What is a miter bend in plumbing?

Nov 15, 2021 · A Miter bend is a bend that is made by cutting pipe ends at an angle and joining the pipe ends. A true miter bend is a 90-degree bend made by cutting two pipes at 45 degrees and joining them by welding. Similarly, three pipes cut at 22.5 degrees will give a 90 degree miter bend. miter bend.

What is miter bend or elbow?

Mar 12, 2020 · A Miter Bend or Elbow is a joint made by beveling each of two pieces to be joined, usually at a 45° angle, to form a corner, usually a 90° angle. There are two types of mitre joint, one Non-perpendicular joints & another is Three-dimensional joints.

What is the miter bend angle in miter saw?

Apr 18, 2021 · Miter bends are fabricated fittings. It is also called Miter Elbow. The thickness of the pipe used for the miter bend may differ from the line to be connected. Highly skilled manpower is required for perfect mitering, end preparation, and …

What is a mitered bend in transmission lines?

Sep 18, 2021 · Miter Elbow or Miter Bend is a Fabricated Fitting used to change the pipeline direction. The Standard Fittings (Wrought Elbows) are not easily available and economical for the larger sizes. Miter elbows are made up through fabricating the numbers of pipe cut pieces and it includes numbers of the weld joint.

How do you make a miter bend?

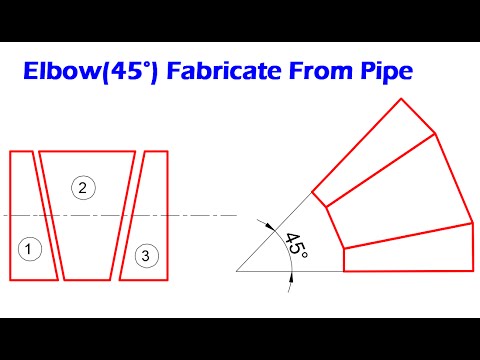

0:582:04Piping_Fabricate 45 Degree Elbow(miter bend) from pipeYouTubeStart of suggested clipEnd of suggested clipCut the spools from pipe and make bevel angle. Now assemble all three spool piece as shown inMoreCut the spools from pipe and make bevel angle. Now assemble all three spool piece as shown in picture give proper gap for welding and put tack weld require.

What do you mean by Mitre in Mitre Bend?

A mitre joint (often miter in American English) is a joint made by cutting each of two parts to be joined, across the main surface, usually at a 45° angle, to form a corner, usually to form a 90° angle, though it can comprise any angle greater than 0 degrees.

How do you Mitre a pipe?

1:5214:57Steel Pipe miter - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd you just take it wrap it around the pipe. Then you hold the back of the front edge pull it backMoreAnd you just take it wrap it around the pipe. Then you hold the back of the front edge pull it back and forth a few times to get it square. Roll it up like.

What does 5D bend mean?

A 5D pipe bending is a pipe bend that the bend radius is 3 times the pipe outside diameter. The RADIUS of a 5D pipe bend is actually what is 5 times the nominal diameter. So if you had a 10″ diameter pipe, the radius of the centerline of the bend would be 50 inches.

What miter means?

a : a surface forming the beveled end or edge of a piece where a joint is made by cutting two pieces at an angle and fitting them together.

Which is correct mitre or miter?

A mitre, also spelled miter, is a term applied to the presence of controlled precision cuts. Mitre joint refers to the presence of these cuts for achieving a functional lap joint, but mitre can also be used to refer to the guiding device attached to the saw that was used in making the cuts.

How do you calculate miter?

To calculate the proper miter angle for trim-work moldings, simply divide this angle reading by 2. In the example shown, the inside corner is 90.5 degrees—nearly square. The precise miter angle of your moldings should be 45.25 degrees.

What is mitered elbow?

A Miter Bend or Elbow is a joint made by beveling each of two pieces to be joined, usually at a 45° angle, to form a corner, usually a 90° angle. There are two types of mitre joint, one Non-perpendicular joints & another is Three-dimensional joints.

How do you calculate Mitre cuts?

0:432:29How to Bisect Angles for Cutting Miters | Ask This Old HouseYouTubeStart of suggested clipEnd of suggested clipAlright now here's the cool part you need to draw one more straight line between these two points.MoreAlright now here's the cool part you need to draw one more straight line between these two points. And that's your bisected a line up the blade of the saw was a line and cut both blocks at the same.

What is 8D Bend?

These 8D Pipe Bend have the bending radius equal to 8 times the outer diameter of the pipes they are fitted on to. There are different types of bends and the 8d bend dimensions vary according to the different standards. The material grades vary based on the application type as well.

What is a 6D Bend?

6d bend dimensions vary according to the application type but the bending radius of this pipe end is 6 times that of the outer diameter of the pipe fitted to it. The manufacturers produce different types of Stainless Steel 6D Pipe Bends in different sizes according to the standard.

What is a 3D bend?

A 3D bend is a bend in which the radius of the curve is equal to 3 times the diameter of the pipe. It is a smoother bend than a 1.5D bend, which looks almost like a regular 90-degree right angle, but it is a sharper bend than a 5D bend, which looks like a smooth arc between two perpendicular pieces.Aug 25, 2015

What is a miter elbow?

A Miter Elbow is a fabricated fitting used for direction change of the line. It is prepared by mitering (a cut at an angle) and then welding the pipe ends of the cut pieces to form a required bend, usually at 45° and 90°.

What is the first and last miter piece?

1: The first and the last miter pieces will be of the same length for any cases#N#2: Other than the last miter piece, all the miter pieces will be the double of the first miter length

What are the different types of fittings used for changing the line direction?

There are mainly three types of fittings used for changing the line direction-. Standard Elbow – Forged or casting fitting |used in high-pressure lines. Pipe Bend – Cold pulled bend| mainly used in the transportation pipeline or if the pigging is required in the pipeline.

Radiused bends

From Harlon Howe's book book on Stripline (see our book page ), we can arrive at a rule of thumb for curving transmission lines:

Mitered bends

Before we continue, let's review the many ways the word "miter" (or "mitre") is (are) used. In the good old U.S. we prefer the "miter" spelling, in the more ancient tea-sipping, bowler-wearing U.K. they use "mitre".

Microstrip miter compensation

The "optimum" mitered bend equations for microstrip were found empirically way back in the 1970s. Here's two references:

Stripline miter compensation

Here's references for optimum stripline miters: Harlan Howe, Jr. Stripline Circuit Design, Artech House Inc., 1982.

Formulas Used For Miter Bend or Miter Elbow as per ASME B31.3

Here, we will see the calculations for design purpose, click here If you want to learn miter bend calculation for fabrication purpose, Let’s see below the formula for miter bend design as per section 304.2.3 of ASME B31.3

Calculation Steps

We required to follow the below calculation steps for miter bend or miter elbow design-

Weight of the Pipe

I'm a graduate in mechanical engineering, and a piping professional. I'm exploring this industry and having a great experience. In the process felt to share my knowledge with the other Piping Engineers and as a result, I am here with you.

What is a miter bend angle?

Miter Bend Angle is the angle of turn of the miter bend. This angle is the Bend angle. Bend angle should be entered in the input is in Degree. Miter angle can be of any degree but normally miter bend is 90 degrees, 45 degrees, or 30 degrees. but you can enter any angle you wish to fabricate.

How many parts are in a miter bend?

Generally, Miter Bend can be fabricated in 3 parts, 4 parts, 5 parts, 6 parts etc. In Miter Bend Ends parts are smaller than the middle parts, normally the Middle part is a Double of the ends parts or the last parts. in this calculator, you have to enter inputs as no. of parts in which you are going to fabricate your miter bend.

How many parts are needed to make a miter bend?

of parts should be an optimum number so that it can be economical. Generally, Miter Bend can be fabricated in 3 parts, 4 parts, 5 parts, 6 parts etc. In Miter Bend Ends parts are smaller than the middle parts, normally the Middle part is a Double of the ends parts or the last parts. in this calculator, you have to enter inputs as no. of parts in which you are going to fabricate your miter bend.

What is bend diameter?

Bend Diameter is the diameter of pipe where fluid is passing through it. In this calculator bend diameter is denoted by “d”. it is shown in the standard figure of this calculator. In this calculator, the bend diameter value is depends upon how you want to develop your layout, if you want to mark the layout on a flat plate then you have to enter the mean diameter of the pipe or if you want to mark the layout directly on the pipe then you have to enter outside diameter of the pipe. This calculator follows the Metric unit system so please enter bend diameter in mm.