Reason one why your compressor pressure switch is leaking air is that, over time, the diaphragm inside the switch has cracked or worn a hole, and air is blowing from inside the tank, through the hole in the diaphragm, and existing the switch housing through any convenient opening.

Full Answer

Why is my air compressor leaking air from pressure switch?

1:443:453 Reasons for an Air Compressor Leaking Pressure Switch - YouTubeYouTubeStart of suggested clipEnd of suggested clipIf they are leaking while the compressor is running the unloader of the switch is bad it can'tMoreIf they are leaking while the compressor is running the unloader of the switch is bad it can't create a seal internally.

Can a pressure switch leak?

Know what to do if any of these warning lights come on in your car. Oil pressure switches are notorious for leaking as they age.

Why does my air compressor keep leaking air?

Old filters, lubricators, regulators, flanges and leaking drains are common air compressor leak points. If you can, repair or replace those old parts as soon as possible. Even a small repair, like changing the filter, can go a long way to ensuring your air compressor is running as efficiently as possible.

How do you stop a high pressure air leak?

Try this: Ongoing and systematic maintenance of the entire compressed air system is the most effective way to prevent new leaks from forming. Be sure to check, clean or replace filters throughout the compressed air system. Filter maintenance goes a long way in decreasing pressure drops and increasing energy efficiency.

What happens if you over tighten oil pressure switch?

When replacing the oil pressure sender it only gets 90 in/lbs. If you over tighten it with this flared type threads then by the time it gets in all the way a cracked housing will be the result.

How do you test a pressure switch on a air compressor?

Checking Your Air Compressor Pressure SwitchStart the testing process by unplugging your air compressor.Next, unscrew and remove the housing from your unit.Disconnect the sets of wires running between your pressure switch and the terminal block. ... Be sure to leave the black-and-white wires connected.More items...•

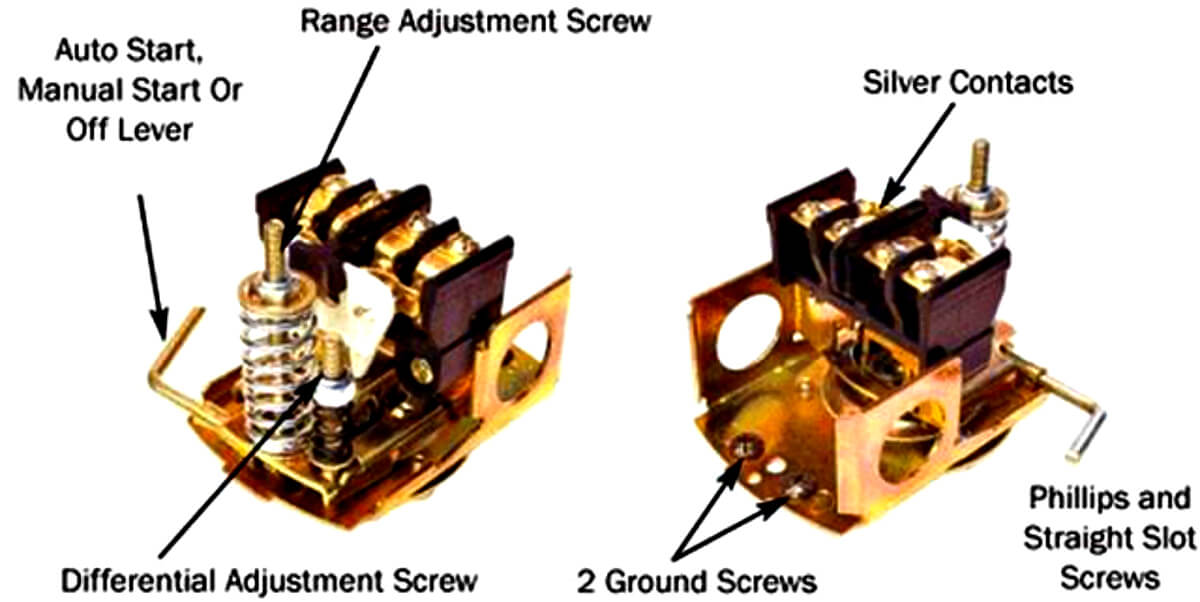

How do you adjust a pressure switch on a air compressor?

1:103:56How To Adjust A Pressure Switch - Mastertoolrepair.com - YouTubeYouTubeStart of suggested clipEnd of suggested clipIt's always clockwise to increase counter clockwise to decrease.MoreIt's always clockwise to increase counter clockwise to decrease.

What is the most common location for compressor leaks?

The most common areas you will typically find a leak in your system are:Couplings.Fittings.Pipe sections.Hoses.Joints.Drains.External unloader valves.

What is an unloader on a pressure switch?

What Is the Unloader Valve? A compressor unloader valve is a small part, typically measuring approximately 4-5 inches in length and width. It performs the critical function of releasing trapped air inside the tank, enabling the motor to restart.

What is the easiest way to determine air leakages in the pressure line?

The best way to detect leaks is to use an ultrasonic acoustic detector, which can recognize the high frequency hissing sounds associated with air leaks. These portable units consist of directional microphones, amplifiers, and audio filters, and usually have either visual indicators or earphones to detect leaks.

What is an acceptable leakage rate for a compressed air system?

Leakage from compressed air in an industrial environment has been reported to be 20-30% of a typical compressor's output. According to the OIT, a typical plant will have a leakage rate equal to 20% of its total compressed air/compressor production capacity from point A to Z throughout its entire system.

How do you fix an air leak?

0:336:53How to seal air leaks in your home - YouTubeYouTubeStart of suggested clipEnd of suggested clipFor added insulation you can even caulk the gap between the outlet and the wall.MoreFor added insulation you can even caulk the gap between the outlet and the wall.

What is an unloader on a pressure switch?

What Is the Unloader Valve? A compressor unloader valve is a small part, typically measuring approximately 4-5 inches in length and width. It performs the critical function of releasing trapped air inside the tank, enabling the motor to restart.

How do you know if your air compressor unloader is bad?

Unloader valve failure — Power lags also result from failed unloader valves. This problem can be diagnosed by manually enacting the valve function. Open the tank and drain out the air and water, then close and power back up. If the compressor bogs down once again, the valve needs to be replaced.

What are pressure switches?

What is a Pressure Switch? A pressure switch is a simple electromechanical device that is triggered by pressure to turn an electrical circuit on or off. The pressure point that activates the switch is called its set point, and the pressure threshold that deactivates the switch is called the cut out point.

How does a pneumatic pressure switch work?

The pneumatic pressure switch does its job by applying a process pressure to a piston or diaphragm to generate a force that is comparable to that of a pre-compressed range spring. The pneumatic pressure switch is also used to detect the presence of fluid pressure.

Why won't my well water pump turn off?

If the well water pump isn’t creating the appropriate pressure, it won’t signal your pressure switch to turn off and on. Aside from checking the pump, check your water pressure gauge to ensure that it’s working before diagnosing a pressure switch issue.

What to do if water pump isn't working?

If it isn’t, make sure your filter isn’t clogged or in need of a change. Check the pressure gauge to make sure it isn’t stuck or damaged. Once you’ve ruled out the water pump and other components, you can turn your attention to the water pump pressure switch.

Why does my pressure switch degrade?

The electrical contacts in your pressure switch can degrade over time. Frequent cycling of power to the switch and the presence of corrosive substances are two common causes. You make a temporary repair to contacts by filing away the affected area, though be sure to kill all power to the pump before you do.

How does a pressure switch work?

Basically, your pressure switch tells your well pump, which delivers water to your home, when to turn on and off. It does this by monitoring pressure and letting more water flow into the system when the pressure falls to ...

What does failure of pressure switch mean?

Failed Connection. A malfunction in your switch could indicate a problem elsewhere in the system. For instance, if your piping is of the wrong size, it can cause a leaky connection. This will stop the pressure switch from doing its job effectively.

Why won't my water pressure switch turn on?

Switch Won’t Turn On. If your switch won’t turn on, this could be a sign your tank pressure is above your switch’s cut-in pressure. Try running some water elsewhere in the building to reduce pressure below the cut-in level. You can also try gently tapping on the pressure gauge, the switch, and the tank.

How to fix a pressure switch that leaks water?

If you notice water leaking under the switch housing or from the switch itself, try tightening the switch’s plumbing connection by turning the brass fitting clockwise with plumber’s pliers to tighten it. If you are still experiencing leaking, it is probably coming from the internal mechanism, which means the pressure switch needs to be replaced.

What does it mean when air leaks from a compressor?

The bottom line is, if air is leaking from that fitting when the compressor is off, the only place that air can be coming from is the tank, and that means that the tank check valve is not blocking air from getting into the unloader tube.

What happens if a compressor drops?

If the compressor is only dropping when there is an air line plugged into the coupler, then the leak will be found downstream from the compressor coupler. To confirm this, unplug the air line. If the air leak stops, the hose has a hole, or a connection downstream of the compressor coupler is the problem.

Why does my pressure switch unloader leak continuously?

A pressure switch unloader valve that leaks continuously after the compressor has stopped indicates that the tank check valve has not closed completely , and compressed air is no longer trapped in the tank.

How do you know if an air compressor is leaking?

Compressor is always leaking air. You know the compressor is always leaking air as when you shut it down with a full charge of air in the tank , after a short while you can see that the tank pressure gauge display is showing that the tank pressure is dropping. Soon, if the air compressor is plugged in, the pressure switch will react to ...

What to do if you can't hear a leak in your air compressor?

If you can’t hear the leak, or feel it with your fingers, you can soap the connections on the air compressor .

What happens when an air compressor is plugged in?

Soon, if the air compressor is plugged in, the pressure switch will react to the falling tank pressure, and start the compressor. That’s a waste of energy and money, for sure. The first thing to do is to determine where the leak on the air compressor is. Here are some tips on that. No obvious leaks.

Can a compressor stop leaking air?

Yes, but only until the cut in pressure in the tank was reached, and then the compressor would start again. If the air is leaking out of the tank after the compressor stops, it can only be 1) leaking tank check valve 2) leaking tank drain valve 3)leaking discharge coupler 4) pin hole in tank. There is no where else the air could be getting out ...

How to use a tire sealant?

You will need a sealant, an air pump, and a pressure gauge. Insert the nose of the sealant into the puncture where the tire loses air slowly from, or the valve. Make sure you adjust it so that the sealant is pouring right on the inside surface of the tire.

Why do valve stems leak air?

Image source: www.peachparts.com. Valve stems deteriorate and leak air due to the exposure to lots of chemicals on the road. Usually, drivers get a new set along with the new tires. However, if a tire loses air slowly yet over 1-3 psi a month, they may need replacement earlier.

How to find a leak in a tire?

If your tire loses air slowly, there are several ways to find the leak: By sound or feel. In the easiest cases, you may manage to find the leak by sound or feel. There will be a distinctive hissing sound, intensifying as you get closer to the leak. Touch the tire in that place and feel whether there’s air loss.

What to use if tire loses air?

There are pre- and post-puncture sealants, so buy the latter if your tire loses air slowly.

What causes tire seals to break?

Any sealing surface between rubber and metal can cause loss of air. Bead chunking, a small piece of debris between the rim and the tire etc., can open a small window for the air. Damaged tire bead. Age also contributes to the seal breaking, as the rubber weakens over the years, losing its elasticity.

How much air does a tire lose?

A tire loses about 2% of the air with every 10°F drop in temperature. Accordingly, it rises 2% with every 10°F rise. So, light passenger cars may lose/gain about 1 psi, while pickups and buses may lose/gain 2 psi. In most part of the US, the difference between day and night temperatures is about 20°F.

What happens if you deflate your tires?

Tire damage. Temperature change. If a has tire deflated more than 25% from the recommended pressure, the likelihood of a tire- related crash increases threefold. Therefore, it’s crucial to know about every leak your tires may have and fix them in time.

What causes noise in a car?

Loose parts — Noise is often the result of loose internal parts. Check for looseness in the pulleys, cooler, flywheel, clamps, belt, accessories, etc. and perform tightening as needed.

What is a Quincy compressor?

Throughout the industries that use compressed air for operations, Quincy Compressor is among the most trusted providers of compressors and air tools.

Why does my air compressor vibrate?

Vibrations from any piece of machinery can be troublesome. In the case of an air compressor, vibration could be the result of looseness in any number of areas. The following parts should be inspected for looseness or alignment problems and tightened or adjusted accordingly if tremors/vibrations persist.

What happens if oil viscosity is off?

Improper oil viscosity — If the oil viscosity is off, it’s time to drain and refill with a different oil and with the right viscosity. Oil can also be lost if the compressor constantly tilts, but this can be fixed by placing the compressor on a different surface with the addition of vibration pads.

How much power does an air compressor need?

Overdrawn power circuit — An air compressor needs the undivided power of a 15-20 amp breaker at minimum. If other machines are also being powered on this same circuit, turn them off so the compressor can receive the full power source.

How to tell if compressor is leaking air?

If you shut down the compressor when the tank is filled with air and then find that the pressure gauge is showing a drop in pressure, you know that the compressor is leaking air. If you plug in the compressor, the pressure switch response to the air leak and dropping compressor pressure will be to start the compressor again. To try and find the leak, do the following.

Why does my compressor not turn on when it is powering on?

Power switch failure — When the compressor fails to power on, it could be due to a lack of contact between the pressure switch and inner circuitry . This can possibly be remedied with adjustments to the pressure switch.

Why do compressors leak air?

Rebuild the air compressor pump if it leaks air through the pump head when the pump runs because a broken valve plate seal is allowing air to escape through the pump head.

Why does the safety valve pop open?

The safety valve pops open to relieve excessive air pressure if the pressure switch fails to shut off the air compressor at the cut-out pressure setting. Replace the safety valve if it leaks or pops open at normal operating pressure.

Why won't my air compressor restart?

If your air compressor won't restart after the tank fills, the check valve might be the problem. This DIY repair guide and video explain how to replace an air compressor check valve in less than 15 minutes.

What does it mean when your air compressor gauges show that the tank isn't building pressure?

If your air compressor's gauges show that the tank isn't building pressure, the pump might be the problem . This DIY repair guide and video shows step-by-step instructions for rebuilding an air compressor pump.

Why replace check valve on a pump?

The check valve prevents tank air from back flowing to the pump and unloader. If air leaks out the unloader when the pump stops, replace the check valve because the check valve leaks air back towards the unloader.

How long does it take to replace an air compressor valve?

You can replace a defective air compressor check valve in about 10 minutes.

What is a check valve?

The check valve prevents tank air from back flowing to the pump. A failed check valve will apply high air pressure to the head of the pump preventing the motor from restarting once the tank has filled. If the motor starts when the tank is empty of air but won't restart when the tank is full, replace the check valve.