Is SGP compatible with other interlayers when manufacturing laminated glass?

SGP is an ionoplast interlayer which means it is not compatible with other interlayers, you cannot combine SGP with PVB/EVA based interlayers when manufacturing custom laminated glass. See more information on our ToughView™ range.

What is the difference between SGP and PVB interlayers?

PVB interlayers used in internal balustrades are not considered structural, and therefore generally require handrails. SGP is 100 times more rigid and 5 times more resistant to tearing when comparing to PVB.

What are the advantages of SGP?

It is a primarily tough plastic that bonds the different layers of glass and increases the structural integrity of the entire assembly. An advantage of SGP is that it does not let the glass disintegrate completely and shatter to pieces in case of an impact.

What is an interlayer glass?

SentryGlas® (SG5000) – interlayer is stronger and more rigid than conventional laminating materials, creating safety glass that protects against storms, impacts, and blasts.

What is SGP interlayer made of?

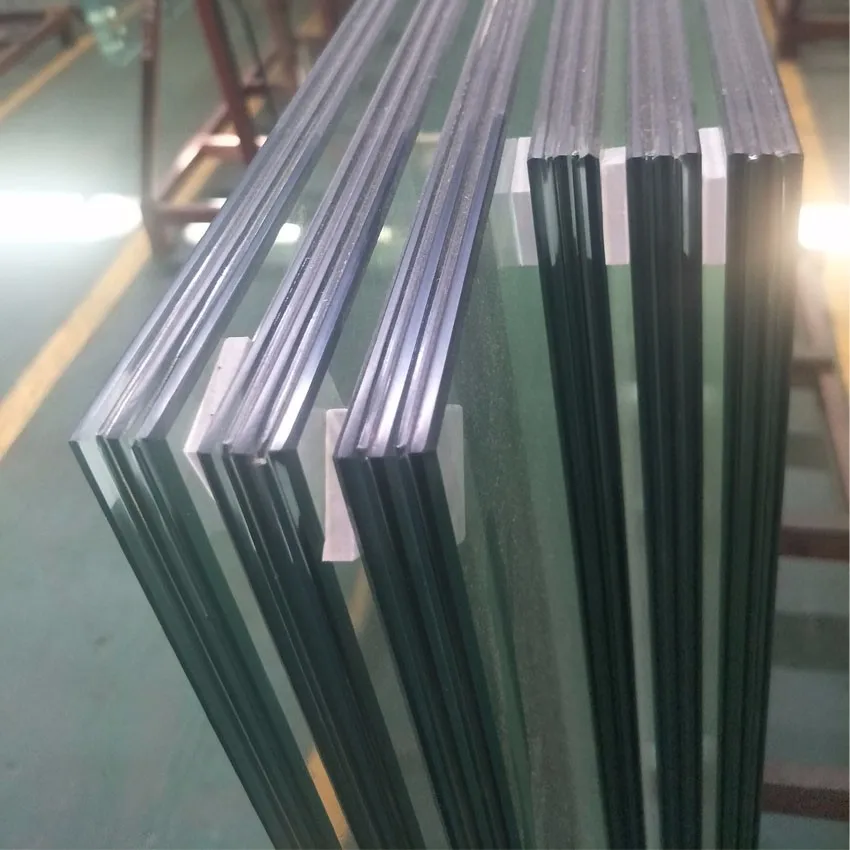

The DuPont Sentry Glass Plus (SGP) is composed of a tough plastic interlayer composite that is laminated between two layers of tempered glass.

Who makes SGP interlayer?

DuPontSGP is called the ionic interlayer film (SentryGlas Plus), which is a high-performance interlayer developed by DuPont. Its high performance is: 1.

How thick is an SGP interlayer?

2.28 mm (90 mil) thickness interlayers are normally specified for anti-intrusion, hurricane and other types of security ap- plications. Glass producers and laminators require interlayers to be supplied either in sheet form or on rolls. SentryGlas® Ionoplast interlayers are available in both formats.

What is the plastic interlayer in laminated glass?

polyvinyl butyral (PVB)Modern laminated glass is produced by bonding two or more layers of ordinary annealed or tempered glass together with a plastic interlayer, usually polyvinyl butyral (PVB), Thermoplastic Polyurethane (TPU) or ethylene-vinyl acetate (cross-linked EVA).

Is EVA better than PVB?

EVA interlayers are high in moisture resistance and can be used in both external and internal glazed applications when the edges are exposed. EVA adheres to glass and other materials better than PVB and is available in many colours making it the ultimate selection when design innovations are a requirement.

What is the difference between annealed glass and normal glass?

Annealed glass, also known as standard glass, is manufactured differently from tempered glass in that it is slowly cooled which helps strengthen the glass making it more durable and less likely to break; however if it does, it will break into large glass shards and splinter into jagged pieces.

Which is better laminated glass or tempered glass?

While considering the strength to withstand breakage, tempered glass is considered to be stronger than laminated glass. Five times stronger and stiffer than regular glass.

What is the difference between tempered glass and heat strengthened glass?

To produce tempered glass, the cooling is much more rapid, thus creating higher surface and/or edge compression in the glass. To produce heat strengthened glass, the cooling is slower and the resultant compression in the glass is lower than fully tempered glass yet still higher than annealed glass.

What does PVB stand for in glass?

Polyvinyl butyral (or PVB) is a resin mostly used for applications that require strong binding, optical clarity, adhesion to many surfaces, toughness and flexibility. It is prepared from polyvinyl alcohol by reaction with butyraldehyde. The major application is laminated safety glass for automobile windshields.

Why is PVB layer used in laminated glass?

Plasticized PVB is used as a laminating film between layers of glass to provide strength and shatter resistance.

What is PVB interlayer?

What is a PVB interlayer? Poly Vinyl Butyral is a tough plastic resin that is used in between two panes of glass to bond them together. It's made from polyvinyl alcohol through reacting it with butyraldehyde.

What is Grade A laminated glass?

VLam™ (Grade A safety glass) laminated glass helps to protect from injury caused by sharp splinters of broken glass. If broken, laminated glass sticks to the interlayer and generally stays in the window frame to provide added safety.

What is the standard thickness of Sentry interlayers?

1.52mmThickness of the interlayer: Sentry 1.52mm. Sentry 2.28mm.

What is SentryGlas interlayer?

Originally developed for the hurricane glazing market, SentryGlas® Interlayer is used in applications where high-performance glass is required such as security and structural glazing, bomb blast, ballistics and marine vessels.

What is PVB interlayer?

What is a PVB interlayer? Poly Vinyl Butyral is a tough plastic resin that is used in between two panes of glass to bond them together. It's made from polyvinyl alcohol through reacting it with butyraldehyde.

What is EVA interlayer?

EVA interlayers are considered an alternate interlayer for safety glass. EVA is not as commonly used as PVB throughout Australia and offers different solutions. EVA interlayers are high in moisture resistance and can be used in both external and internal glazed applications when the edges are exposed. EVA adheres to glass and other materials better ...

Can PVB interlayers be used in internal balustrades?

It is not advisable to use common PVB interlayers where the laminate will have prolonged exposure to moisture or water as it can cause de-lamination over time. PVB interlayers used in internal balustrades are not considered structural, and therefore generally require handrails.

Is SGP more rigid than PVB?

SGP is 100 times more rigid and 5 times more resistant to tearing when comparing to PVB. When frameless, laminated glass applications are required externally such as; balustrades & canopies, the SGP interlayer is a superior selection due to its ability to withstand weather conditions and resist moisture where other laminates cannot.

Can you use SGP with PVB?

SGP is an ionoplast interlayer which means it is not compatible with other interlayers, you cannot combine SGP with PVB/EVA based interlayers when manufacturing custom laminated glass. See more information on our ToughView™ range. Frameless balustrade using a structural interlayer – SGP.

What is SGP interlayer?

SentryGlas Plus Interlayer, also known as SGP interlayer, being the only structural material for laminated glass. It draws tremendous attention since its birth in 1998.

What is the name of the SG5000?

This is a new kind developed in 2016, with only 81% visible light transmission compared to 88% of SentryGlas Plus Clear interlayer. Nomenclature is SG5000 or SGR5000 , same as Clear SentryGlas interlayer.

How is SentryGlas processed?

SentryGlas has to be processed by disposable vacuum bag while the SGP Xtra can be done by normal roller process with specific rolling pressure.

Which is better, SentryGlas Xtra or SGR6000?

Nomenclature is SG6000 or SGR6000. SentryGlas Xtra got better processability than the SentryGlas interlayer. It has better fluidity when heating and pressing, offset the tempered glass deformation caused by the air grid. With less moisture absorbance capability.

How long does it take to build an interlayer?

Minimum 1-2 months lead time is needed to get the interlayer, timeframe needs to be considered since the beginning of the project.

How thick is a ply of a sandpaper?

With special thickness starts from 0.80mm per ply, normally processed with 2 plies approximate overall thickness of 1.52mm.

Who sold SentryGlas Interlayers?

Though the SentryGlas Interlayers division sold to Kuraray, DuPont got the core material still.

What is a PVB interlayer?

Poly Vinyl Butyral is a tough plastic resin that is used in between two panes of glass to bond them together.

What is an SGP interlayer?

SentryGlas Plus is an ionoplast interlayer that when used to laminate glass boasts extremely high weather resistance and strength levels.

What are the main differences between the two?

Both interlayers provide strength and security in the event of breakage, however there are significant differences in their performance levels.

Which one is right for my project?

We recommend using PVB for internal glazing as SGP can be more costly and the higher performance levels are not required.