQL) AQL (Acceptable Quality Limit) Sampling is a method widely used to define a production order sample to find whether or not the entire product order has met the client's specifications. Based on the sampling data, the customer can make an informed decision to accept or reject the lot.

What is the purpose of acceptance sampling quizlet?

The purpose of acceptance sampling is to decide whether a batch of items satisfies pre-determined standards.

What is AQL in quality control?

The acceptable quality level (AQL) is a measure applied to products and defined in ISO 2859-1 as the “quality level that is the worst tolerable.” The AQL tells you how many defective components are considered acceptable during random sampling quality inspections.

How do you do acceptance sampling?

0:544:55Evaluating Acceptance Sampling Plans - YouTubeYouTubeStart of suggested clipEnd of suggested clipLet's start with an example of an OC curve that has a lot size of 4,000 sample size of 300. AndMoreLet's start with an example of an OC curve that has a lot size of 4,000 sample size of 300. And acceptance number of 4. This way we can make sense out of these concepts. We need to introduce a new

How do you determine acceptance sampling?

2:414:04Determining Probability of Acceptance in Sampling - YouTubeYouTubeStart of suggested clipEnd of suggested clipWe can use the Poisson probability distribution as an approximation of the binomial probabilityMoreWe can use the Poisson probability distribution as an approximation of the binomial probability distribution.

How do you design acceptance sampling plans?

In the acceptance-sampling plan to be constructed, a sample of size is taken from a lot of size and all units in the sample are inspected. If the number of defects found in the sample is above a specified value , the lot is rejected.

What is an acceptance sampling used for quizlet?

Terms in this set (16) What is acceptance sampling? it is a method of measuring random samples of lots or batches of products against predetermined standards.

What is the purpose of acceptance sampling quizlet?

The purpose of acceptance sampling is to decide whether a batch of items satisfies pre-determined standards.

How do you determine acceptance sampling?

0:552:47Determining Sample Size in Acceptance Sampling - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo let's determine an example in which case we have a producer's risk or alpha of 5%. And we want toMoreSo let's determine an example in which case we have a producer's risk or alpha of 5%. And we want to determine how many samples are required. When we have acceptance numbers of one four or seven all

Which of these is not an advantage of acceptance sampling over the 100% sampling plan?

1. Which of these is not an advantage of acceptance sampling over the 100% sampling plan? Explanation: As lesser number of units are checked while using the acceptance sampling plan instead of the 100% sampling plan, it is less expensive, applicable to destructive testing, and needs lesser manpower.

What is acceptance sampling?

If you're just getting started in the world of quality improvement, or if you find yourself in a position where you suddenly need to evaluate the quality of incoming or outgoing products from your company, you may have encountered the term "acceptance sampling." It's a statistical method for evaluating the quality of a large batch of materials from a small sample of items, which statistical software like Minitab can make much easier.

What is sampling in statistics?

Basic statistics courses usually teach sampling in the context of surveys: you administer the survey to a representative sample of individuals, then extrapolate from that sample to make inferences about the entire population the samples comes from. We hear the results of such sampling every day in the news when the results of polls are discussed.

How to do acceptance sampling in Minitab?

In Minitab, you select Acceptance Sampling by Variables - Create / Compare to either devise a new sampling plan or to contrast different possible sampling plans. After you've collected data according to your variables plan, you need to calculate the mean, standard deviation, and Z value using those measurements. Just select Acceptance Sampling by Variables - Accept / Reject in Minitab to do those calculations and make a determination about the batch your sample came from.

How many measurements can be examined in a sampling plan?

One thing to remember about variables sampling plans is that only one measurement can be examined per sampling plan. So if you need to assess the lead length of sample resistors as well as their performance, two separate sampling plans are required. However, variables sampling plans require much smaller sample sizes than attributes plans.

What is a rejection of a good quality batch?

Rejecting a good-quality batch, also known as producer's risk , or a . Accepting a poor-quality batch, also known as consumer's risk, or b . When you use Minitab for acceptance sampling, the software graphs an operating characteristic curve (OC curve) to quantify these risks.

How to do attribute plans?

Attribute plans are generally easy to carry out: you randomly select a specified sample of n units from a lot of N units. If there are c or fewer defectives, accept the lot. If there are more than c defectives, reject it.

Does acceptance sampling give you quality?

But it's important to remember that acceptance sampling won't give estimates of quality levels, and because you're inspecting items that are already complete, it doesn't give you any direct process control.

What is sample testing?

Samples are tested to determine the number of defectives in a batch or population. Items with no defectives are conforming, and those with defectives are nonconforming. A decision is made to accept or reject the whole batch based on the number of allowable defectives.

What is double sampling?

With a double sampling plan, two sample sizes (n1 and n2) and two acceptance levels (c1 and c2) are selected. If the initial sample is equal to or below c1, the batch is accepted. If the defectives are greater than c2, the batch is rejected. If the number of defectives are between c1 and c2, a larger sample is drawn. In the second sample, if the number of defectives is less than c2, the batch is accepted.

What is quality in toilet paper?

Quality is defined as producing to a pre-determined standard. For example, toilet paper used in a chain store is not the same quality as toilet paper purchased for home use. The toilet paper in chain stores may be narrower, have less paper per sheet, may not contain lotion, etc. Samples are tested to determine the number ...

When is the number of acceptable defectives determined?

Usually, this determination is made when the product leaves the producer or when the consumer receives the product.

Do you have to be a Study.com member to unlock this lesson?

To unlock this lesson you must be a Study.com Member.

Is a batch accepted or rejected based on the number of defectives?

Depending on the sampling plan used, the batch is accepted or rejected based on the number of defectives.

What is acceptance sampling?

Acceptance Sampling is a practice whereby a sample is tested from a population (lot), and a decision to accept or reject that entire population (lot) is based on the test results of the sample.

Who invented acceptance samplingoriginated?

Acceptance Samplingoriginated in the 1930’s at Bell Labs through the work of Harold Dodge and was later popularized during World War II by the U.S. Military for munitions (bullets) production.

What is LTPD in sampling?

LTPD is another common metric in acceptance sampling and it reflects the quality limit, in percent defective, that is the poorest quality that can be tolerated. LTPD is related to the consumer risk, and typically represents the percent defective that is associated with a 10% probability of acceptance.

What is Dodge-Romig sampling table?

While the Z1.4 and Z1.9 standards provide sampling plans based on AQL, the Dodge-Romig sampling tables provide sampling plans based on a desired Lot Tolerance Percent Defective (LTPD), or Average Outgoing Quality Limit (AOQL).

What is the ideal sampling plan?

The ideal sampling plan would accept all lots with less than 3% non-conformances, and reject all lots with 3% or more non-conformances.

What is the probability of acceptance?

You can see that the probability of acceptanceis 100% for all incoming quality levelsless than 3% non-conforming, and 0% for all incoming quality levels of more than 3% non-conforming.

Do we accept lots whose quality is poor?

Sometimes we accept lots whose quality is poor, and sometimes we reject lots whose quality is good.

What is sampling plan?

A sampling plan allows an auditor or a researcher to study a group (e.g. a batch of products, a segment of the population) by observing only a part of that group, and to reach conclusions with a pre-defined level of certainty.

What is double stage sampling?

A “ double-stage sampling plan” is a bit more efficient. The inspector would start by taking a smaller number of sample (n1). If the finding is not clear (not very good, not very bad), more samples are picked. There are also multiple and sequential plans.

What is the most popular inspection plan?

The most popular plan was developed by the US Department of Defense, and was formalized in standards MIL-STD 105E, 2859-1, and ANSI Z1.4. Many people call it an “AQL inspection”.

Who wrote the quality progress article?

Manuel E. Peña-Rodríguez wrote an article about this in Quality Progress April 2018. He makes a distinction between three stages:

Can we suggest a scheme for an activity your company will perform regularly?

We don’t suggest such a scheme for an activity your company will perform regularly. There are two reasons for this:

How many sampling possibilities are there in Snap?

With over 10,000 sampling possibilities, Snap Sampling Plans! guides you in selecting the correct AQL sampling plan.

How much does Snap Sampling cost?

Use Snap Sampling Plans! to quickly find the correct sampling plan for your company. Snap includes multiple AQL plans from many industrial sampling plans. Only $49. Satisfaction guaranteed.

What are the parameters of AQL?

Two of the common parameters for each plan is AQL percentage and lot size. Other parameters include defect percentage, sampling level, inspection level, and inspection type.

What is AQL sampling table?

Quality professionals use AQL sampling tables to determine the acceptance or rejection of inspection material. Inspection material can be raw goods, purchased parts, inprocess production, final goods and services, pre and post shipment parts, etc. Inspectors depend on AQL plans to determine the amount of parts to inspect.

What happens after you select the inspection sample?

After you select the inspection sample you then inspect the parts. As you inspect the parts, you separate the good parts from the bad parts.

Why did the authors write each plan?

The main reason that the authors wrote each plan was to determine the sample size, accept and reject criteria. After finding this you are done with the standards until the next inspection.

What happens when the number of defects is less than or equal to the accept number?

If the number of defects is less then or equal to the accept number you accept the parts. Move the parts to the next step.

Why is it important to understand AQL?

When you import consumer products, it is vital to understand AQL so that you can work collaboratively with your inspectors. If you don’t understand the methodology fully, you risk misinterpreting your inspection results, which can lead to quality disasters.

Why do you need to inspect fewer units?

Sometimes, inspecting fewer units (Level I) can reduce costs since the inspection takes less time. The downside is that you can have less confidence in the result. You should only conduct a Level I inspection if you have a long history and degree of trust with your supplier.

What is the AQL level for minor defects?

In our example above, we made certain assumptions. This first was that you would use General Inspection Level II in Table 1. The second was that you would use a 2.5% AQL level for major defects and a 4.0% level for minor defects. Below we will discuss some other alternatives.

Why is product inspection important?

As a consumer goods importer, the quality of your products is key to your success. Good quality products will earn you favorable reviews and repeat purchases. Thus, product inspections are essential. Having a good grasp of AQL sampling allows you to work with your third-party inspectors more effectively.

What is the standard AQL level?

For most general consumer products, the standard AQL levels are 2.5% for major defects, 4.0% for minor defects, and 0% for critical defects. That’s why we’ve underlined ‘2.5’ and ‘4.0’ above.

Is it reasonable to have a 100% inspection?

You may think to yourself, “A 100% inspection would give me 100% certainty that my products are ok.” If you are purchasing low volumes, this is reasonable. But it’s essential to keep in mind that it becomes less feasible as your order quantities go up. The amount of time it takes to complete an inspection goes up significantly, and the cost goes up as well.

Who developed quality control standards for inspecting US military equipment?

These tables are based on the work of Harold F. Dodge and other statisticians who worked to improve them over the years. During World War II, Dodge worked at the Pentagon and developed quality control standards for inspecting US military equipment.

What Is Acceptance Sampling?

- Acceptance sampling is a statistical measure used in quality control. It allows a company to determine the quality of a batch of products by selecting a specified number for testing. The quality of this designated sample will be viewed as the quality level for the entire group of products. A company cannot test every one of its products at all time...

Understanding Acceptance Sampling

- Acceptance sampling tests a representative sampleof the product for defects. The process involves first, determining the size of a product lot to be tested, then the number of products to be sampled, and finally the number of defects acceptable within the sample batch. Products are chosen at random for sampling. The procedure usually occurs at the manufacturing site, just bef…

A History of Acceptance Sampling

- Acceptance sampling in its modern industrial form dates from the early 1940s. It was originally applied by the U.S. military to the testing of bullets during World War II. The concept and methodology were developed by Harold Dodge, a veteran of the Bell Laboratories quality assurance department, who was acting as a consultant to the Secretary of War.1 While the bulle…

Special Considerations

- When done correctly, acceptance sampling can be effective for quality control. Probability is a key factor in acceptance sampling, but it is not the only factor. If a company makes a million products and tests just 10 units with one default, an assumption would be made on the probability that 100,000 of the 1,000,000 are defective. However, this may be grossly inaccurate. More reliable c…

Process of Acceptance Sampling

Attributes and Variables

- An attributehas two responses of either yes or no, works or does not work, etc. It has quality characteristics that meet or does not meet predetermined criteria. An example would be producing light bulbs, and the test would be if they produced light when turned on. After being sure the electrical source working, the number of defective light bulbs as well as those that wor…

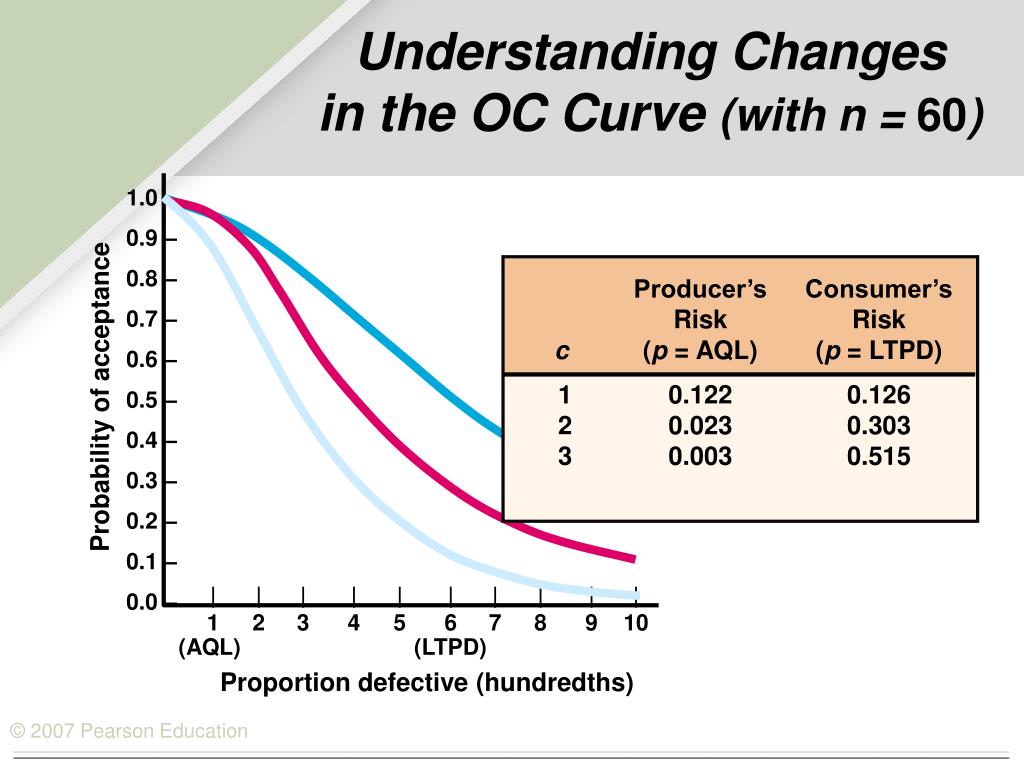

Operating Characteristics Curve

- The operating characteristics curveprovides a tool to assist in making decisions concerning accepting or rejecting a batch of items based on the outcome of the sample. Refer to Chart 3. An operating characteristics curve involves four factors: 1. Acceptable Quality Level (AQL): maximum number of defectives the producer is willing to accept 2. alpha ( α ): producer's risk of rejecting …

Types of Acceptance Sampling Plans

- The purpose of acceptance sampling plans is to determine the quality in a batch of products and to make a decision to accept or reject the batch.